Installation method of torsion bar assembly, installation structure of torsion bar assembly

An installation method and torsion bar technology are applied in the field of anti-rolling torsion bar system installation, which can solve problems such as high cost and complex structure, and achieve the effects of easy connection, high structure compactness and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

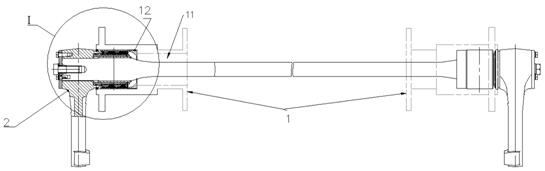

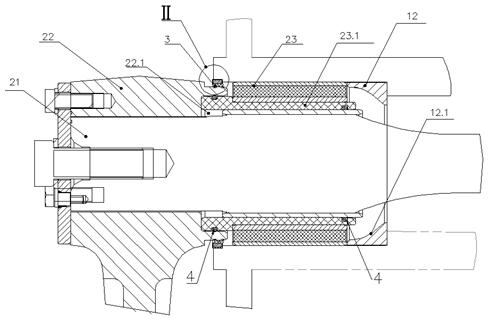

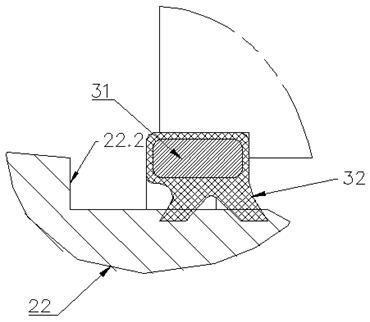

[0030] Combine below Figure 1 to Figure 5 Embodiments of the present invention are described in detail.

[0031] The installation method of the torsion bar assembly is characterized in that the installation hole 11 corresponding to the torsion bar assembly 2 is processed on the frame 1 of the bogie, the torsion bar assembly 2 is traversed in the installation hole 11 and the torsion bar assembly 2 is installed with the torsion bar assembly. The holes 11 are connected by interference fit, and a stop 12 for axially limiting the torsion bar assembly 2 is provided in the installation hole 11 , and the stop 12 is in close contact with the torsion bar assembly 2 .

[0032] Such as figure 1 As shown, the installation hole 11 corresponding to the torsion bar assembly 2 is processed on the frame 1 of the bogie, and the torsion bar assembly 2 and the installation hole 11 are connected by interference fit, that is, the torsion bar assembly 2 is directly installed on the frame, saving T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com