Test device and test method for current-carrying characteristic of high-temperature superconducting stripe

A high-temperature superconducting strip material and characteristic testing technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of large errors and inaccurate test results, and achieve the effect of small errors and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

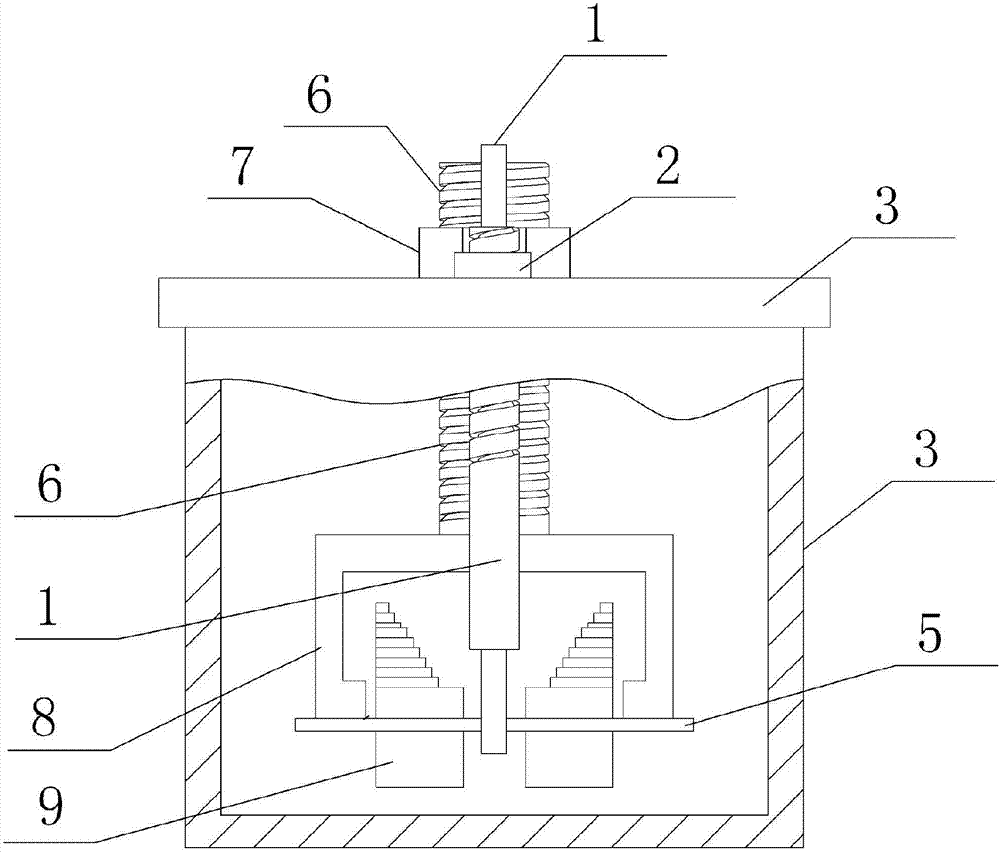

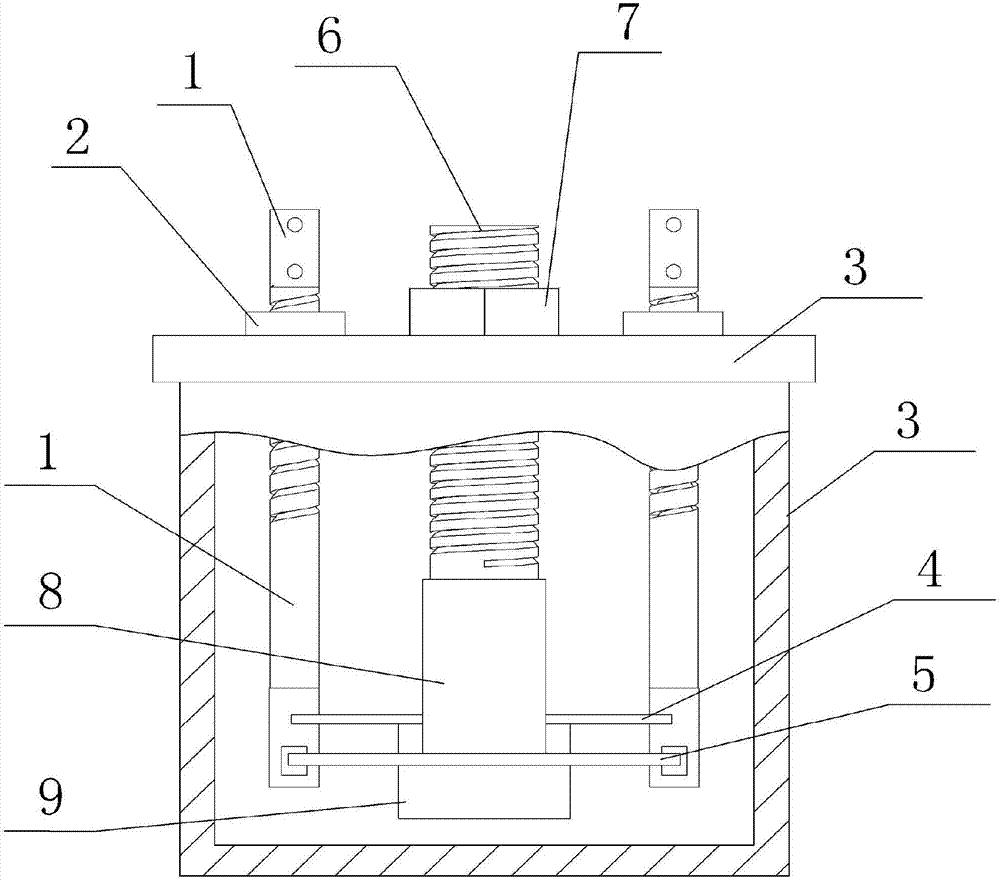

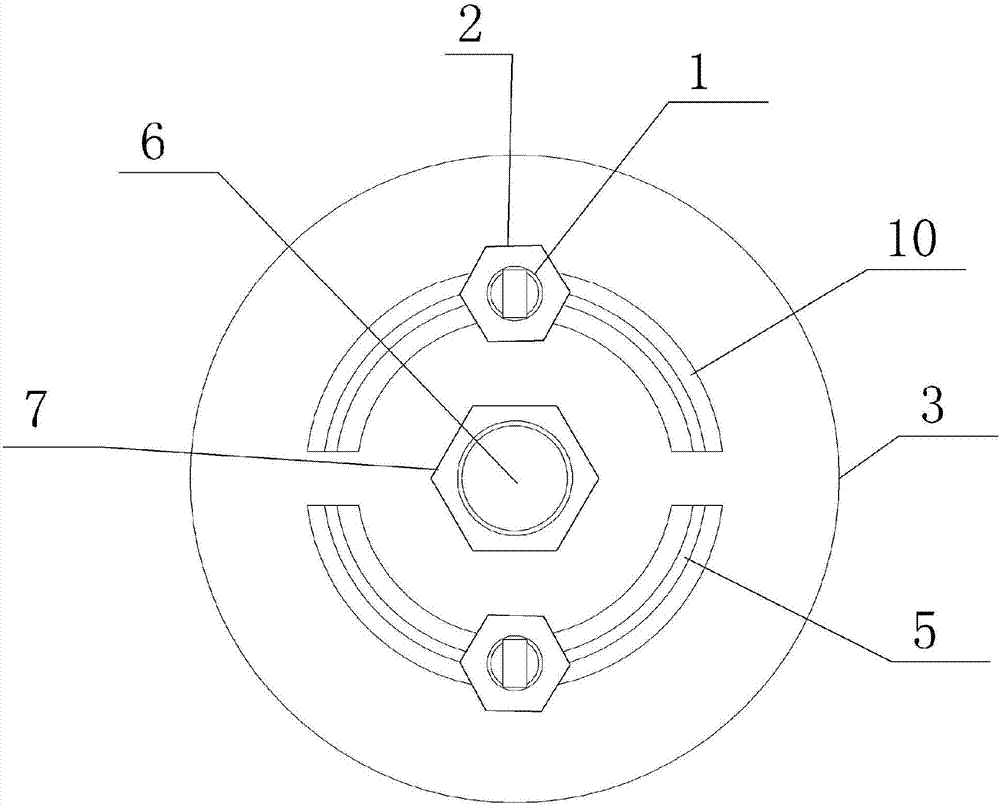

[0033] Figure 1-3 Shown, a specific embodiment of the present invention is, a kind of current-carrying characteristic test device of high-temperature superconducting strip, comprises liquid nitrogen Dewar 3, the high-temperature superconducting strip 4 in liquid nitrogen Dewar 3, and high temperature A direct current source and a nanovoltmeter connected to the superconducting strip 4, characterized in that:

[0034] The top of the liquid nitrogen Dewar 3 is provided with two opposite semicircular guide grooves 10, and each guide groove 10 is inserted with a copper threaded rod 1, and there are two threaded rods 1; The nut 2 connected to the upper part of the threaded rod 1 is suspended in the liquid nitrogen Dewar 3, and the top of the threaded rod 1 is connected to the DC source; the threaded rod 1 is movably fitted on the circular guide rail 5 through the guide hole at the lower part ; The guide rail 5 is made of non-conductive glass fiber reinforced plastic; the end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com