A flexible product bending linkage mechanism

A linkage mechanism and product technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of high work intensity, high defect rate, poor versatility, etc., and achieve the effect of high production efficiency, accurate operation, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

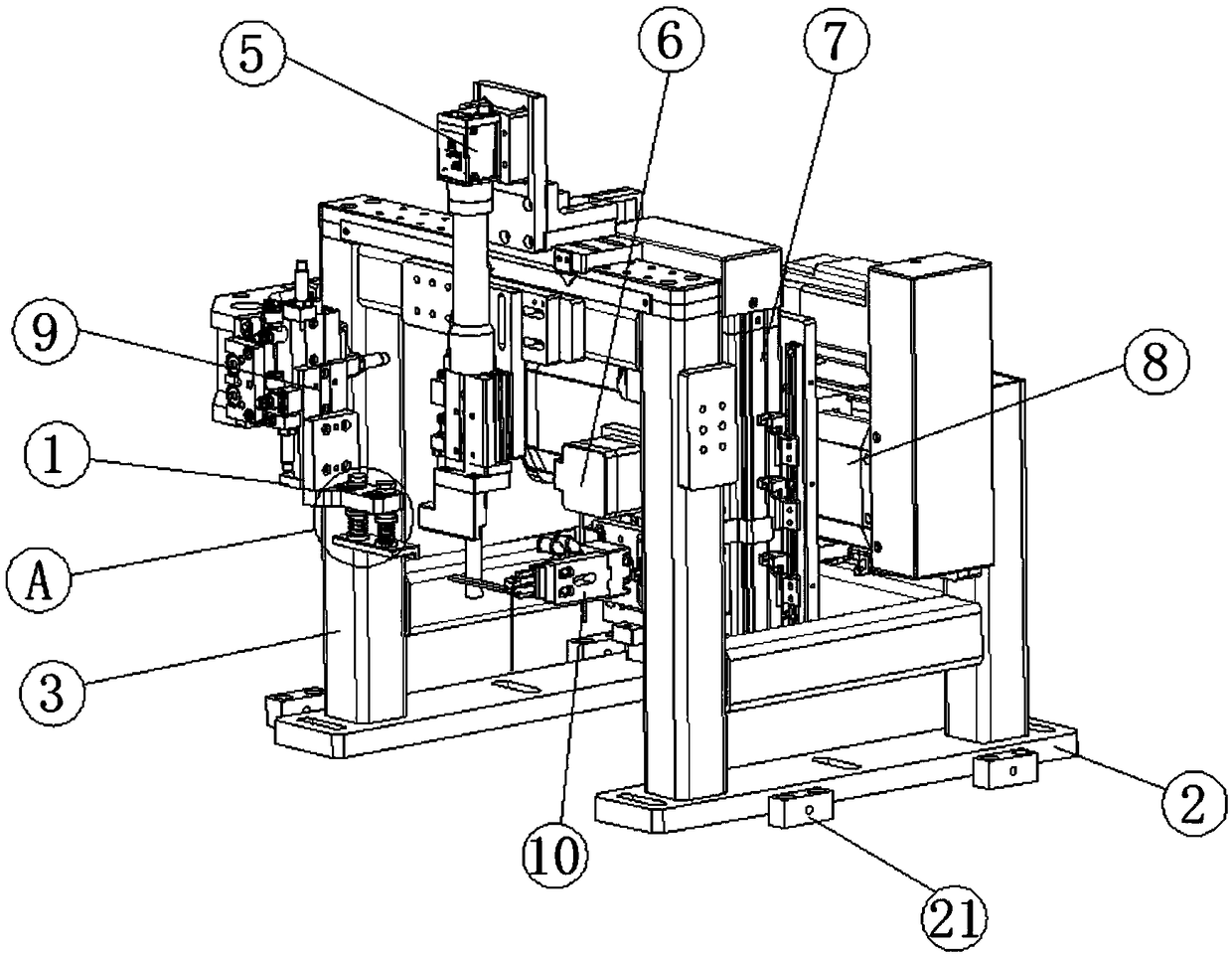

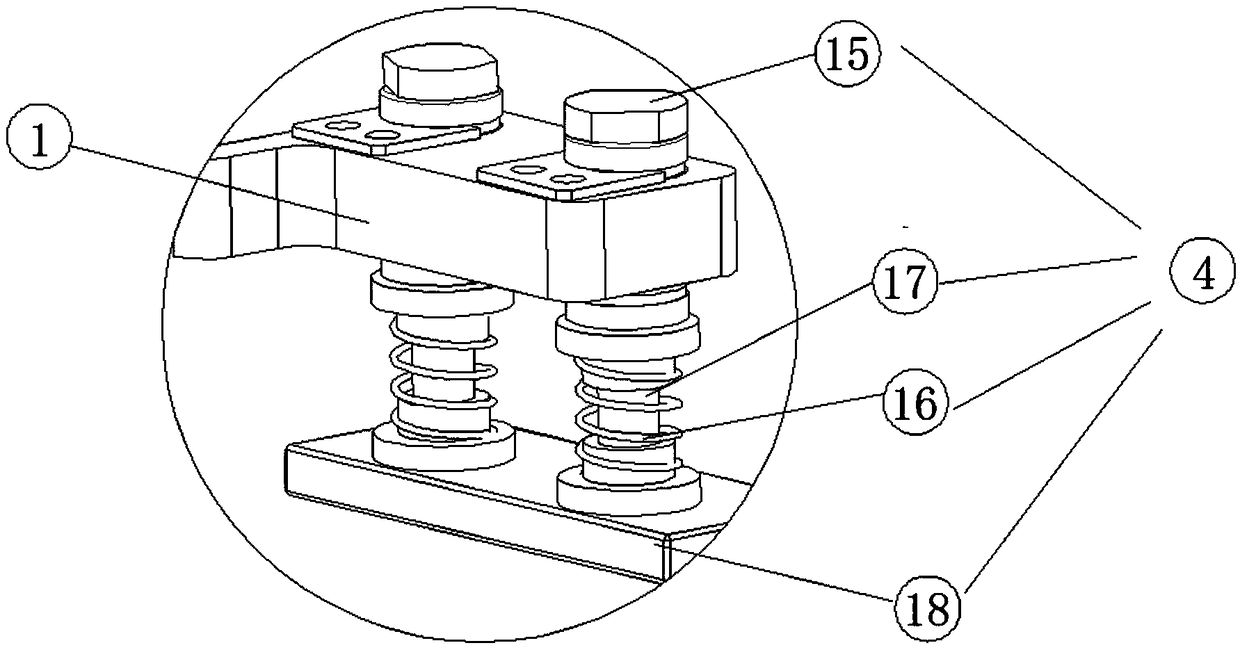

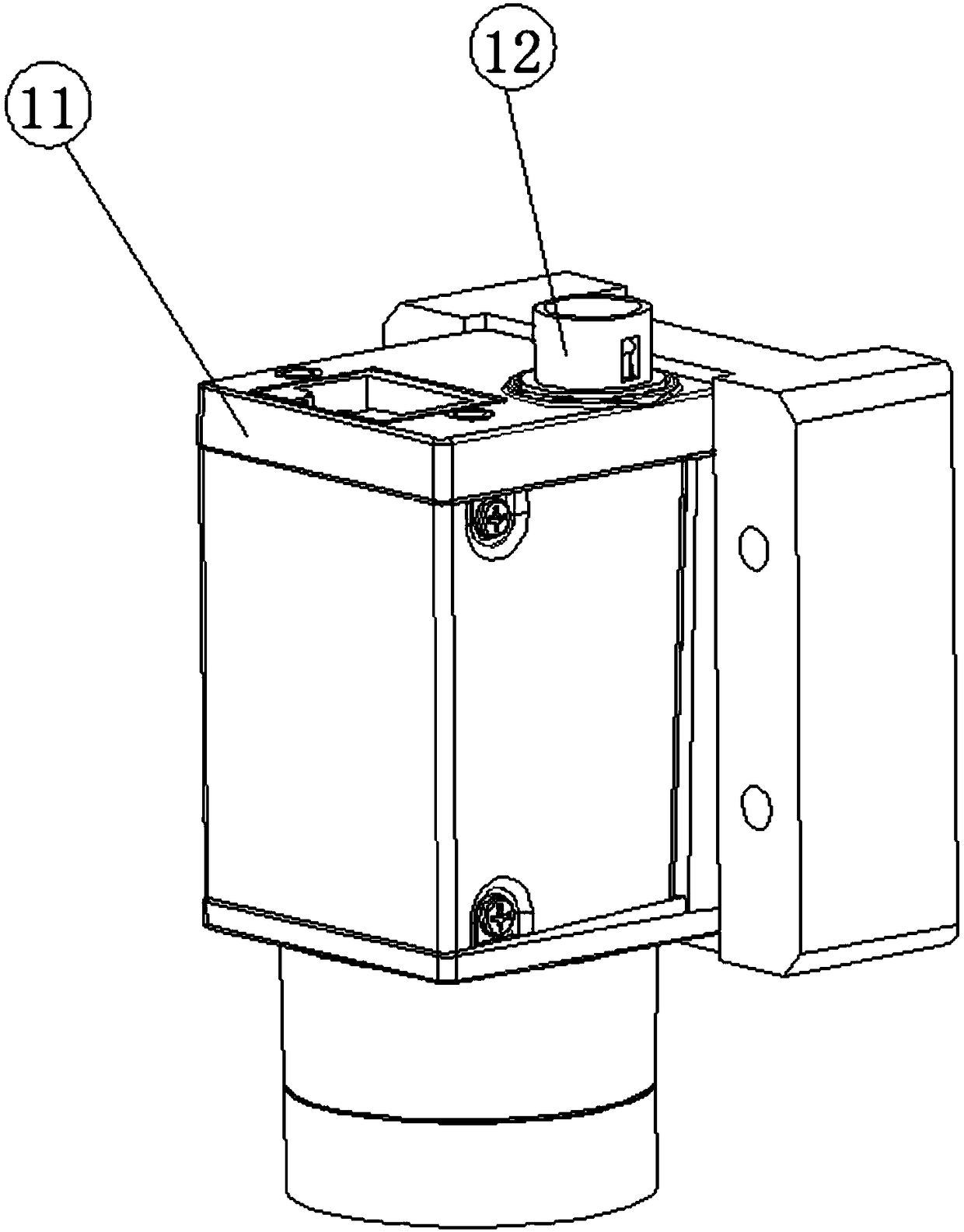

[0028] see Figure 1-5 , a bending linkage mechanism for flexible products according to an embodiment of the present invention, including a connecting plate 1, a lower frame 2, a support frame 3, a spring mechanism 4, a CCD module 5, a rotating module 6, and a Z-axis lifting screw Module 7, X-axis translation lead screw module 8, pressure maintaining module 9 and clamping module 10, the support frame 3 is fixedly connected to the lower frame 2, and the middle part of the support frame 3 is provided with a Z-axis Lifting screw module 7, one side of the Z-axis lifting screw module 7 is provided with an X-axis translation screw module 8, and the Z-axis lifting screw module 7 is far away from the X-axis translation screw module One side of the group 8 is provided with a rotary module 6, the below of the rotary module 6 is provided with a clamping module 10, one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com