Space pipe fitting flexible bending and torsion forming device

A pipe fitting and bending technology, which is applied in the field of flexible bending and torsion forming devices for space pipe fittings, can solve the problems of many degrees of freedom of the movable die and troublesome motion control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

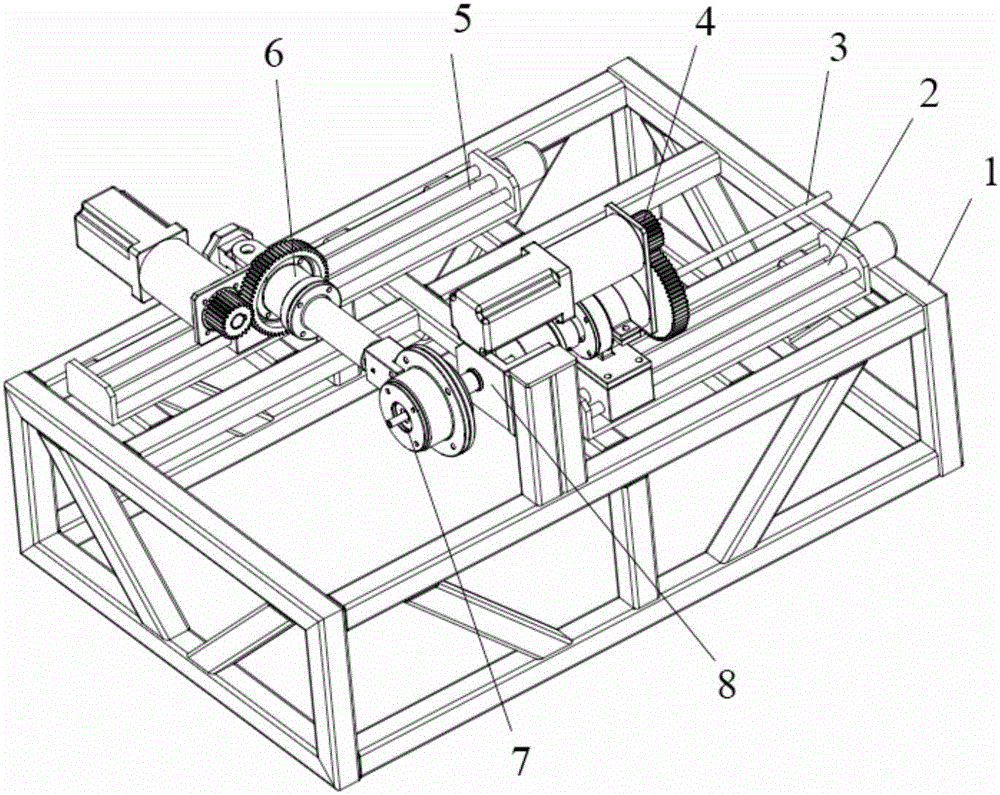

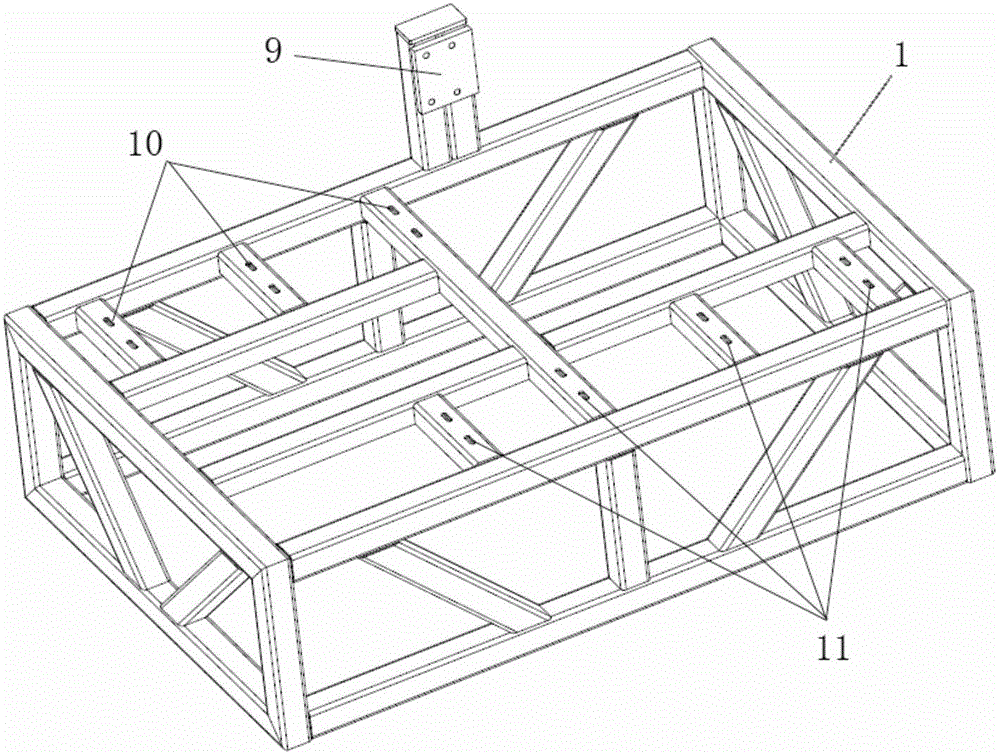

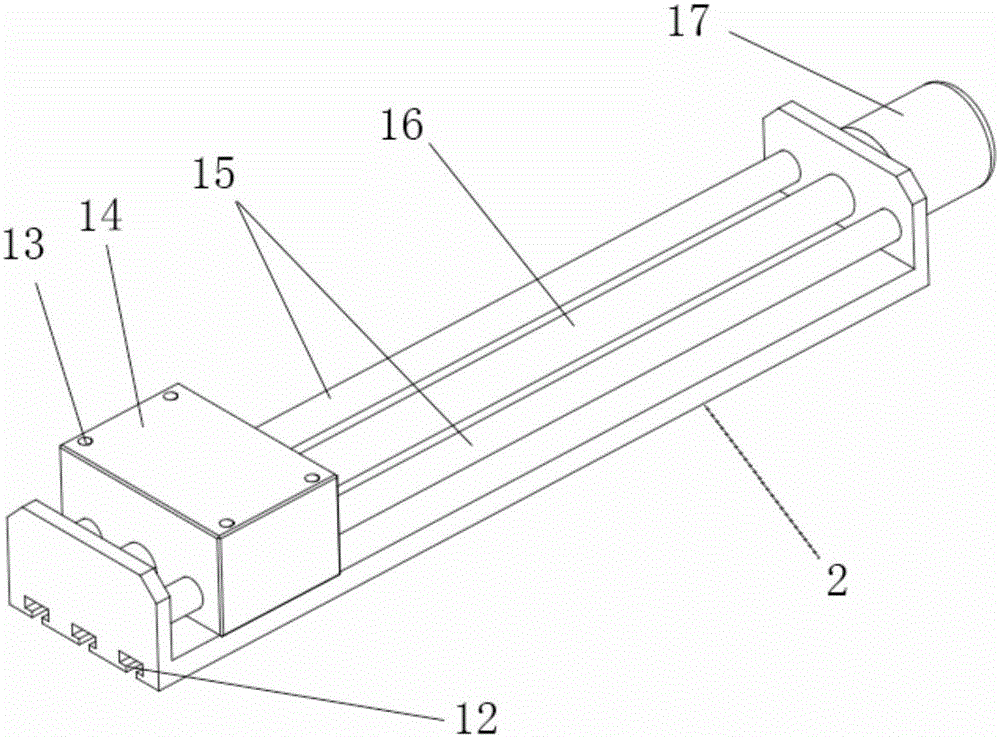

[0027] This embodiment is a flexible bending torsion forming device for a space pipe. Through the coordinated control of the feeding mechanism, the movable mold control mechanism and the torsion mechanism, the space pipe is formed. The pipe 3 is inserted into the fixed mold assembly 8 and the bending mold assembly 7 through the hollow shaft 22 on the torsion mechanism 4, and the pipe 3 is clamped by the three-jaw chuck 28 to realize the pipe torsion movement. The first feeding mechanism 2 drives the torsion mechanism 4 and the pipe 3 to approach the fixed die assembly 8 to realize the pipe feeding movement. The second feeding mechanism 5 drives the movable mold control mechanism 6 to rotate the movable mold assembly 7 relative to the fixed mold assembly 8 to achieve bending in one direction. The movable mold control mechanism 6 is provided with a feather key cylinder 44 and a feather key shaft 45, which is adapted to the change of the distance between the sliding block 14 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com