Bending equipment used for machining copper pipe

A copper tube and equipment technology, applied in the field of bending equipment, can solve the problems of end material waste, difficult sealing, and fixing difficulties, and achieve the effect of reducing the waste of copper tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

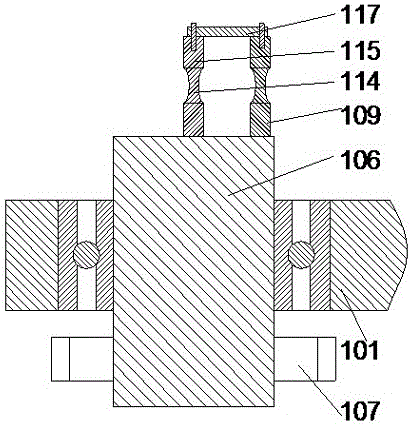

[0031] In this embodiment, in order to improve the accuracy of drilling, preferably, a through hole is provided in the middle of the support block 110, and the axis of the drilling device 113 and the axis of the through hole on the support block 110 coincide with each other. The drilling operation can be realized by using a drill bit or laser drilling. After the drilling device penetrates the copper pipe, a positioning device can be set in the through hole to position the drilling depth.

Embodiment 2

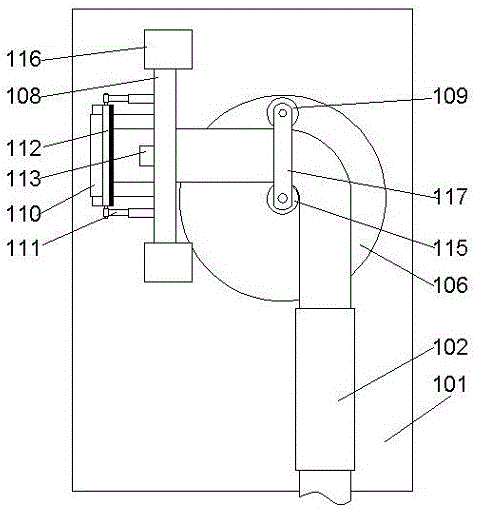

[0033] Such as Figure 4 As shown, in this embodiment, a preferred structure of a drilling device liftable structure is disclosed at the same time. Preferably, two brackets 116 are arranged on the frame 101, so that the brackets are perpendicular to the upper end surface of the frame, The upper ends of the two described supports 116 are connected to each other by cross beams 108, so that the upper ends of the supports are connected to each other, which can improve the stability of the supports, and a support that can slide vertically relative to the described supports 116 is arranged between the two described supports 116. plate 105, so that both ends of the support plate are slidably connected to the same side of the two brackets, and the drilling device 113 is fixedly connected to the support plate 105, so that the drilling device is located in the middle of the support plate. When the two brackets move longitudinally, the drilling device is driven to move synchronously, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com