External force adjusting and automatic residue discharging type axial powder actuated tool

An automatic slag discharge and nail shooter technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of difficult slag cleaning tasks, nail shooting damage, noise impact of on-site construction personnel, etc., to save slag discharge maintenance procedures, reduce The effect of part temperature and reducing the difficulty of slag discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

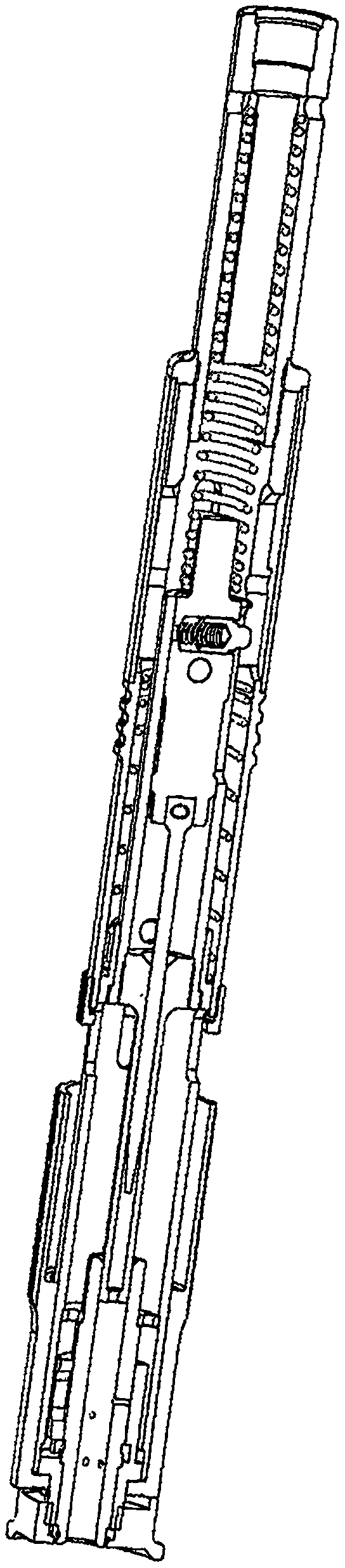

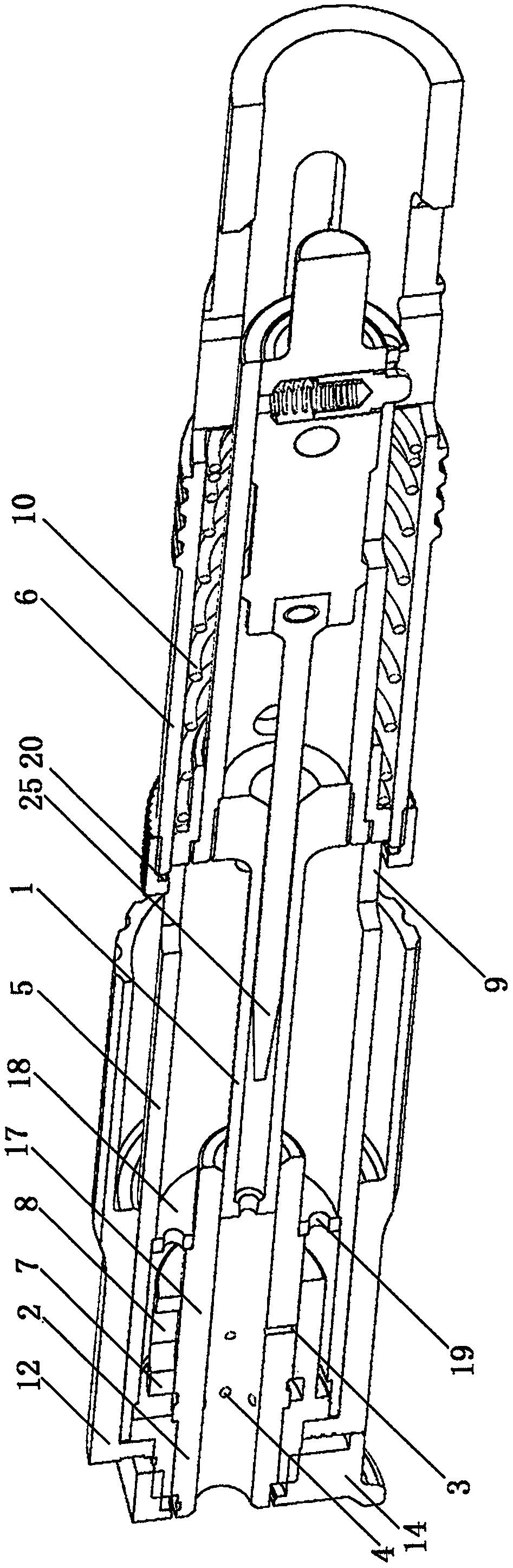

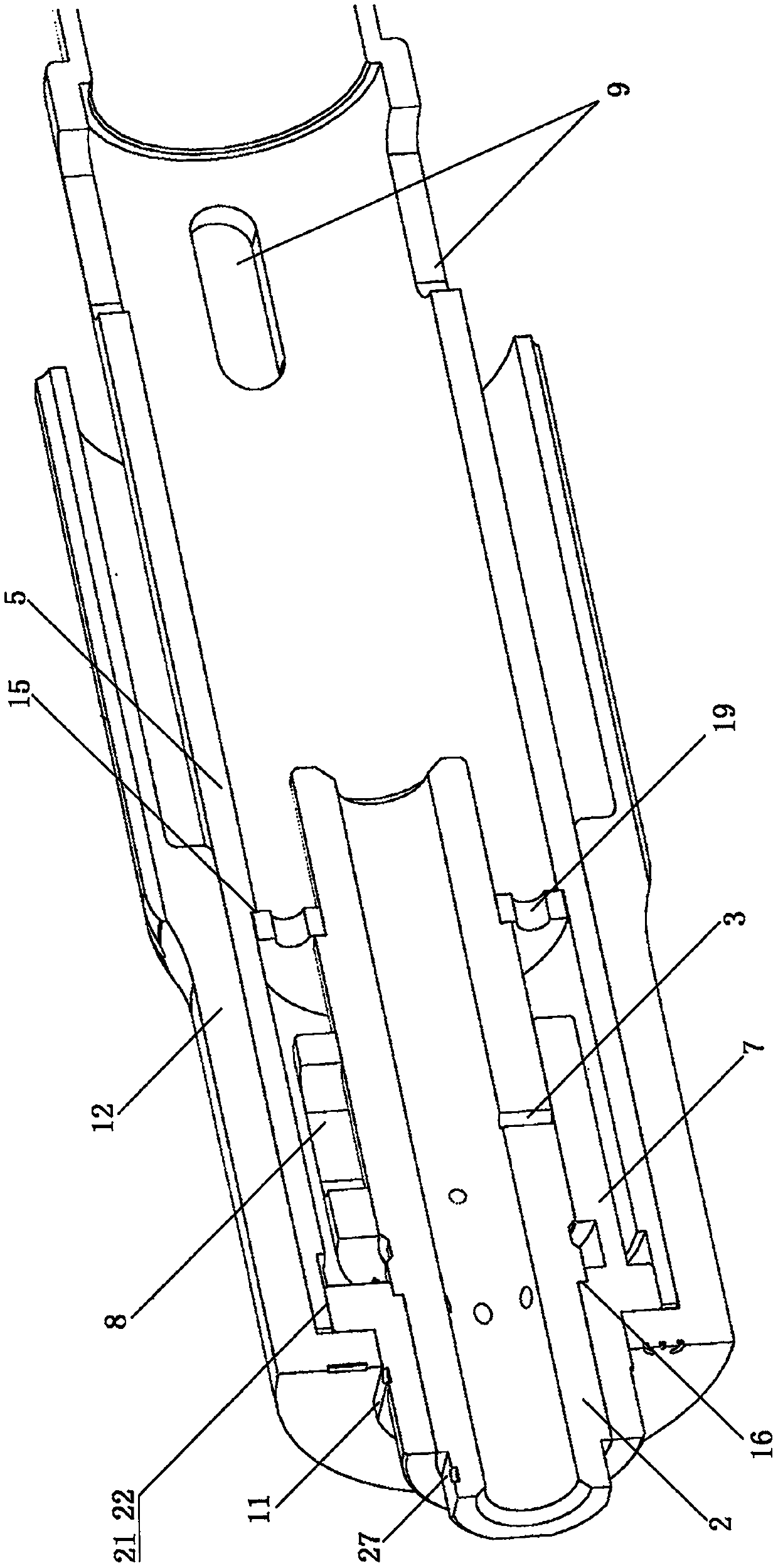

[0031] As shown in the figure, 1 is the cartridge seat, 2 is the nail tube, 3 is the pressure relief through hole, 4 is the silencer hole, 5 is the outer cover, 6 is the main cover, 7 is the power adjustment cover, 8 is the slag discharge channel, and 9 It is the slag discharge heat dissipation hole, 10 is the reset spring, 11 is the anti-rotation ring, 12 is the anti-rotation sleeve, 13 is the anti-rotation hole, 14 is the gland, 15 is the convex ring, 16 is the inner boss, 17 is the nail tube body , 18 is the nail tube seat, 19 is the connecting channel, 20 is the sealing ring, 21 is the external thread, 22 is the internal thread, 23 is the external thread, 24 is the internal thread, 25 is the firing pin, 27 is the square edge, 28 is the row 气 Channel.

[0032] The loading, firing and resetting process of this nail shooter is similar to that of previous products. The opening direction of the nail tube is forward.

[0033] As shown in the figure, the nail tube 2 is installed from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com