Patents

Literature

30results about How to "Realize the bending operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

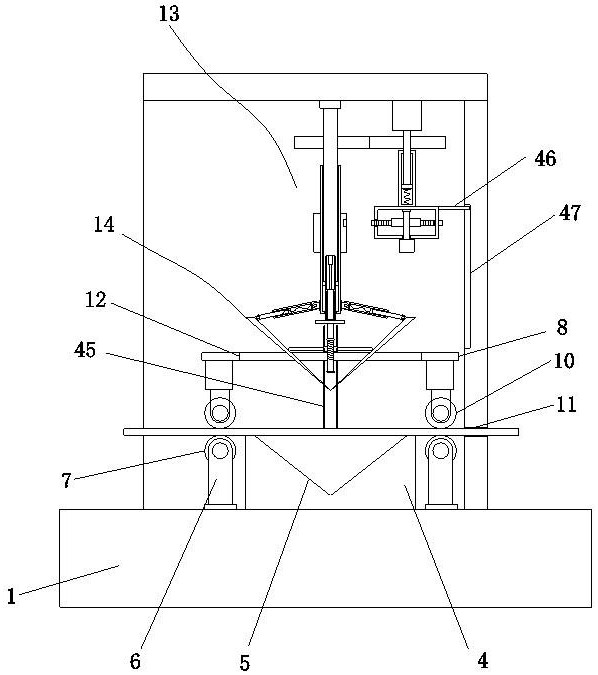

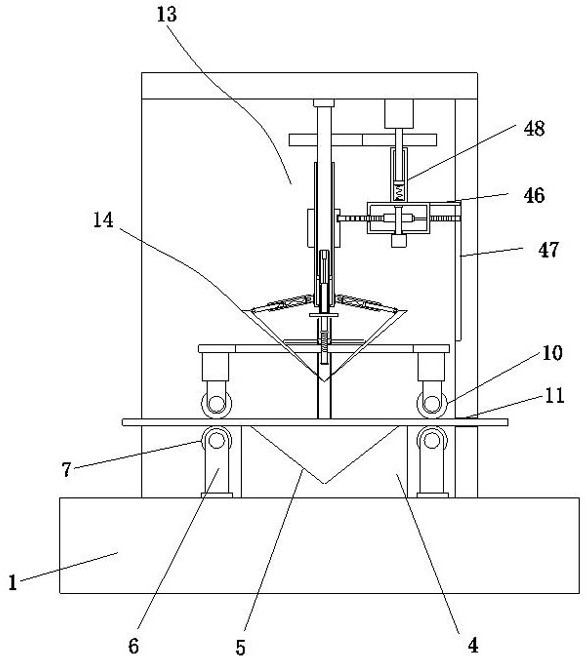

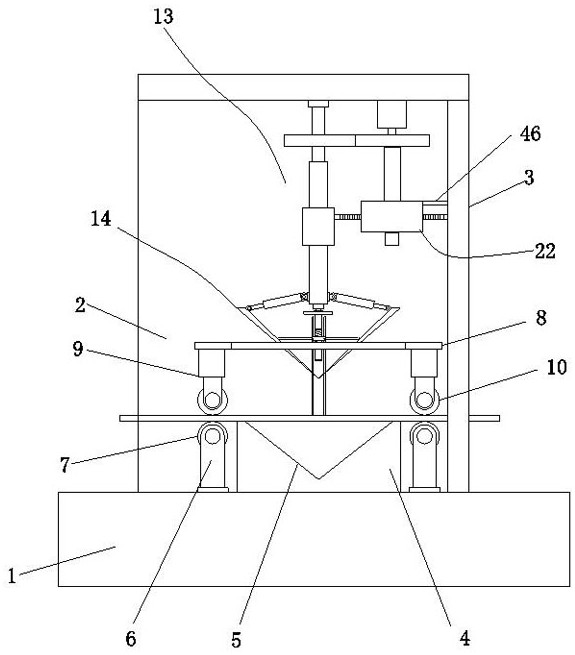

Intelligent metal pipe bender

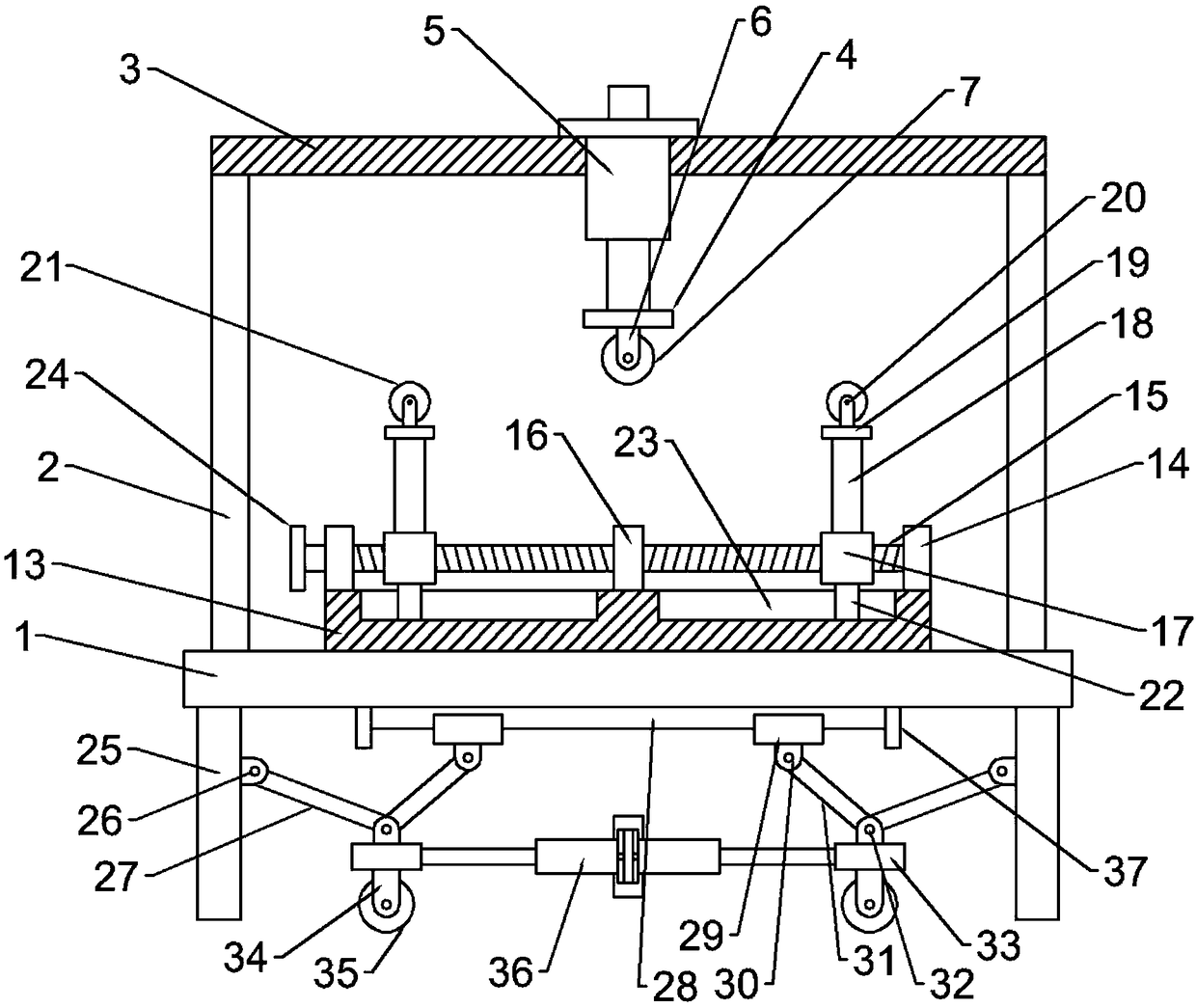

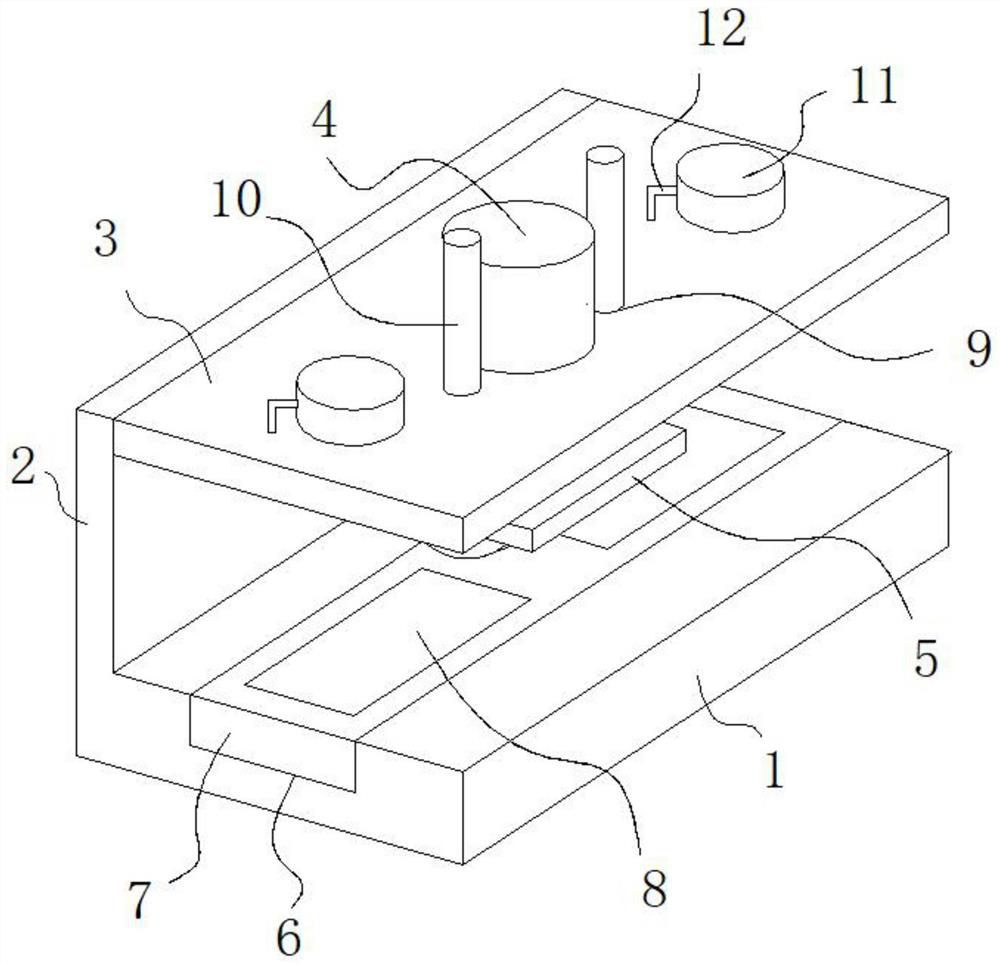

The invention discloses an intelligent metal pipe bender. The intelligent metal pipe bender comprises a bottom plate, supporting posts, a top plate, a lifting device, a first connection plate, a firstsupport, a pressing wheel, an assembly base, assembly blocks, a threaded rod, threaded sleeves, supporting rods and bearing wheels; supporting leg plates are vertically arranged on the left and rightsides of the lower end of the bottom plate; central parts of opposite side surfaces of the two supporting leg plates are provided with first hinge bases; the first hinge bases are connected with theupper ends of first connection rods; second hinge bases are arranged on the lower ends of sliding bases; the second hinge bases are connected to the upper ends of second connection rods; and the lowerends of the first connection rods and the second connection rods are all arranged on third hinge bases. By adopting the intelligent metal pipe bender, a metal pipe can be placed on the upper ends ofthe two bearing wheels; the pressing wheel is driven to press downwards by the lifting device, so that bending operation for the metal pipe is realized; the application range is wide; and besides, rollers can be in contact with the ground, so that moving of the bottom plate is realized.

Owner:NANJING CHINA UNIV INTPROP CO LTD

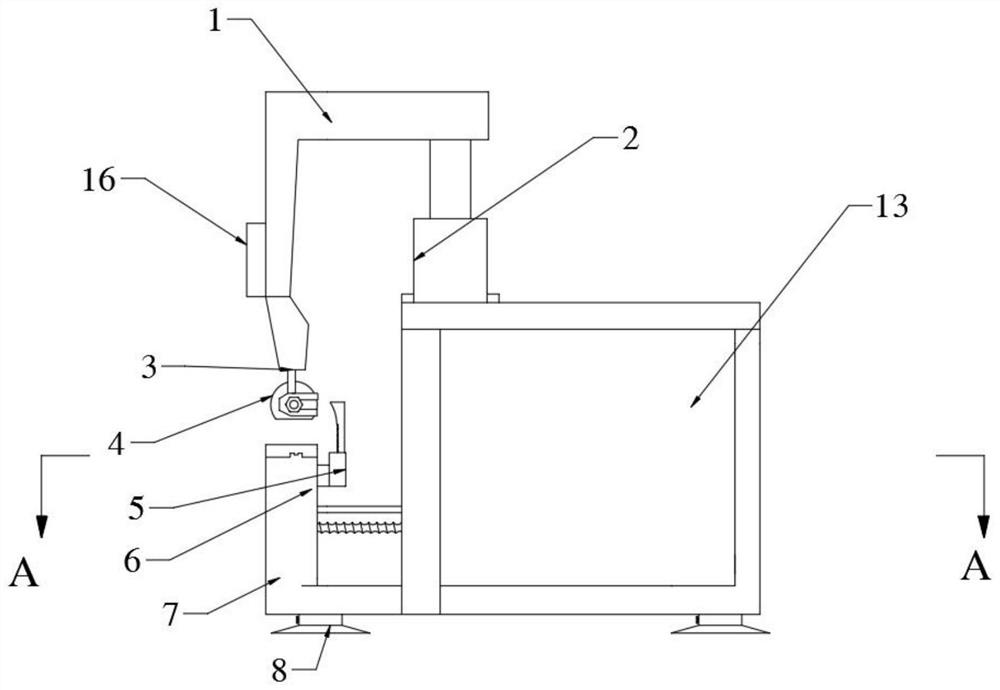

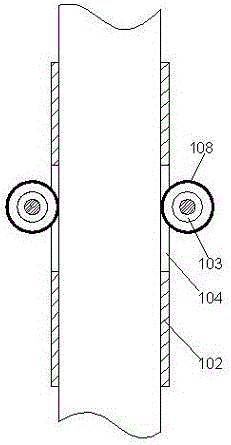

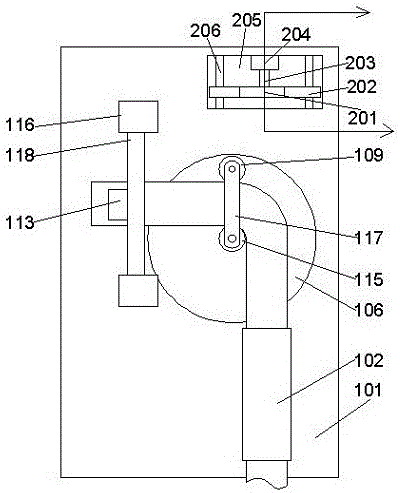

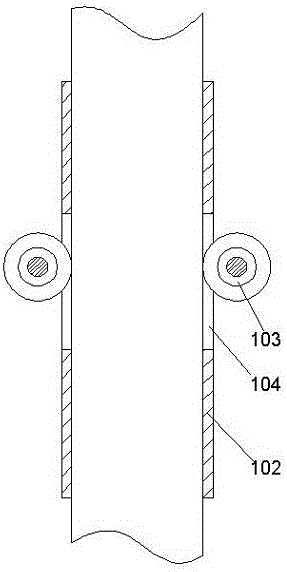

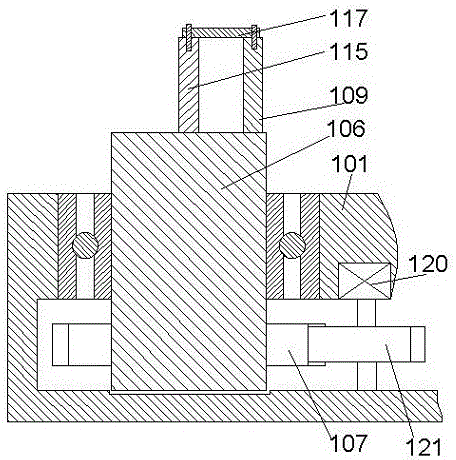

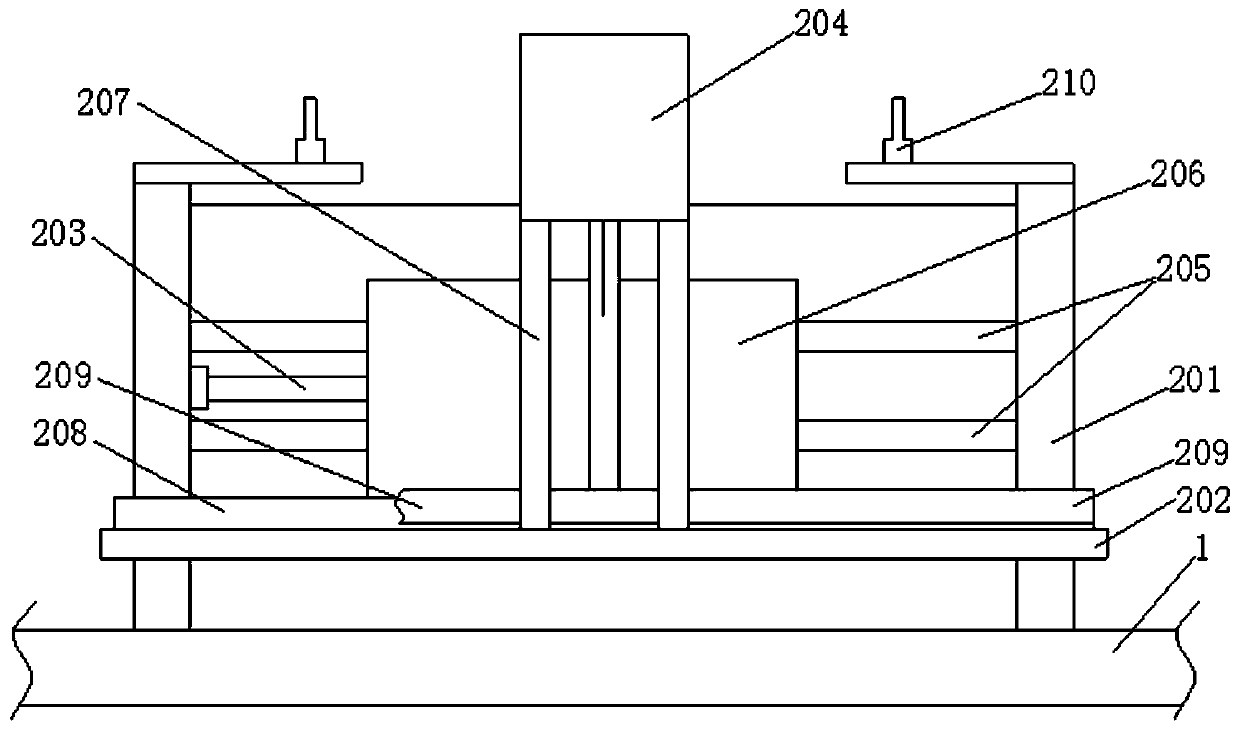

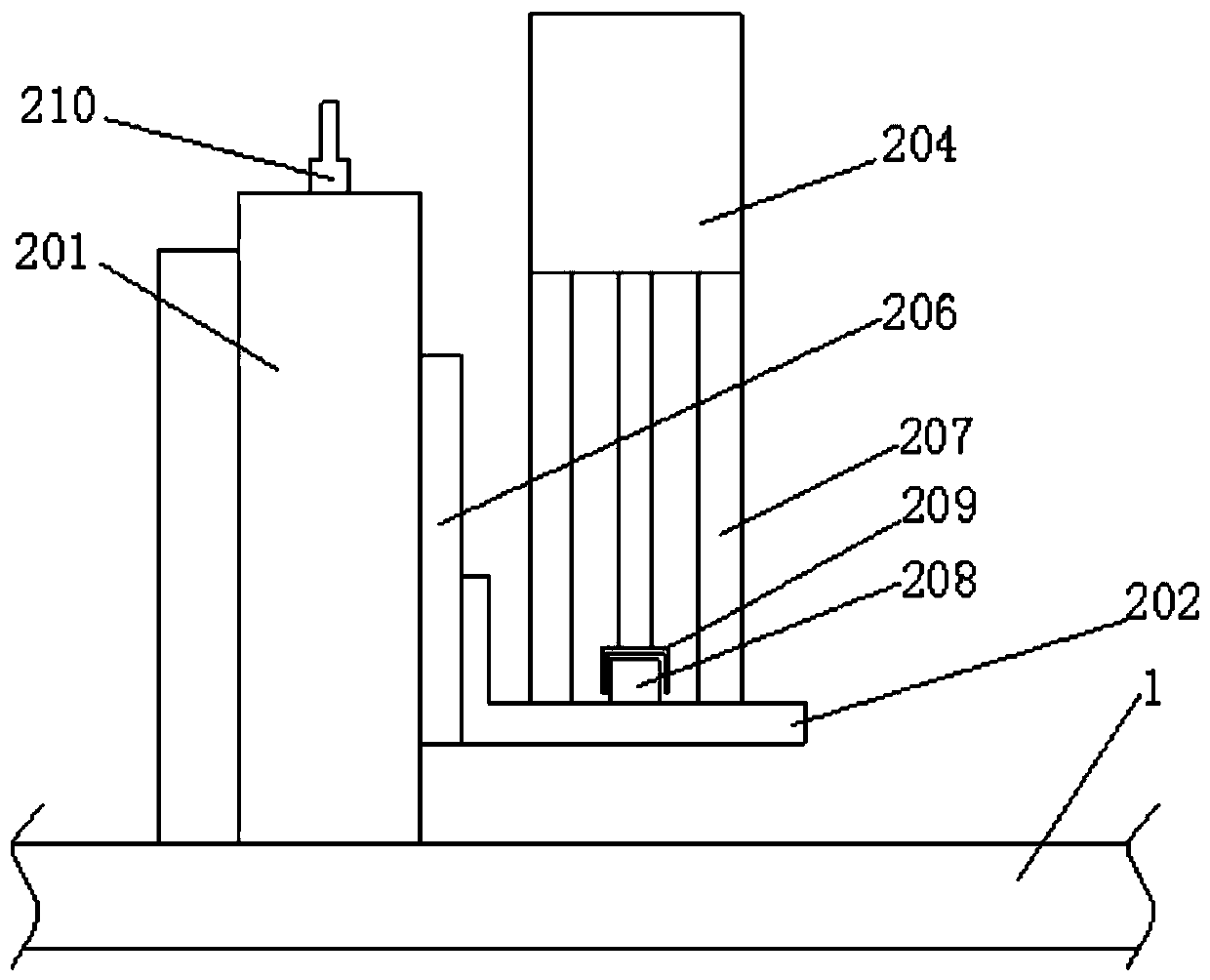

Test device and test method for current-carrying characteristic of high-temperature superconducting stripe

ActiveCN107167681ASolve the problem of the influence of current carrying capacityRealize the bending operationElectrical testingSuperconductor elements usageHigh temperature superconductingEngineering

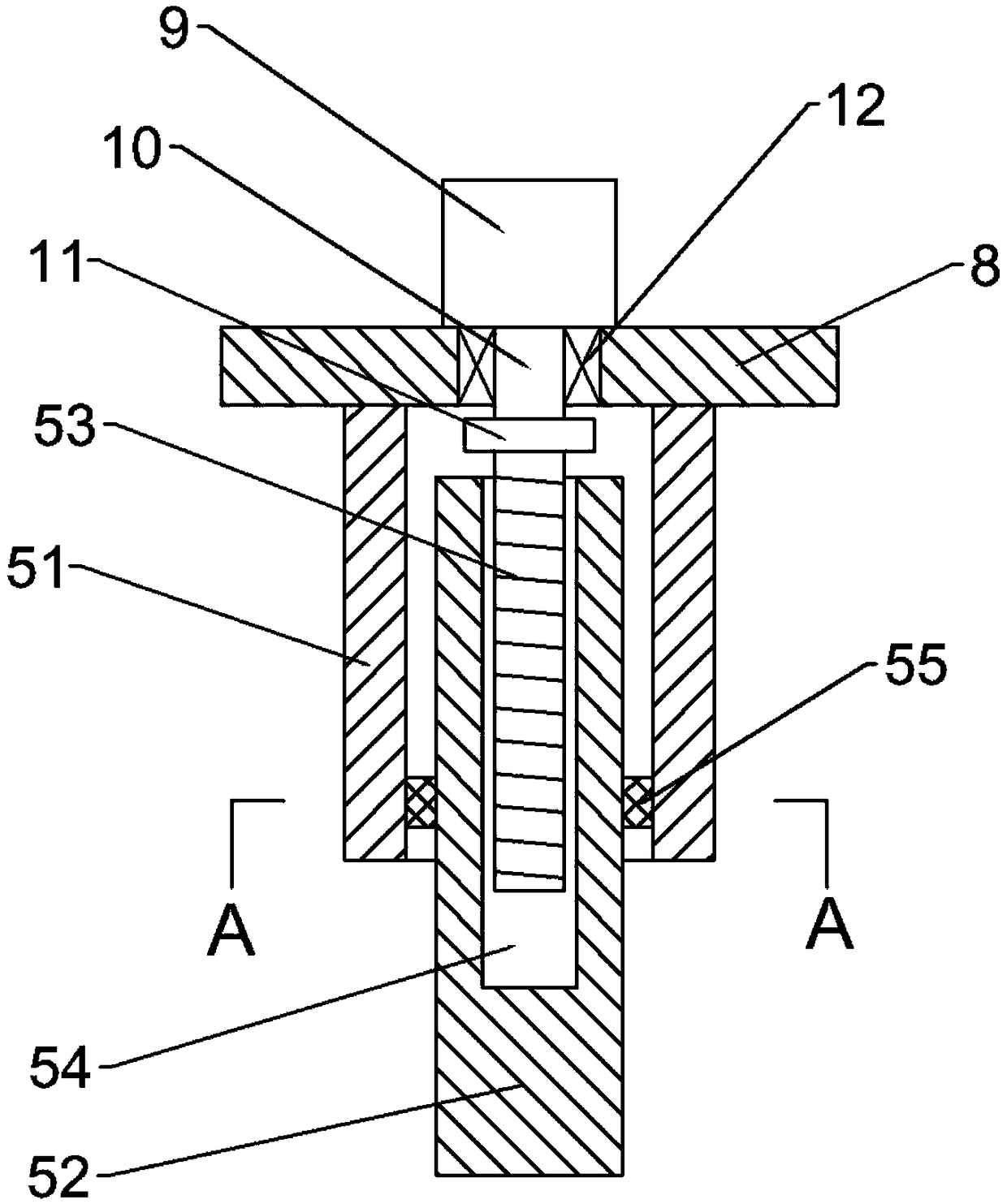

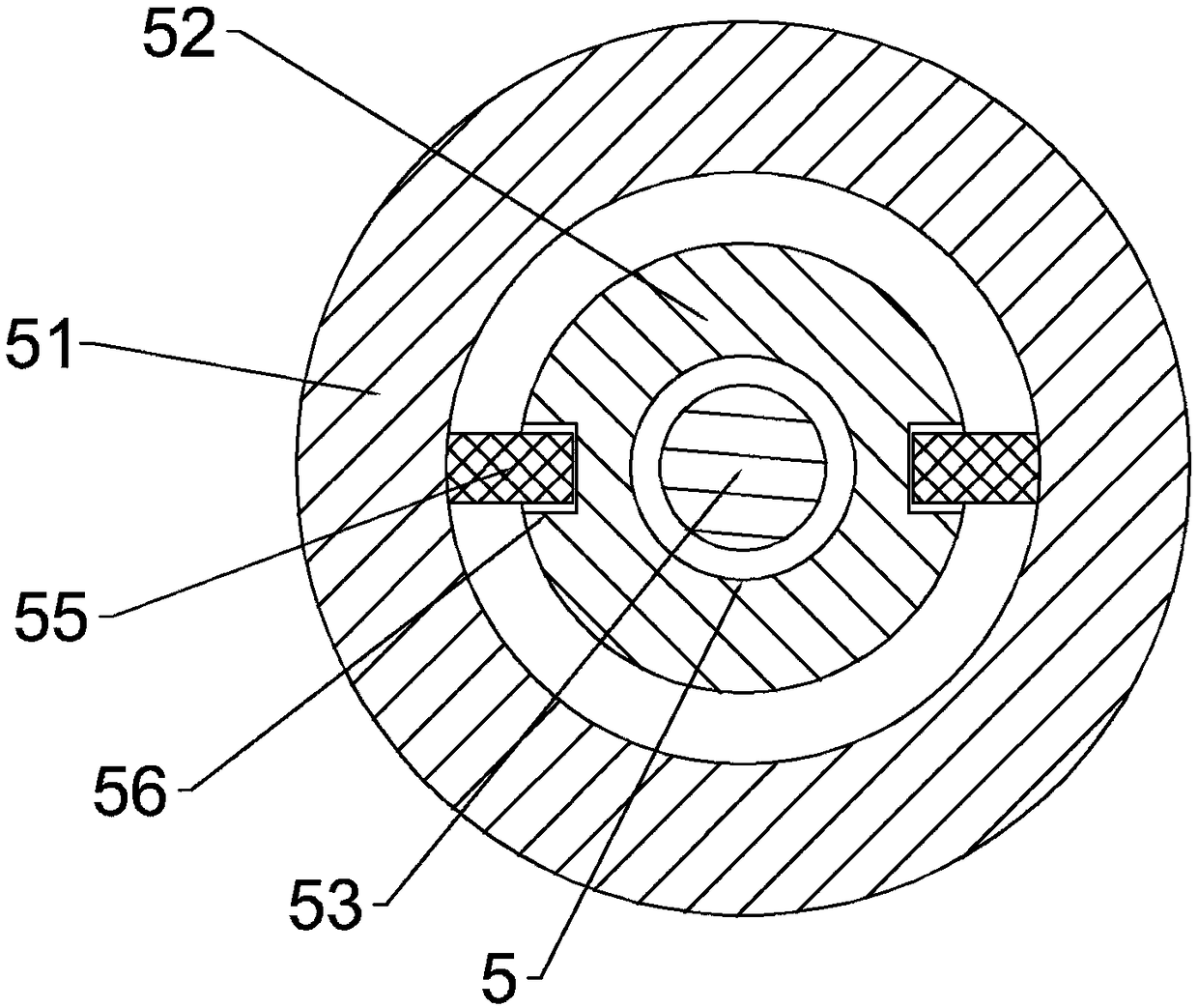

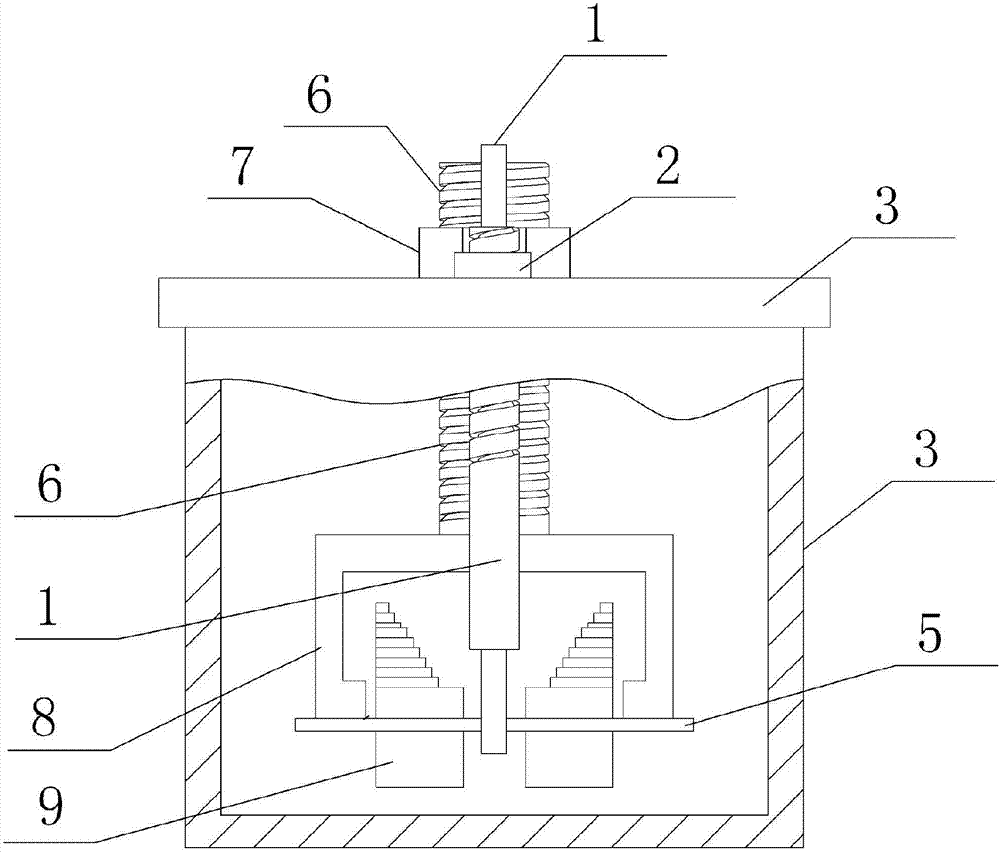

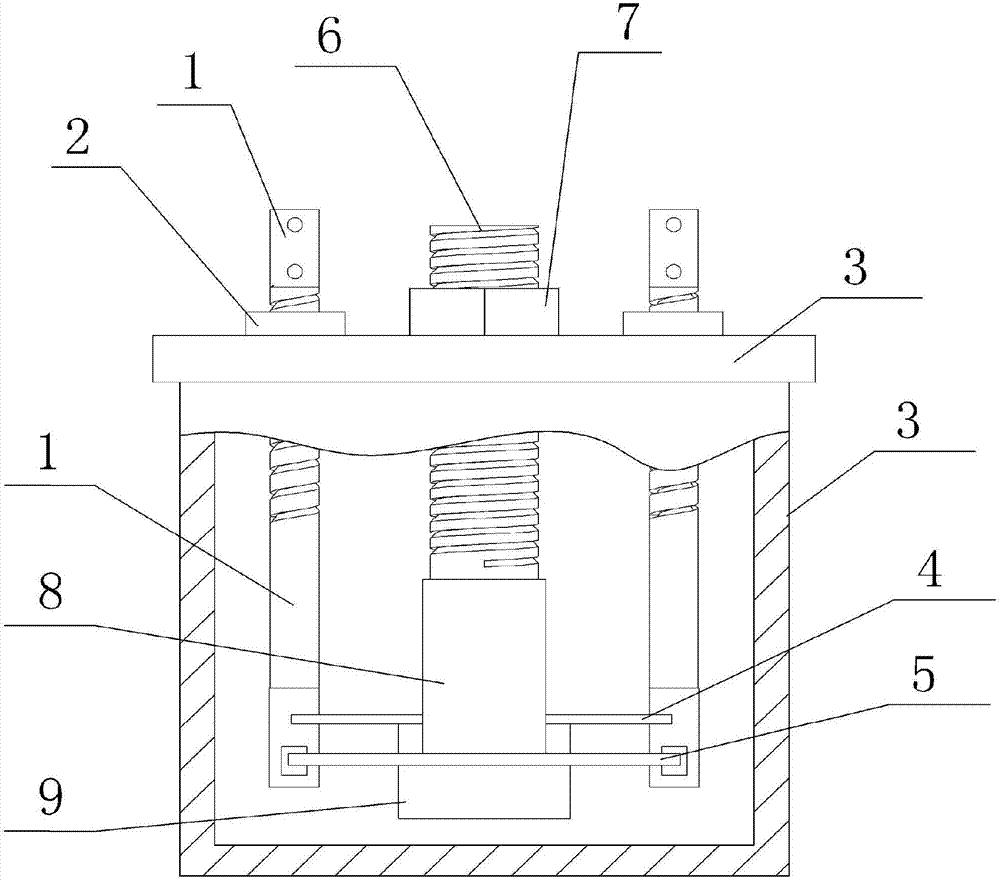

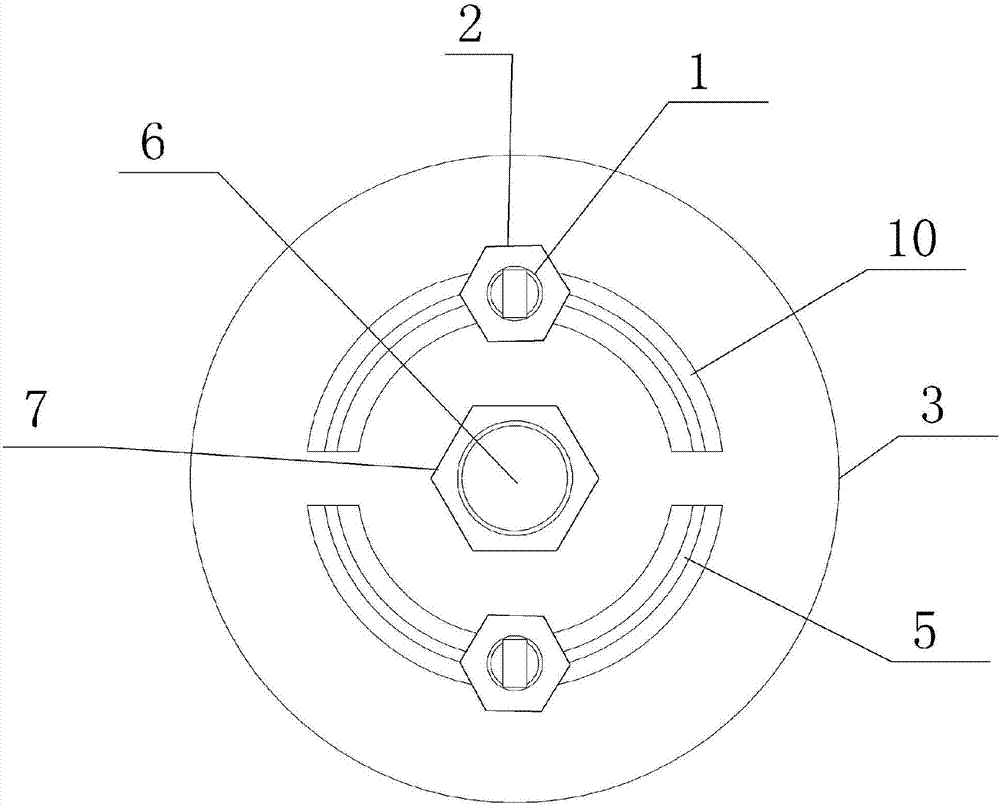

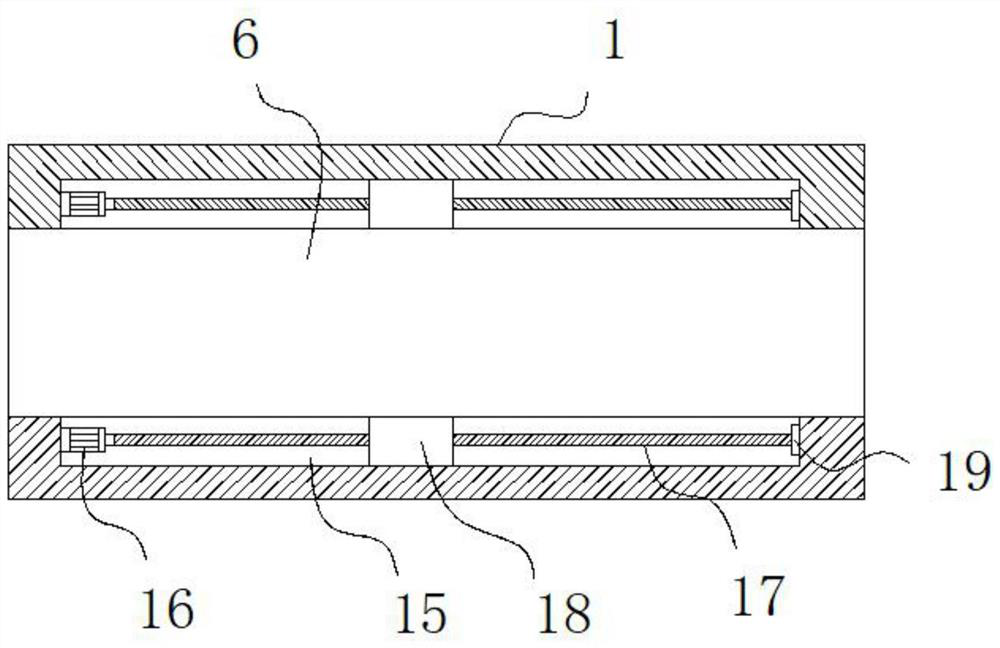

The invention relates to a test device and test method for a current-carrying characteristic of a high-temperature superconducting stripe. The test device is characterized in that two opposite semicircular guide grooves are formed in the top of a liquid nitrogen Dewar unit; and copper threaded rods are inserted into the guide grooves and are suspended in the liquid nitrogen Dewar unit by nuts. The top ends of the threaded rods are connected with a direct-current source; and the threaded rods are sleeve at a circular-ring-shaped guide rail movably by guide holes. The end portions of a high-temperature superconducting stripe are welded to the lower ends of the threaded rods. A lead of a nanovoltmeter is welded to a non-end portion part of the high-temperature superconducting stripe. A lifting screw rod is inserted into a lifting hole in the center of the top of the liquid nitrogen Dewar unit and is suspended in the liquid nitrogen Dewar unit by a lifting cap; and the bottom of the lifting screw rod is fixedly connected with the top of an inverted-U-shaped electromagnet; and the bottom of the electromagnet is fixedly connected with the guide rail. Two multi-stage-stepped semi-circular truncated cones are fixed at the bottom of the liquid nitrogen Dewar unit and the arc surfaces of the two semi-circular truncated cones are opposite. Therefore, the critical current change of the high-temperature superconducting stripe at different magnetic fields under different bending radiuses can be measured.

Owner:SOUTHWEST JIAOTONG UNIV

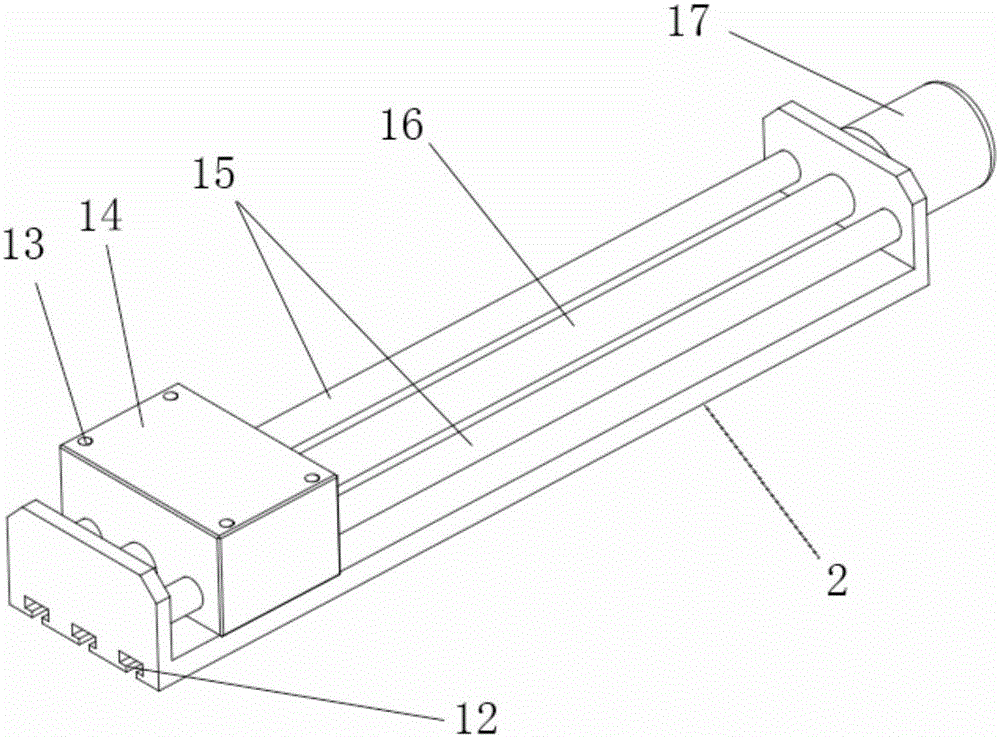

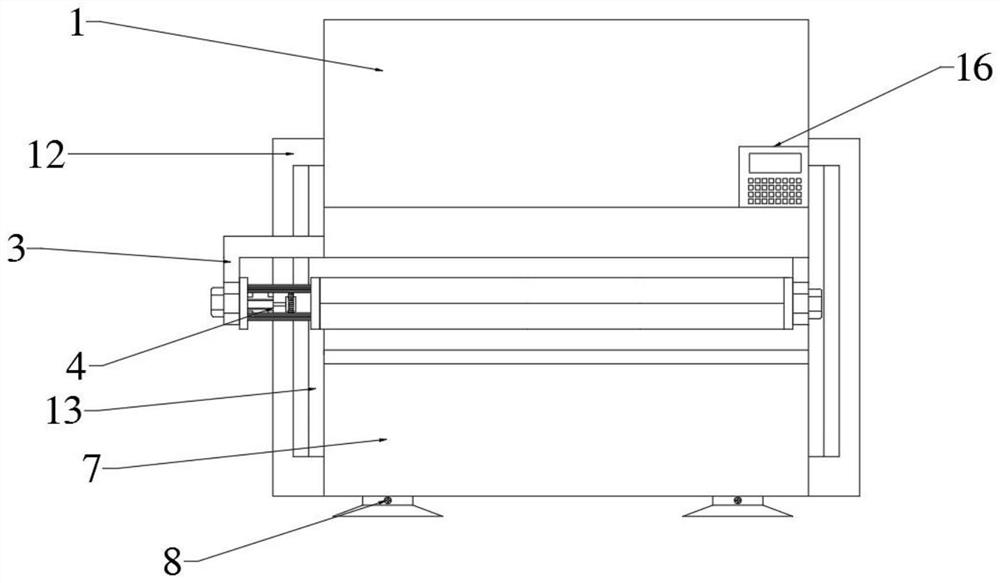

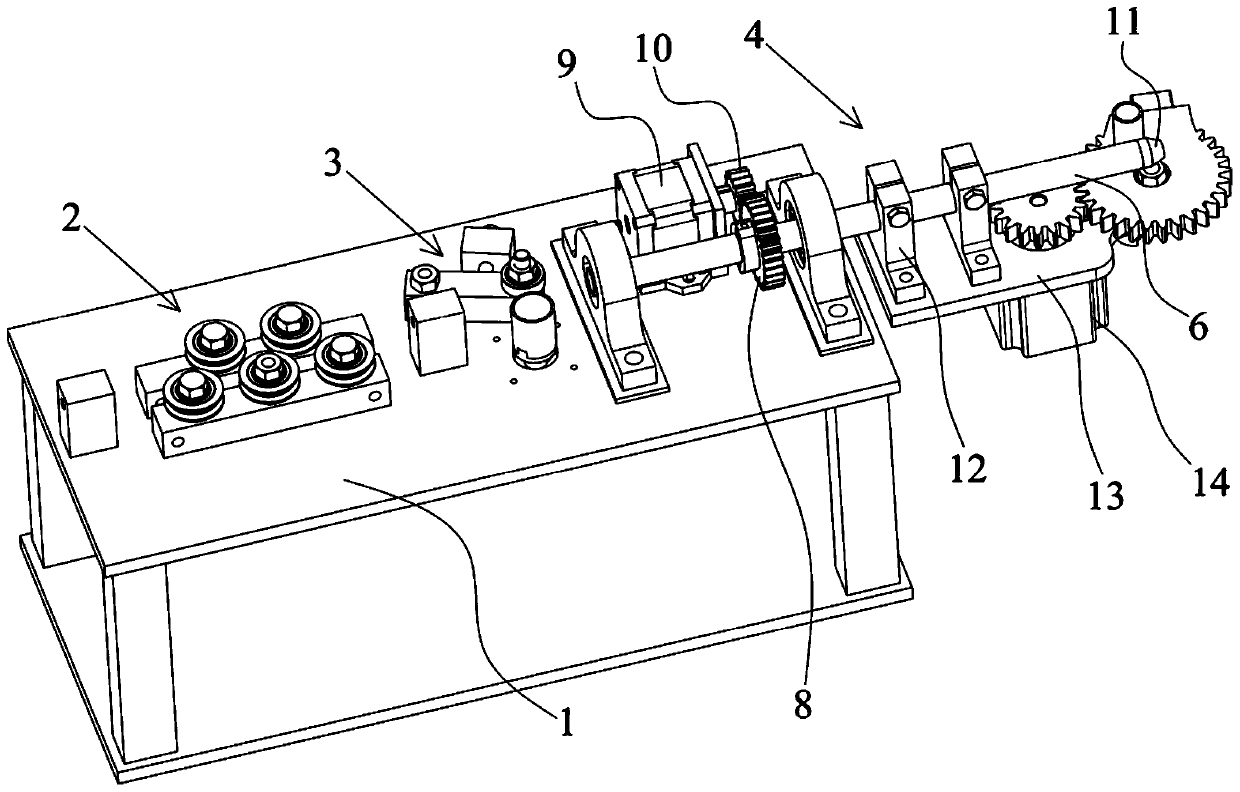

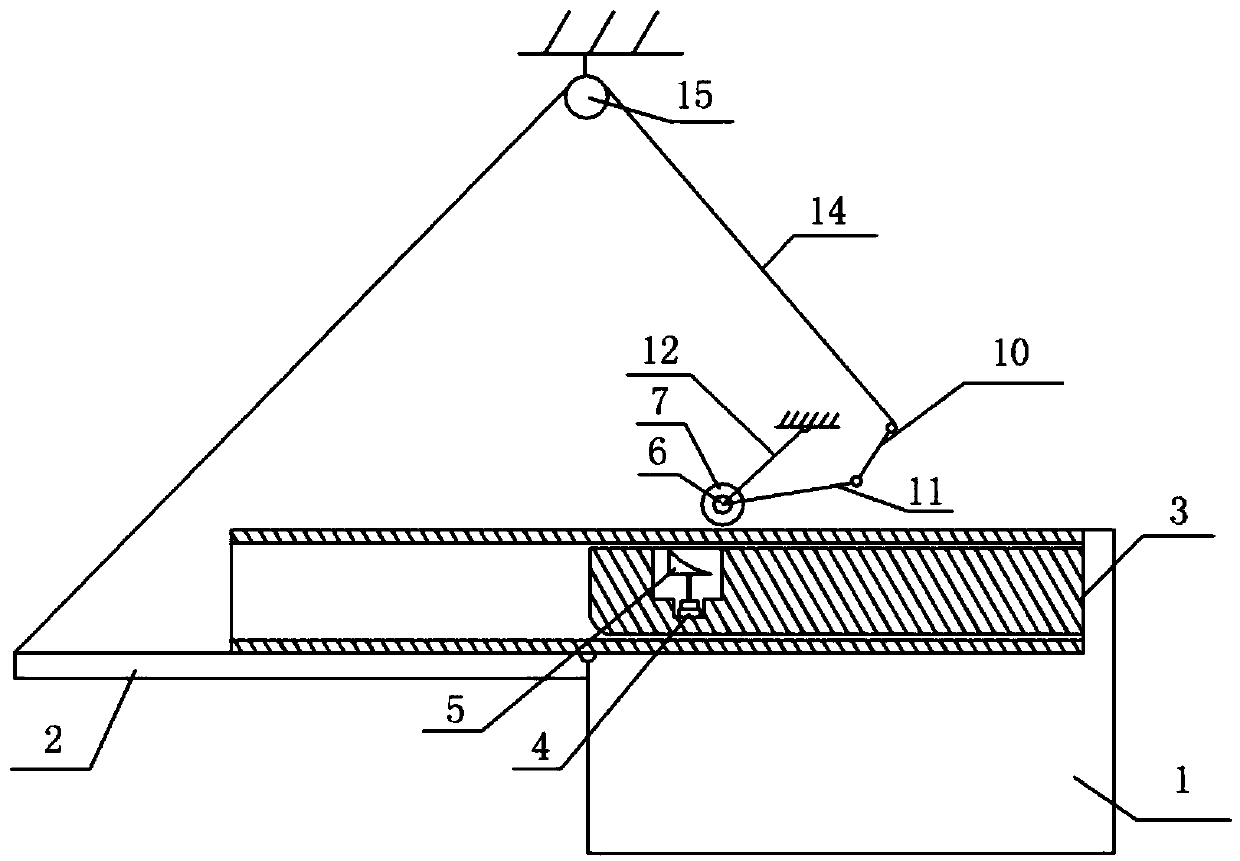

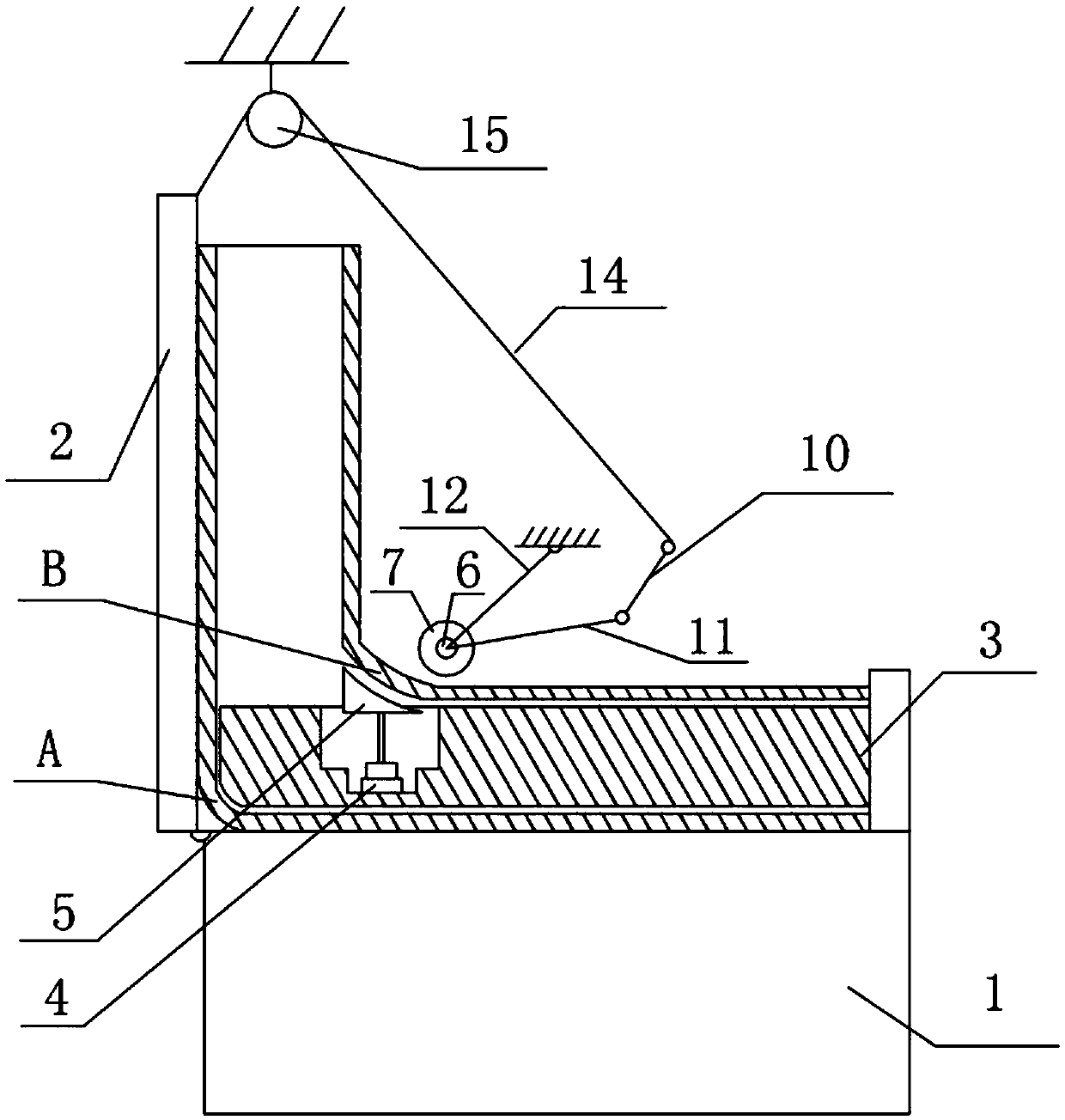

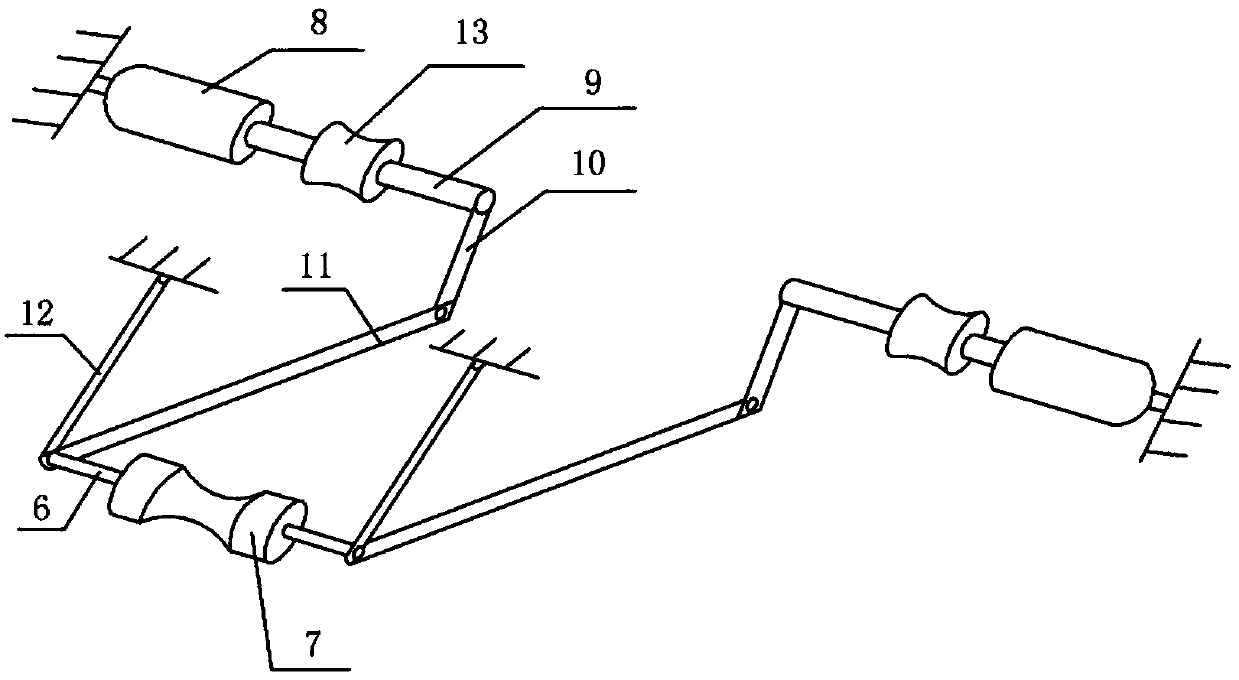

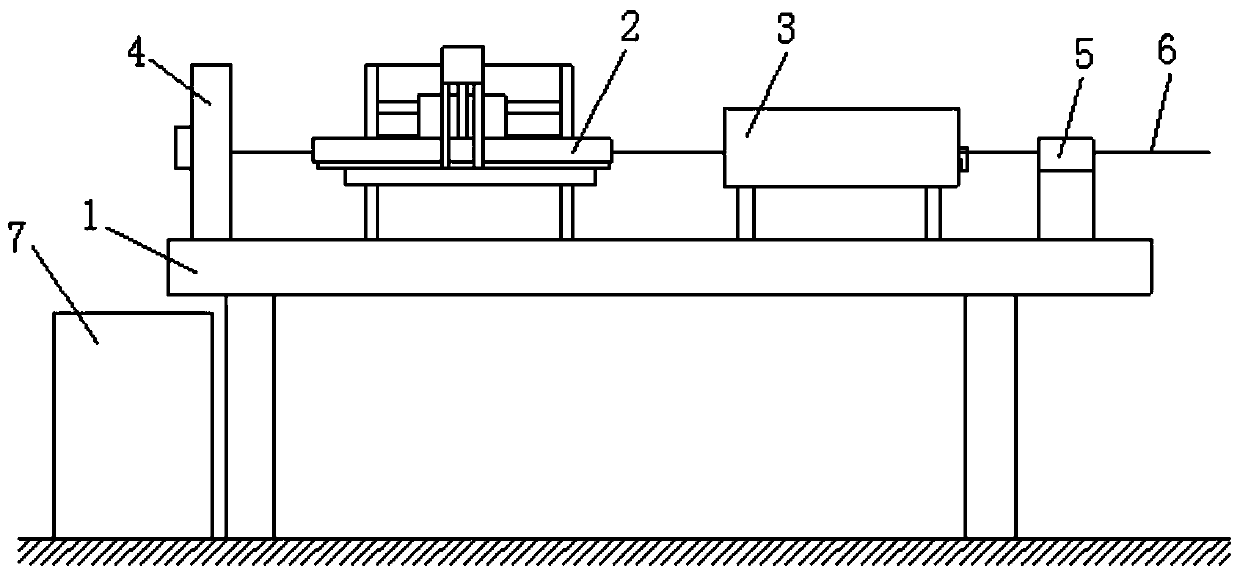

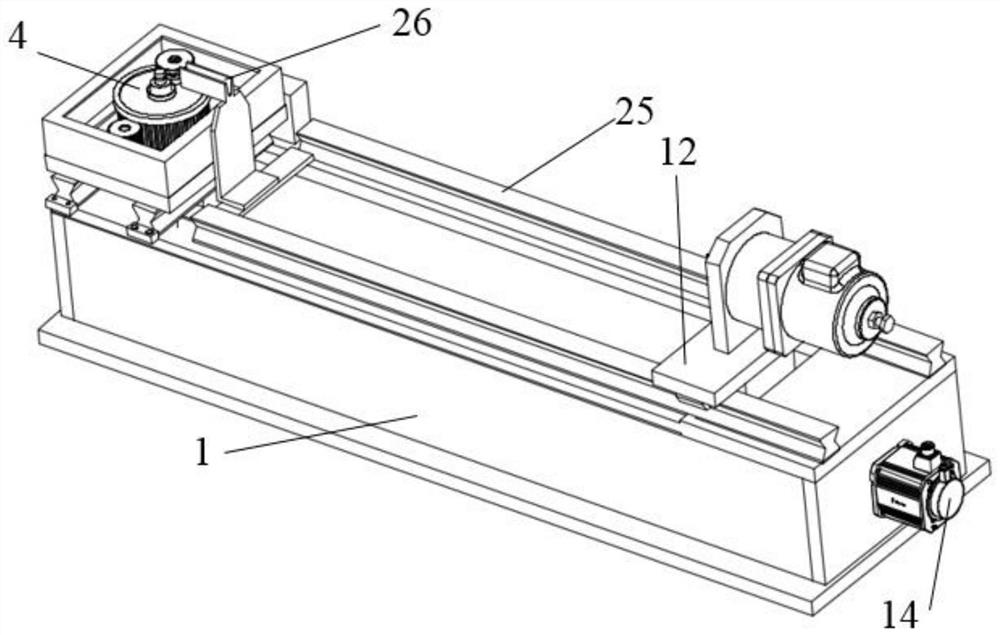

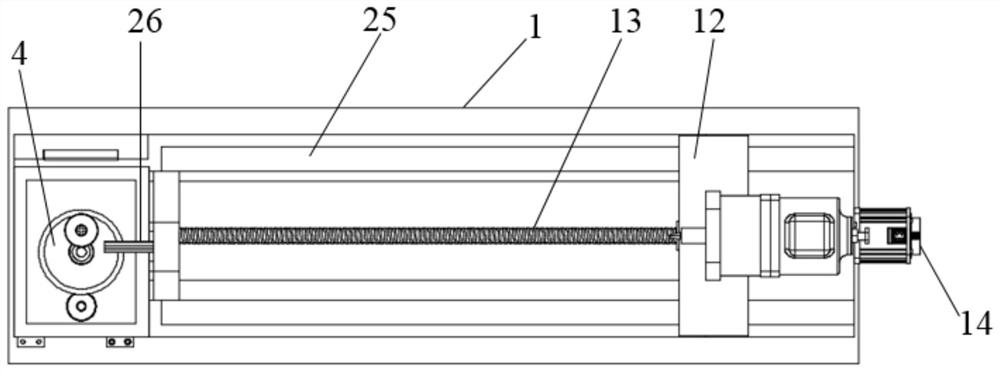

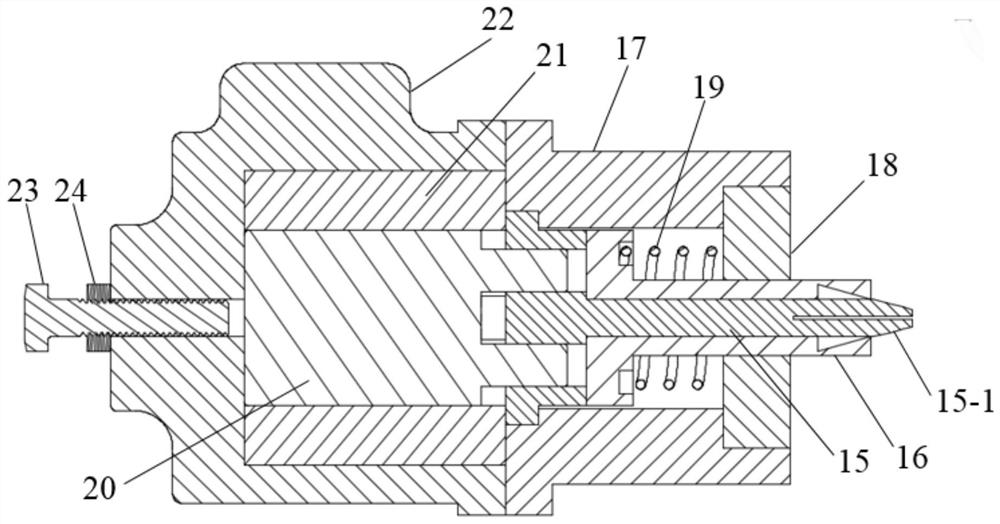

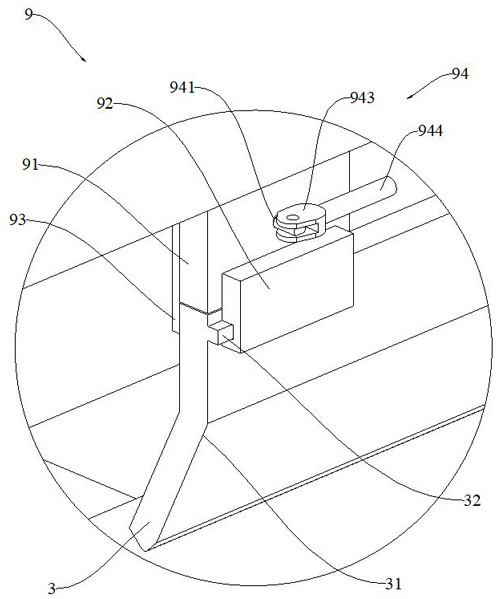

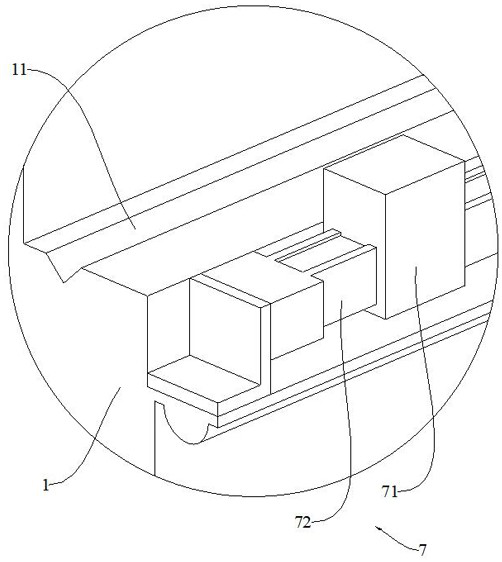

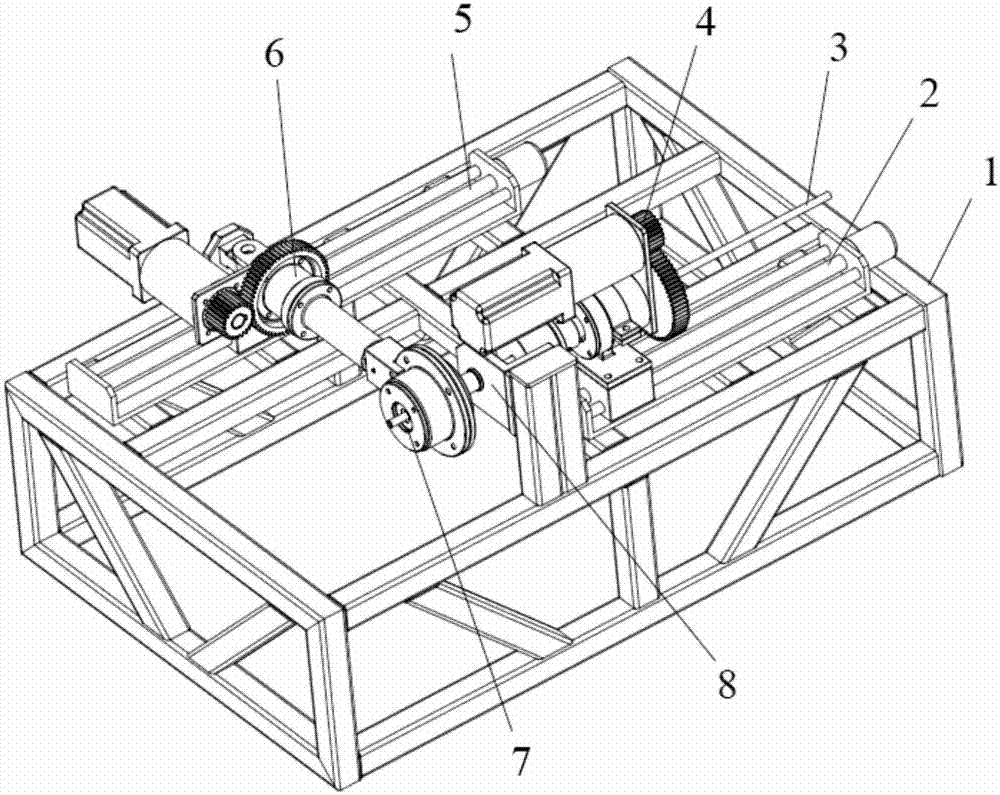

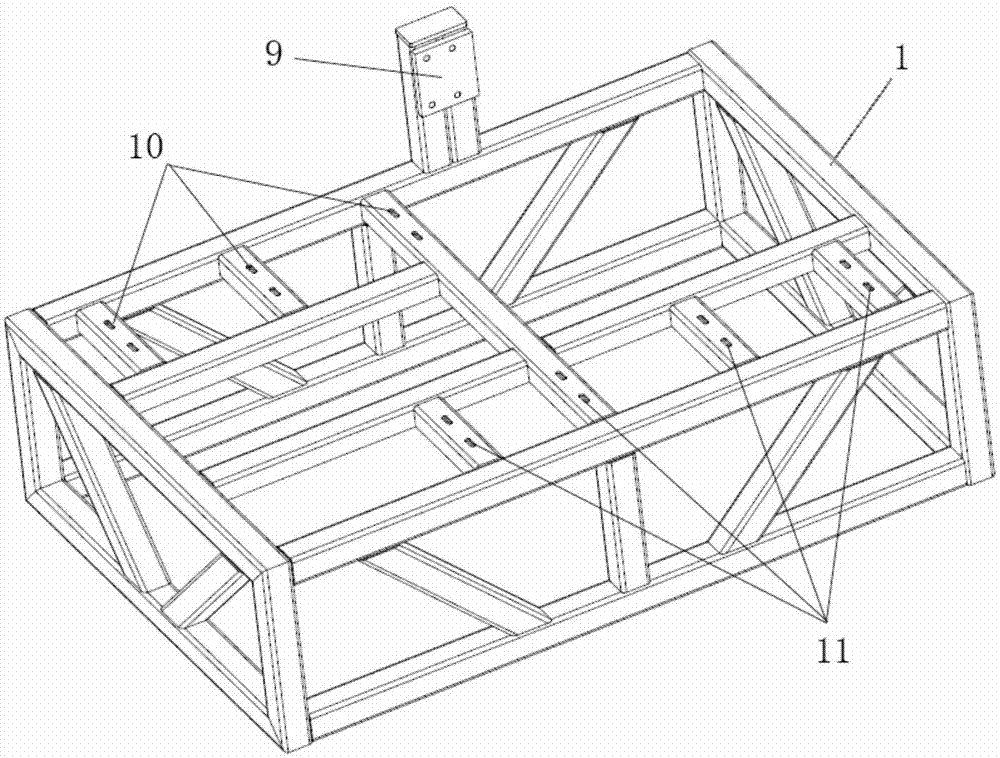

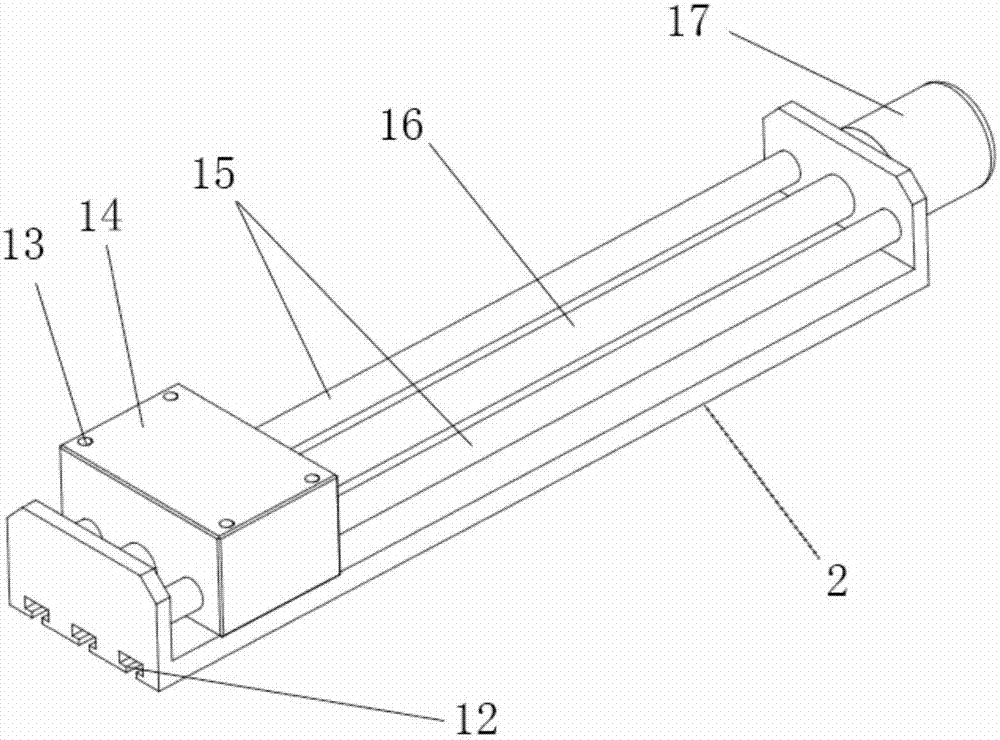

Space pipe fitting flexible bending and torsion forming device

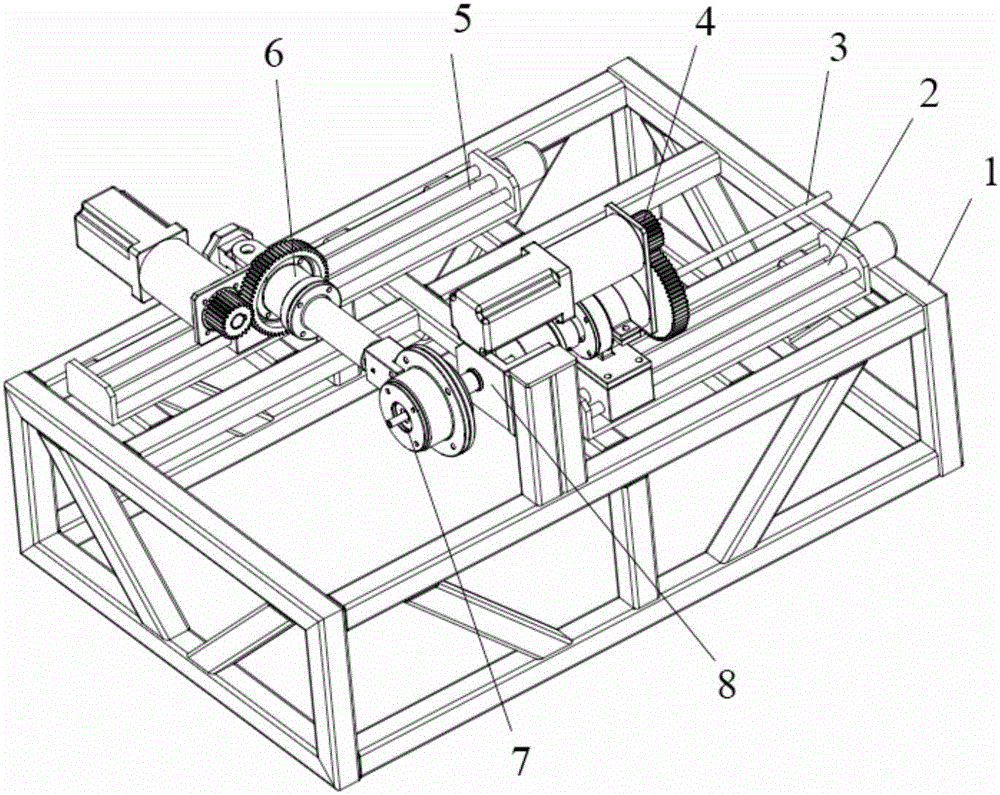

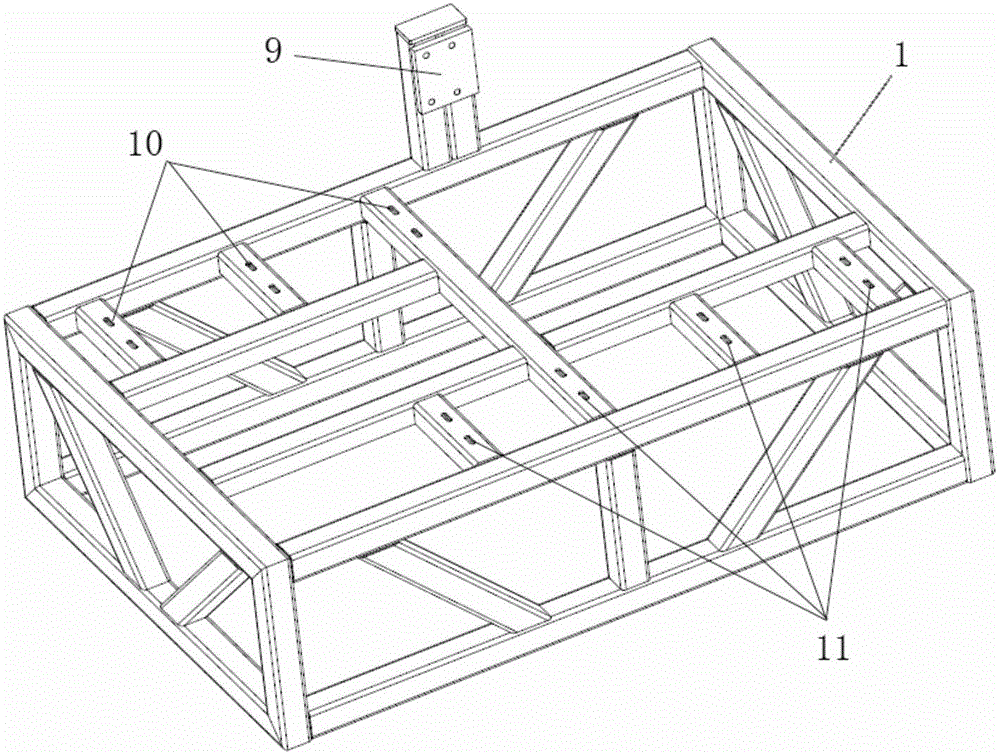

The invention discloses a space pipe fitting flexible bending and torsion forming device which is used for forming space pipe fittings of any geometric shape. A movable die control mechanism controls the relative position of a movable die and a fixed die to control the bending radius, the torsion angle of a torsion mechanism is controlled to change the bending plane, feeding mechanisms are controlled to achieve continuous feeding, and thus the space pipe fittings are formed. A three-jaw chuck on the torsion mechanism is utilized to clamp the pipe fittings, and torsion movement of the pipe fittings is achieved. The torsion mechanism is fixed to the first feeding mechanism to achieve feeding movement of the pipe fittings. The movable die control mechanism is installed on the second feeding mechanism and drives a movable die assembly to be deviated relative to a fixed die assembly when the second feeding mechanism works to achieve bending operation. The movable die control mechanism drives the movable die to rotate relative to the fixed die, and adjustment is flexible. The feeding mechanisms are driven by motors, and the torsion mechanism and a bending mechanism are driven to achieve bending and torsion forming of the space pipe fittings in multiple directions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

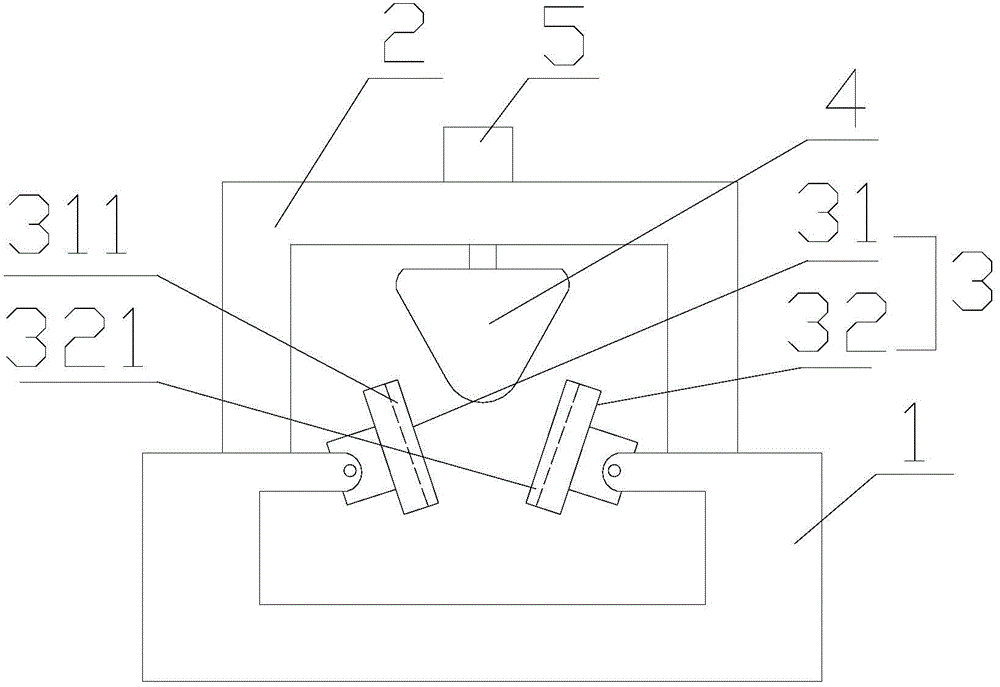

Pipe fitting bending device

InactiveCN104858271AControllable bending angleImprove bending efficiencyShaping toolsEngineeringPipe fitting

The invention provides a pipe fitting bending device which comprises a base, a mounting rack, female dies, a male die, a driving device, a first fixing part and a second fixing part, wherein the female dies comprise a first female die and a second female die, which are arranged oppositely and rotationally connected with the base respectively; a bending space used for a pipe fitting to be bent is formed between the first female die and the second female die; a first female die pipe fitting groove and a second female die pipe fitting groove are respectively formed in the first female die and the second female die in the length directions; the first fixing part used for clamping and positioning a first end of a pipe fitting is mounted in the first female die pipe fitting groove in a slideable manner; the second fixing part used for clamping and positioning a second end of the pipe fitting is mounted in the second female die pipe fitting groove in a slideable manner; the mounting rack is mounted on the base; the driving device is mounted on the mounting rack; the driving device drives and is connected with the male die positioned above the bending space, so that the male die can enter the bending space. The pipe fitting bending device provided by the invention has the advantages that the bending angle of the pipe fitting is controllable, and the bending efficiency is high.

Owner:安徽奇祥汽车零部件有限公司

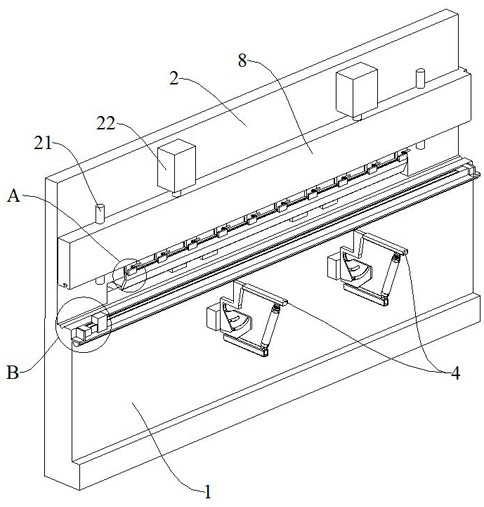

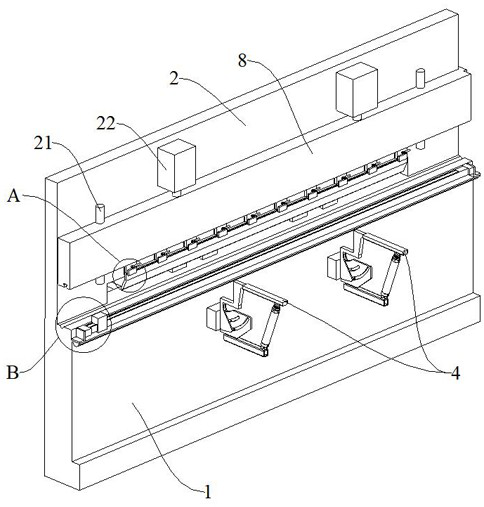

Flexible bending center

PendingCN113968016ASolve the deformationIncrease the degree of bendingGlass productionClassical mechanicsEngineering

The invention discloses a flexible bending center, and belongs to the technical field of bending machines. The flexible bending center comprises a bending assembly and a positioning assembly, the bending assembly comprises a downward pressing cross beam, downward pressing hydraulic rods, cutter frames, downward pressing cutters, an upward pressing assembly, a compensation hydraulic rod, an upward pressing base plate and supporting cross beams; the cutter frames are correspondingly arranged on the two sides of the bottom end of the downward pressing cross beam, the downward pressing cutters are arranged on the cutter frames, the downward pressing hydraulic rods are arranged at the ends, away from the cutter frames, of the downward pressing cross beam, cylinder parts of the downward pressing hydraulic rods are fixedly connected with the upward pressing base plate, the output ends of the downward pressing hydraulic rods are fixedly connected with the downward pressing cross beam, a plurality of compensation hydraulic rods are arranged on the upward pressing base plate, a downward pressing assembly is arranged at the output end of the compensation hydraulic rod, the upward pressing assembly is located below the downward pressing cutter, and the supporting cross beams are arranged on the two sides of the upward pressing base plate. The flexible bending center has the effect of accurately bending flexible materials.

Owner:QINGDAO SHENGTONG MECHANICAL TECH

Wire bending machine tool

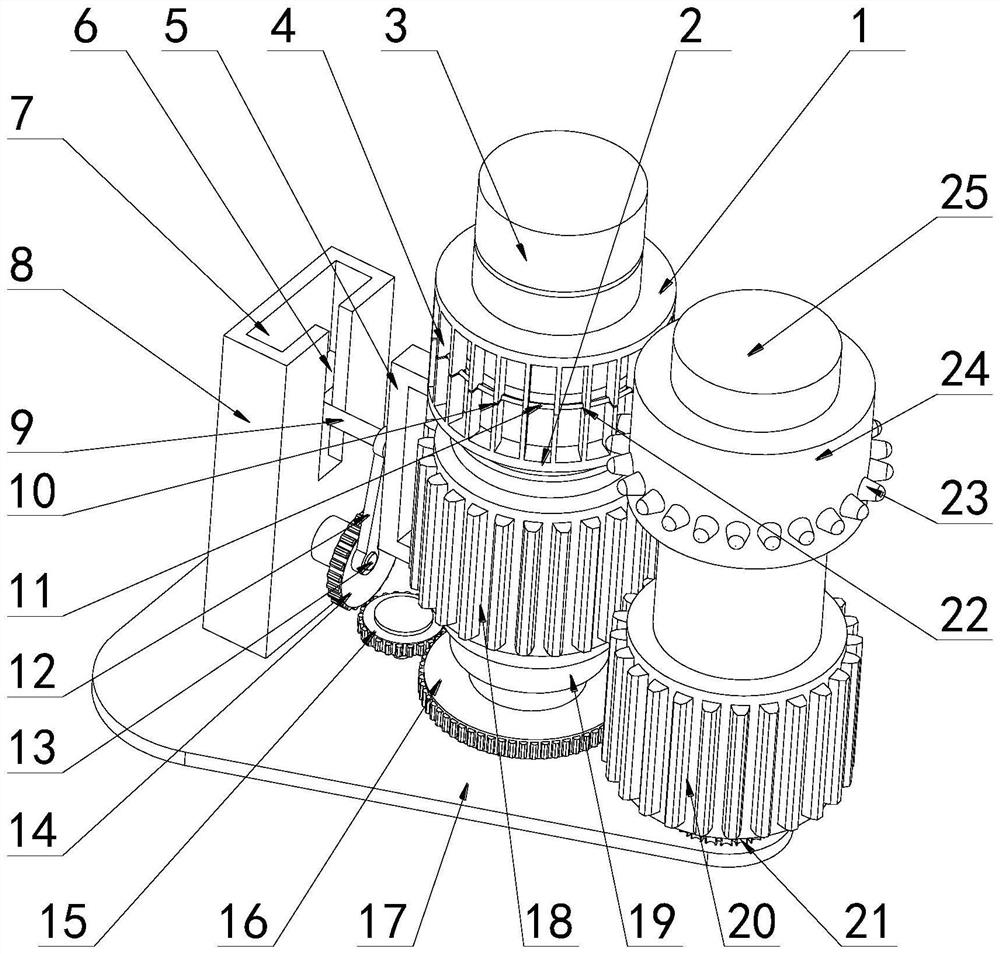

InactiveCN110560602ARealize the bending operationReasonable structureThree-dimensional spaceGear wheel

The invention discloses a wire bending machine tool. The tool comprises a rack, the rack comprises a straightening module, a conveying module and a bending module, the conveying module is used for clamping a steel wire and conveying the steel wire to the bending module from the straightening module, the bending module comprises two pipe bases fixed to the rack and a long pipe, the long pipe is rotatably arranged on the pipe bases through bearings, the long pipe is provided with a hollow cavity and used for allowing the steel wire to penetrate through, a first gear is fixed to the middle of theouter side wall of the long pipe, a first motor is arranged on the rack, a second gear is connected to the first motor, the second gear is engaged with the first gear to transmit so as to drive the long pipe to rotate, and the outer end of the long pipe is provided with a shrinkage cavity sleeve to be used for guiding the steel wire penetrating through the long pipe. The wire bending machine toolonly adopts one bending head, through cooperation motion of the gears and a sliding sleeve, bending work of the three-dimensional space shape can be achieved, the structure is reasonable, design is ingenious, and practicability is achieved.

Owner:汪海军

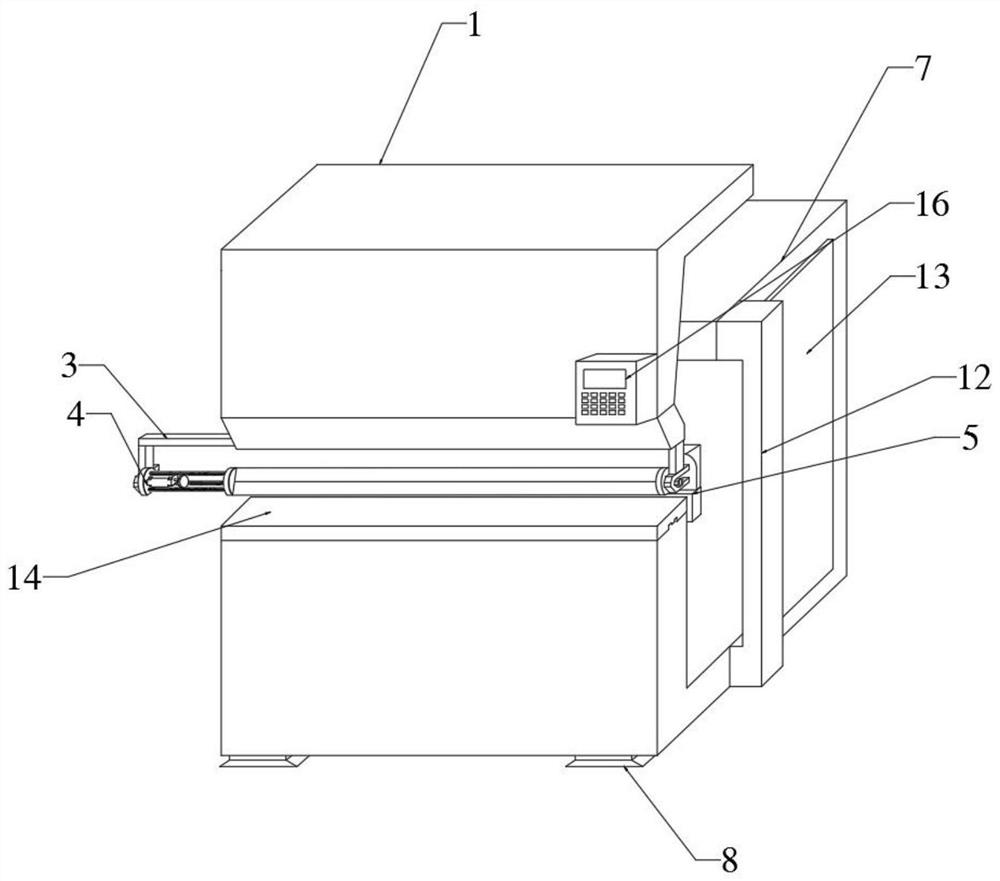

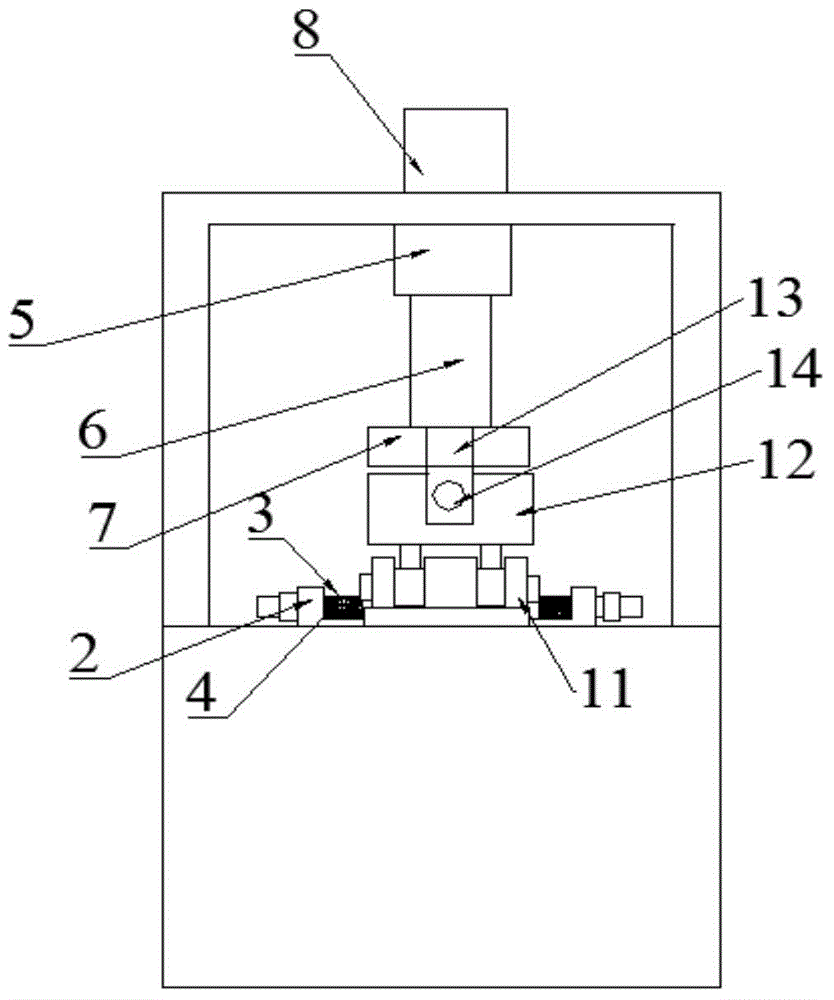

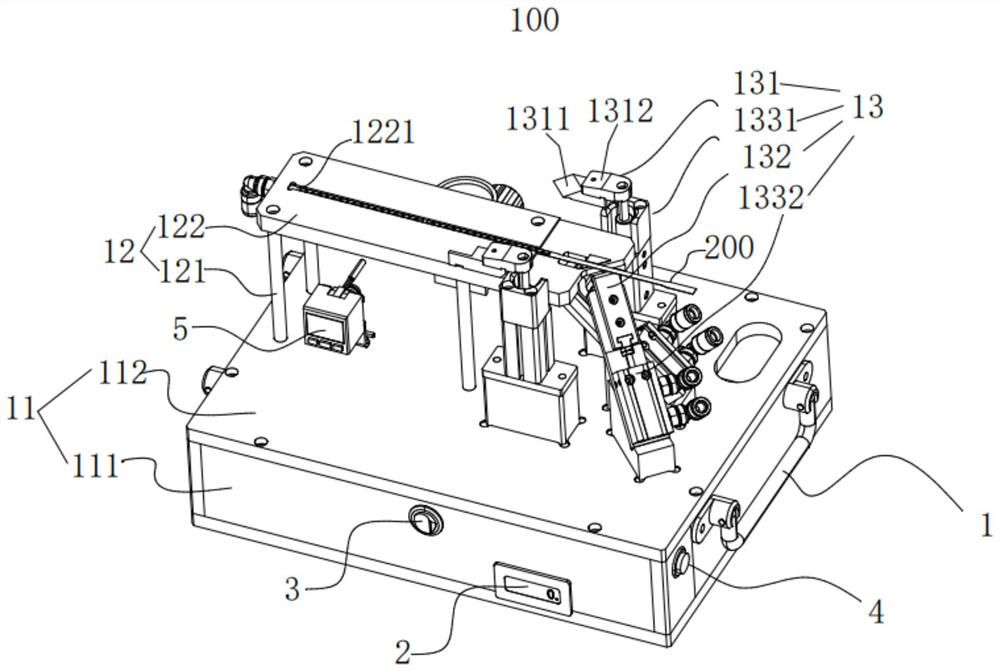

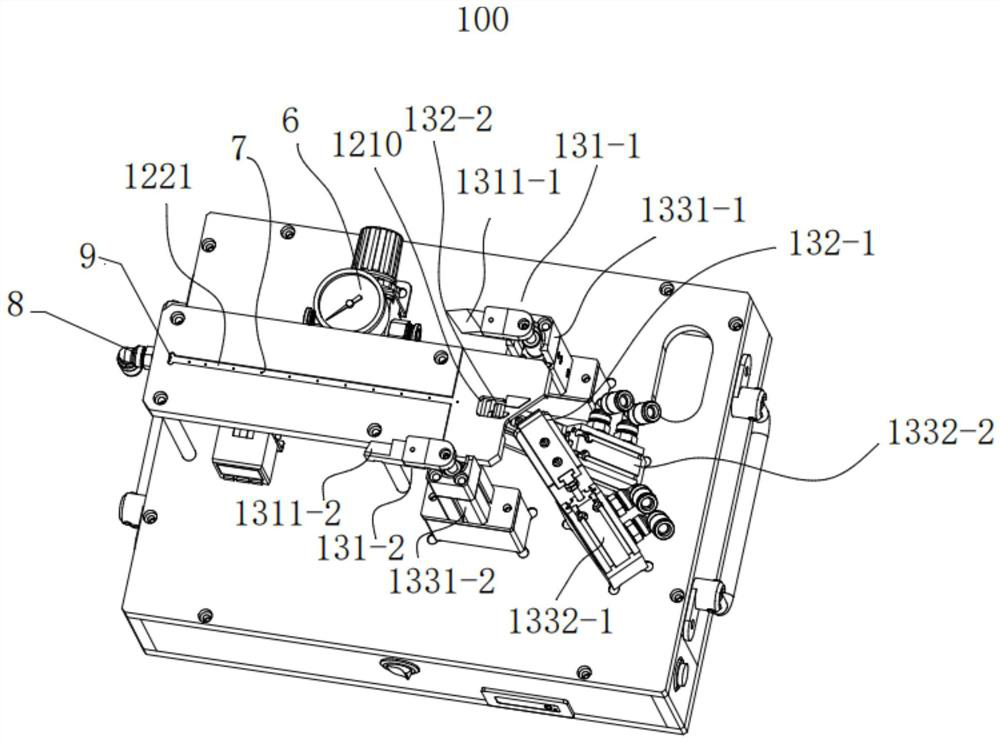

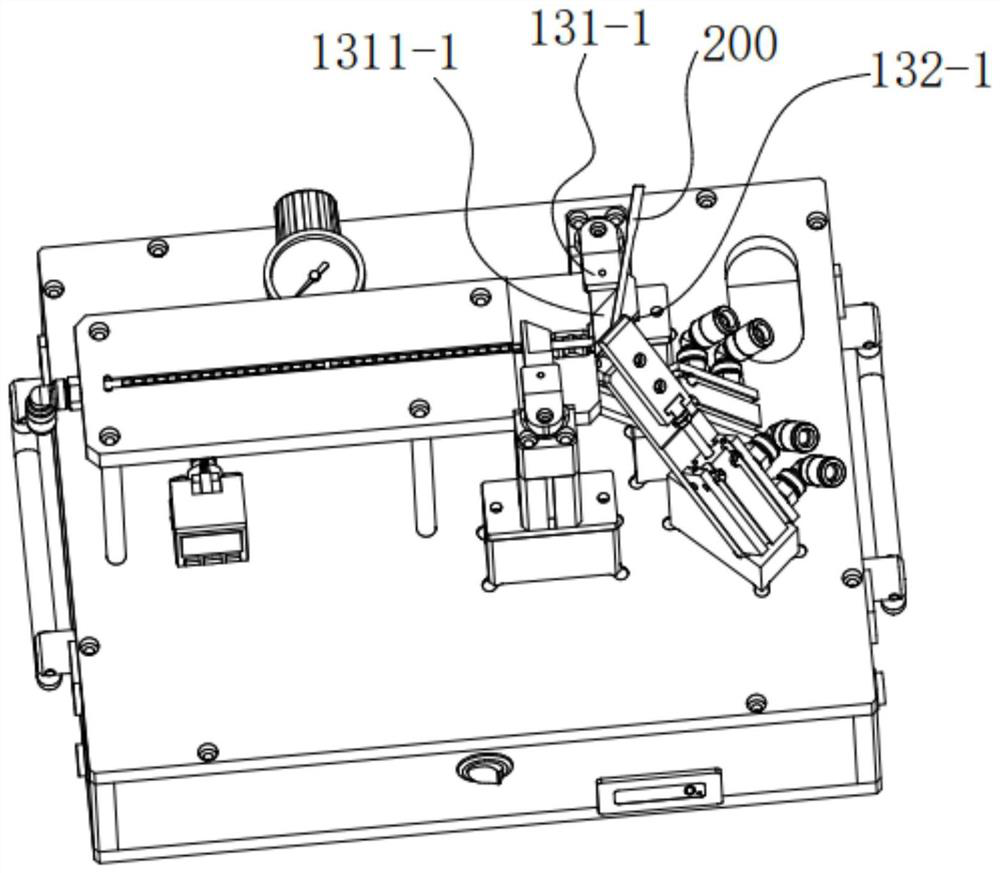

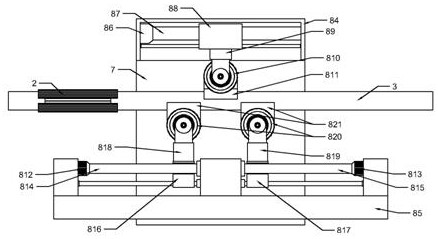

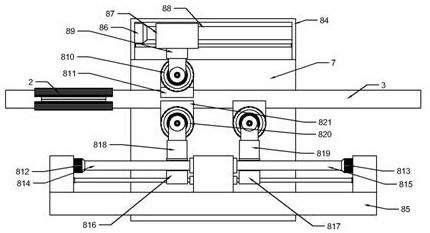

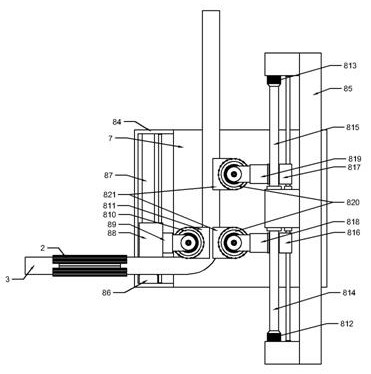

A flexible product bending linkage mechanism

PendingCN109195336ARealize the bending operationAccurate operationPrinted circuit manufactureEngineeringSafe operation

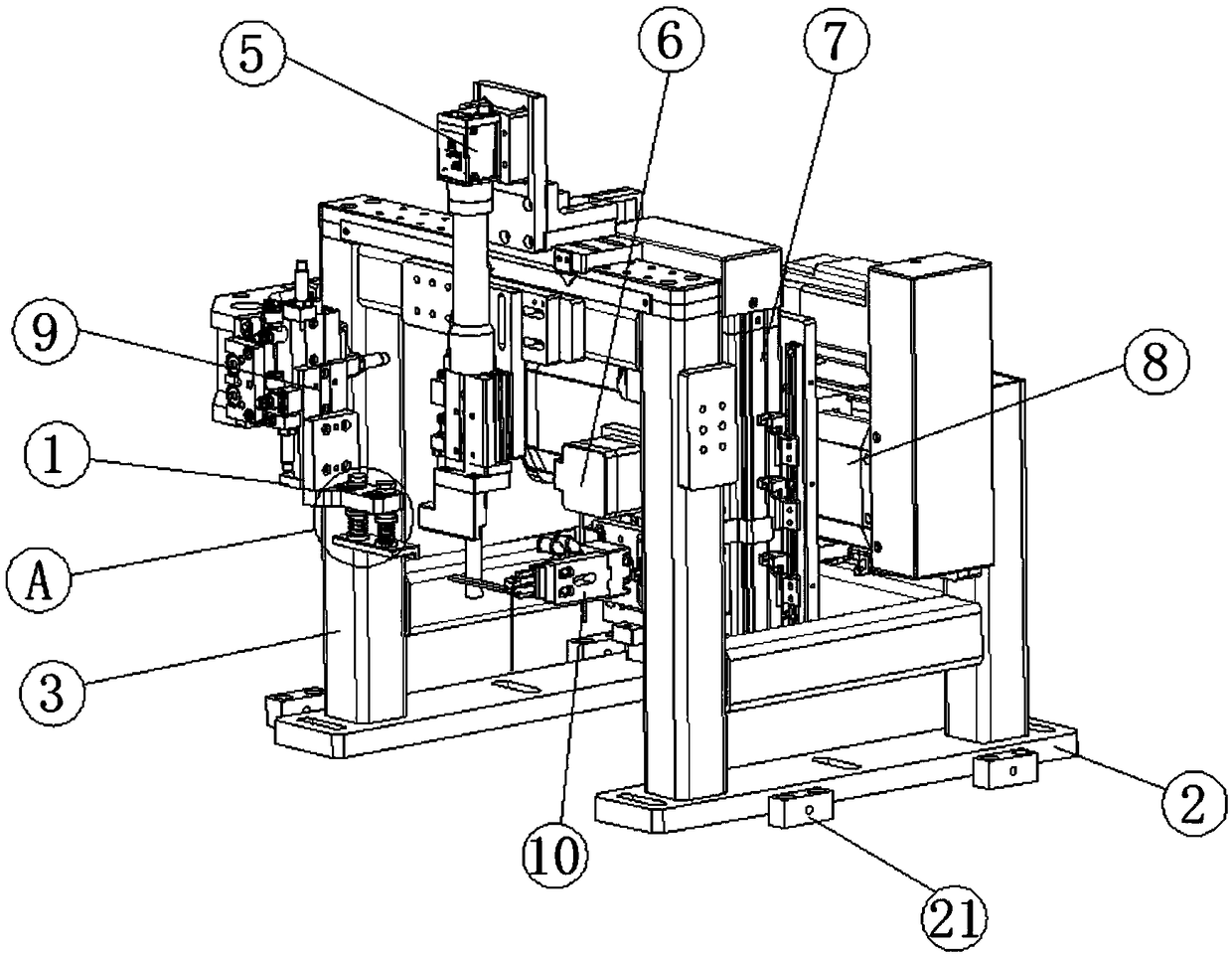

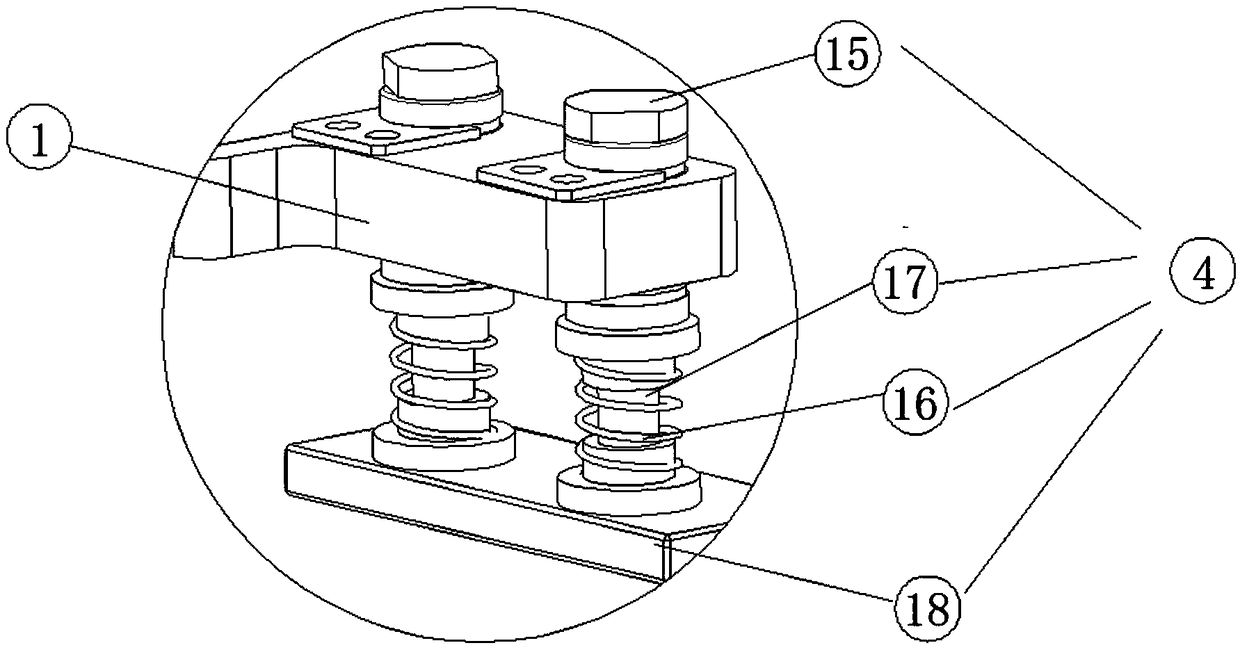

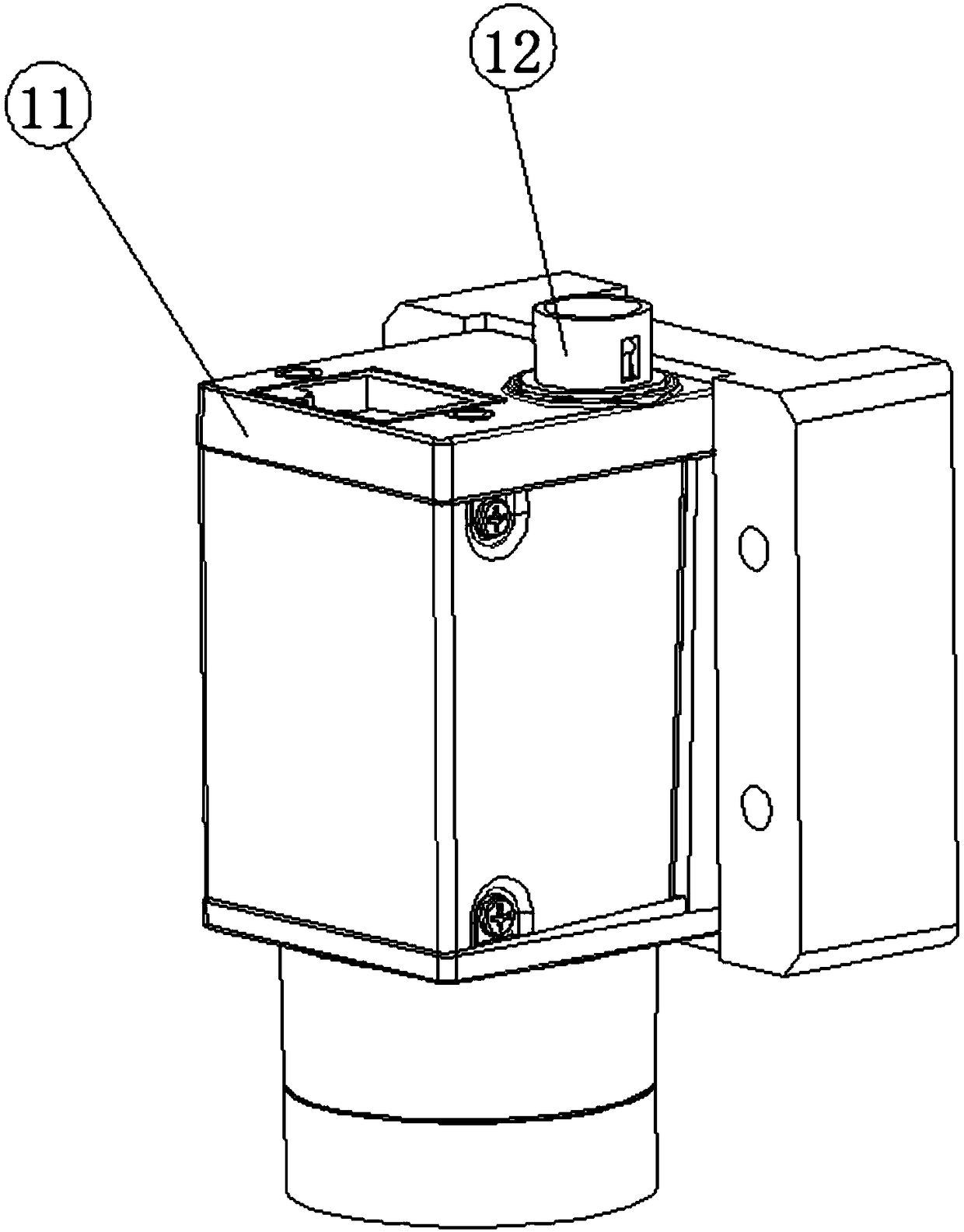

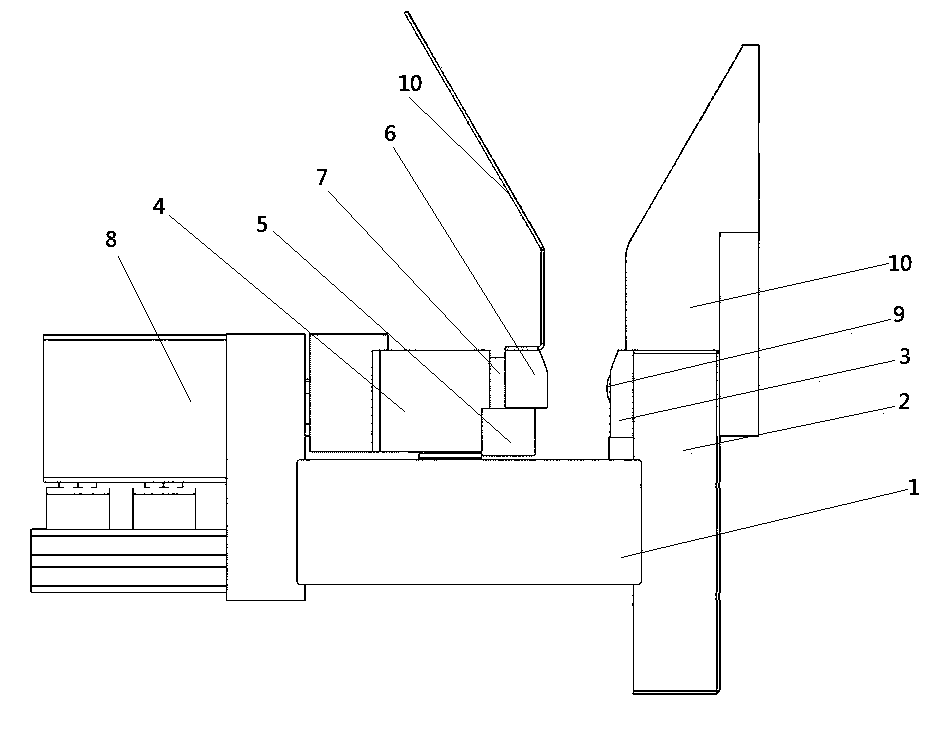

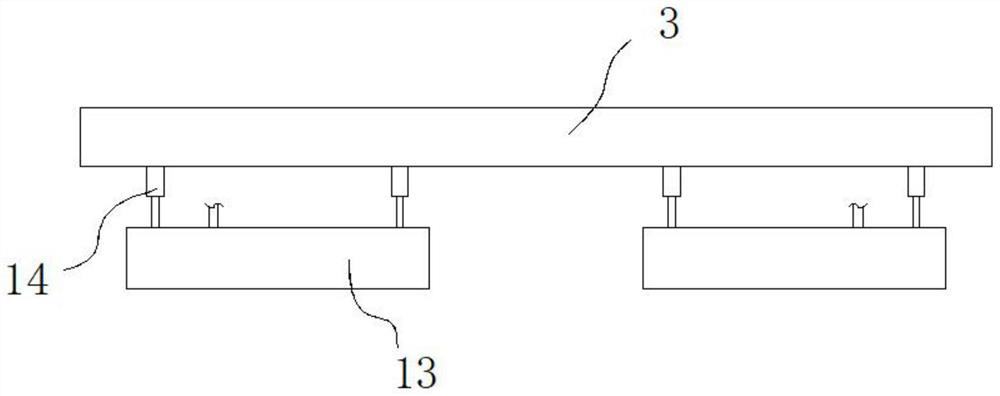

The invention discloses a flexible product bending linkage mechanism, including a connecting plates, a lower rack, bracket, spring mechanism, CCD module, rotating module, Z-axis lifting screw module,X-axis translation screw module, a pressure-retaining module and a clamping module, the support frame is fixedly connected with the lower frame, the middle part of the support frame is provided with aZ-axis lifting and lowering screw module, one side of the Z-axis lifting screw module is provided with an X-axis translating screw module, a side of the Z-axis lifting and lowering screw module far from the X-axis translating screw module is provided with a rotating module, a clamping module is arranged below the rotating module set, a CCD module is arranged on one side of the rotating module set, and the CCD module is fixedly connected with the support frame; a pressure-keeping module is arranged on the side of the CCD module set far away from the rotating module set, and the pressure-keeping module is connected with the support frame. The invention has the advantages that the angle and the position can be adjusted simultaneously, and the invention has the advantages of versatility, highproduction efficiency and safe operation.

Owner:SHENZHEN QIANGRUI ELECTRONICS

Device for bending overturned edge

The invention relates to the technical field of bending devices, in particular to a device for bending an overturned edge. The device for bending the overturned edge is simple in structure, operation of bending the overturned edge can be achieved at one time, and efficiency is improved. The device for bending the overturned edge comprises a base, wherein a locating base is arranged on one side of the base, a locating block is arranged on the locating base, a punching base which is used in cooperation with the locating base is arranged on the other side of the base, a clamping block is arranged at the lower end of the punching base, a punching block which is used in cooperation with the clamping block is arranged at the upper end of the clamping block, a punching air cylinder is arranged on the punching base, the punching block is connected with the punching air cylinder, and the punching base is connected with a locating air cylinder.

Owner:WUXI AMTEX AUTOMATION TECH

Bending device for producing composite wear-resistant lining plate

InactiveCN113600646AEfficient removalAvoid re-bendingCleaning using toolsCleaning using gasesHydraulic cylinderStamping

The invention belongs to the field of lining plate processing, and particularly relates to a bending device for producing a composite wear-resistant lining plate. The device comprises a base, a support plate is fixedly mounted on the left side of the top of the base, a top plate is fixedly connected to the top of the support plate, and a hydraulic cylinder is fixedly mounted in the middle of the top of the top plate. A piston rod of the hydraulic cylinder penetrates through the top plate and is fixedly connected with a punching head. A stamping head can be cleaned through a brush plate, so that chippings fall into a stamping groove, then a second electric push rod on one side can drive a bent lining plate to incline in the stamping groove, then the lining plate is vibrated through an electromagnetic vibrator, so that the chippings are vibrated off, negative pressure is generated through a dust collector, the chippings can be sucked away through a dust suction hood, therefore, the chippings can be effectively removed, the influence on secondary bending is avoided, meanwhile, a second electric push rod can push the lining plate, and material taking is convenient.

Owner:江苏东超耐磨材料有限公司

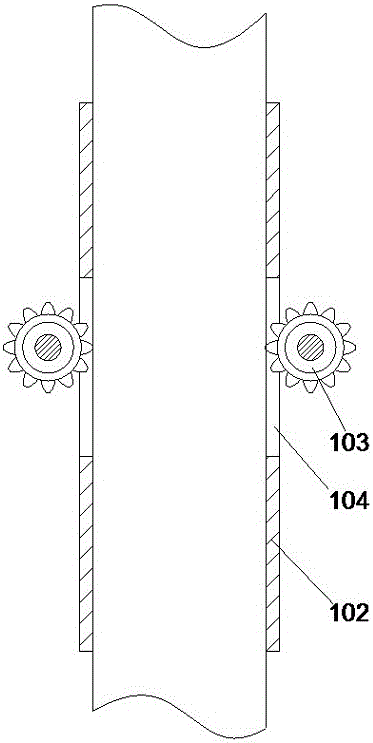

Bending equipment used for machining copper pipe

InactiveCN106270049ARealize the bending operationReduce wasteMetal-working feeding devicesOther manufacturing equipments/toolsGear driveEngineering

The invention discloses bending equipment used for machining a copper pipe. The bending equipment comprises a rack, a conveying device and a bending device, wherein the conveying device and the bending device are arranged above the rack. The conveying device comprises a positioning pipe and gears arranged on the two sides of the positioning pipe. Through grooves are formed in the two sides of the positioning pipe. The rack is provided with a gear drive motor and a speed reduction box matched with the gear drive motor. The gears are arranged on an output shaft of the speed reduction box in a sleeving manner. When the gears rotate, the outer circumferences of the gears are located on the inner sides of the through grooves of the positioning pipe. According to the bending equipment, the copper pipe can be directionally and stably conveyed, further bending operation is conducted, and the structure is simple; and in addition, end portion waste generated by bending is less, and more materials are saved.

Owner:安溪县桃舟乡同盛茶叶专业合作社

Novel transformer insulation plate bending device

InactiveCN104999710AReduce labor intensityReduce springback deformationMechanical working/deformationEngineeringTransformer

The invention provides a novel transformer insulation plate bending device, which comprises a stock, a clamping part, and a bending part, wherein the clamping part comprises a fixing plate, a leadscrew nut mechanism, a cylinder mechanism and a lower pressing plate, the middle of the fixing plate is provided with a rectangular placement groove along the length direction, the left side and the right side of the placement groove are convex, the leadscrew nut mechanism transversely passes through the convex part of the placement groove, the cylinder mechanism is fixed on the top wall of the stock, and the lower pressing plate is located at the upper part of the placement groove and fixed on the cylinder mechanism; and the bending part comprises a supporting shaft seat, a rotating pressing plate and a handle, the rotating pressing plate and the supporting shaft seat are hinged and connected, and the handle is fixed on the rotating pressing plate. The level principle is used for realizing bending operation on the insulation plate, multidirectional positioning is carried out on the insulation plate during the bending process, the insulation plate is stably fixed, labor intensity is reduced, and the problem of rebound deformation of the insulation plate can be effectively reduced.

Owner:TIANJIN TONGAN TRANSFORMER

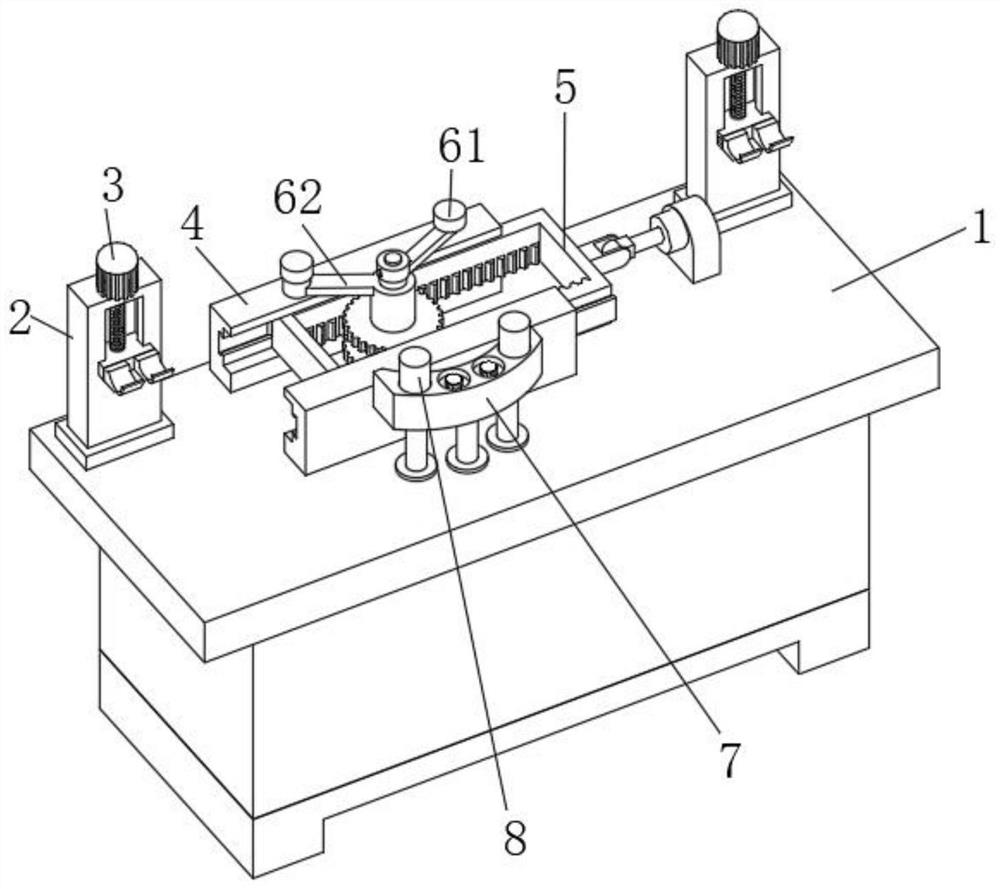

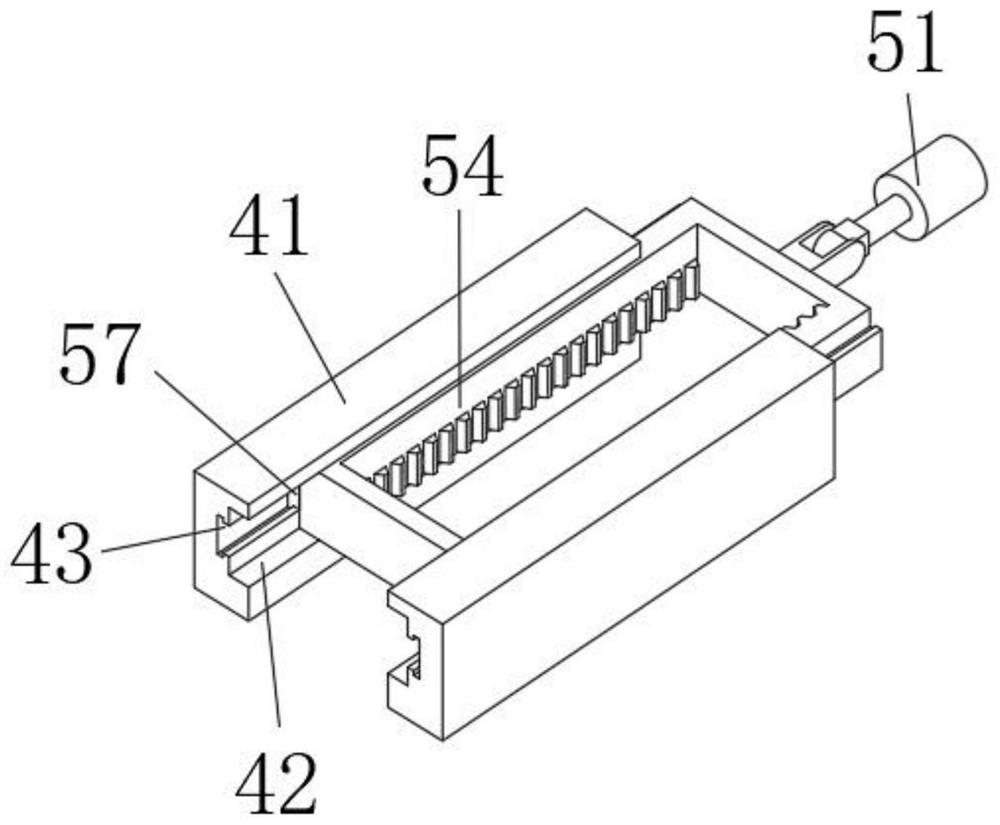

Pipe Bending Tooling

The invention relates to the field of pipe-fitting machining, in particular to a pipe-fitting bending tool. The pipe-fitting bending tool comprises a supporting table, a bending plate, a repairing rod, an expansion mechanism, a transferring mechanism and a smooth transition mechanism; the bending plate and the supporting table are hinged, and one end of the repairing rod is connected with the supporting table; a groove is formed in the circumferential wall of the repairing rod, and the expansion mechanism is arranged in the groove; the smooth transition mechanism comprises a rotating rod, a round roller and two flat-rolling mechanisms; and the transferring mechanism comprises two transferring units. During adopting the technical scheme, bending operation is conducted on a pipe fitting, meanwhile, arc stretching and repairing are conducted on the inner wall of the bending position of the pipe fitting, and the inner wall of the bending position of the pipe fitting is prevented from deforming; and meanwhile, the inner wall of the bending position of the pipe fitting is subjected to expansion, the situation that the interior of the pipe fitting is blocked during bending of the pipe fitting is prevented, then the outer wall of the bending position of the pipe fitting is subjected to flat rolling, and smooth transition at the bending position of the pipe fitting is achieved.

Owner:华汉致信(宁波)供应链管理有限公司

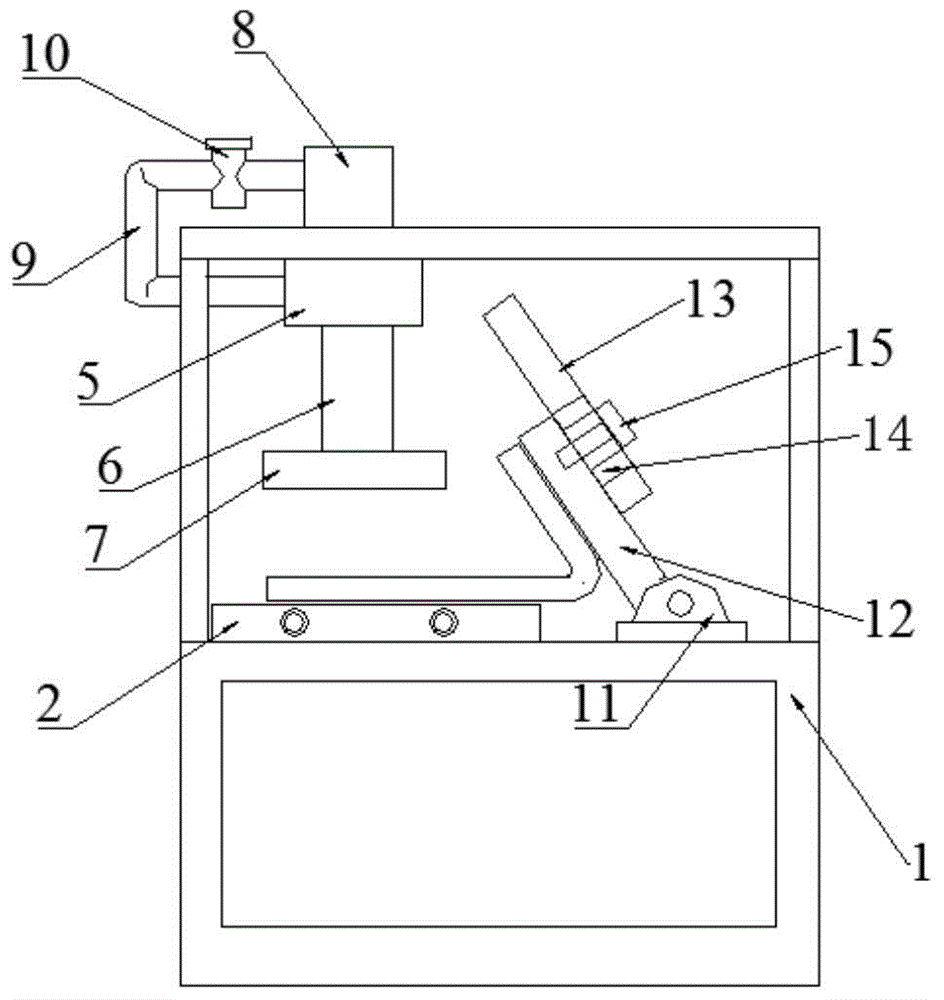

Cable bending device

InactiveCN106345938ARealize the bending operationAdjustable lengthMetal working apparatusEngineeringDrive wheel

The invention discloses a cable bending device. The cable bending device comprises a frame body, a feeding device and a bending device, wherein the feeding device and the bending device are arranged at the upper part of the frame body; the feeding device comprises a guide pipe fixedly mounted on the frame body and driving wheels arranged on two sides of the guide pipe; front-to-back grooves are formed in two sides of the guide pipe; the peripheral walls of the driving wheels are located at the inner sides of the front-to-back grooves of the guide pipe during rotating; the bending device comprises a circular rotating frame arranged on the frame body; the circular rotating frame is located at the rear side end of the guide pipe; a central cylindrical rod is arranged at the middle part of the circular rotating frame; a rotating groove is formed in the frame body; the circular rotating frame is mounted in the rotating groove via a rotary support part; a driven gear is mounted on the outer side of the lower part of the circular rotating frame; a driving gear matched with the driven gear is mounted on the right side of the driven gear; a bending and acting part parallel to the central cylindrical rod is arranged on the circular rotating frame.

Owner:张辉海

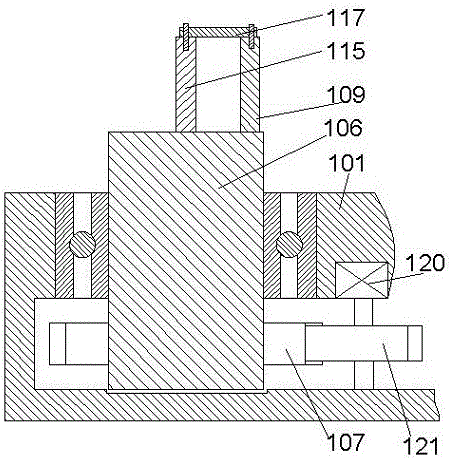

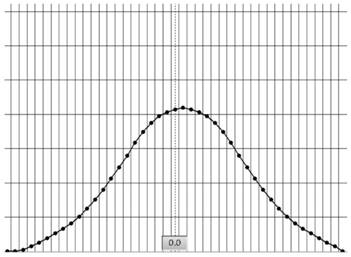

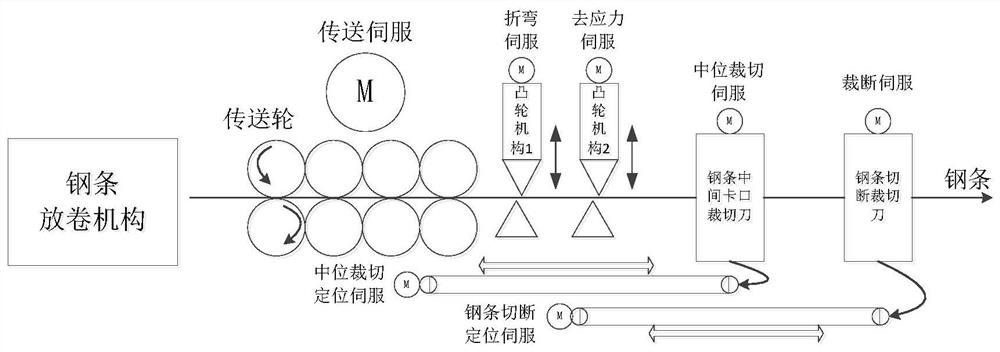

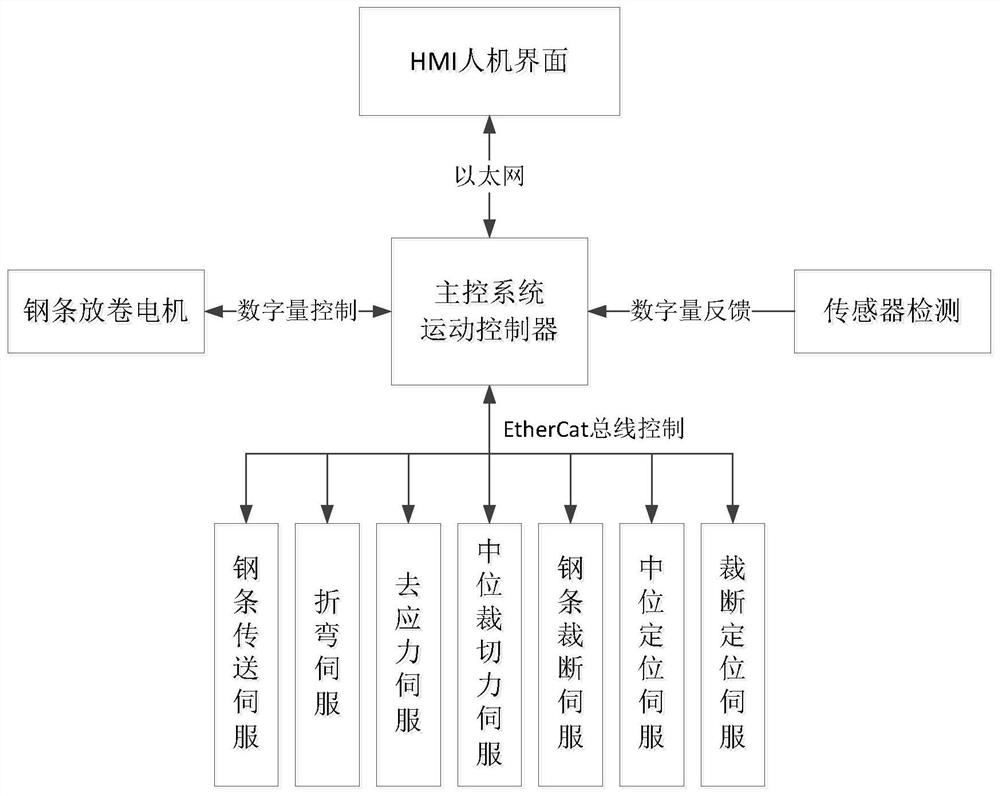

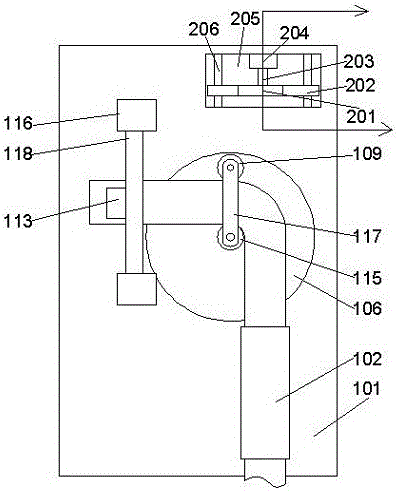

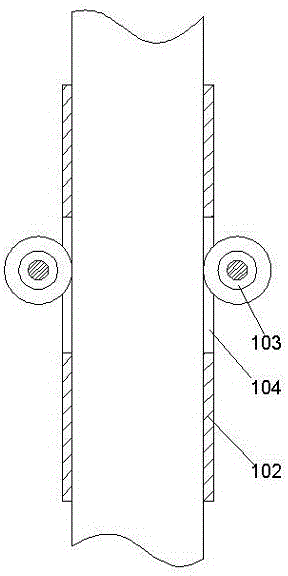

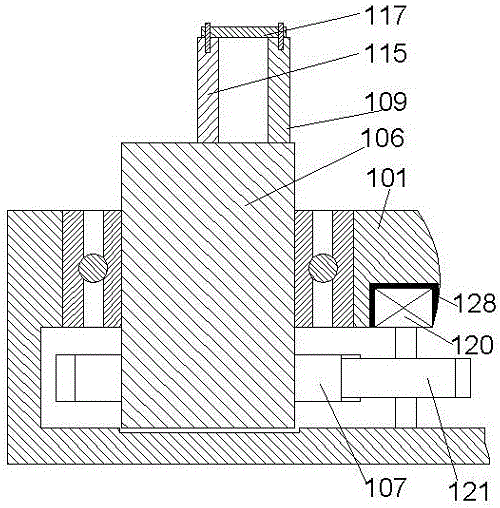

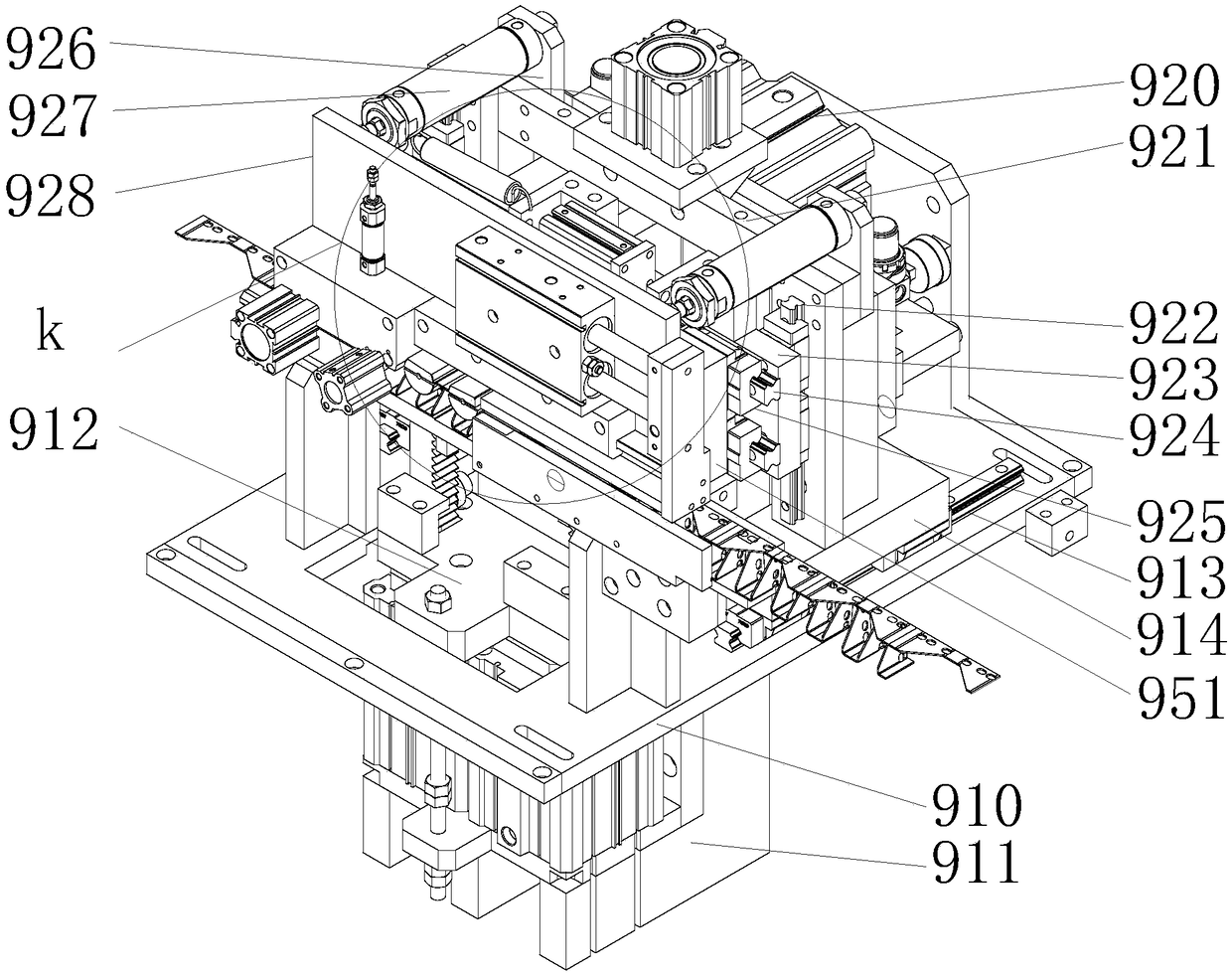

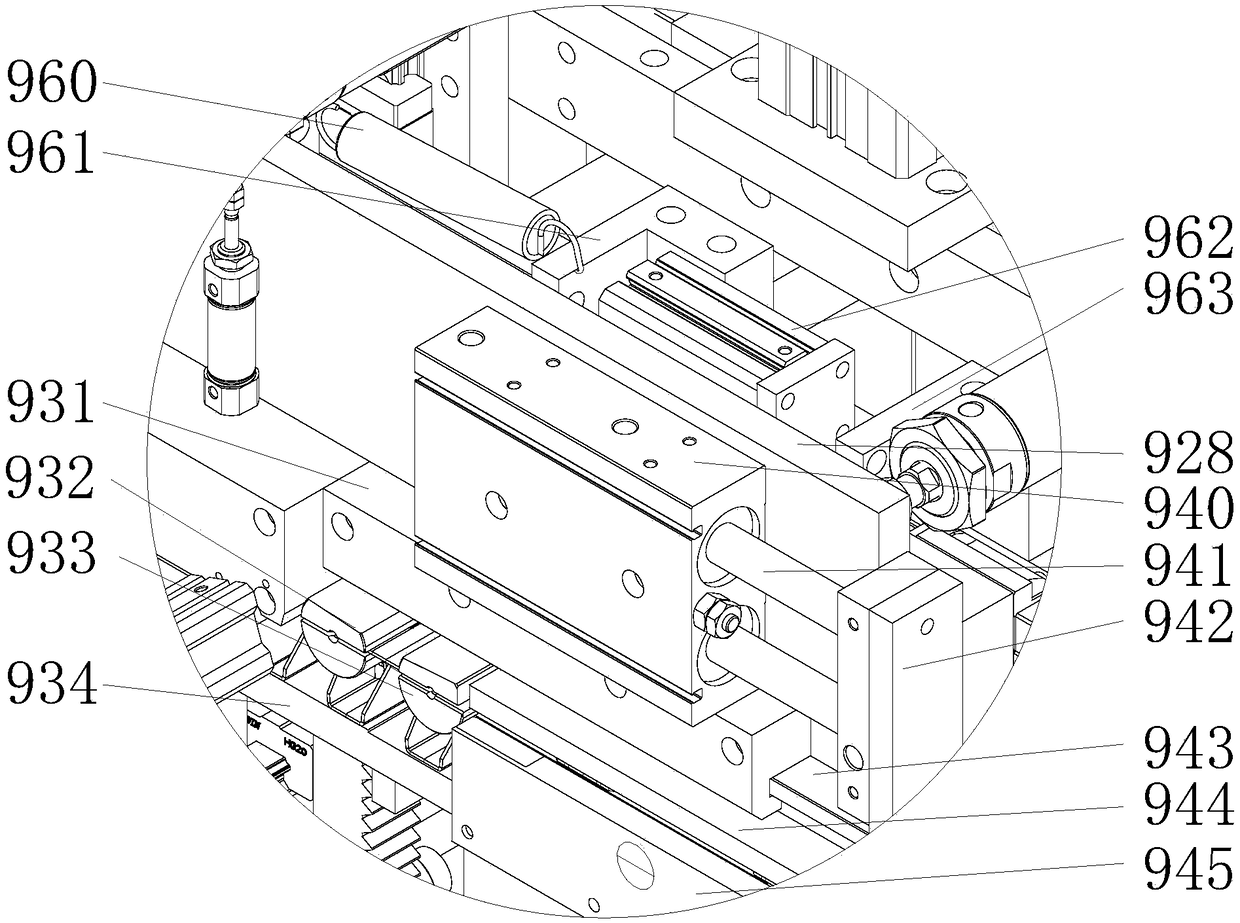

Windscreen wiper steel bar bending equipment and method thereof

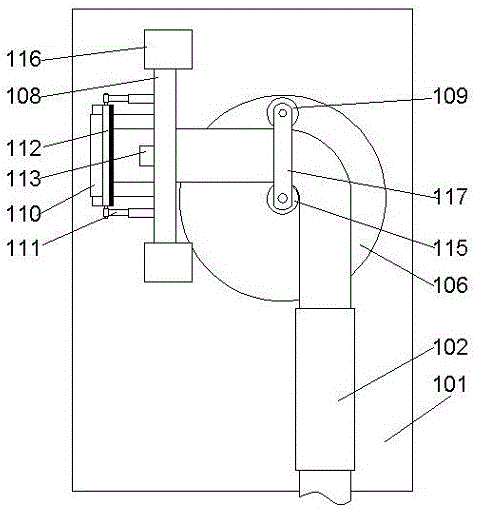

ActiveCN113059040ARealize the bending operationRelieve bending stressMetal-working feeding devicesMetal working apparatusSteel barCam

The invention discloses windscreen wiper steel bar bending equipment and a method thereof. Bending operation of a steel bar is achieved by arranging a first cam mechanism, meanwhile, a second cam mechanism is arranged between the first cam mechanism and a middle-position cutting servo, and by means of movement of the second cam mechanism, bending stress generated when the steel bar passes through the first cam mechanism is eliminated. The middle-position cutting servo is arranged on a middle-position cutting transmission device, a steel bar cutting-off servo is arranged on a steel bar cutting-off transmission device, the middle-position cutting servo and the steel bar cutting-off servo can act on a first transmission track of the middle-position cutting transmission device and a second transmission track of the steel bar cutting-off transmission device respectively, and a cutting point and a cutting-off point are controlled, so that the cutting length of the steel bar is convenient to control, and on the other hand, shaking of the steel bar during cutting or cutting off can be reduced, and the accuracy of the cutting and cutting-off positions of the steel bar is guaranteed.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

Bending device for cable

InactiveCN106493259ARealize the bending operationAdjustable lengthMetal working apparatusEngineeringMechanical engineering

The invention discloses a bending device for a cable. The bending device comprises a frame body, a feed device and a bending device body, wherein the feed device and the bending device body are arranged above the frame body. The feed device comprises a guide pipe fixedly mounted on the frame body and transmission wheels arranged on the two sides of the guide pipe. Front-and-back grooves are formed in the two sides of the guide pipe. When each transmission wheel rotates, the outer circumferential wall of the transmission wheel is located on the inner side of the corresponding front-and-back groove of the guide pipe. The bending device body comprises a round rotary frame arranged on the frame body. The round rotary frame is located at the rear side end of the guide pipe. A center cylindrical rod is arranged in the middle of the round rotary frame. A rotating groove is formed in the frame body. The round rotary frame is mounted in the rotating groove through a rotating bearing piece. A driven gear is mounted on the outer side of the lower portion of the round rotary frame. A driving gear matched with the driven gear is mounted on the right side of the driven gear. A bending acting piece parallel to the center cylindrical rod is arranged on the round rotary frame.

Owner:张辉海

Positioning assembly for heart stent metal mold processing machine tool

The present invention discloses a positioning assembly for a heart stent metal mold processing machine tool. The positioning assembly comprises a base disc, a driving pair and a vertical frame which are fixedly arranged above the base disc, and the base disc is rotationally connected with a first horizontal transmission gear disc, a second horizontal transmission gear disc and an intermittent gear through a rotating shaft; a first gear transmission roller and a second gear transmission roller are arranged above the base disc, an eccentric rod is fixedly arranged on the side face of the vertical transmission gear disc, and a transmission rod is connected between the eccentric rod and the connecting rod in a transmission manner. According to the present invention,by adopting a circulating up-and-down extrusion forming structure, the annular extrusion teeth drive a mold circular ring in an annular groove to bend, and by adopting a clearance transmission rotating structure, the annular extrusion teeth conduct extrusion forming on the mold circular ring, and meanwhile by adopting a co-power linkage transmission structure, the mold circular ring is extruded and formed to be of an uneven structure after being subjected to linkage transmission, and meanwhile, convenience is brought to disassembly and material taking after being formed at a lantern ring.

Owner:黄国强

Automatic bending machine

ActiveCN112404203AReduce laborRealize the bending operationMetal-working feeding devicesPositioning devicesStructural engineeringWorkbench

The invention discloses an automatic bending machine. The automatic bending machine comprises a workbench, a mounting frame, a bending tool and a first supporting plate, a V-shaped groove is formed inthe upper end face of the workbench in the left-right direction, the mounting frame is arranged above the workbench, the bending tool is arranged on the mounting frame in an up-down movable mode, andthe lower end of the bending tool is located over the V-shaped groove. When the bending tool moves downwards into the V-shaped groove, a steel wire framework above the V-shaped groove is forced to bebent to form a V-shaped structure. The first supporting plate is arranged on the front side of the workbench, and the end, away from the workbench, of the first supporting plate can rotate up and down around the end, close to the workbench, of the first supporting plate. When the first supporting plate rotates to the horizontal position, the upper end face of the first supporting plate is flush with the upper end face of the workbench. The steel wire framework of a horizontal net structure can be bent twice to form a C-shaped grid bridge frame, operation is easy, the working efficiency is high, the labor amount is small, and the situation that longitudinal ribs need to be bent in advance, and consequently the efficiency of welding operation is affected can be avoided.

Owner:VICHNET COMM SCI & TECH

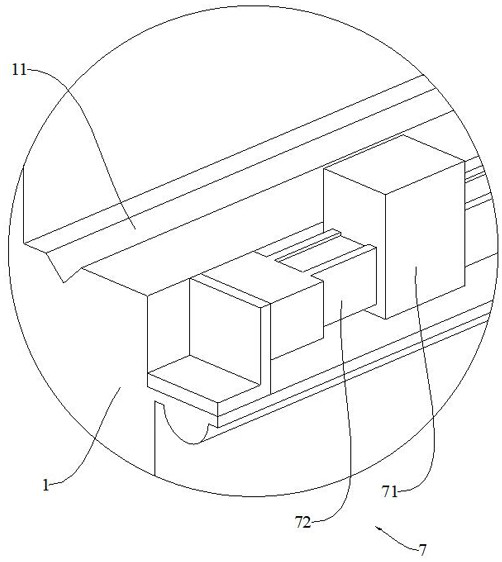

FPC bending jig

PendingCN113573479AImprove stabilityImprove work efficiencyPrinted circuit manufactureStructural engineeringPress brake

Owner:KUNSHAN WAYS ELECTRONICS

Cable bending device

InactiveCN106513534ARealize the bending operationAdjustable lengthMetal working apparatusDrive wheelEngineering

The invention discloses a cable bending device. The cable bending device comprises a rack body and a feeding device and a bending device which are arranged above the rack body. The feeding device comprises a guide tube which is fixedly mounted on the rack body and driving wheels which are arranged on two sides of the guide tube, front and back grooves are formed in two sides of the guide tube, and the outer circumferential walls of the driving wheels which rotate are located on the inner sides of the front and back grooves of the guide tube; the bending device comprises a round rotary rack which is arranged on the rack body, the round rotary rack is located at the back side end of the guide tube, a central cylindrical rod is arranged on the middle part of the round rotary rack, a rotary groove is formed in the rack body, the round rotary rack is mounted in the rotary groove through a rotary supporting piece, a driven gear is mounted on the outer side of the lower part of the round rotary rack, a driving gear matched with the driven gear is mounted on the right side of the driven gear, and a bended acting piece which is parallel to the central cylindrical rod is arranged on the round rotary rack.

Owner:张辉海

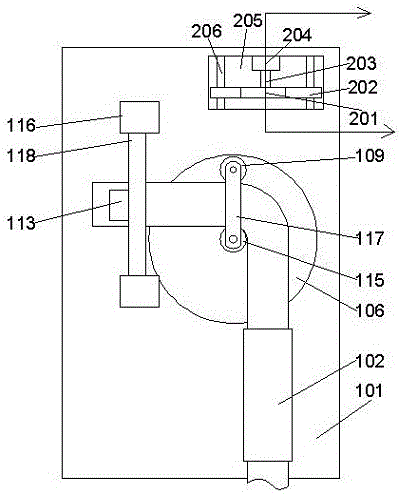

Motor coil middle head cushion paper forming discharging device

PendingCN110641080AReduce labor intensityUnified shape standardPaper/cardboard articlesMetal working apparatusMolding machineCushion

The invention discloses a motor coil middle head cushion paper forming discharging device which comprises a support, a feeding mechanism, a forming mechanism and a cutting mechanism. The feeding mechanism, the forming mechanism and the cutting mechanism are arranged on the support. Due to pulling of the feeding mechanism, cushion paper enters the forming mechanism for conducting forming operationthrough an auxiliary limiting device, then under the push of the feeding mechanism, the formed cushion paper is pushed to enter the cutting mechanism to be cut, and the cut cushion paper falls into astorage box body to be stored. By means of the motor coil middle head cushion paper forming discharging device, due to the fact that the feeding mechanism, the forming mechanism and the cutting mechanism which are matched and used are arranged on the support, the feeding mechanism is used for pulling the cushion paper to penetrate the forming mechanism for conducting forming operation, the formedcushion paper is pushed to enter the cutting mechanism to be cut, existing manual bending cutting is changed into automatic bending cutting, shape standards can be unified, the work efficiency is improved, and the labor intensity of personnel is lowered.

Owner:XINXIANG HUIHUANG SPRING

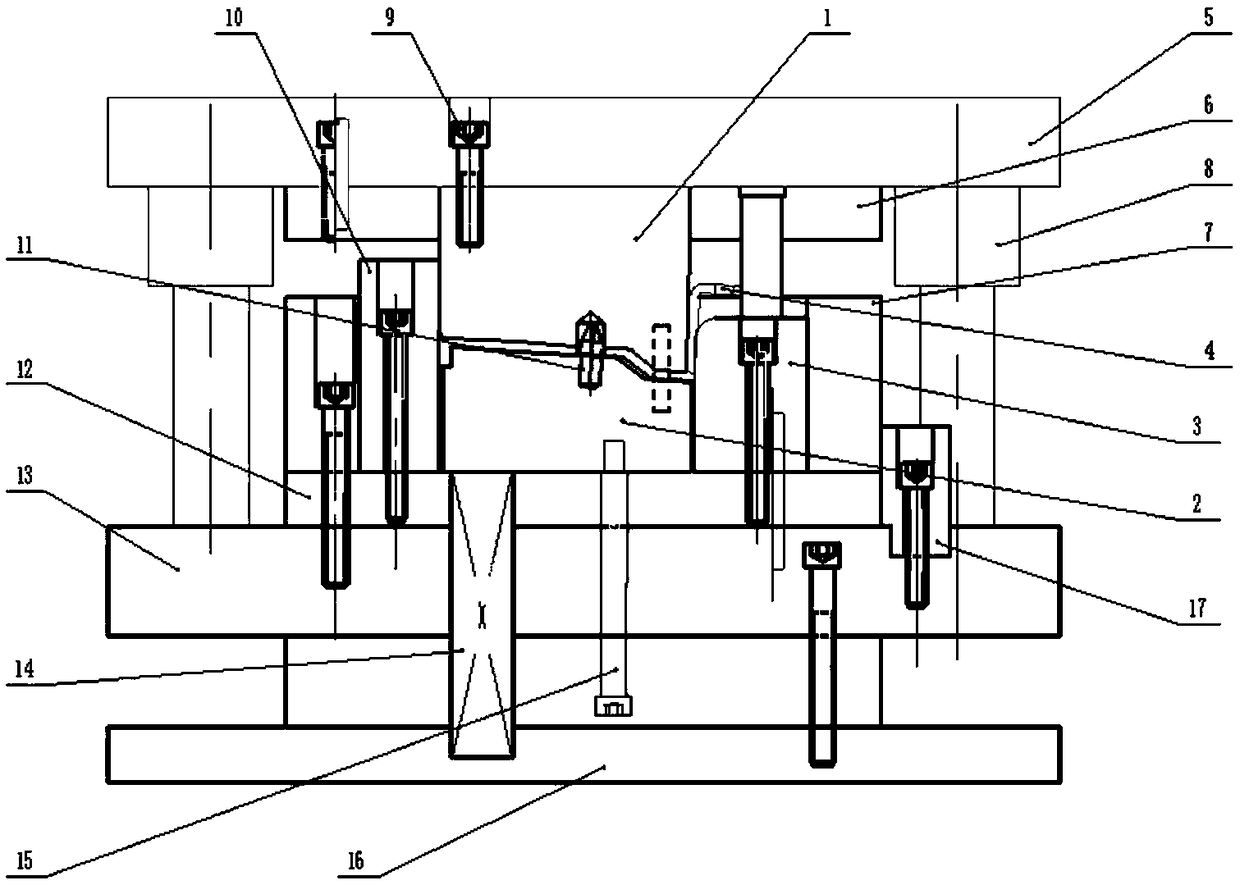

Automobile engine thermostat housing supporting and bending die

The invention provides an automobile engine thermostat housing supporting and bending die, which comprises an upper die seat and a lower die seat. A lower cushion plate is arranged on the end face, facing the upper die seat, of the lower die seat, and an upper clamping plate is arranged on the end face, facing the lower die seat, of the upper die seat. A convex die is arranged on the end face, facing the lower die seat, of the upper clamping plate. The upper clamping plate surrounds the outer side of the convex die, and a concave die and a float block are arranged on the end face of one side,facing the upper die seat, of the lower cushion plate. The concave die surrounds the outer side of the float block, and the end face, facing the float block, of the convex die is provided with a positioning hole. A positioning pin is arranged on the float block and inserted into the positioning hole, and contact end faces of the convex die and the float block are both inclined faces. By inclined contact faces of the convex die and the float block, product bending is realized, once forming of workpieces can be realized, separated procedures for workpiece machining are avoided, and accordingly labor cost is reduced, actual economic benefits are brought to enterprises, formed products are high in surface precision, and user demands can be well met.

Owner:沈阳聚和源汽车部件有限公司

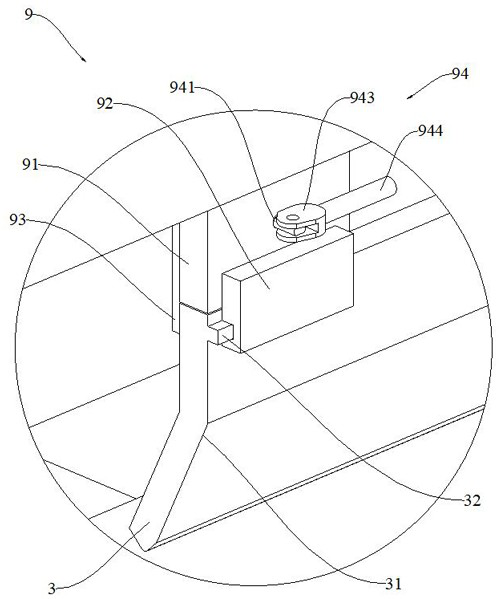

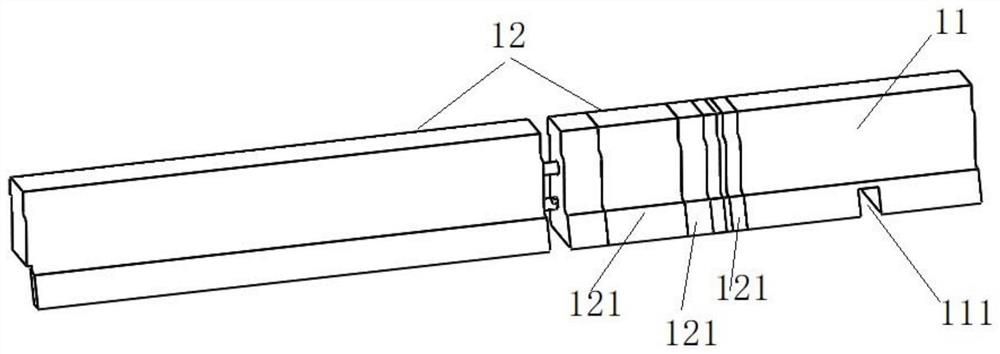

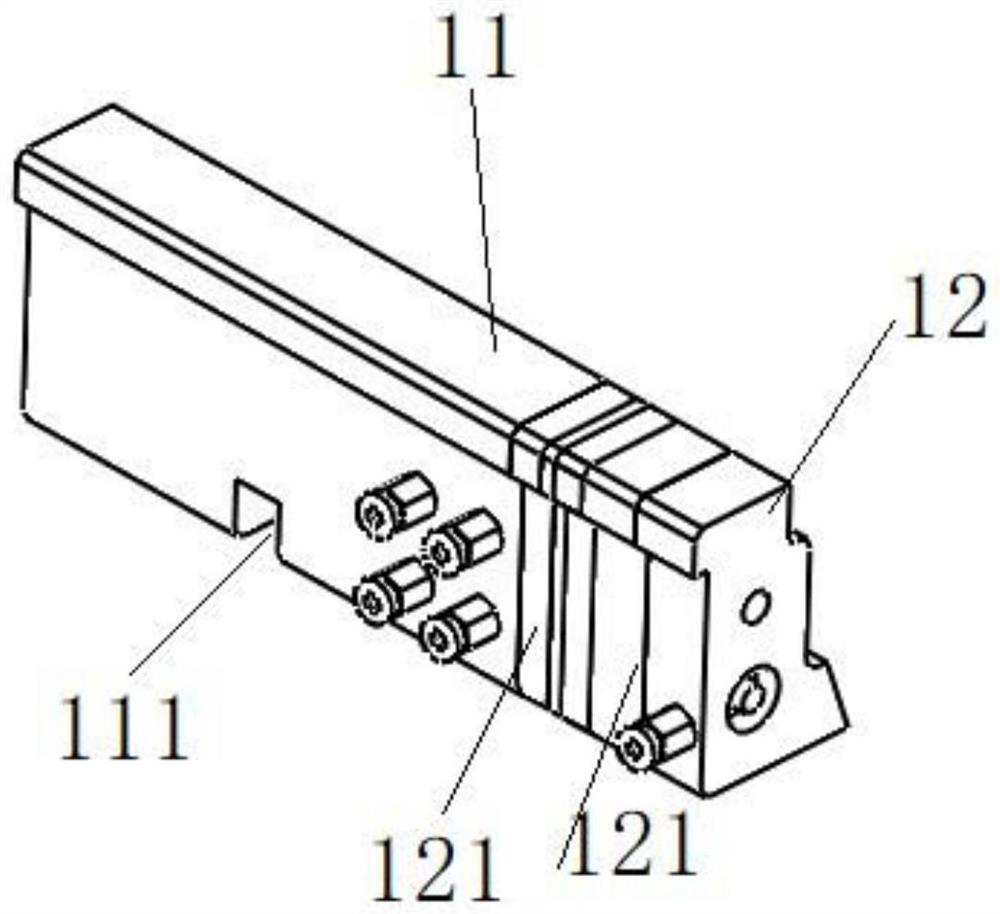

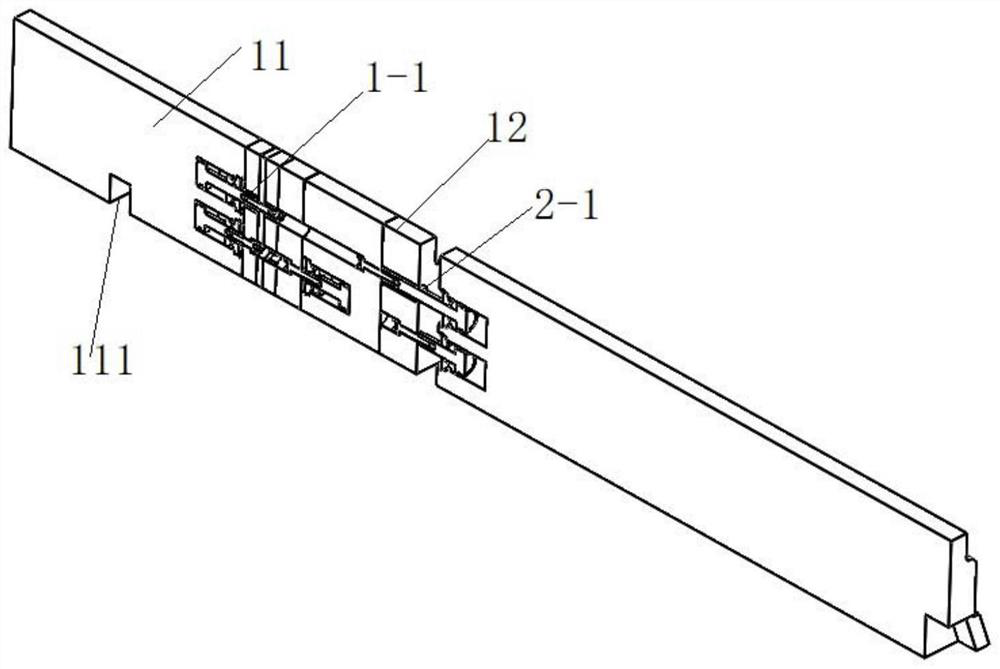

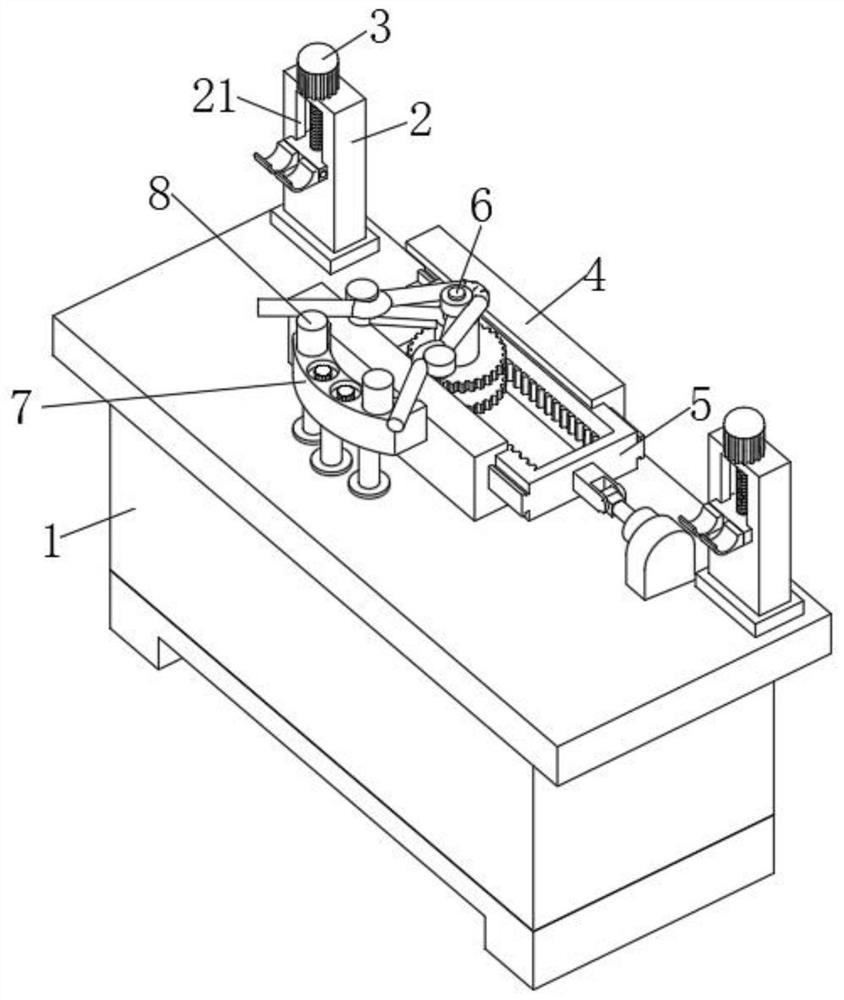

Self-adjusting die strip assembly and bending equipment adopting same

PendingCN114871316ARealize the bending operationAvoid damageShaping toolsStructural engineeringMechanical engineering

The invention relates to the field of bending equipment, in particular to a self-adjusting die strip assembly and bending equipment adopting the die strip assembly.The self-adjusting die strip assembly comprises an upper die strip; the upper die strip comprises a die strip body; the mold strip body comprises a fixed mold strip; the fixed mold strip is connected with an adjusting mold strip; the adjusting mold strip is provided with a plurality of single mold strips; the adjacent single mold conditions are connected in sequence; an avoiding groove is formed in the fixed mold strip; according to the self-adjusting type die strip assembly, by optimizing the structure of an upper die strip, die strip lengths of different lengths can be selected according to needs in the actual use process, then bending operation of the ends of plates of different sizes is achieved, in addition, an avoiding groove is formed in a fixed die strip, the interval between the single die strips is controlled, the die strip length can be adjusted, and the die strip length can be adjusted. Therefore, the die strip length, participating in work, of the upper die strip is provided with two groove body structures, an avoiding effect is achieved, and the situation that when the die strip assembly is bent, a flanging structure at the edge of a plate is damaged is avoided.

Owner:江苏天辰智能装备有限公司

Bending device for hardware machining and production

The invention discloses a bending device for hardware machining and production. The bending device comprises an operation table, each of the left side and the right side of the upper end of the operation table is fixedly provided with a fixing frame, each of the front ends of the two fixing frames is provided with a movable groove, each of the upper ends of the two fixing frames is connected with a lifting mechanism in a penetrating and inserting mode, a stabilizing frame is fixedly installed in the middle of the upper end of the operation table, a driving mechanism is slidably connected into the stabilizing frame, a bending mechanism is movably connected to the upper end of the operation table through a bearing, the bending mechanism is located in the middle of the interior of the stabilizing frame and is in transmission connection with the driving mechanism, radian control mechanisms are fixedly installed on the front portion and the rear portion of the upper end of the operation table, and each of the left side and the right side of the upper end of the radian control mechanism is detachably provided with a limiting blocking column. The bending device for hardware machining and production is compact in structure, high in automation degree, capable of achieving bending of multiple positions of reinforcing steel bars through one-time operation, adjustable in bending angle, high in bending precision and capable of being widely used and popularized.

Owner:屈洁

Spacing-adjustable steel belt bending mechanism

InactiveCN108941435AAdjustable bending distanceRealize the bending operationMetal-working feeding devicesPositioning devicesSteel beltArchitectural engineering

The invention discloses a spacing-adjustable steel belt bending mechanism. The spacing-adjustable steel belt bending mechanism comprises a horizontally-arranged bending bottom plate, wherein a secondbending bottom plate is vertically arranged on the bending bottom plate; the second bending bottom plate is sequentially provided with a bending fixed block, a left sliding bottom plate, a resetting driving source and a right sliding bottom plate from left to right; both the bending fixed block and the resetting driving source are fixedly arranged being relative to the second bending bottom plate;the bending fixed block is connected with the left sliding bottom plate through a spring; the bending fixed block is further provided with an adjusting bolt, and the end of the adjusting bolt abuts against the left sliding bottom plate; the motion output end of the resetting driving source abuts against the right sliding bottom plate; the left sliding bottom plate is provided with a left clampingplate capable of clamping a steel belt and rotating; and the right sliding bottom plate is provided with a right clamping plate capable of clamping the steel belt and rotating. The spacing-adjustablesteel belt bending mechanism is high in precision and efficiency, wide in application range, and compact in structure and saves manpower, the spacing between channel bodies of a great wall chain canbe adjusted according to requirements.

Owner:苏州市翔耀精密自动化设备有限公司

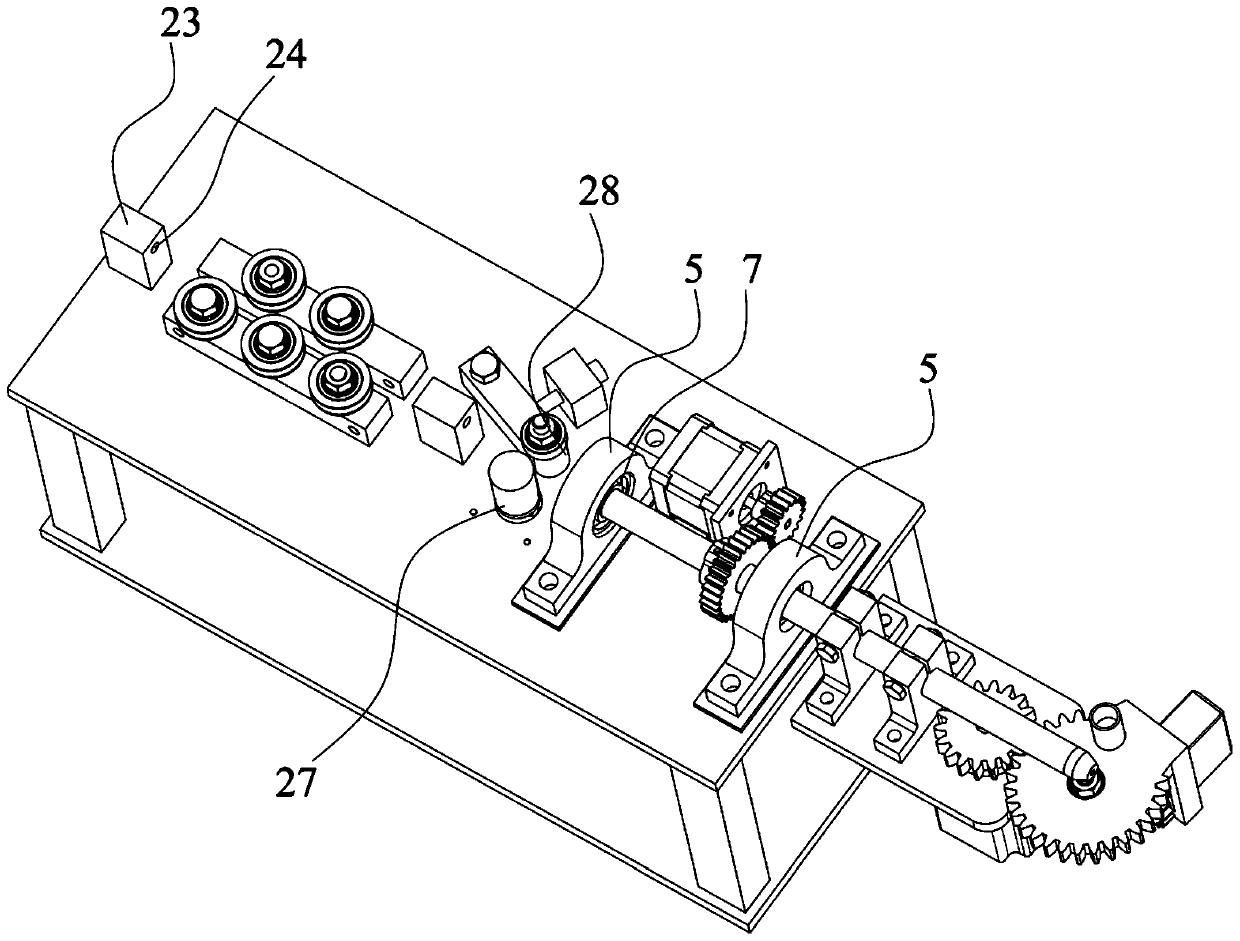

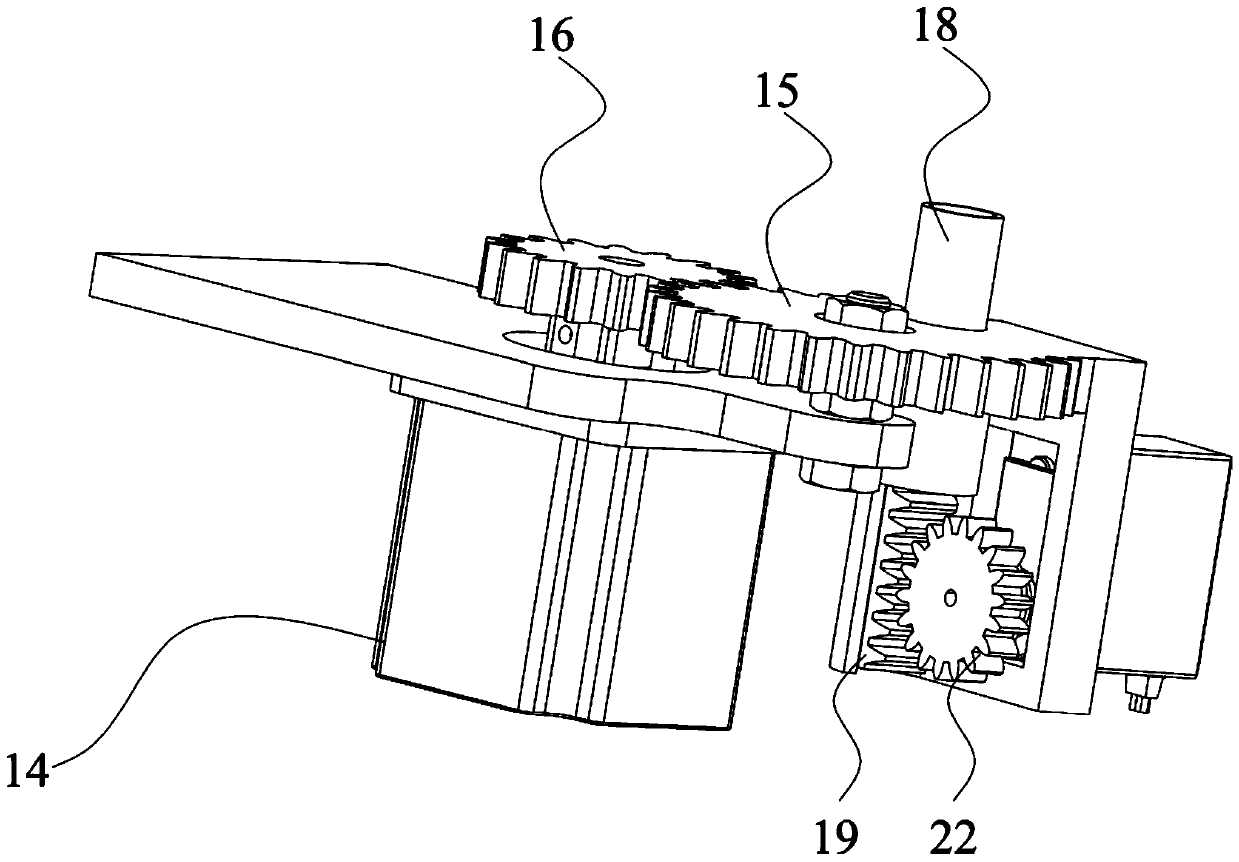

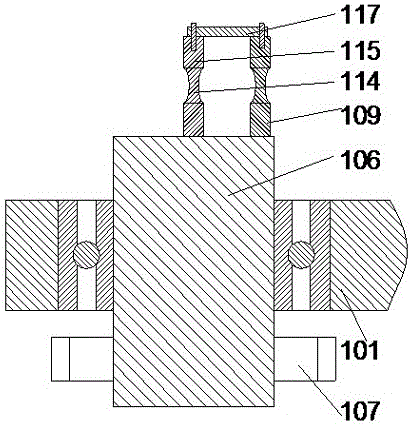

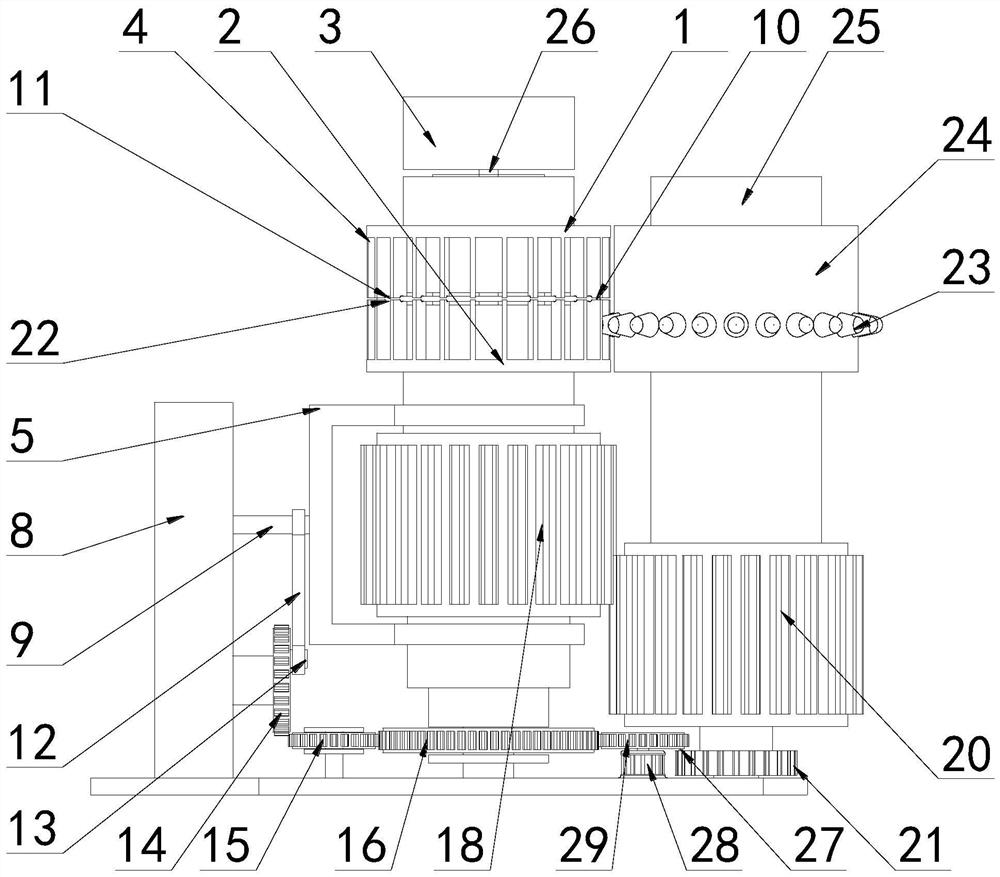

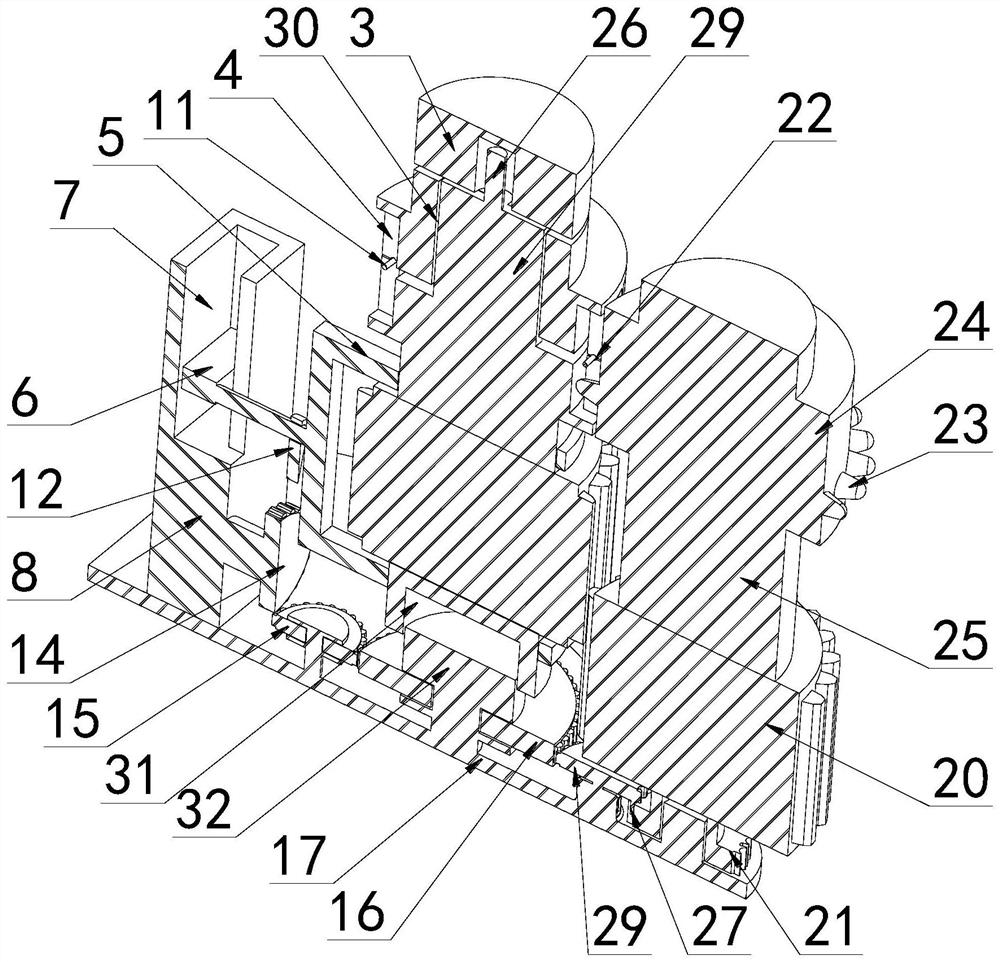

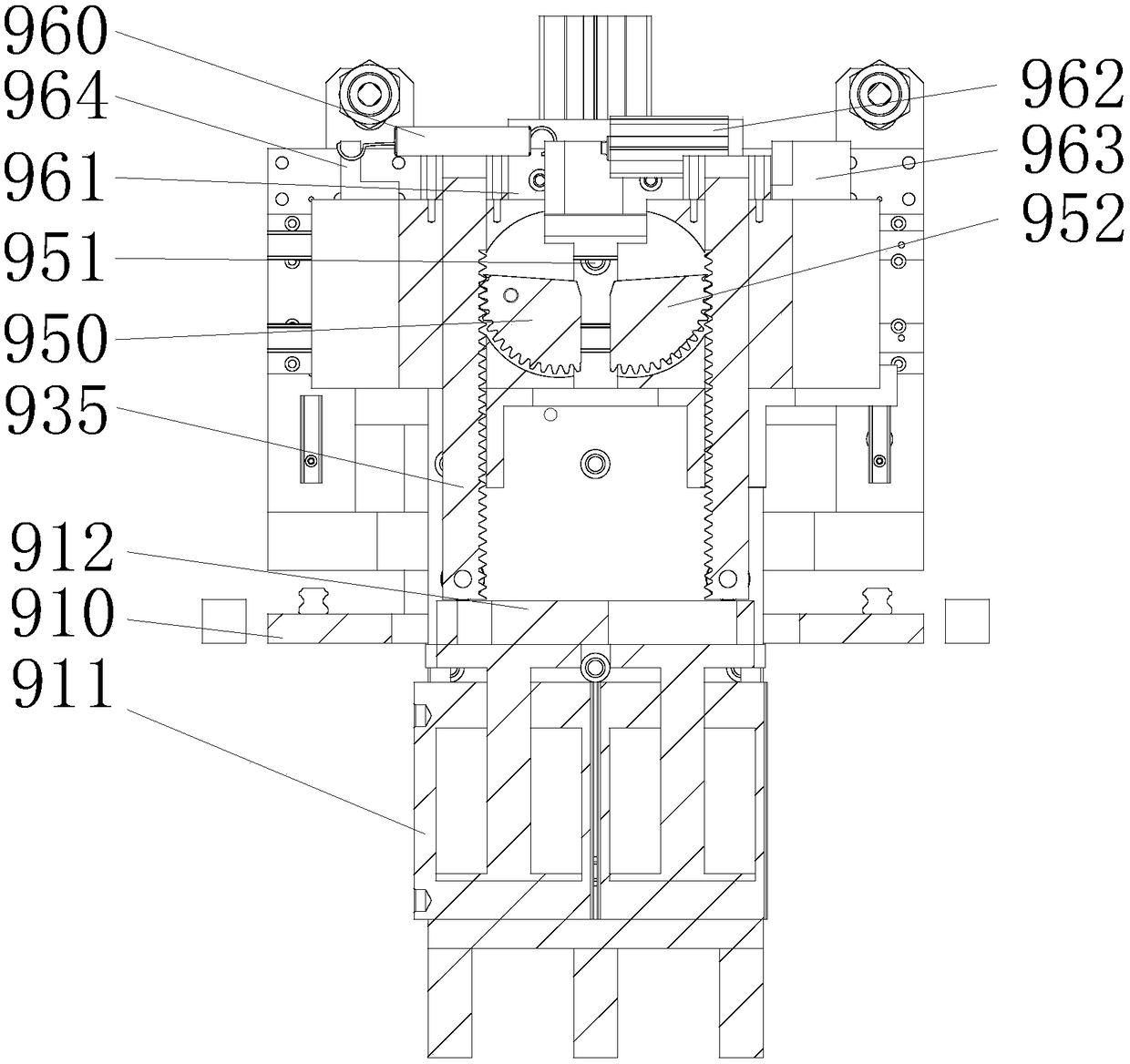

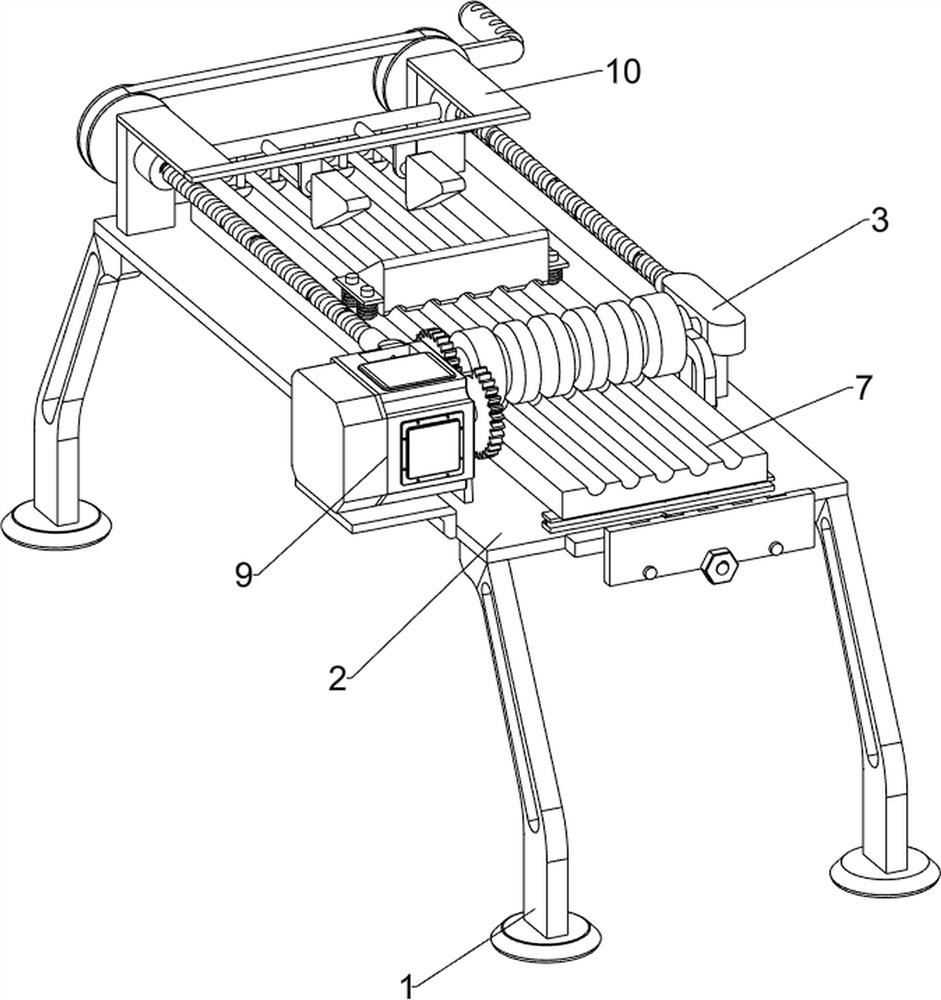

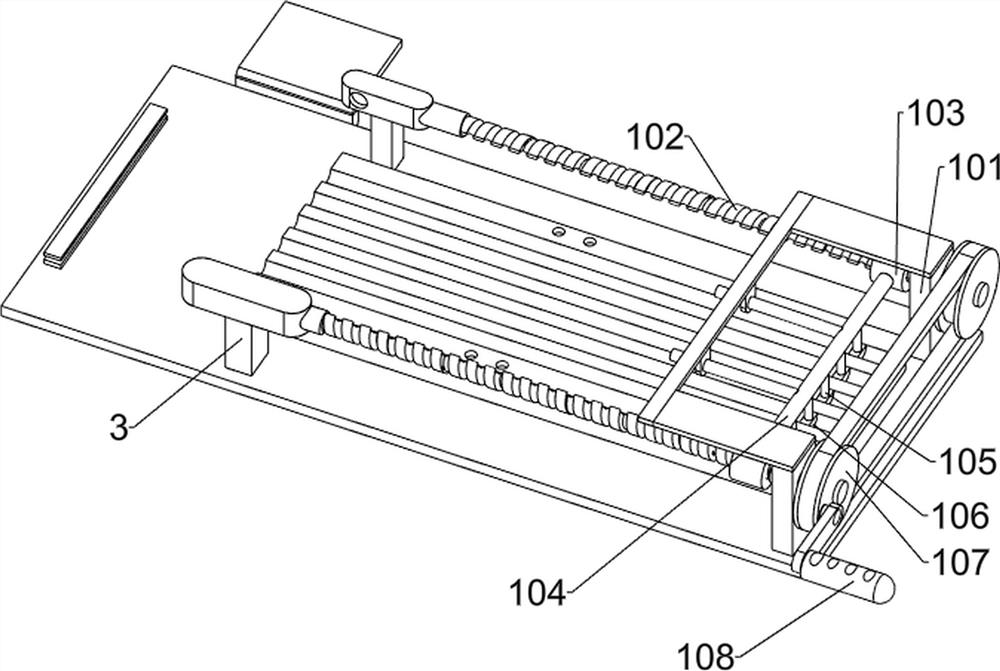

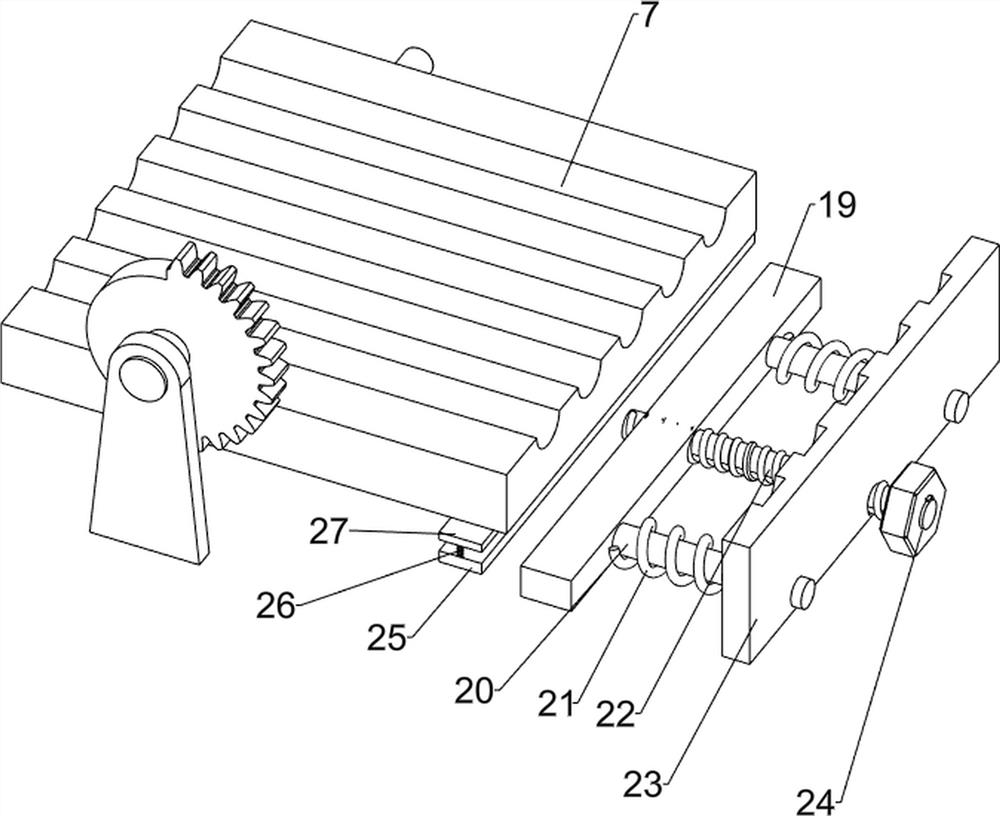

A bending device for thin-diameter thin-walled metal pipes

ActiveCN113333531BRealize the bending operationReduce deformation effectsMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention discloses a bending device for small-diameter and thin-walled metal pipes. The bending device comprises a frame. One end of the frame is provided with a clamping mechanism, and the other end is provided with a bending mechanism. The bending mechanism includes a first motor and a The first gear is sleeved on the first motor, the first gear is meshed with the second gear, the center of the second gear is provided with a first positioning shaft, the bottom of the first positioning shaft is fixed on the base plate, and the base plate is installed on the frame The upper end face of the first positioning shaft is fixed with a fixed wheel, the large gear is provided with a second positioning shaft that is not coaxial with the first positioning shaft, and the upper end face of the second positioning shaft is fixed with a bending wheel, a fixed wheel and a bending wheel There is a matching gap for accommodating thin-walled metal pipes with small diameters. The invention bends the pipe material to a preset angle through the bending mechanism, has little influence on the deformation of the pipe material during the bending process, the transition of the bending part is smooth, the degree of automation is high, and the processing precision is high, and it can be widely used in small diameters of different specifications. Bending of thin-walled metal pipes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of CNC bending equipment for metal product production

ActiveCN113458191BAvoid repeated replacementEasy to realize bending operationMetal-working feeding devicesPositioning devicesNumerical controlOperating table

The invention relates to the technical field of bending, and discloses a numerically controlled bending equipment for metal product production, which solves the problem that the numerically controlled bending equipment requires staff to continuously replace different bending parts to change the bending size of metal products, thereby causing bending The problem of low efficiency includes the operating table, the top of the operating table is provided with a support frame, one side of the support frame is provided with a mounting plate connected to the operating table, the mounting plate is provided with a through hole, and the top of the operating table is provided with a The bending seat is located on one side of the support frame and the mounting plate. There is a bending groove in the middle of the top of the bending seat. The two sides of the bending seat are symmetrically provided with support seats connected to the top of the console; this design is convenient for changing the bending position. The angle between the first bending plate and the second bending plate can avoid repeated replacement of bending parts of different sizes, thereby increasing the bending range of metal products, saving resources, and improving bending efficiency.

Owner:南通东睦金属制品有限公司

An automatic bending machine

ActiveCN112404203BReduce laborRealize the bending operationMetal-working feeding devicesPositioning devicesStructural engineeringMachine

The application discloses an automatic bending machine, which includes a workbench, a mounting frame, a bending tool and a first pallet. The upper end surface of the workbench is provided with a V-shaped groove along the left and right directions, and the mounting frame is arranged above the workbench. The bending tool can be moved up and down on the mounting frame, and the lower end of the bending tool is located directly above the V-shaped groove; when the bending tool moves down into the V-shaped groove, the steel wire skeleton above the V-shaped groove can be forced to bend. Fold to form a V-shaped structure; the first pallet is arranged on the front side of the workbench, and the end of the first pallet far away from the workbench can rotate up and down around the end of the first pallet close to the workbench; when the first pallet rotates When reaching the horizontal position, the upper end surface of the first supporting plate is flush with the upper end surface of the workbench. It can bend the steel wire skeleton of the horizontal mesh structure twice to form a "匚"-shaped grid bridge frame, which is easy to operate, high in work efficiency, and small in labor, and can avoid the need to bend the longitudinal ribs in advance and affect the welding operation. efficiency.

Owner:VICHNET COMM SCI & TECH

A flexible bending and twisting forming device for space pipe fittings

The invention discloses a space pipe fitting flexible bending and torsion forming device which is used for forming space pipe fittings of any geometric shape. A movable die control mechanism controls the relative position of a movable die and a fixed die to control the bending radius, the torsion angle of a torsion mechanism is controlled to change the bending plane, feeding mechanisms are controlled to achieve continuous feeding, and thus the space pipe fittings are formed. A three-jaw chuck on the torsion mechanism is utilized to clamp the pipe fittings, and torsion movement of the pipe fittings is achieved. The torsion mechanism is fixed to the first feeding mechanism to achieve feeding movement of the pipe fittings. The movable die control mechanism is installed on the second feeding mechanism and drives a movable die assembly to be deviated relative to a fixed die assembly when the second feeding mechanism works to achieve bending operation. The movable die control mechanism drives the movable die to rotate relative to the fixed die, and adjustment is flexible. The feeding mechanisms are driven by motors, and the torsion mechanism and a bending mechanism are driven to achieve bending and torsion forming of the space pipe fittings in multiple directions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Connecting piece bending equipment for high-end equipment manufacturing

The invention relates to the technical field of bending machining, and provides connecting piece bending equipment for high-end equipment manufacturing, the connecting piece bending equipment for high-end equipment manufacturing comprises a mounting table, a connecting piece bending device and a bending device, the mounting table is provided with a fixing assembly, and the fixing assembly is provided with a connecting piece body in a matched mode; the supporting column is mounted on the mounting table, a top plate is mounted at one end of the supporting column, and a first motor is mounted on the top plate; and the fixing plate is installed at the output end of the first motor, and a bending assembly is installed on the fixing plate. The bending assembly is modified, so that the bending assembly can be matched with continuous annular bending and fixed-angle bending at the same time, the use effect is better, operation is easy, and two bending effects can be achieved without multiple devices; and the fixing assembly is additionally arranged, the connecting piece can be fixed before the connecting piece is bent, the fixing effect is better, the connecting piece bending device can adapt to various connecting pieces of different specifications and shapes, and the adaptation range is wider.

Owner:詹若思

Device for bending air conditioner copper pipe of new energy automobile

The invention belongs to the technical field of new energy automobile machining, and particularly relates to a device for bending an air conditioner copper pipe of a new energy automobile. The device for bending the air conditioner copper pipe of the new energy automobile can realize rapid bending and is simple to operate. The device for bending the air conditioner copper pipe of the new energy automobile comprises supporting legs, supporting seats, a transmission shaft, connecting blocks, connecting shafts and a movable plate, wherein a workbench is arranged at the tops of the supporting legs; the supporting seats are symmetrically arranged at the top of the workbench; the transmission shaft is rotationally arranged between the two supporting seats; the connecting blocks are arranged at the two ends of the transmission shaft; the connecting shafts are arranged on the two connecting blocks; and the movable plate is arranged between the two connecting shafts, and semi-arc grooves are evenly formed in the movable plate. The copper pipe can be adjusted through a pushing mechanism, and then the copper pipe is bent through a driving mechanism.

Owner:熊武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com