Spacing-adjustable steel belt bending mechanism

A technology of bending mechanism and steel strip, which is applied in the field of mechanical processing, can solve the problems of low mechanical bending precision, irregular deformation of steel strip, easy damage to steel strip, etc., to save manpower, improve work efficiency and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

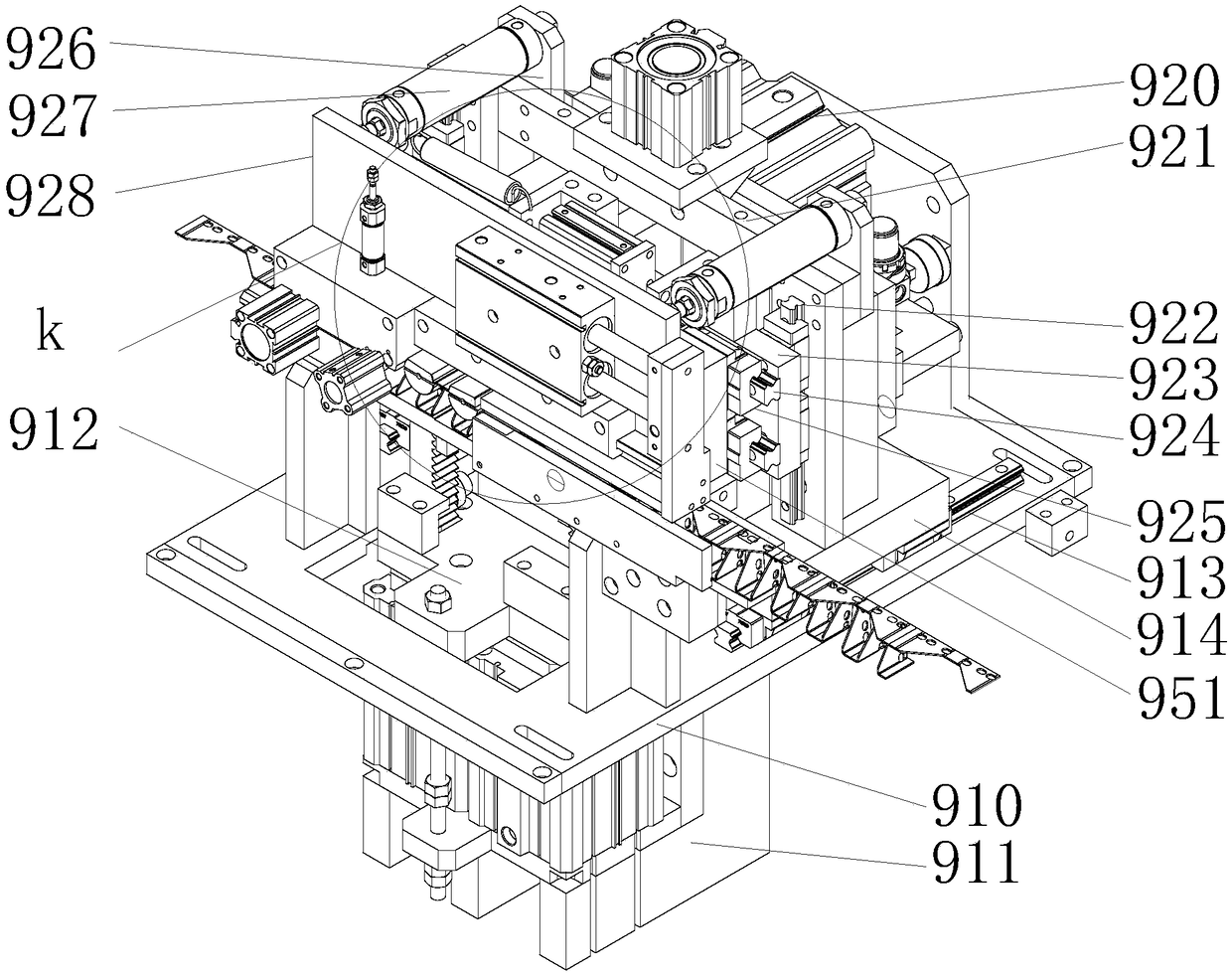

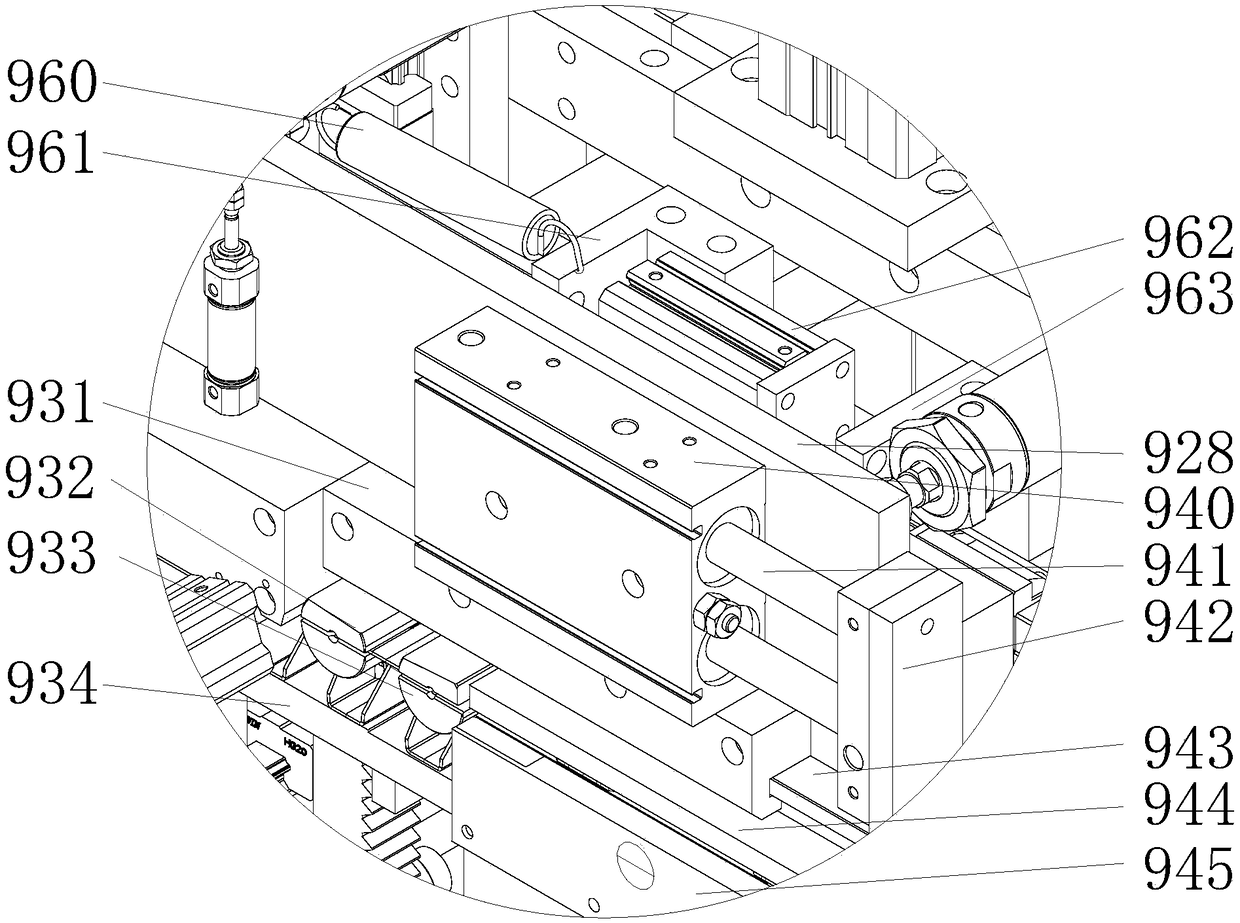

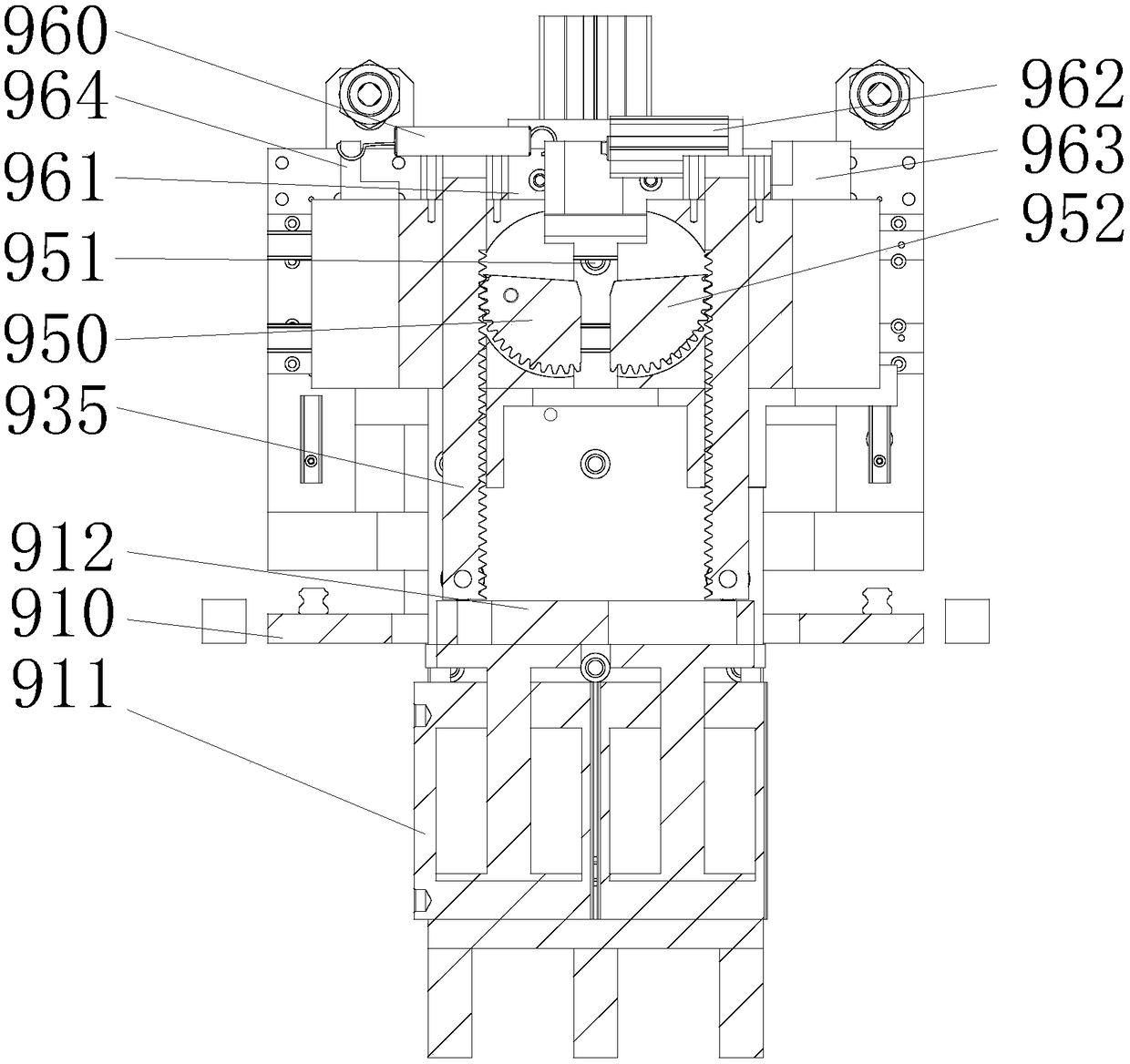

[0025] refer to Figure 1 to Figure 4 As shown, the present invention discloses a steel strip bending mechanism with adjustable spacing, which includes a horizontally arranged bending bottom plate 910, on which a bending side plate 2 951 is vertically arranged, and the bending side plate The second 951 is provided with a bending fixing block 964, a left sliding base plate 961, a reset driving source 962 and a right sliding base plate 963 from left to right, and the bending fixing block 964 and the reset driving source 962 are opposite to the folding The second bent side plate 951 is fixedly arranged, the said bent fixed block 964 is connected with the said left sliding bottom plate 961 through a spring 960, said bent fixed block 964 is also provided with an adjusting bolt 965, the end of said adjusting bolt 965 abuts against the left sliding bottom plate 961, the motion output end of the reset drive source 962 abuts against the right sliding bottom plate 963, and the left spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com