FPC bending jig

A jig and bending head technology, applied in electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of unstable bending performance and low work efficiency, saving manpower, improving work efficiency, and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

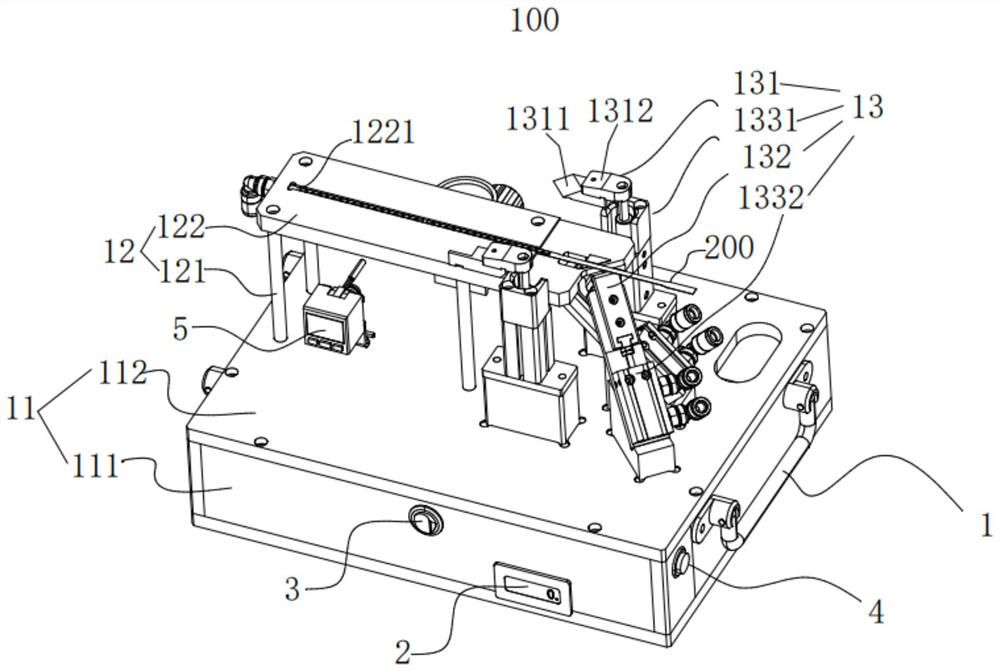

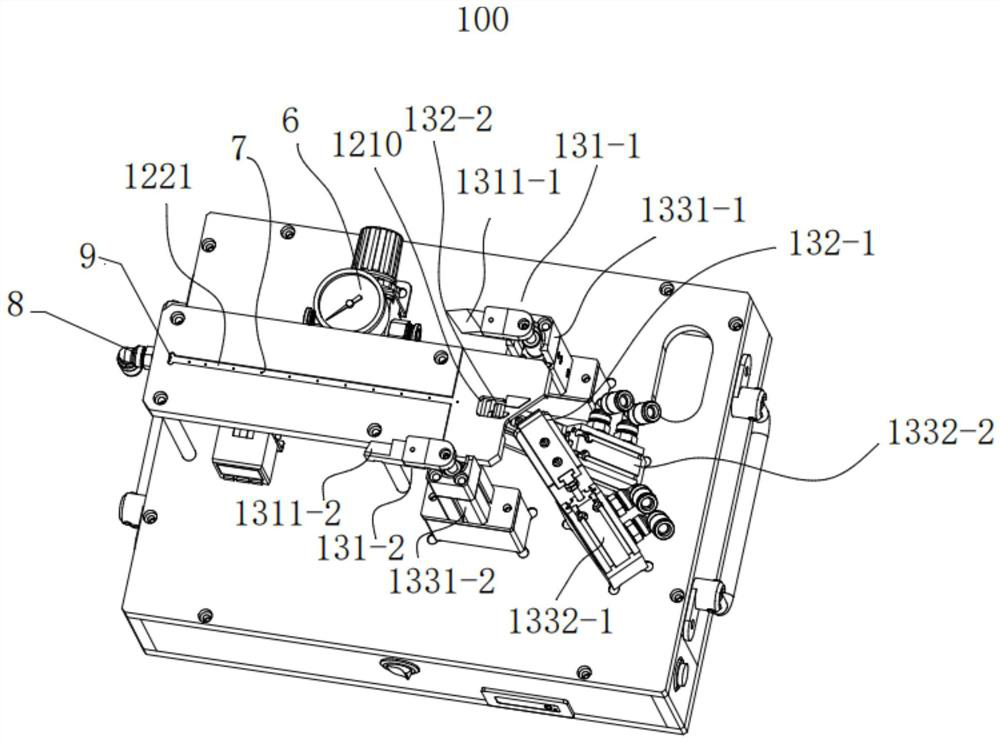

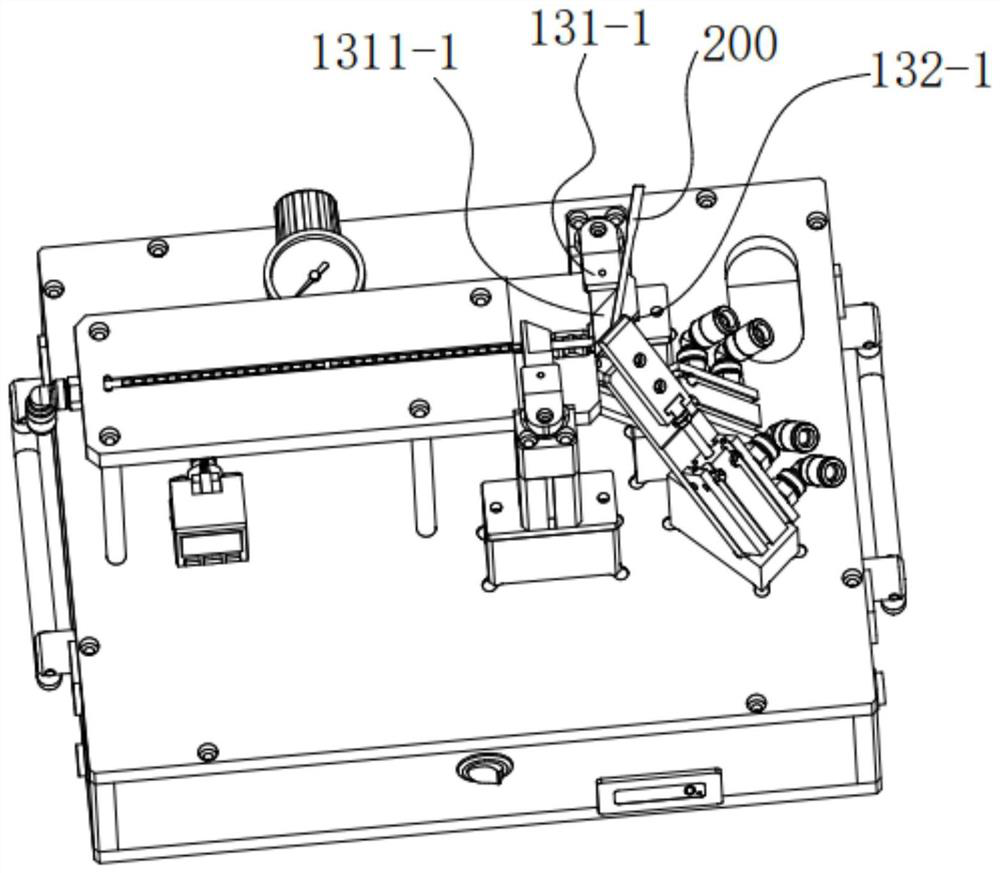

[0022] figure 1 It is a structural schematic diagram of the FPC bending fixture shown in one embodiment of the present invention when placing the FPC, figure 2 It is a structural schematic diagram of the FPC bending fixture shown in one embodiment of the present invention when no FPC is placed, as shown in figure 1 and figure 2 As shown, the FPC bending fixture 100 of the present invention is suitable for bending the FPC200, and the FPC200 is as figure 1 As shown, it is in the shape of thin strips, but it is not limited thereto, and it can also be in other shapes, such as a square sheet structure. The FPC bending fixture 100 provided by the present invention includes a chassis 11, a carrying mechanism 12, and a bending mechanism 13. The carrying mechanism 12 is fixedly arranged above the chassis 11. Including a limiting device 131, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com