Patents

Literature

72results about How to "Relieve bending stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

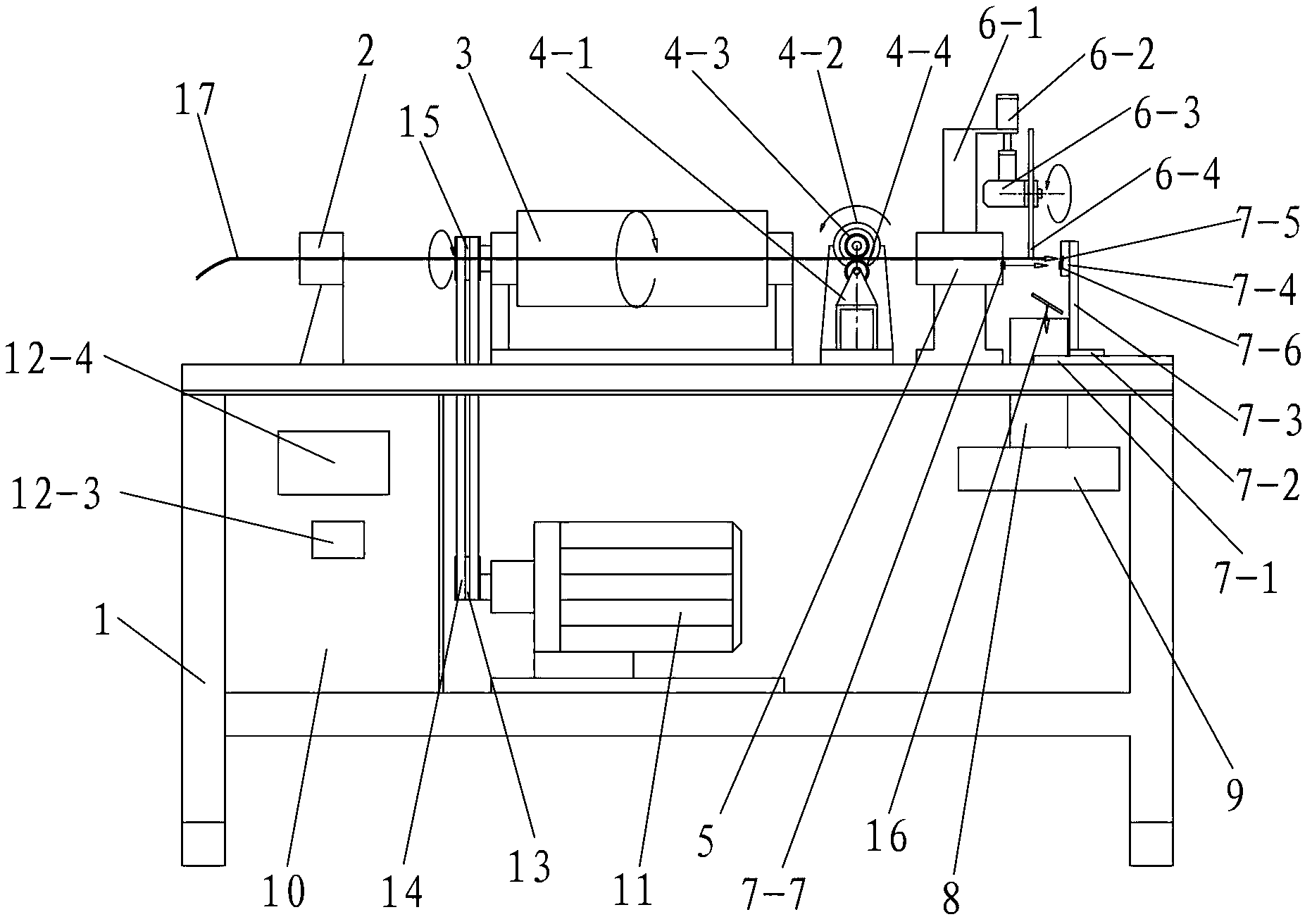

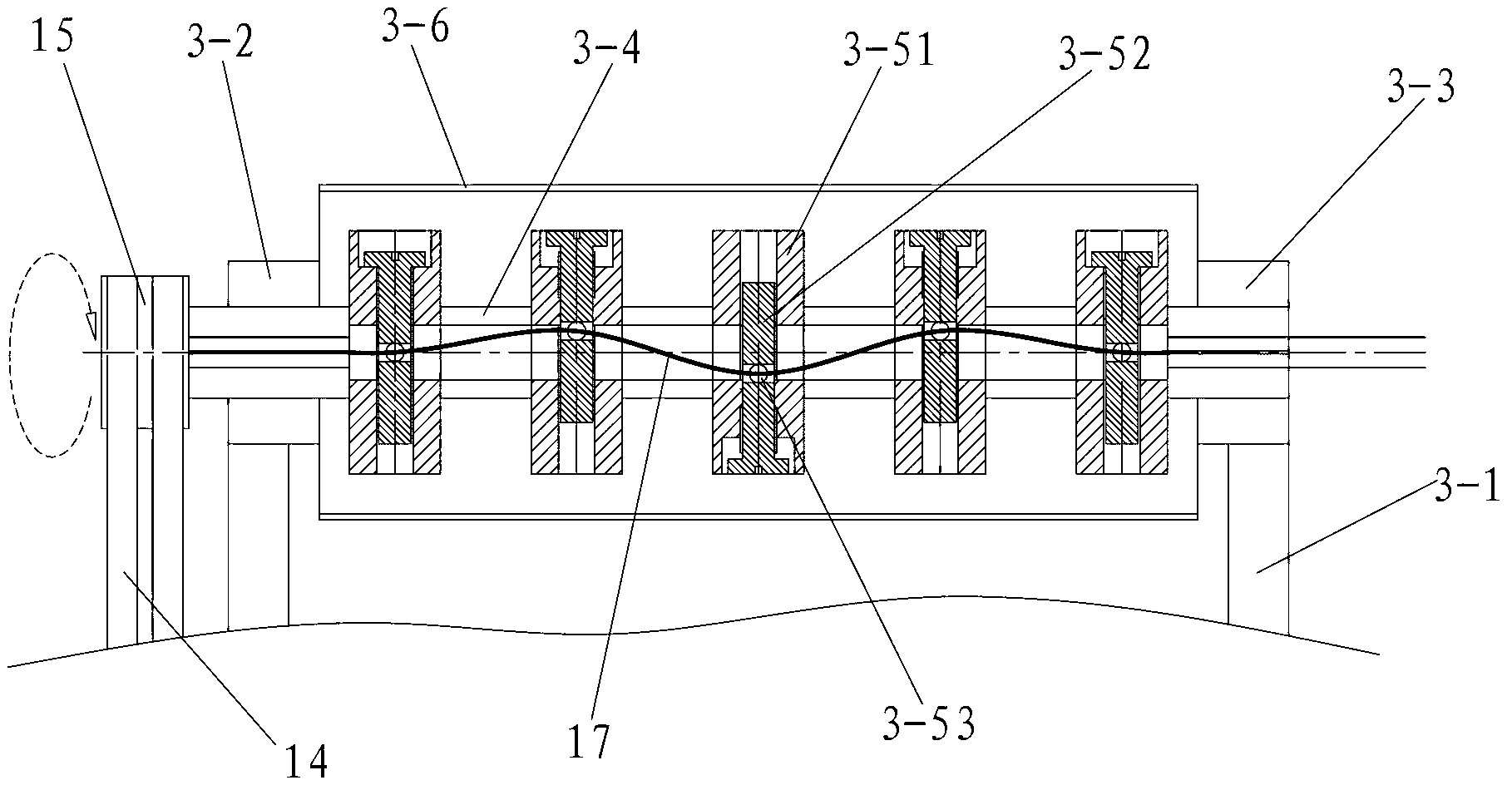

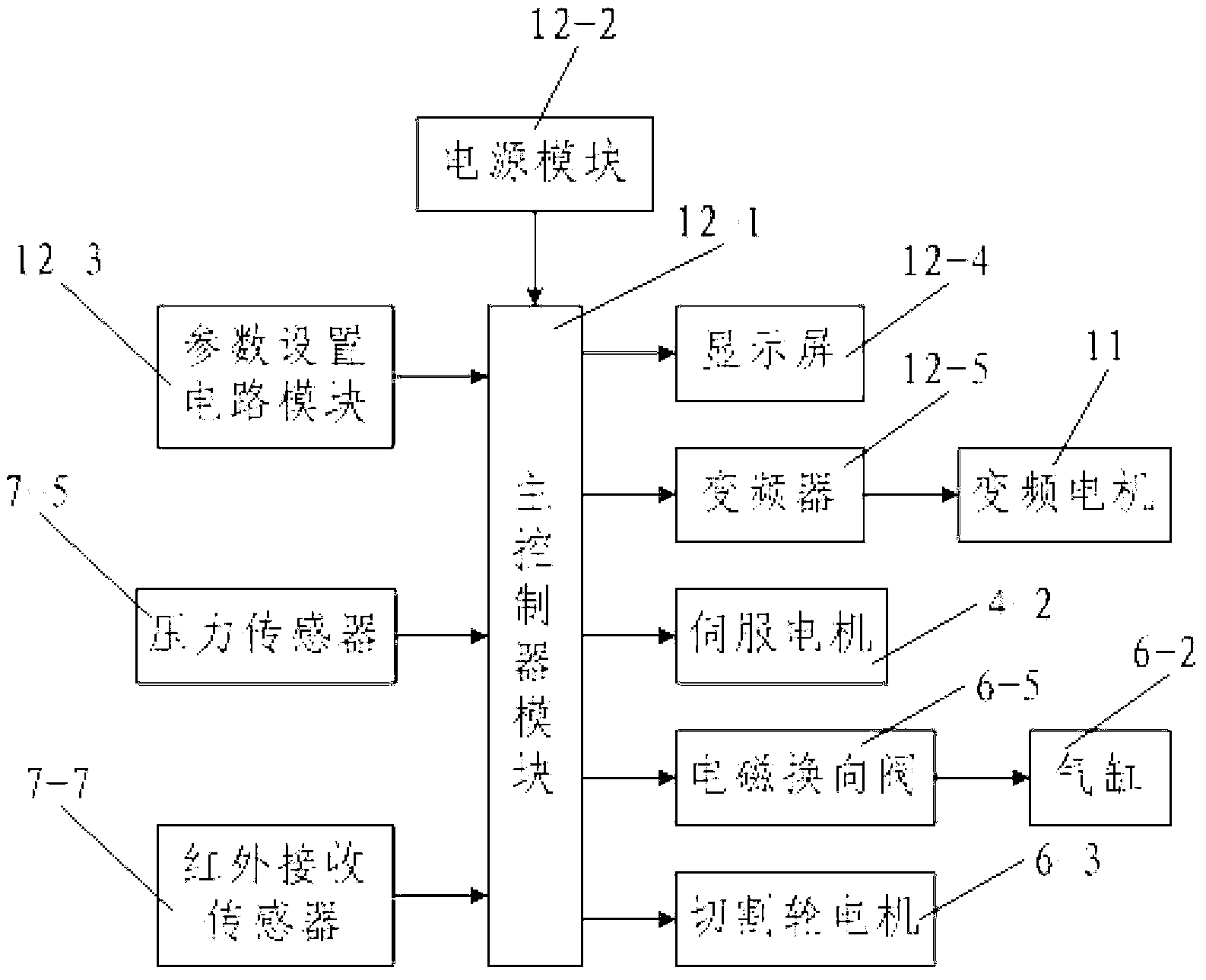

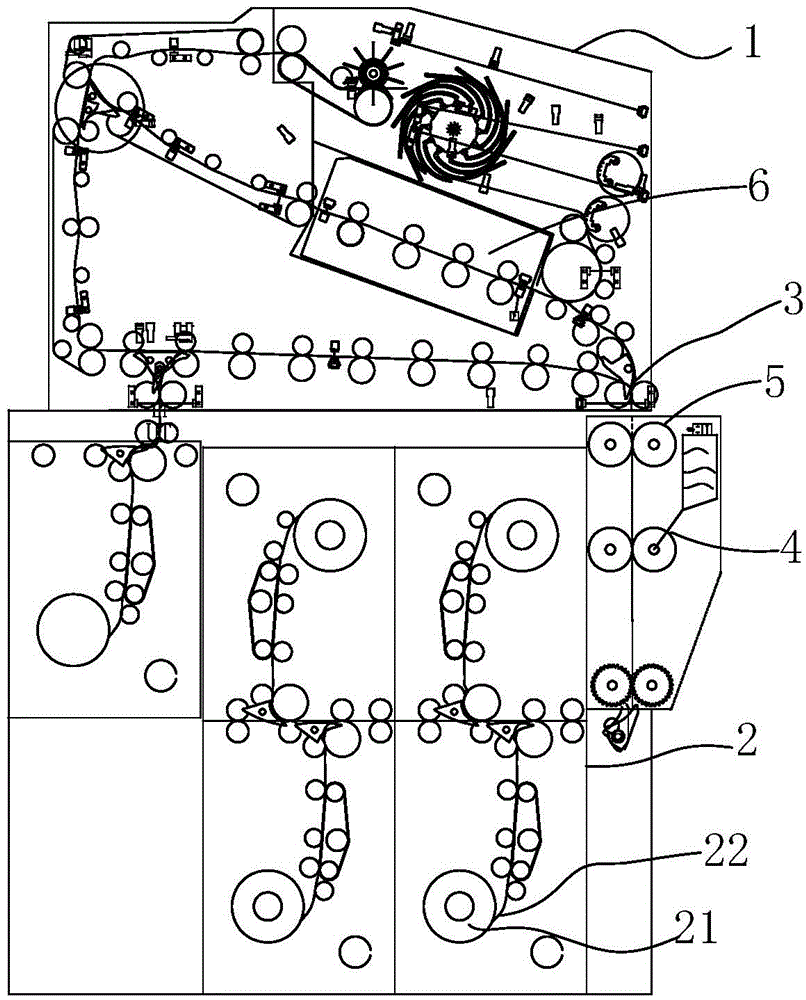

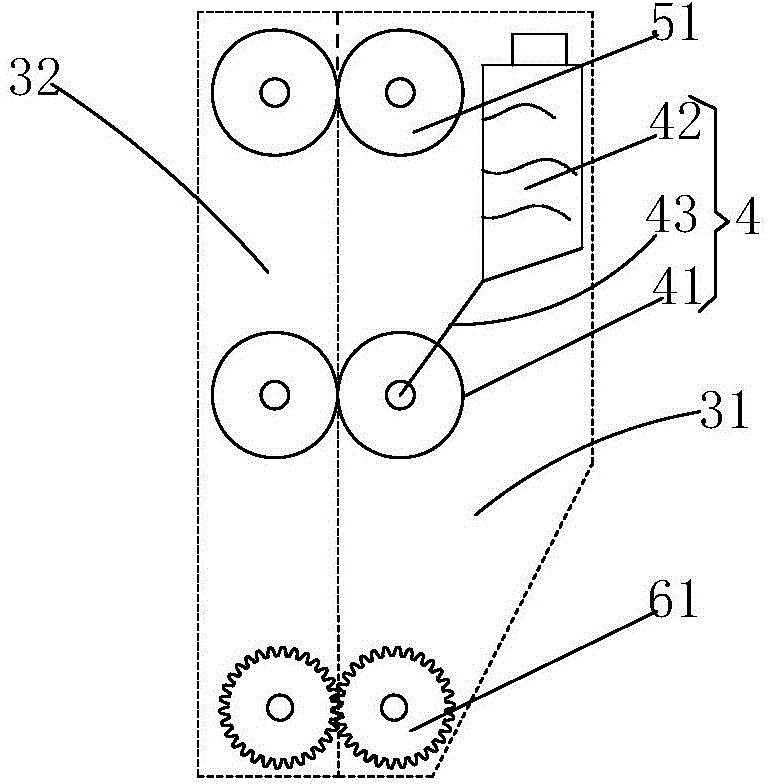

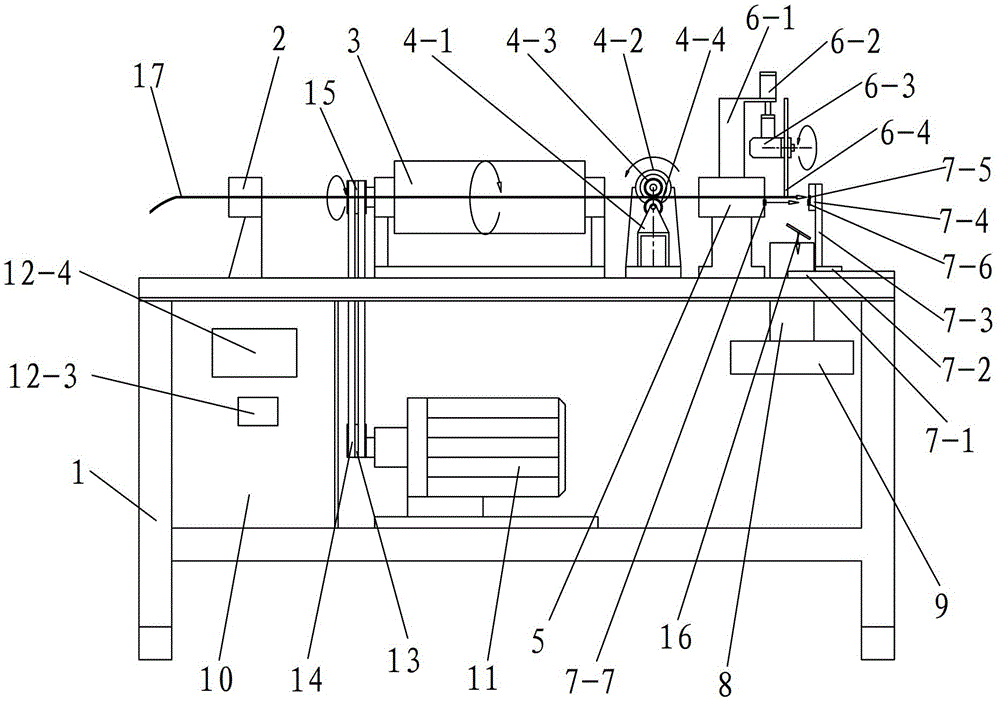

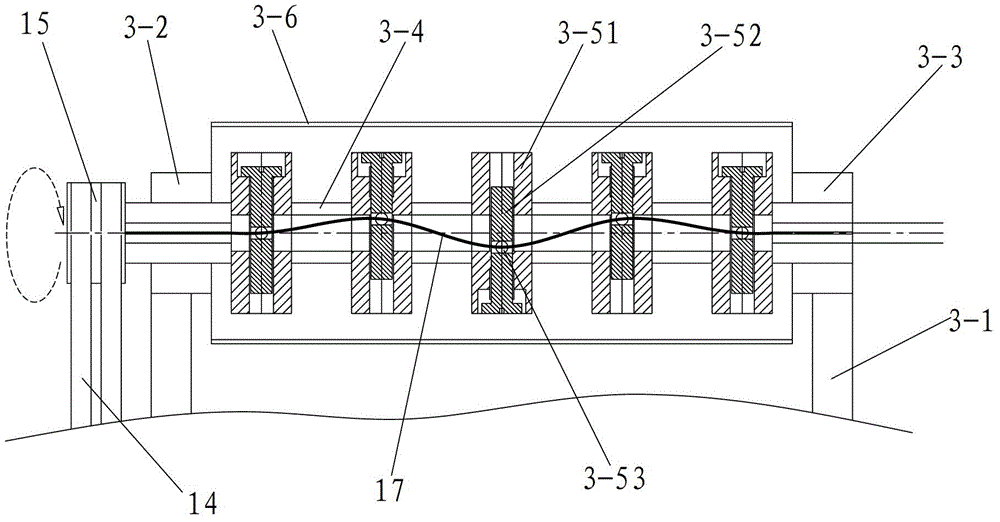

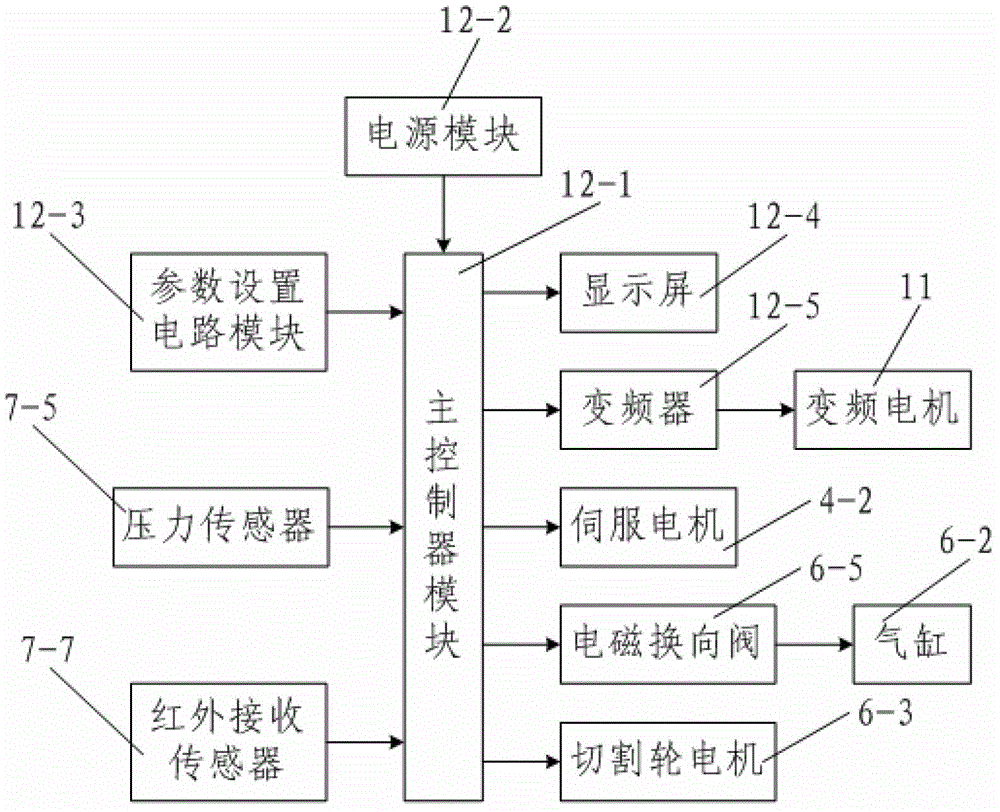

Metal wire rod precision alignment cutting device and method

The invention discloses a metal wire rod precision alignment cutting device and a method. The device comprises a double-layer machine frame. A front end guiding tank, a revolving alignment tank, a traction mechanism, a back end guiding tank, a cutting mechanism and a machinery sizing mechanism are arranged on the top portion of the double-layer machine frame. The revolving alignment tank comprises a revolving alignment straight tank support seat, an alignment guiding tank, a plurality of alignment modules and a protection cover. The traction mechanism comprises a traction mechanism support seat, a servo motor, a driving friction wheel and a driven friction wheel. The cutting mechanism comprises a cutting wheel support frame, an air cylinder, a cutting wheel motor and a slice-shaped cutting wheel. The machinery sizing mechanism comprises a horizontal scale plate, a pressure sensor, an infrared transmitting sensor and an infrared receiving sensor. The method includes the steps that the metal wire rod enters the revolving alignment tank through a front end guiding rank. The metal wire rod is alignmented, tracted, cut and prepared and enters the next working circulation. The metal wire rod precision alignment cutting device and the method is high in automatic degree. The shape of the cut metal line segment and the size precision are high. The cutting opening is smooth, free of deckle edge and free of splitting off. The metal wire rod precision alignment cutting device and the method are strong in practicality.

Owner:JINDUICHENG MOLYBDENUM CO LTD

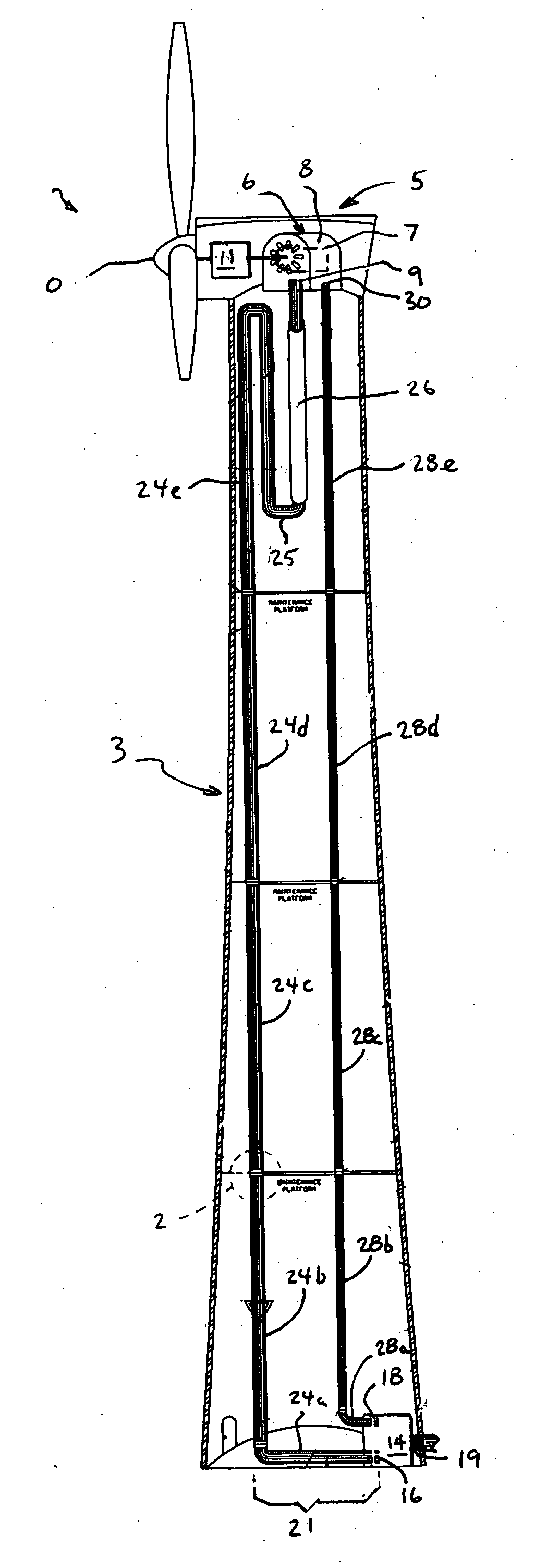

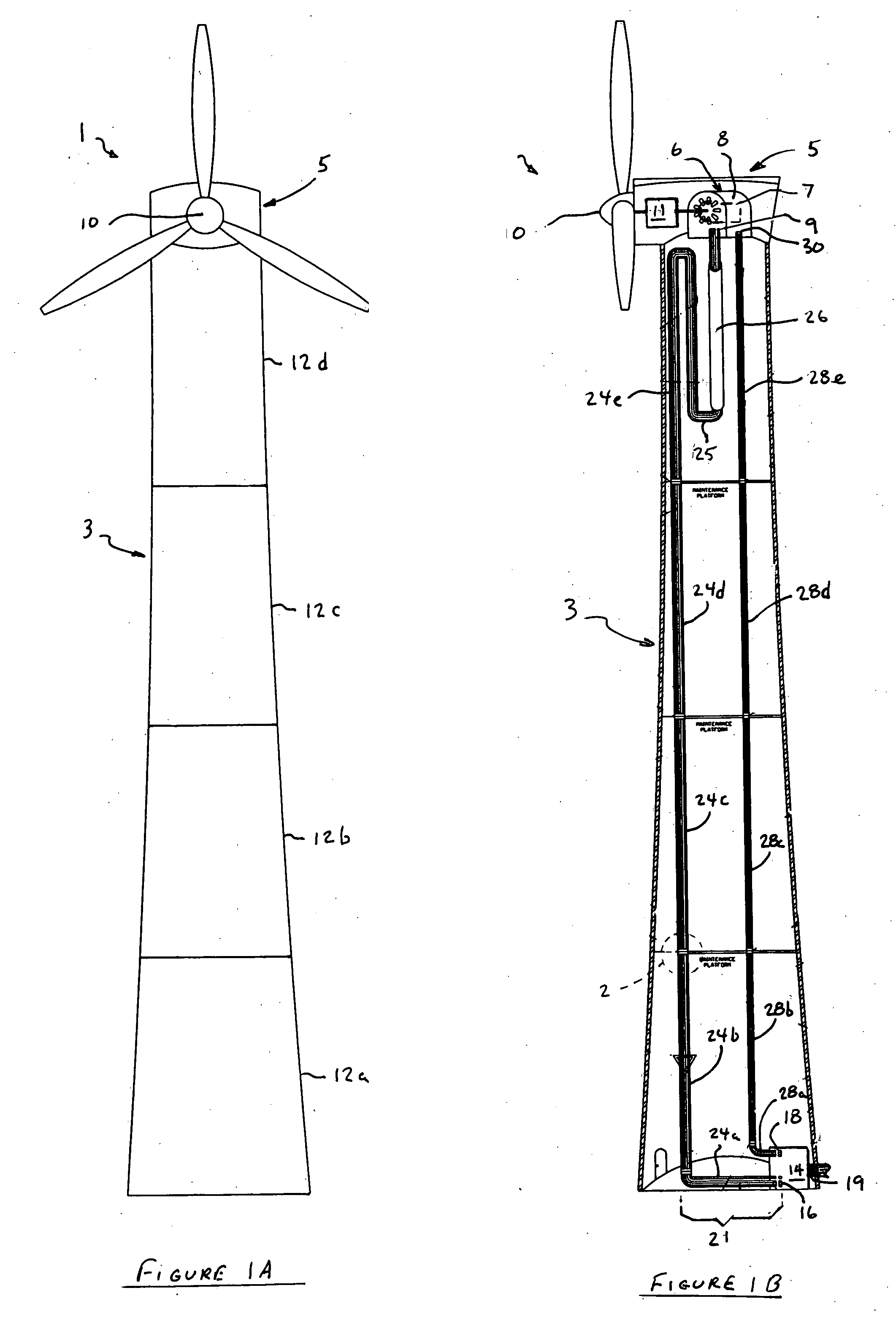

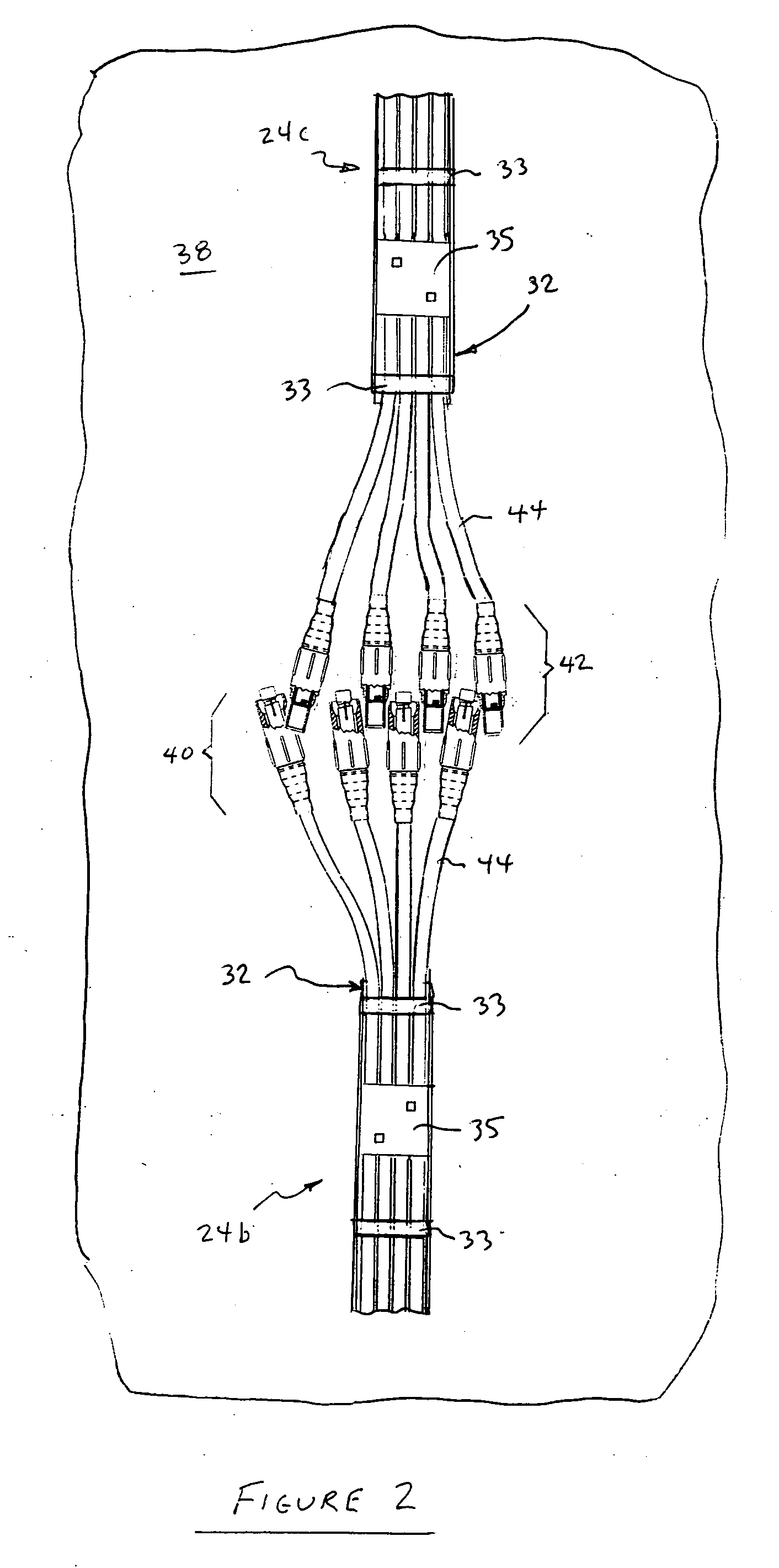

Windmill cable system and method

InactiveUS20060199411A1Quantity minimizationPrevent disengagementEngagement/disengagement of coupling partsMachines/enginesElectricityPower cable

An improved cable system and method for an electricity generating windmill having a base formed from a plurality of stacked base sections is provided. Each base section includes a bundle of both power and control cables which are alignable with one another when the base sections are stacked and assembled. Mating electrical connectors which may be easily interlocked are provided at the ends of the power and control cables, and in the terminals of the generator and inverter of the windmill. In the preferred embodiment, bayonet-type connectors are used to provide a secure, interlocking coupling between adjacent cable ends with a minimum amount of twisting motion between the cables, which are necessarily of heavy gauge to conduct the current produced by the generator. The system greatly facilitates installation of the cable system as well as repair or replacement of damaged or worn cables during the lifetime of the windmill.

Owner:RENEWABLES ENG SERVICES GROUP +1

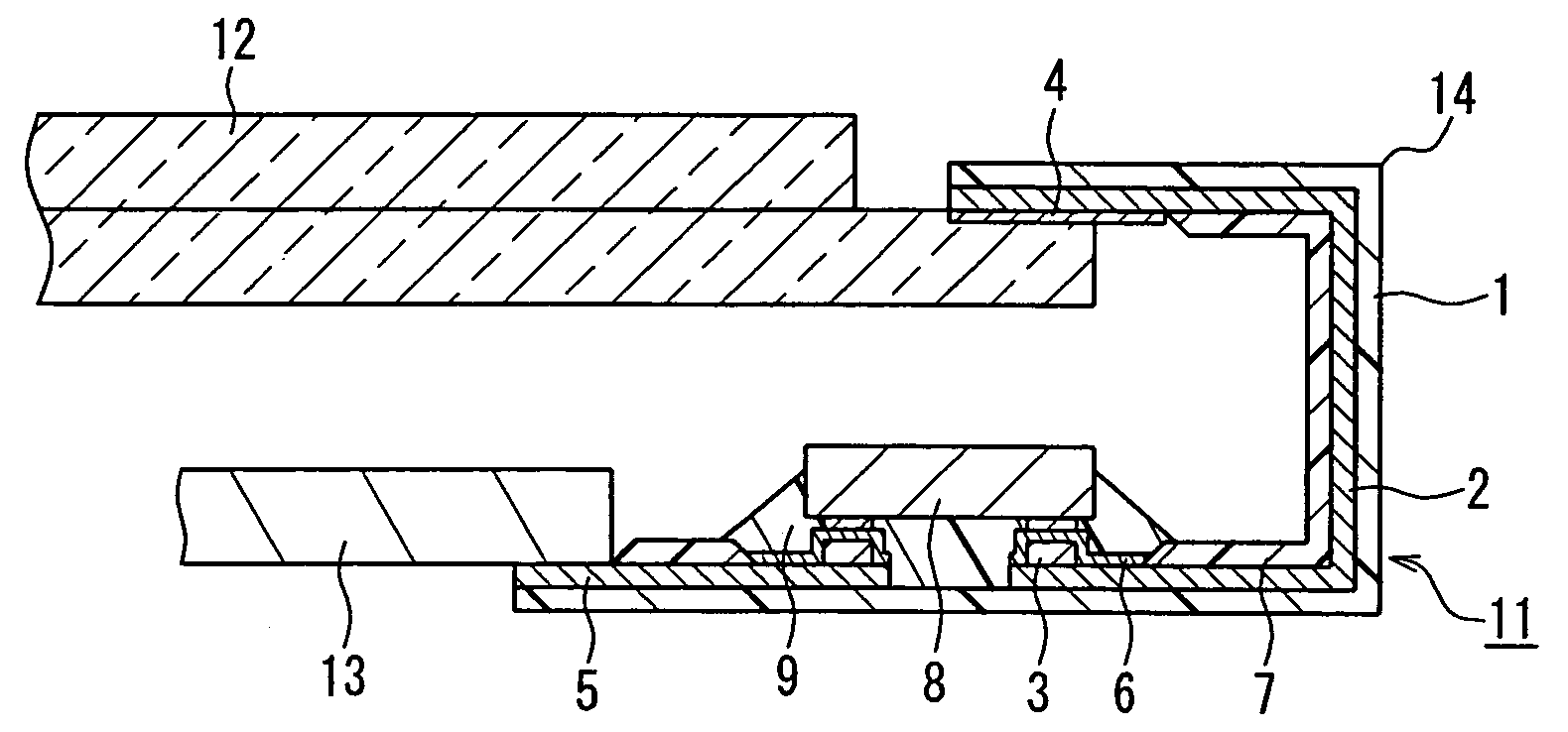

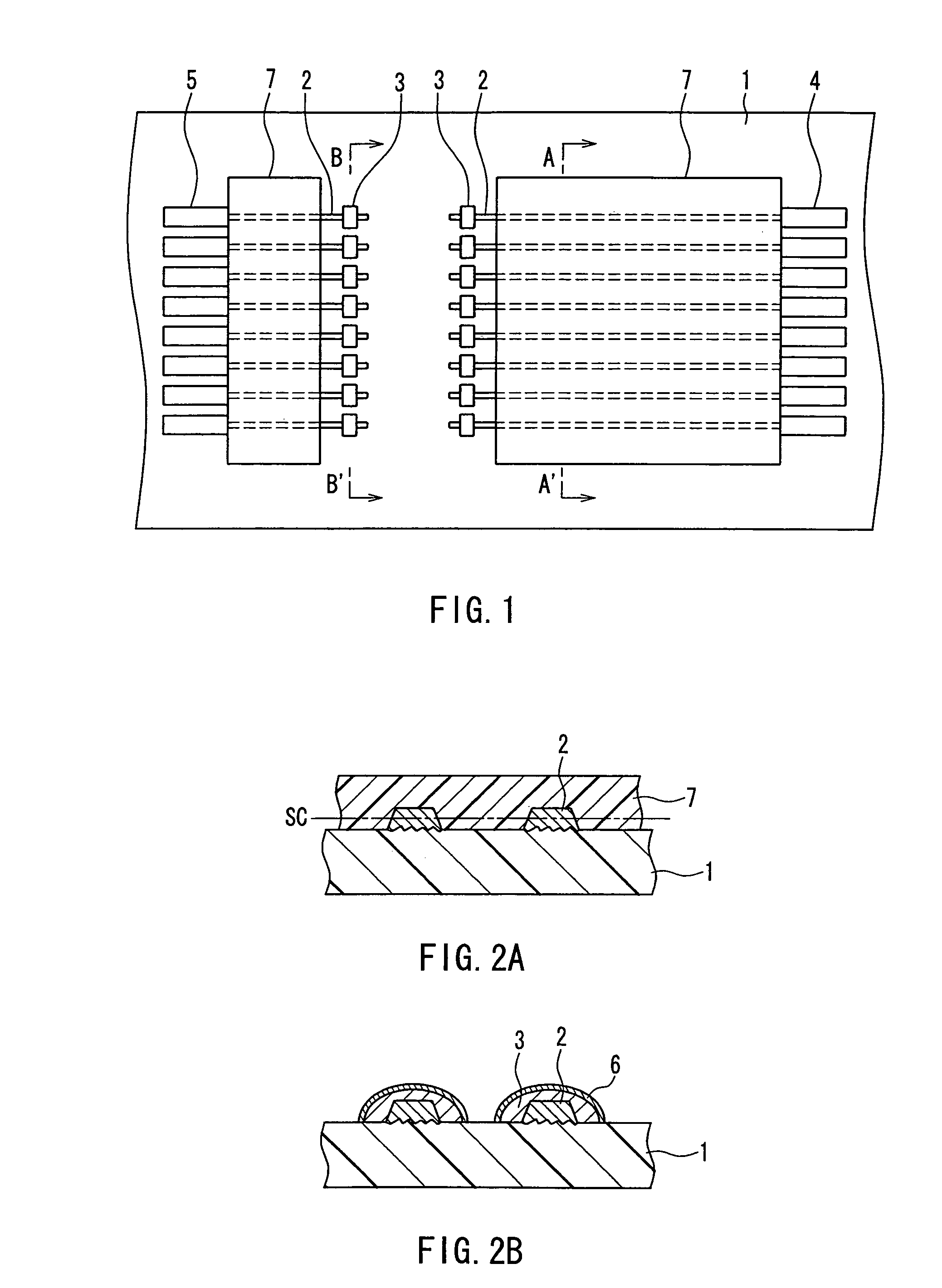

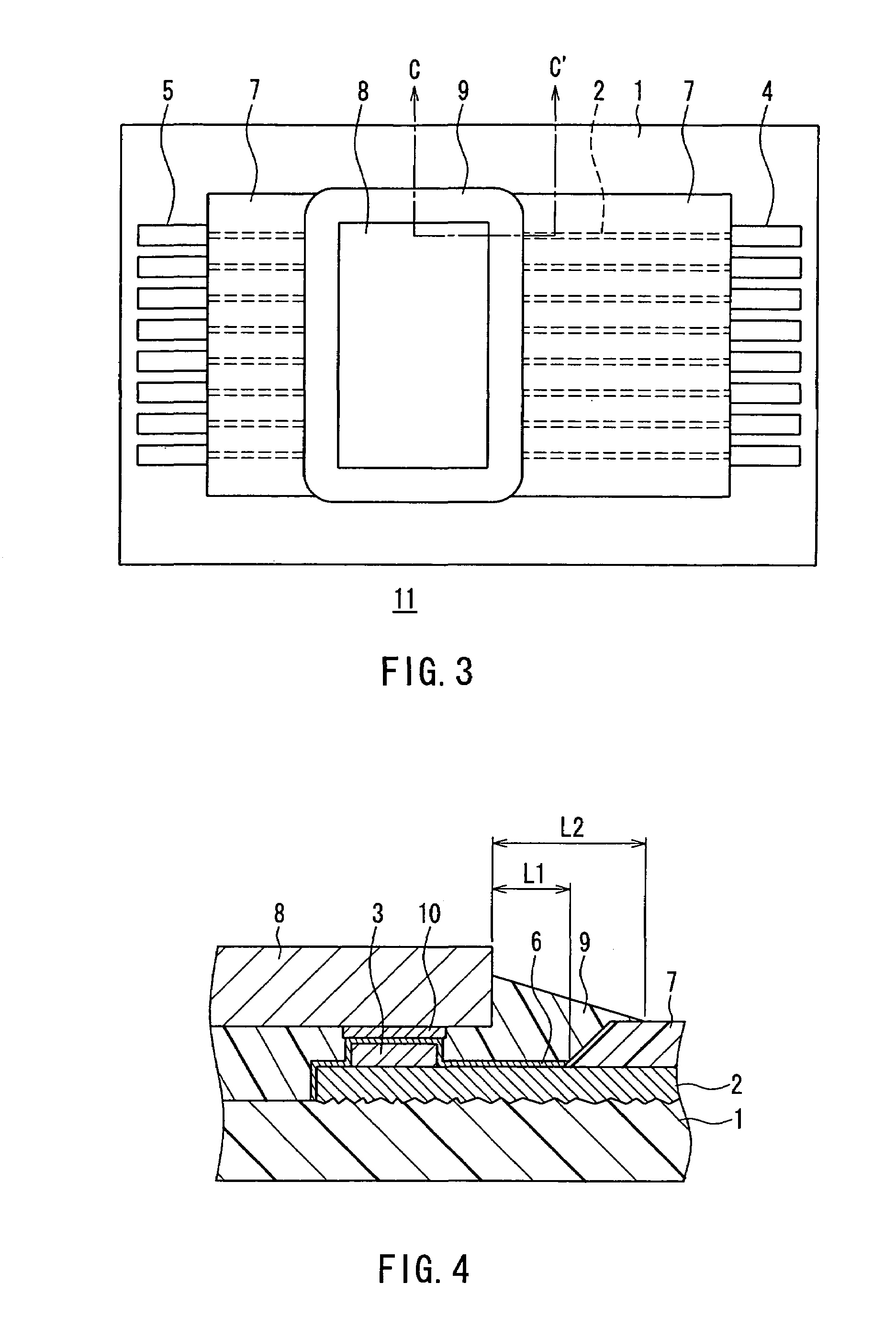

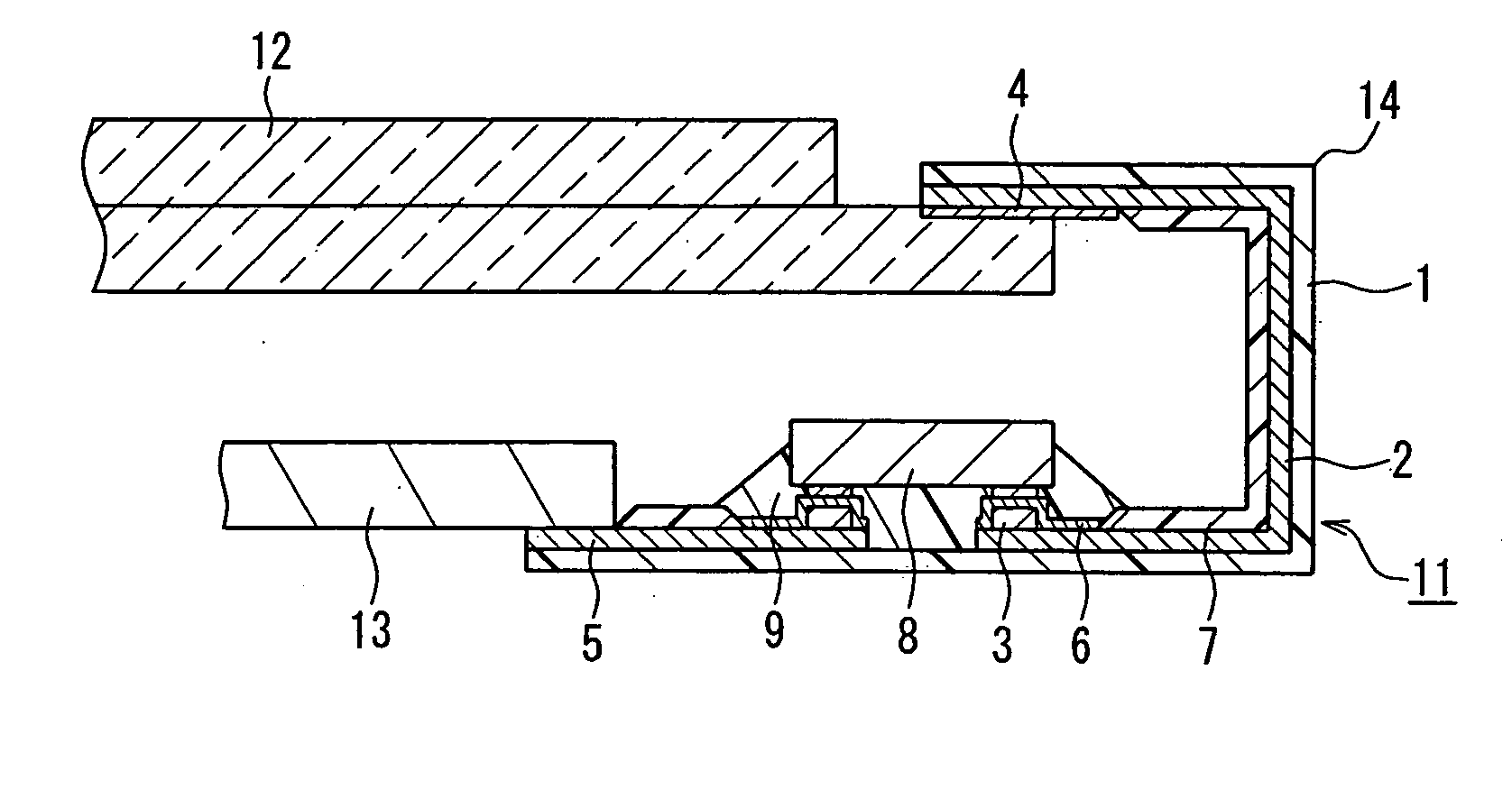

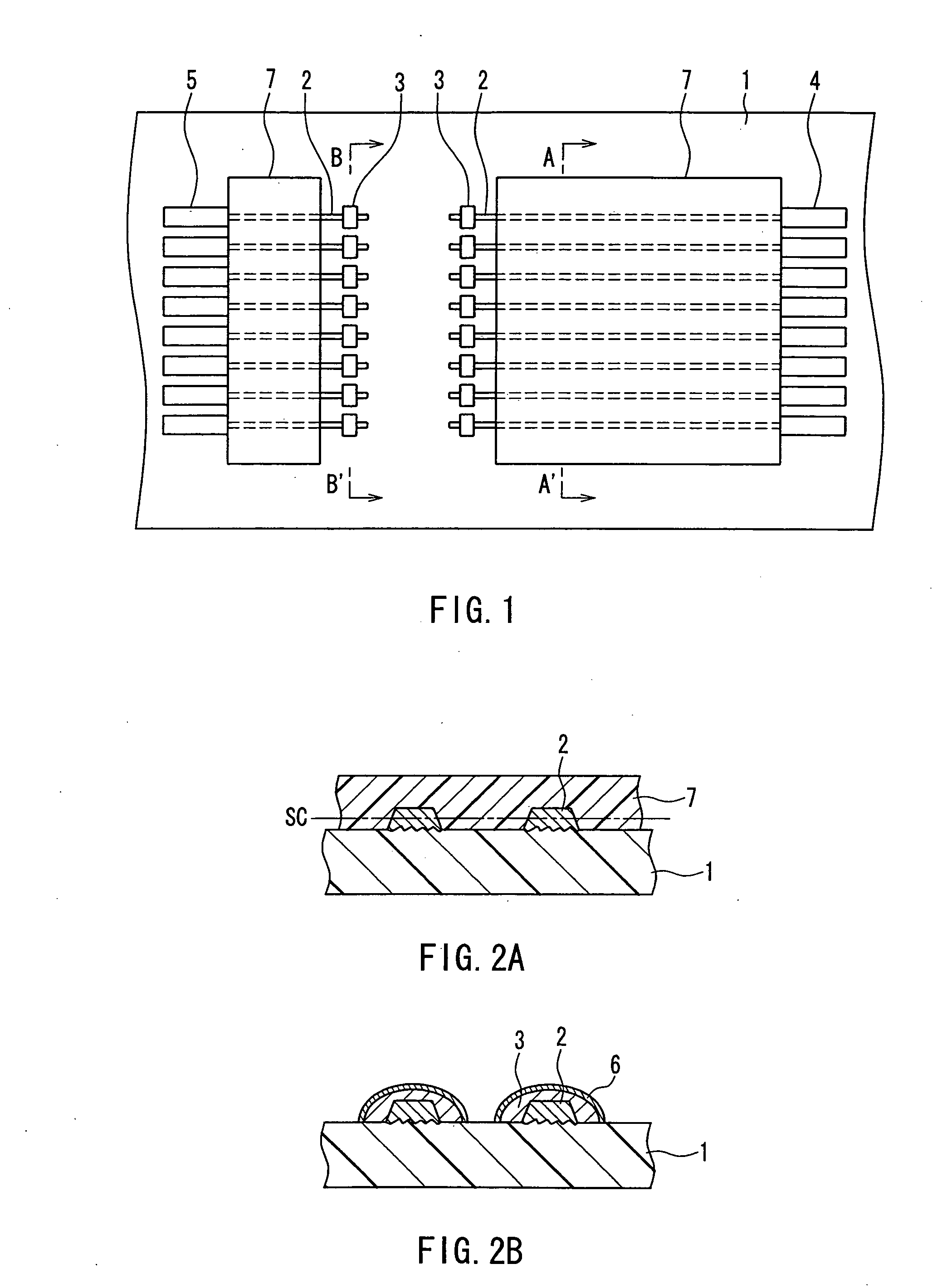

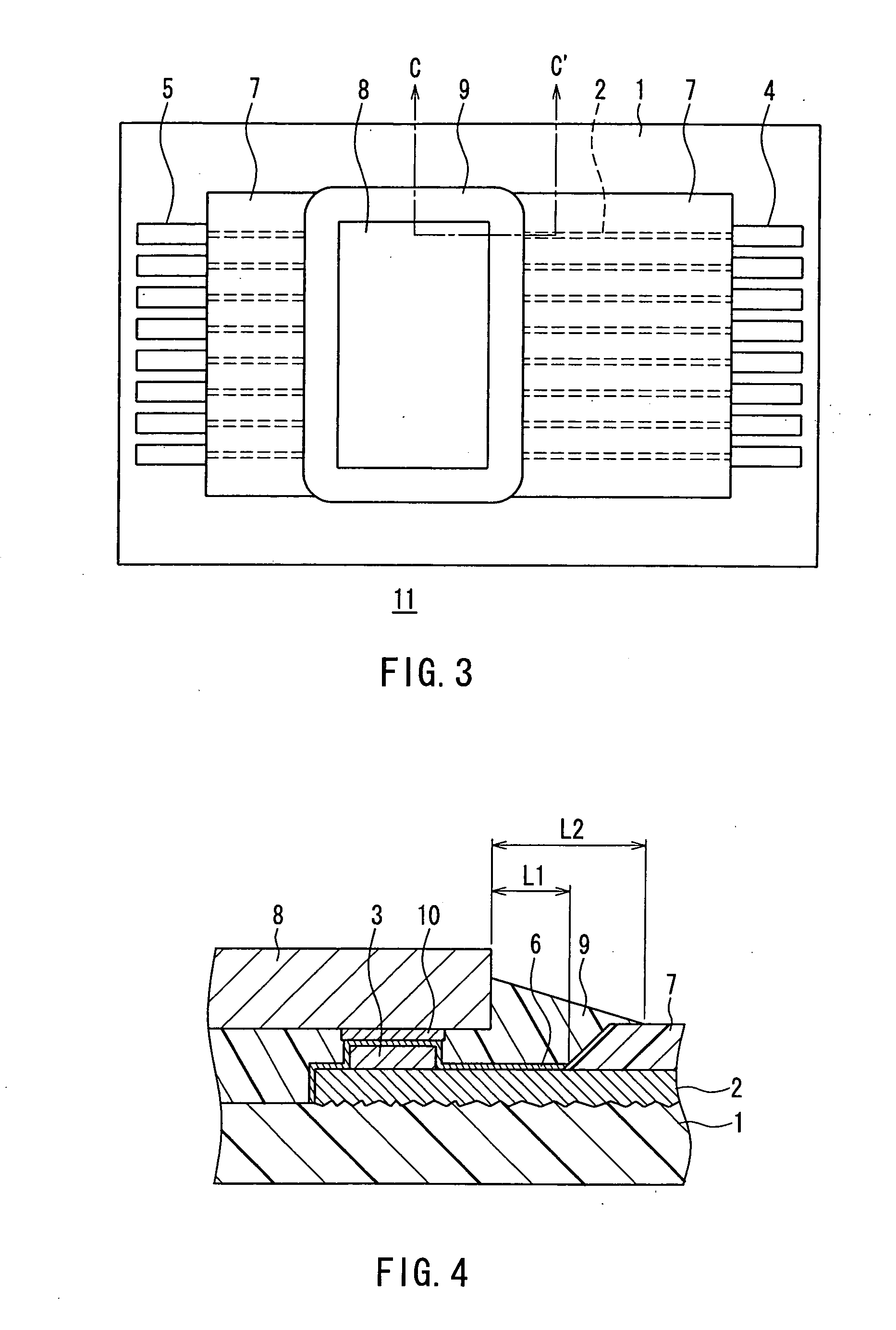

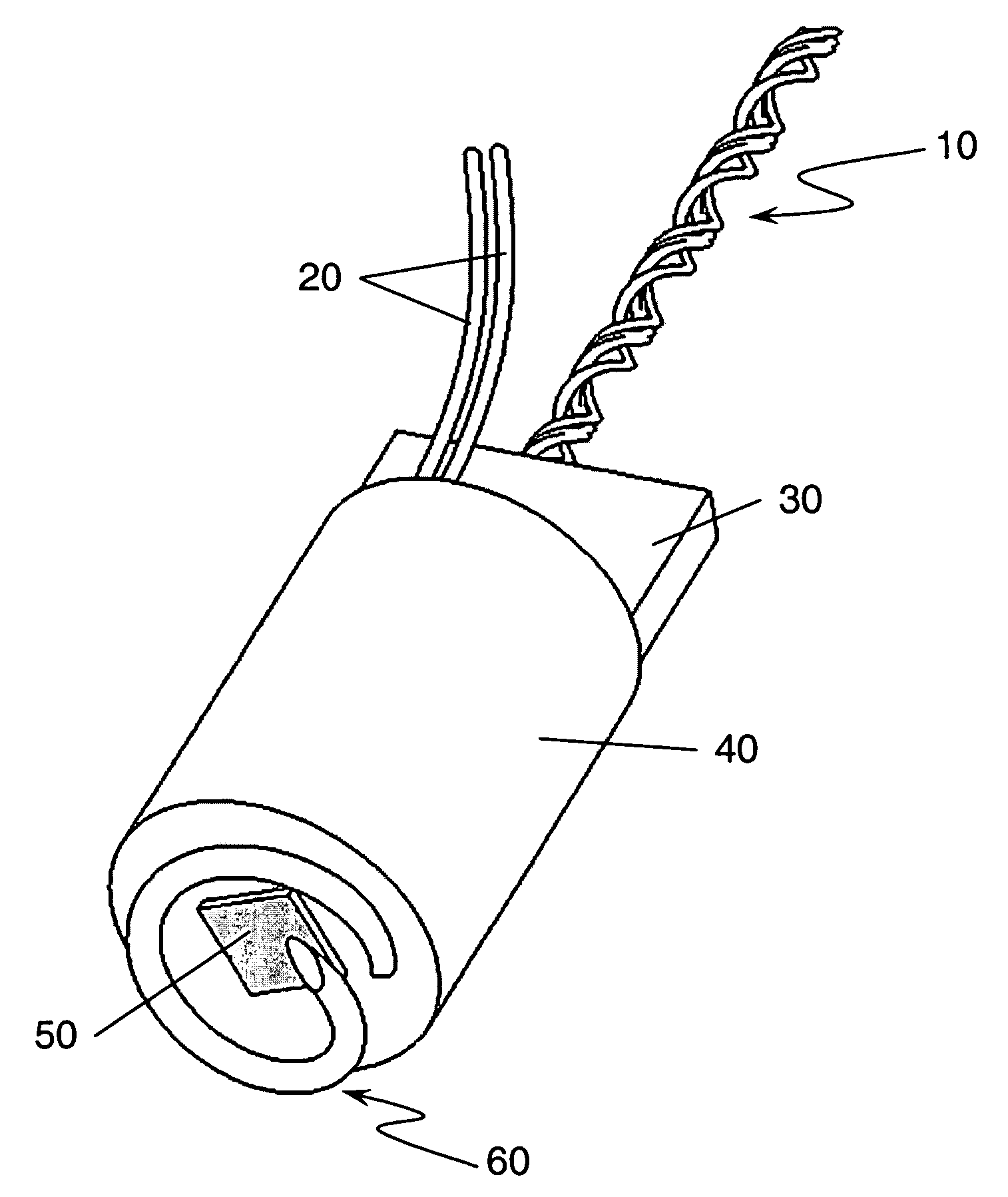

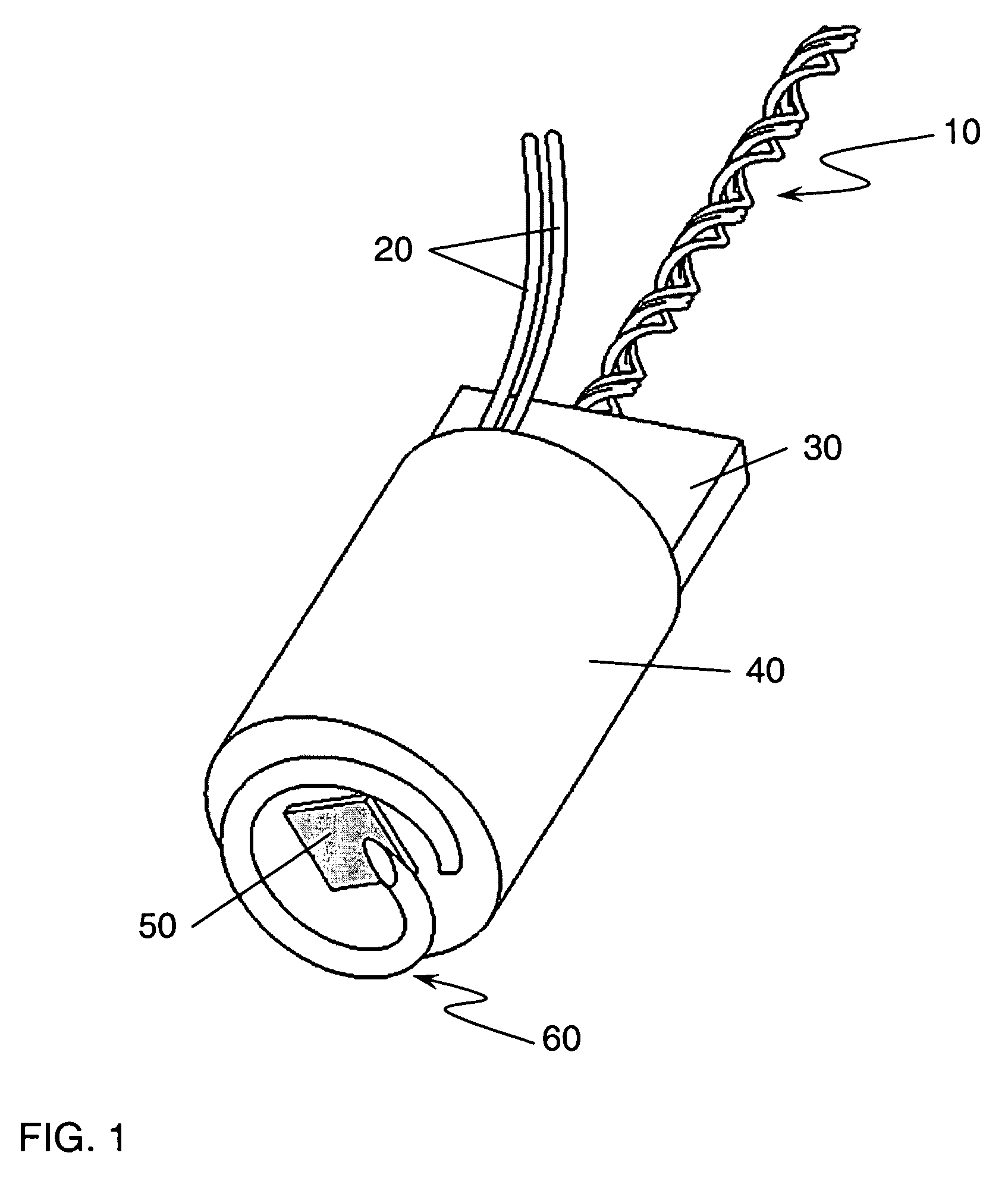

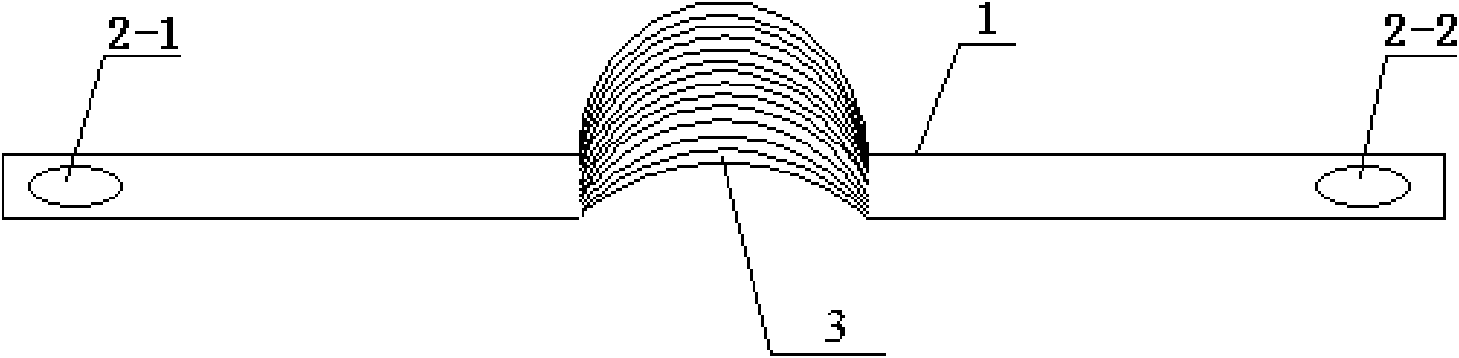

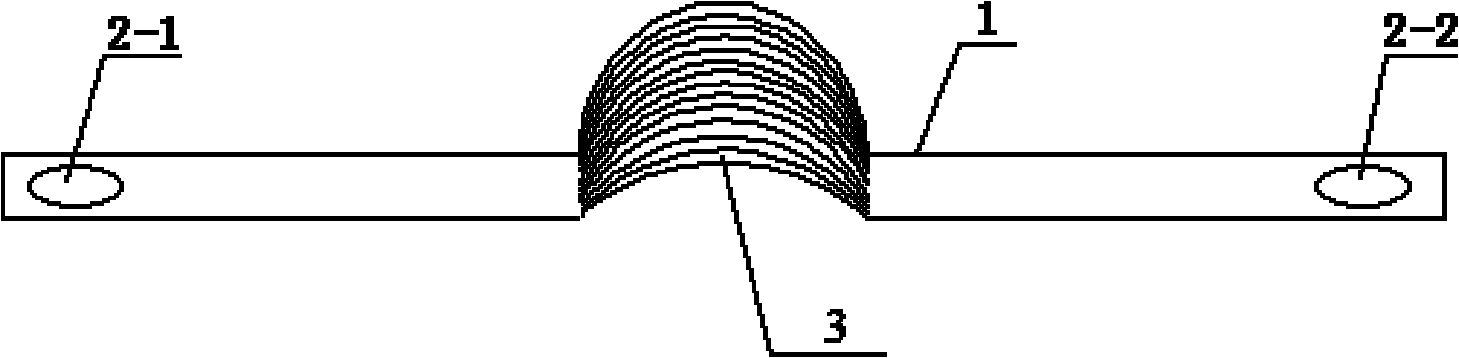

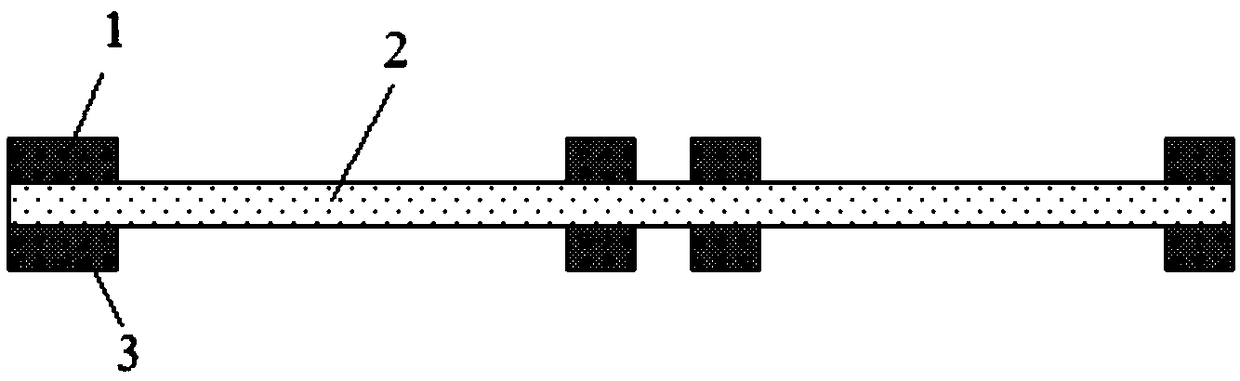

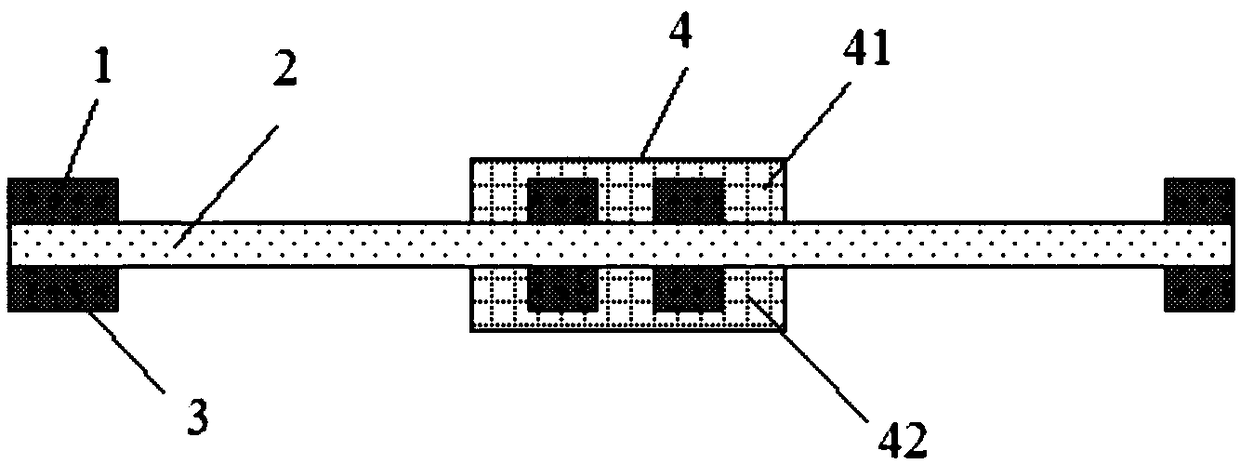

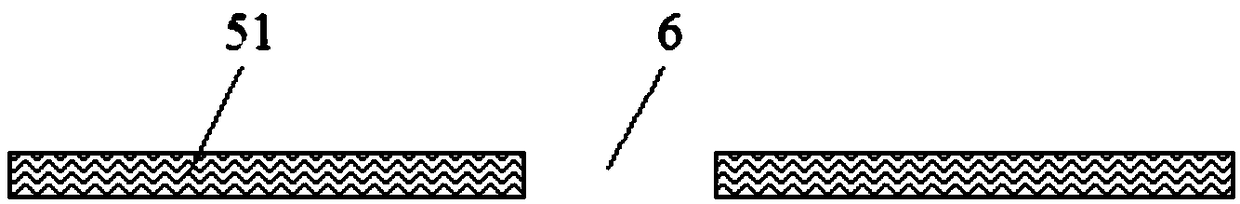

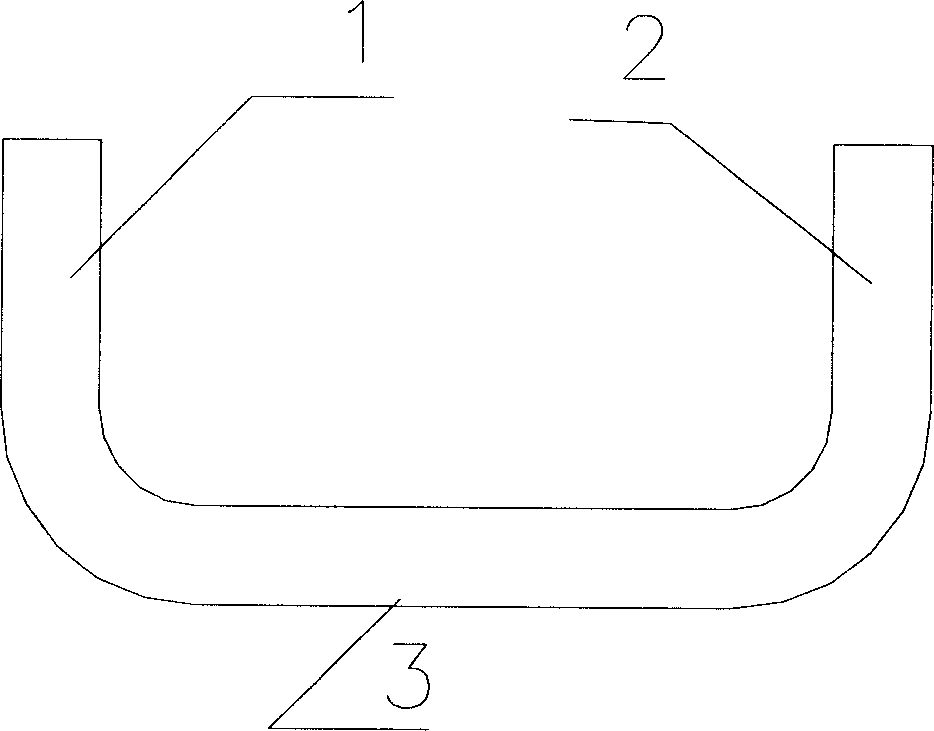

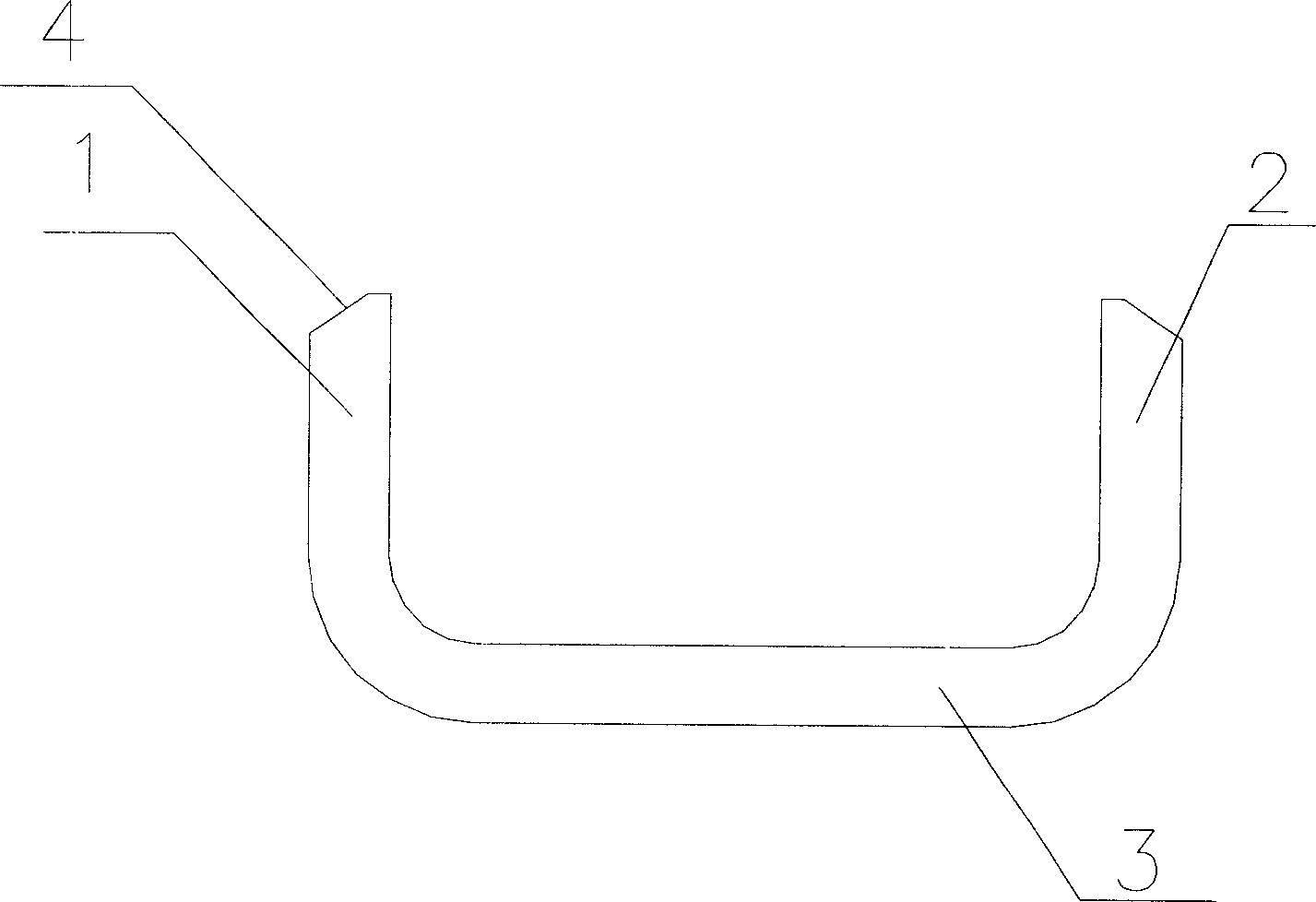

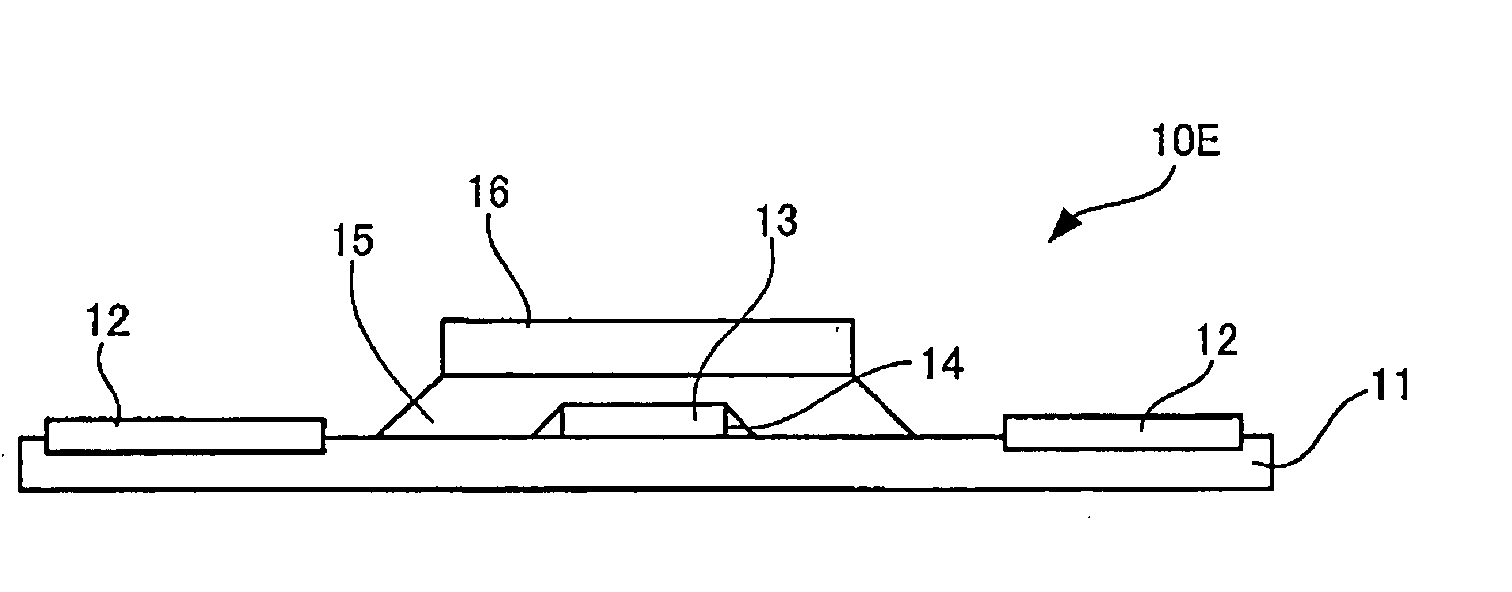

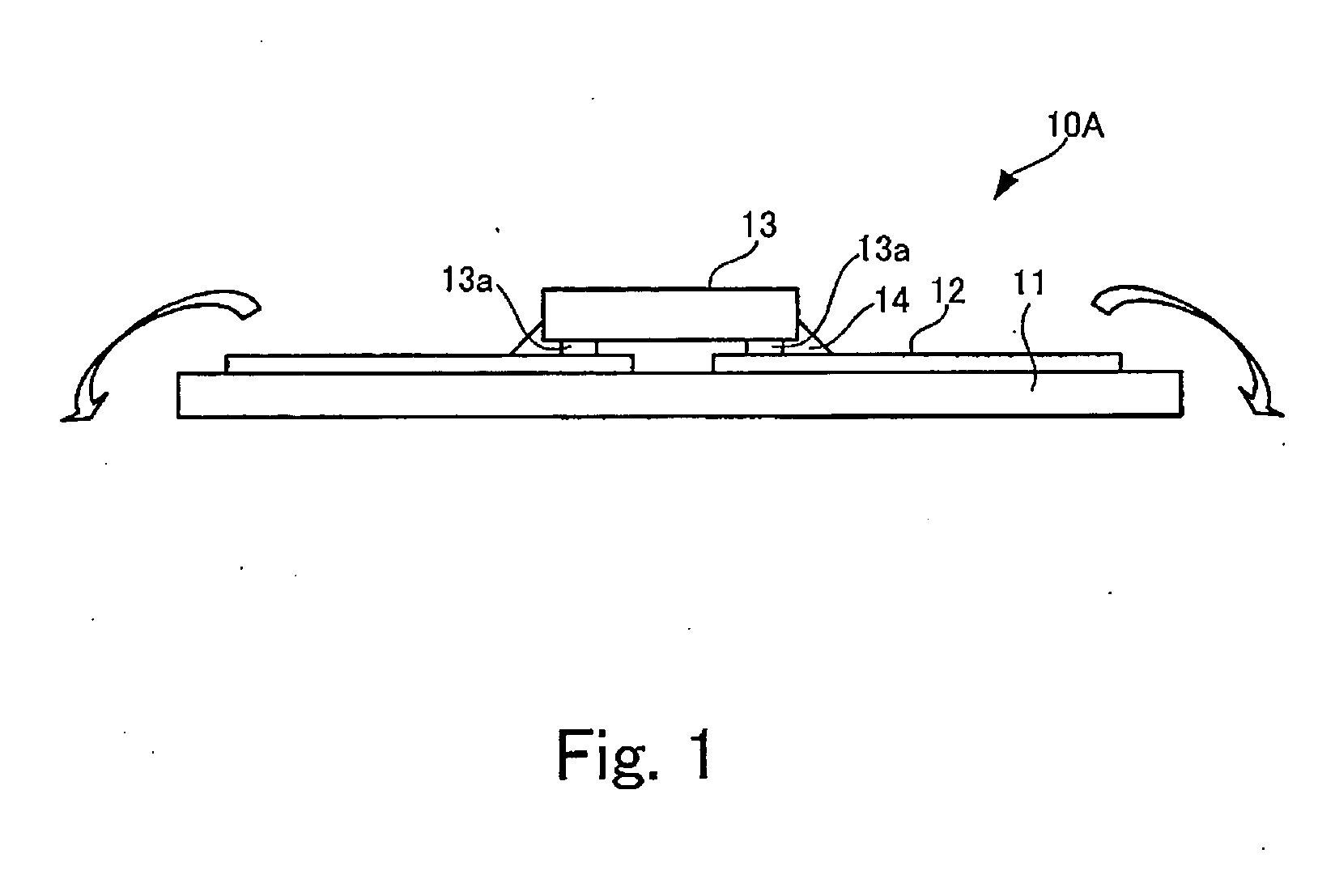

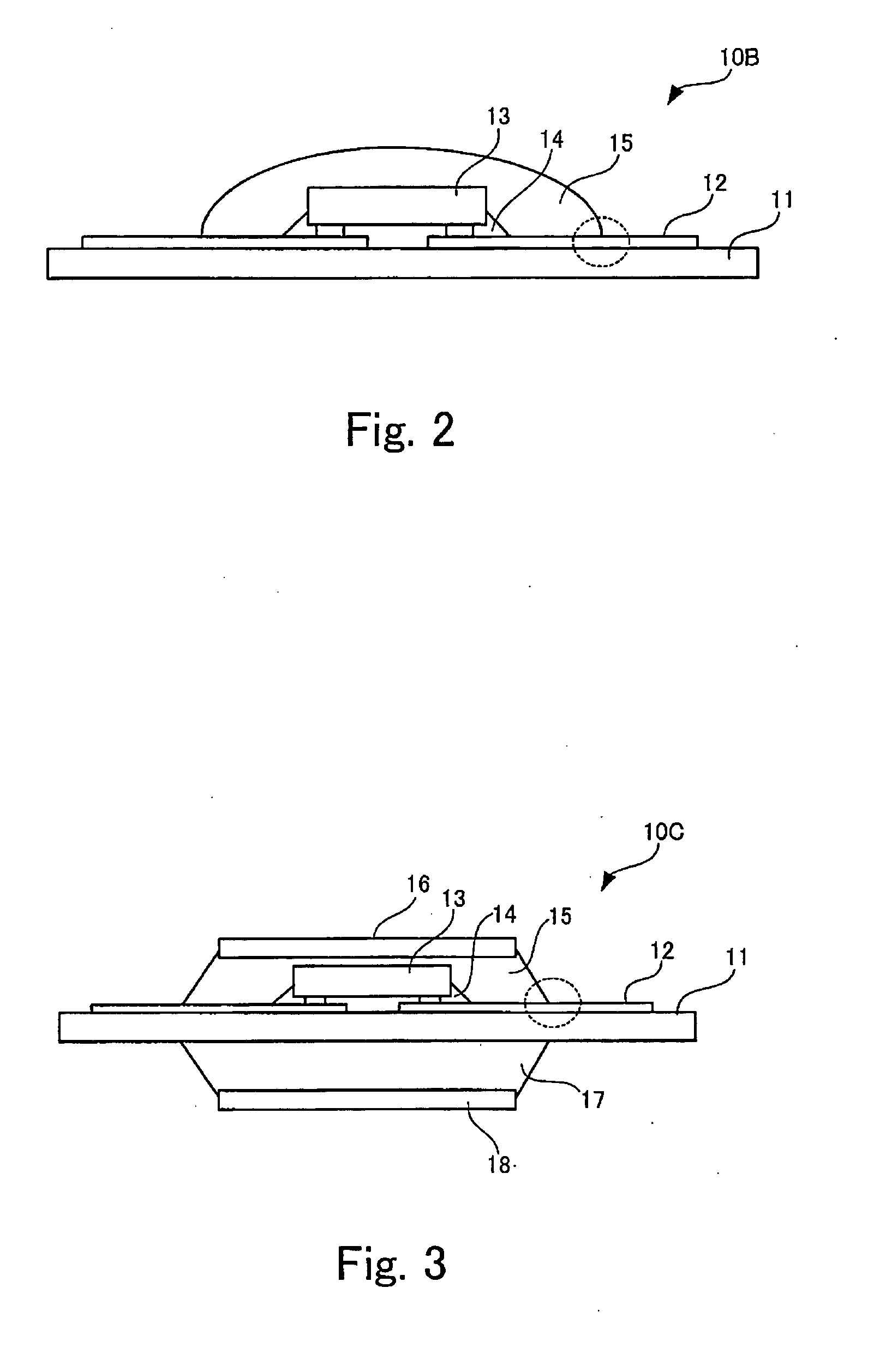

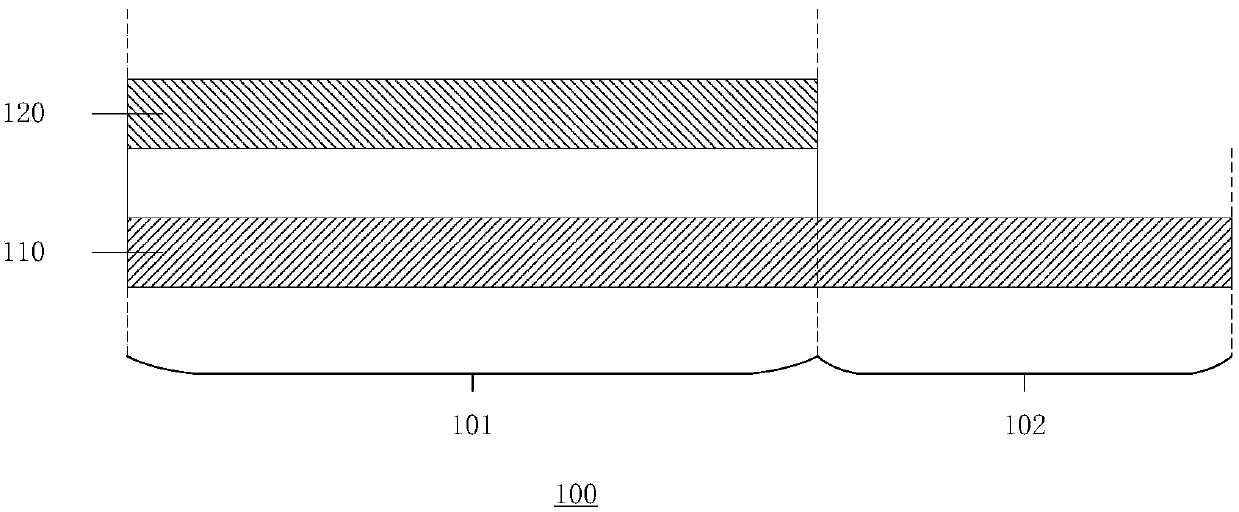

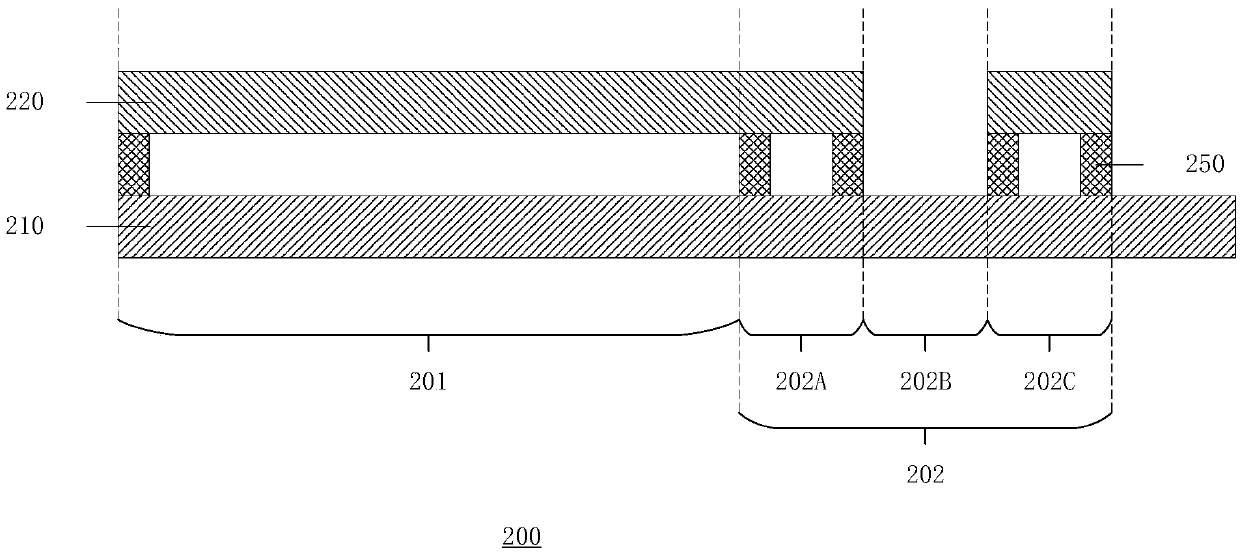

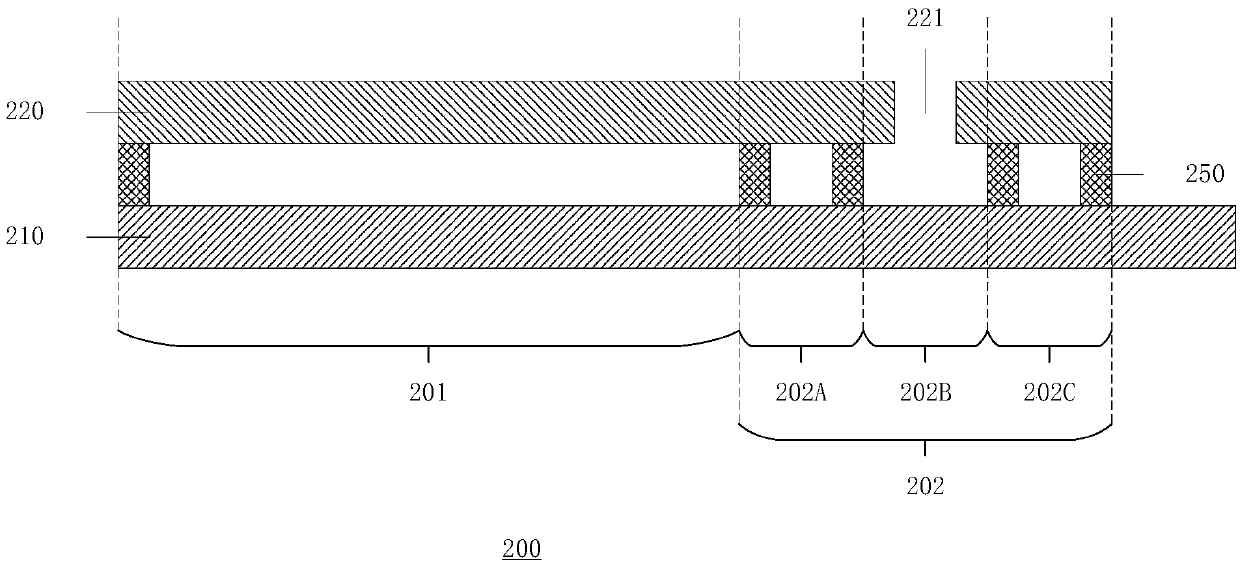

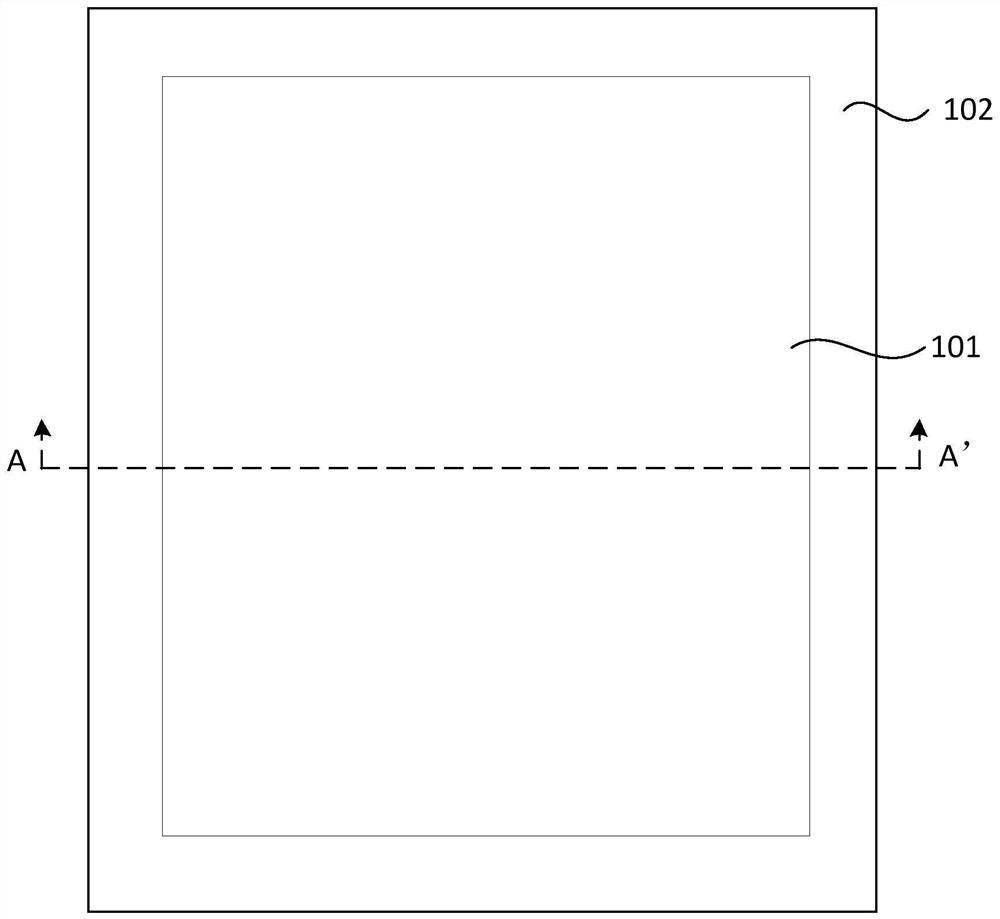

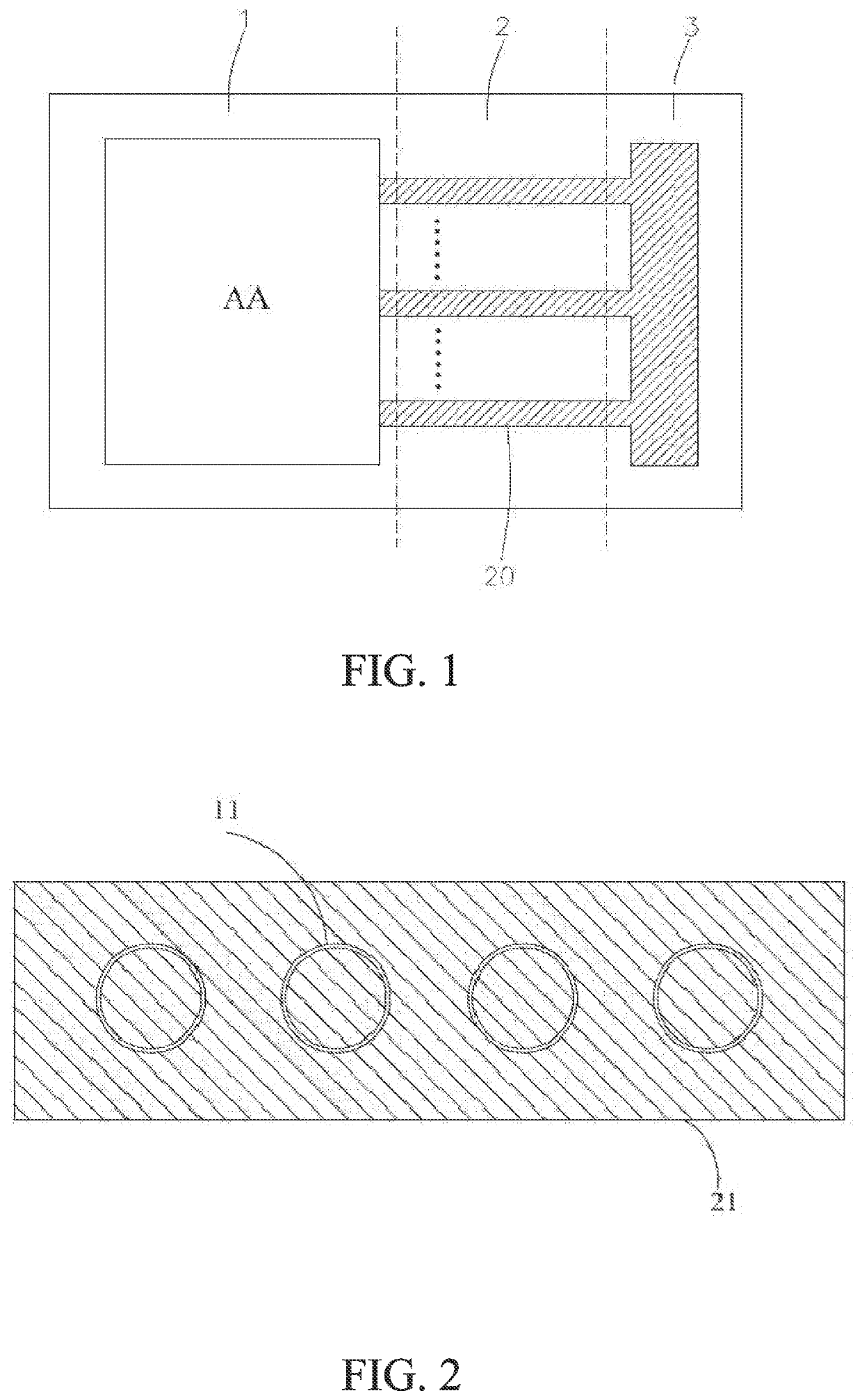

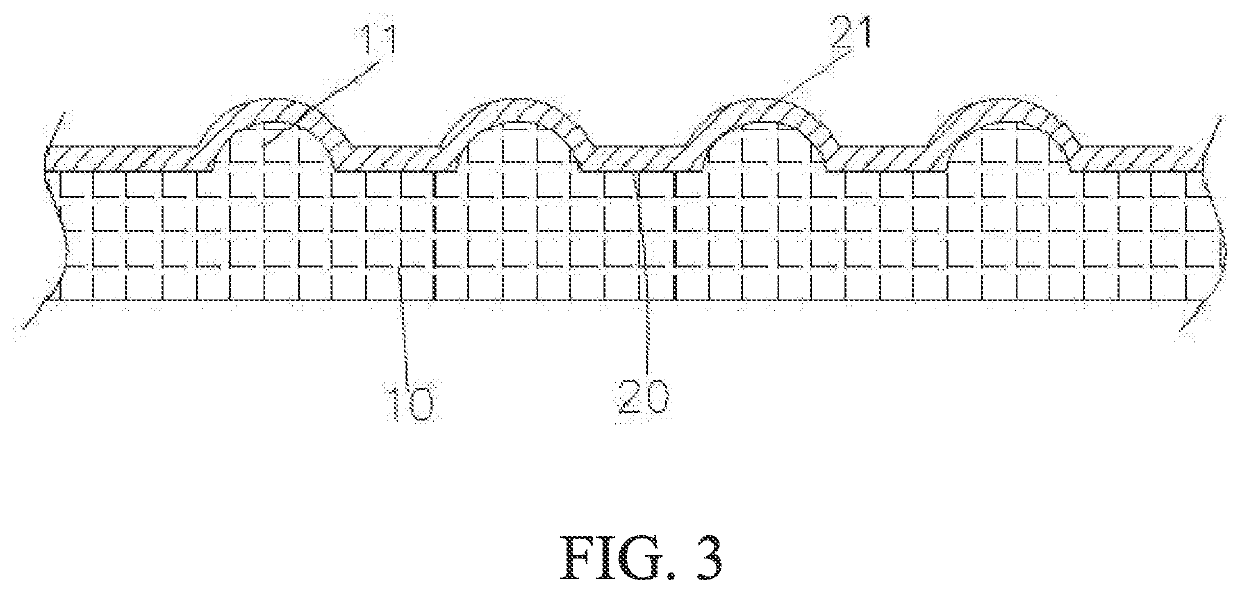

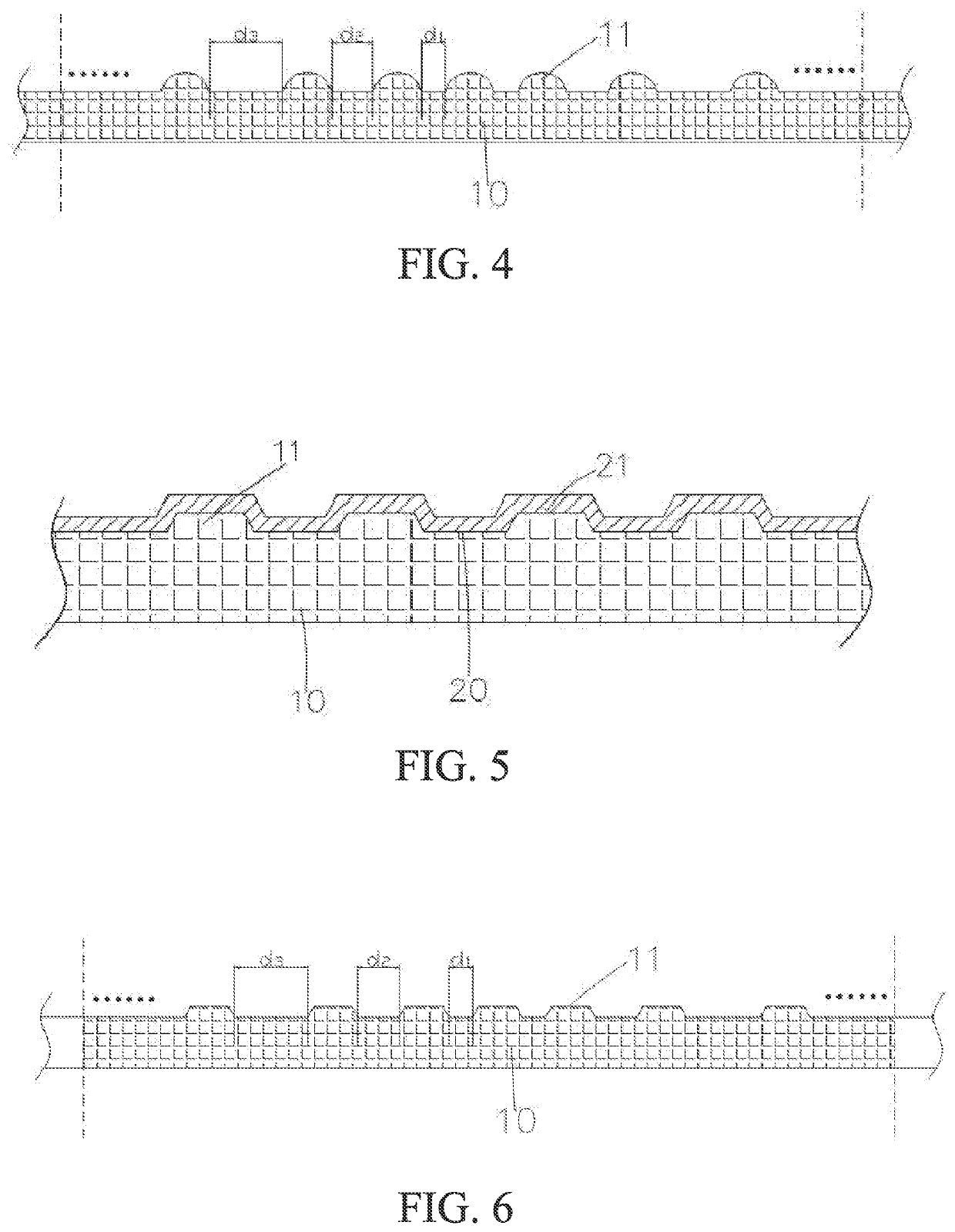

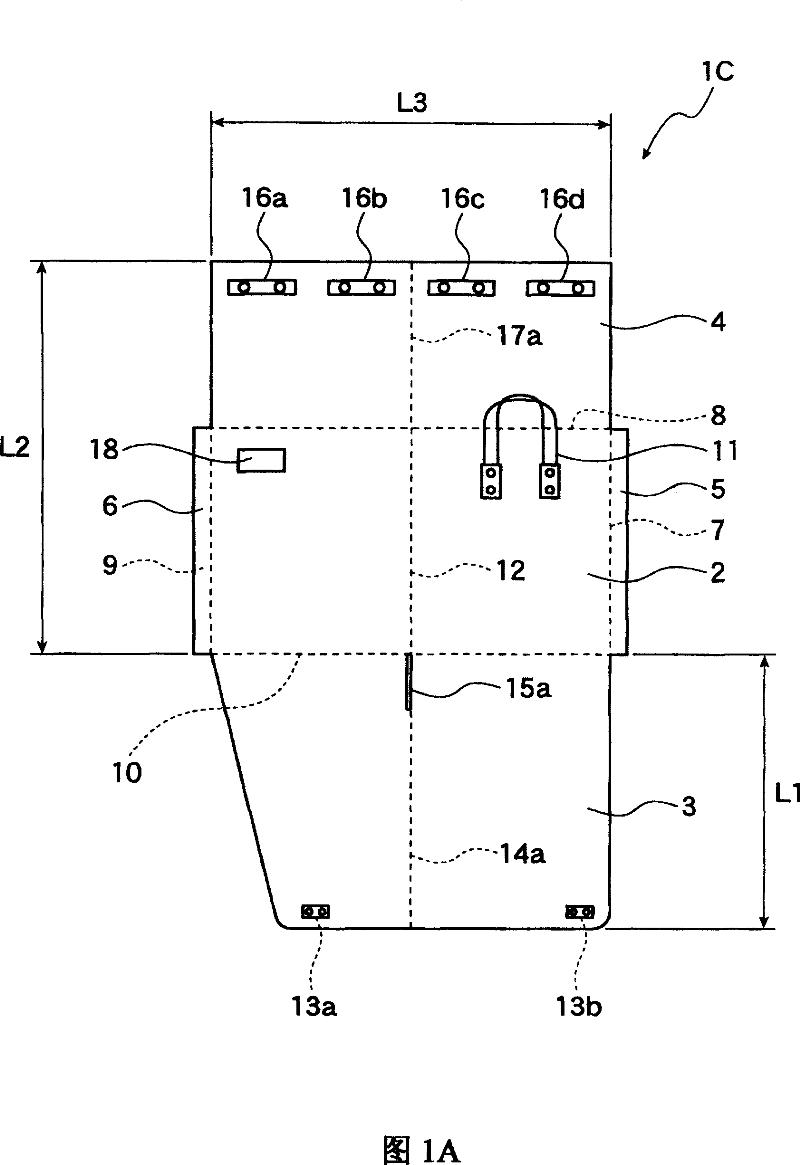

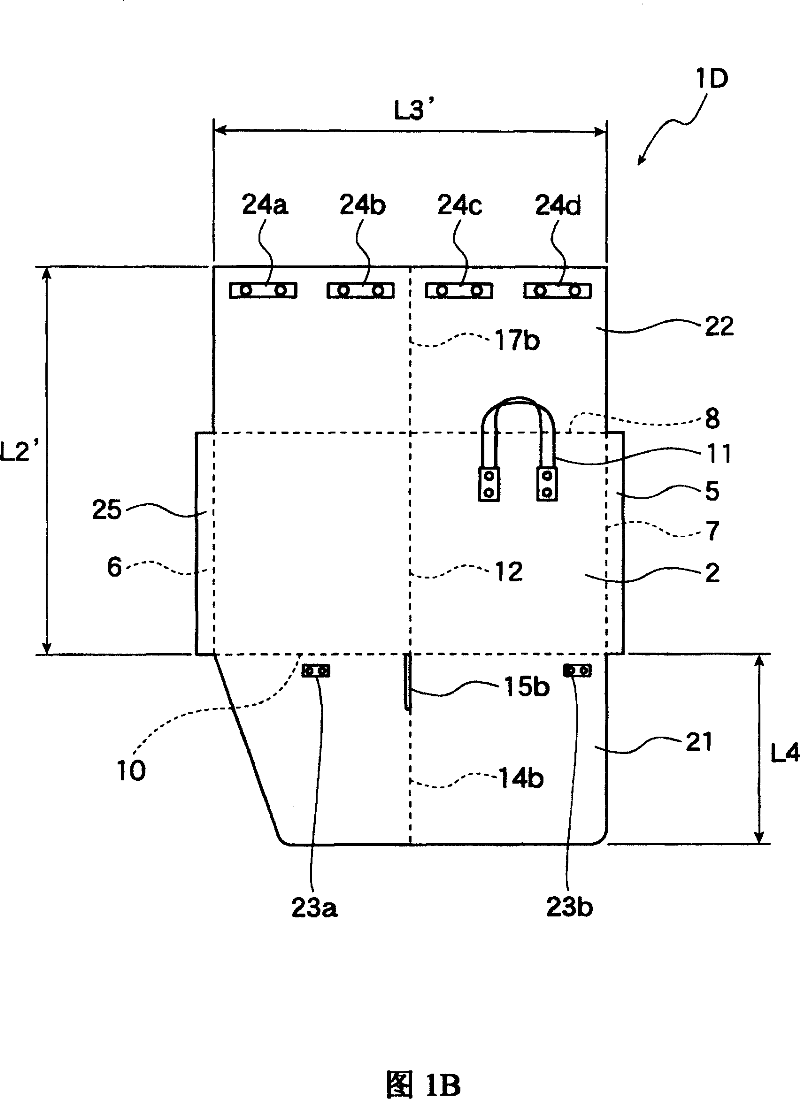

Wiring board, semiconductor device and display module

InactiveUS7250575B2Occurrence of breaks in the wirings can be suppressedRelieve bending stressFinal product manufactureSemiconductor/solid-state device detailsResistSolder mask

A wiring board includes: a flexible insulating base 1; a plurality of conductive wirings 2 arranged on the flexible insulating base 1; protruding electrodes 3 provided respectively at an end portion of the same side of each of the conductive wirings; external terminals 4, 5 formed respectively at the other end portions of each of the conductive wirings; metal plating layers applied on the conductive wirings, the protruding electrodes and the external terminals; and solder resist layers 7 formed respectively by coating the conductive wirings in regions between the end portions at which the protruding electrodes are provided and the external terminals. In the regions where the solder resist layers are formed, no metal plating layers are formed on the conductive wirings, and the surfaces of the conductive wirings to be contacted with the flexible insulating base are rougher than the surfaces not to be contacted with the flexible insulating base. Even when a film base is thin, bending stress applied to the conductive wirings is relieved sufficiently, and thus breaks in the wirings are suppressed.

Owner:PANASONIC CORP

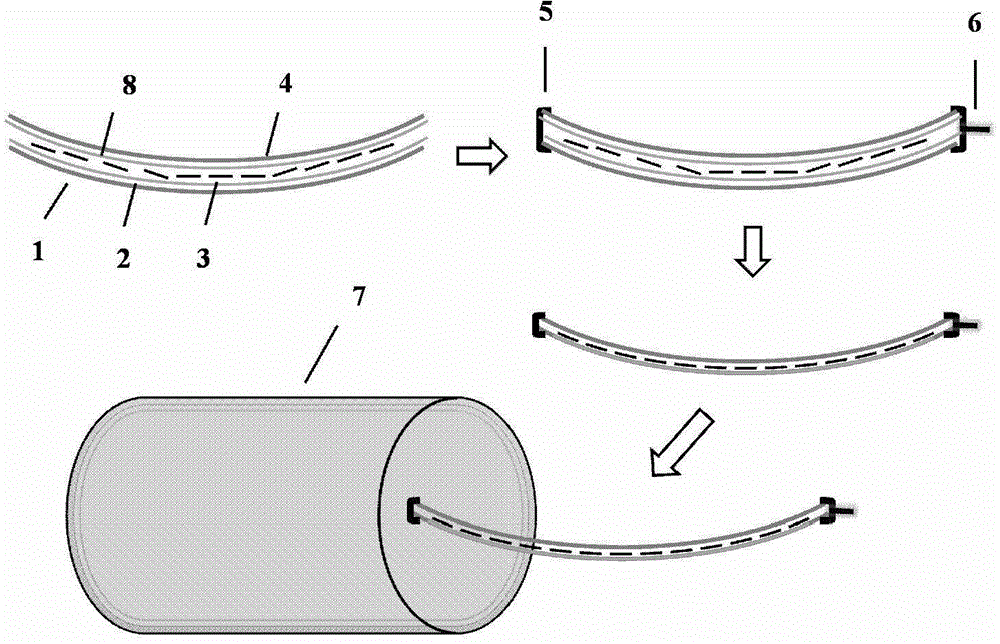

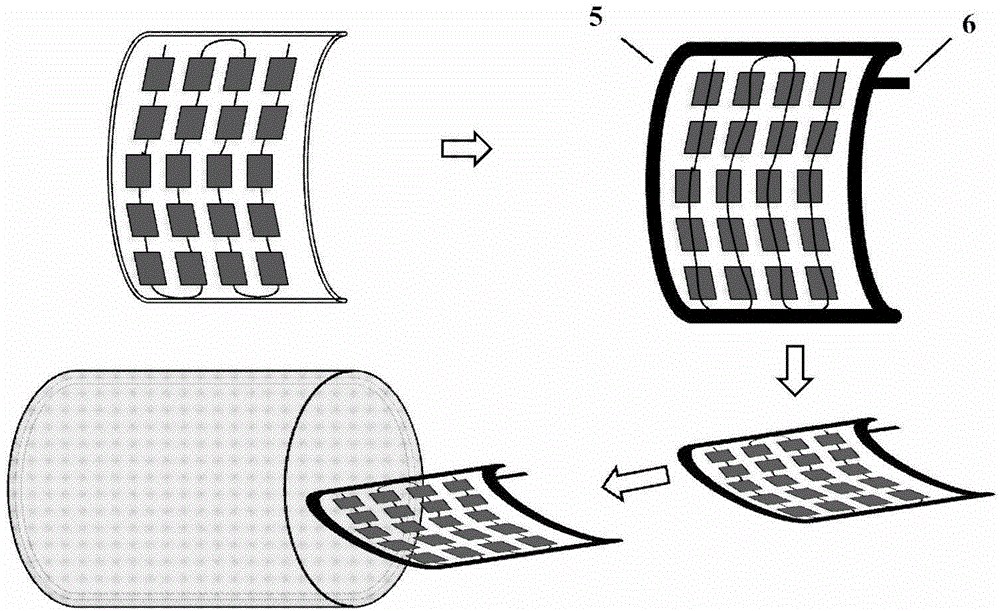

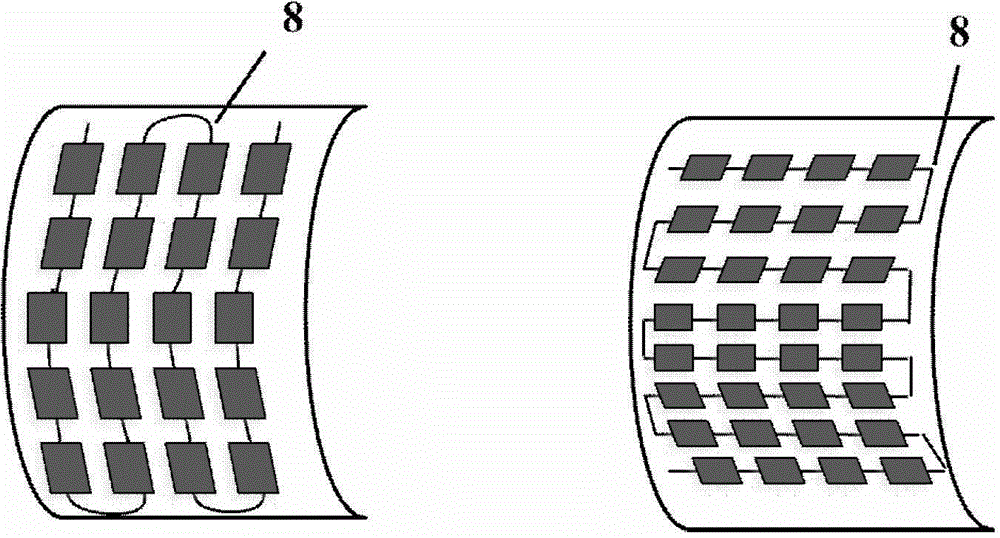

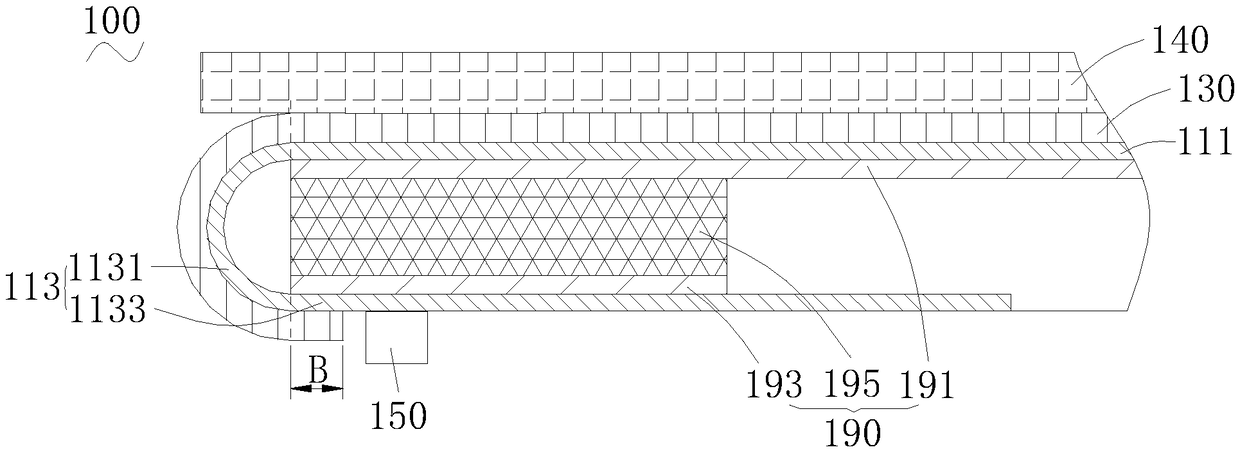

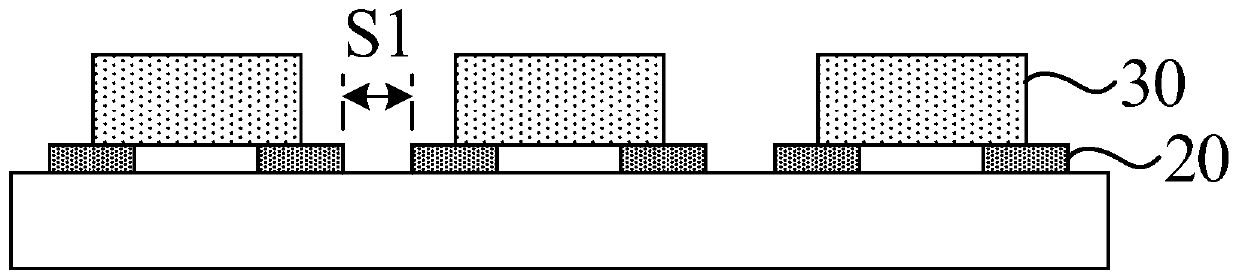

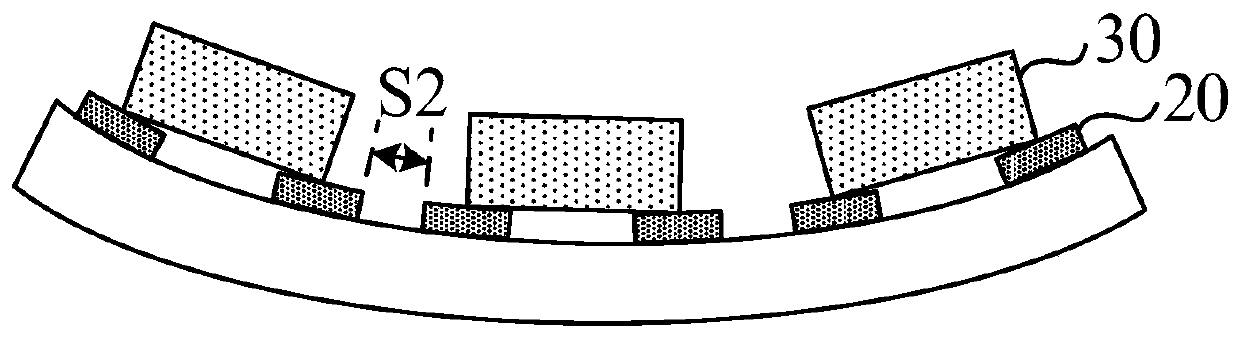

Lamination preparation process of curved-surface double-glass photovoltaic module

InactiveCN102983213AAchieve initial shapePrevent slidingFinal product manufactureLaminationRubber ringGlass cover

The invention discloses a lamination preparation process of a curved-surface double-glass photovoltaic module. Firstly, a layer of binding material covers face plate bent glass, a solar cell is arranged on the binding material, a layer of binding material covers the solar cell, and then rear plate bent glass covers on the binding material. After the panel bent glass is aligned to the rear plate bent glass, a vacuum rubber ring is sleeved on the periphery of the face plate bent glass and the rear plate bent glass, the solar cell and the two layers of binding materials are enabled to be in a closed space formed by the face plate bent glass, the rear plate bent glass and the vacuum rubber ring, the closed space is vacuumized then, the face plate bent glass and the rear plate bent glass compact the solar cell and the binding materials arranged between the face plate bent glass and the rear plate bent glass to prevent relative sliding, and an assembly to be packaged is obtained. The assembly to be packaged is placed into a high-pressure autoclave laminating machine to be carried out with lamination, and the vacuum rubber ring is removed and the curved-surface double-glass photovoltaic module is obtained after the lamination. The lamination preparation process of the curved-surface double-glass photovoltaic module can utilize one device to prepare photovoltaic modules with different radiuses of curvature.

Owner:CHINA SUNERGY CO LTD

Wiring board, semiconductor device and display module

InactiveUS20060268530A1Occurrence of breaks in the wirings can be suppressedRelieve bending stressFinal product manufactureSemiconductor/solid-state device detailsResistSolder mask

A wiring board includes: a flexible insulating base 1; a plurality of conductive wirings 2 arranged on the flexible insulating base 1; protruding electrodes 3 provided respectively at an end portion of the same side of each of the conductive wirings; external terminals 4, 5 formed respectively at the other end portions of each of the conductive wirings; metal plating layers applied on the conductive wirings, the protruding electrodes and the external terminals; and solder resist layers 7 formed respectively by coating the conductive wirings in regions between the end portions at which the protruding electrodes are provided and the external terminals. In the regions where the solder resist layers are formed, no metal plating layers are formed on the conductive wirings, and the surfaces of the conductive wirings to be contacted with the flexible insulating base are rougher than the surfaces not to be contacted with the flexible insulating base. Even when a film base is thin, bending stress applied to the conductive wirings is relieved sufficiently, and thus breaks in the wirings are suppressed.

Owner:PANASONIC CORP

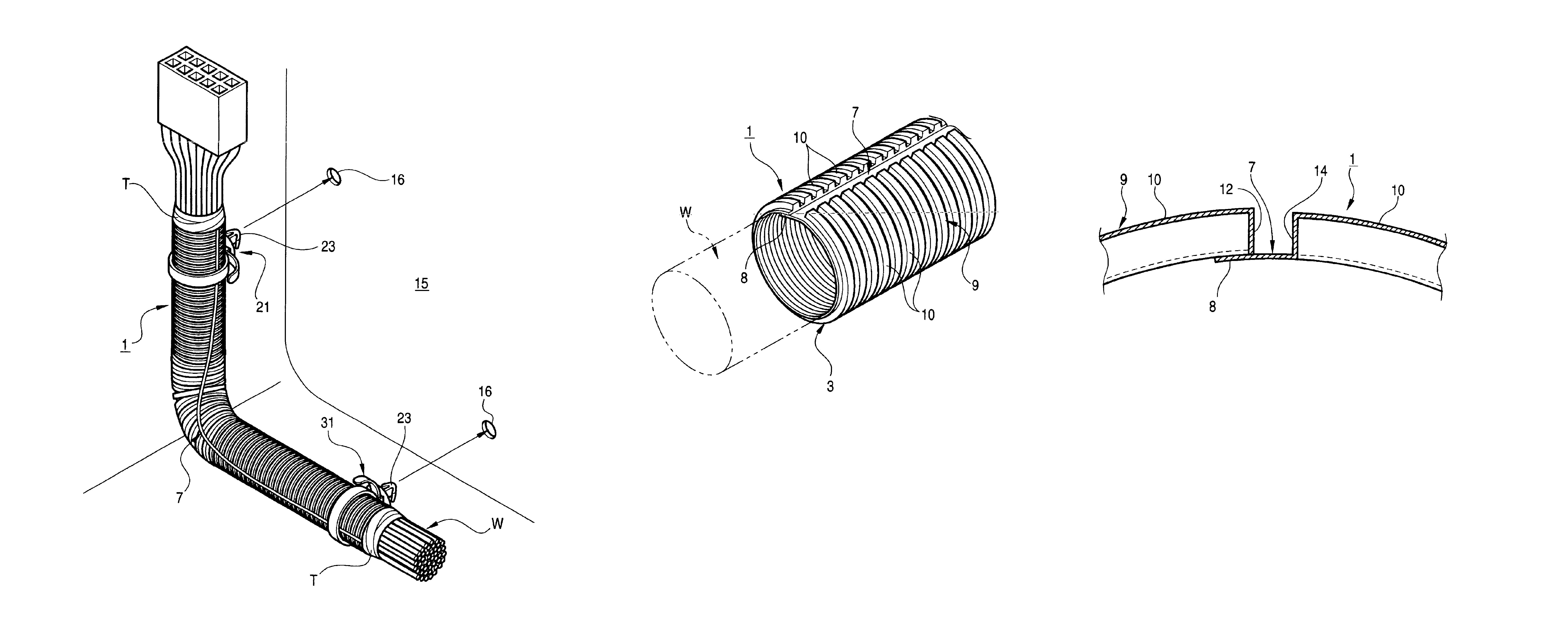

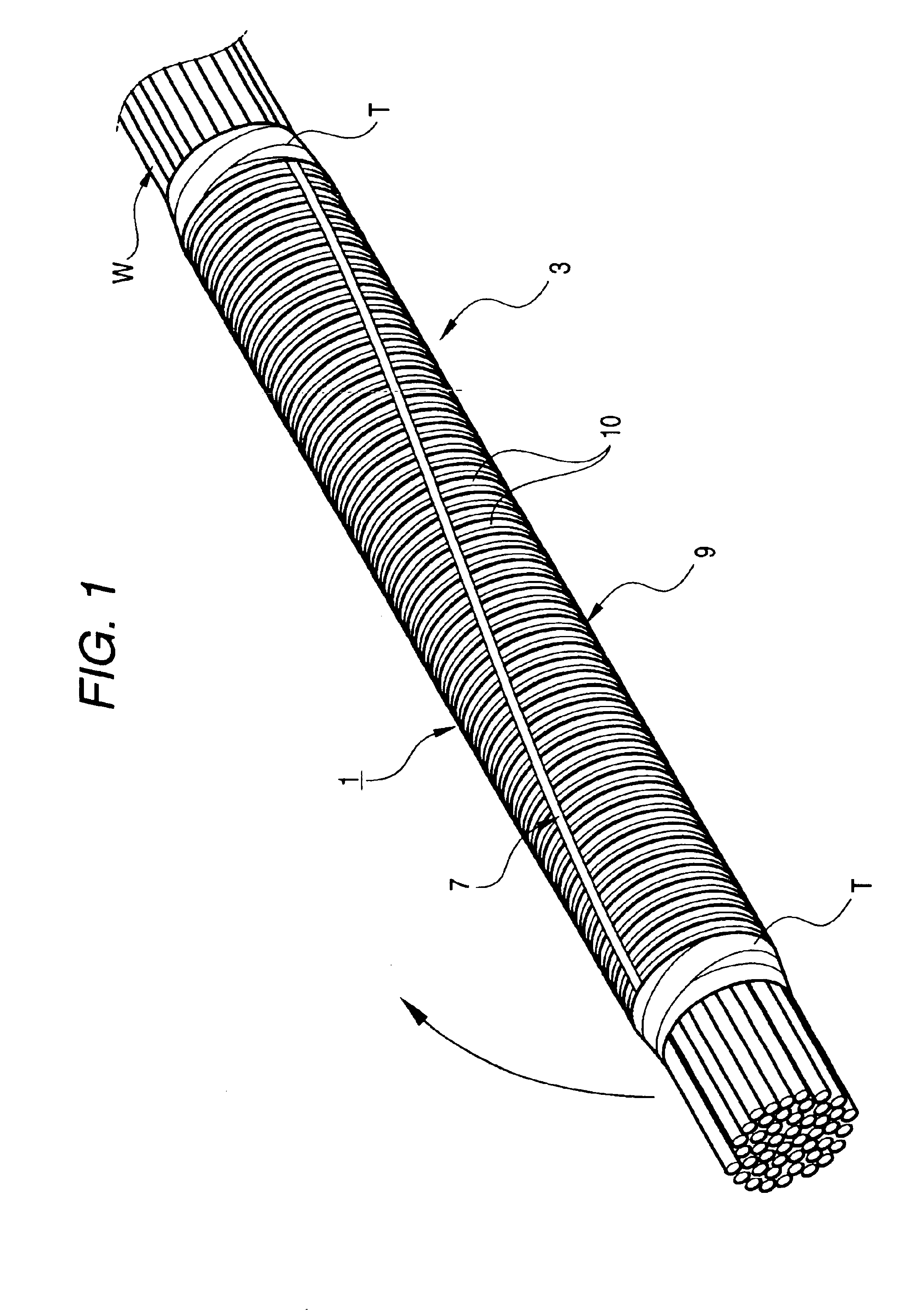

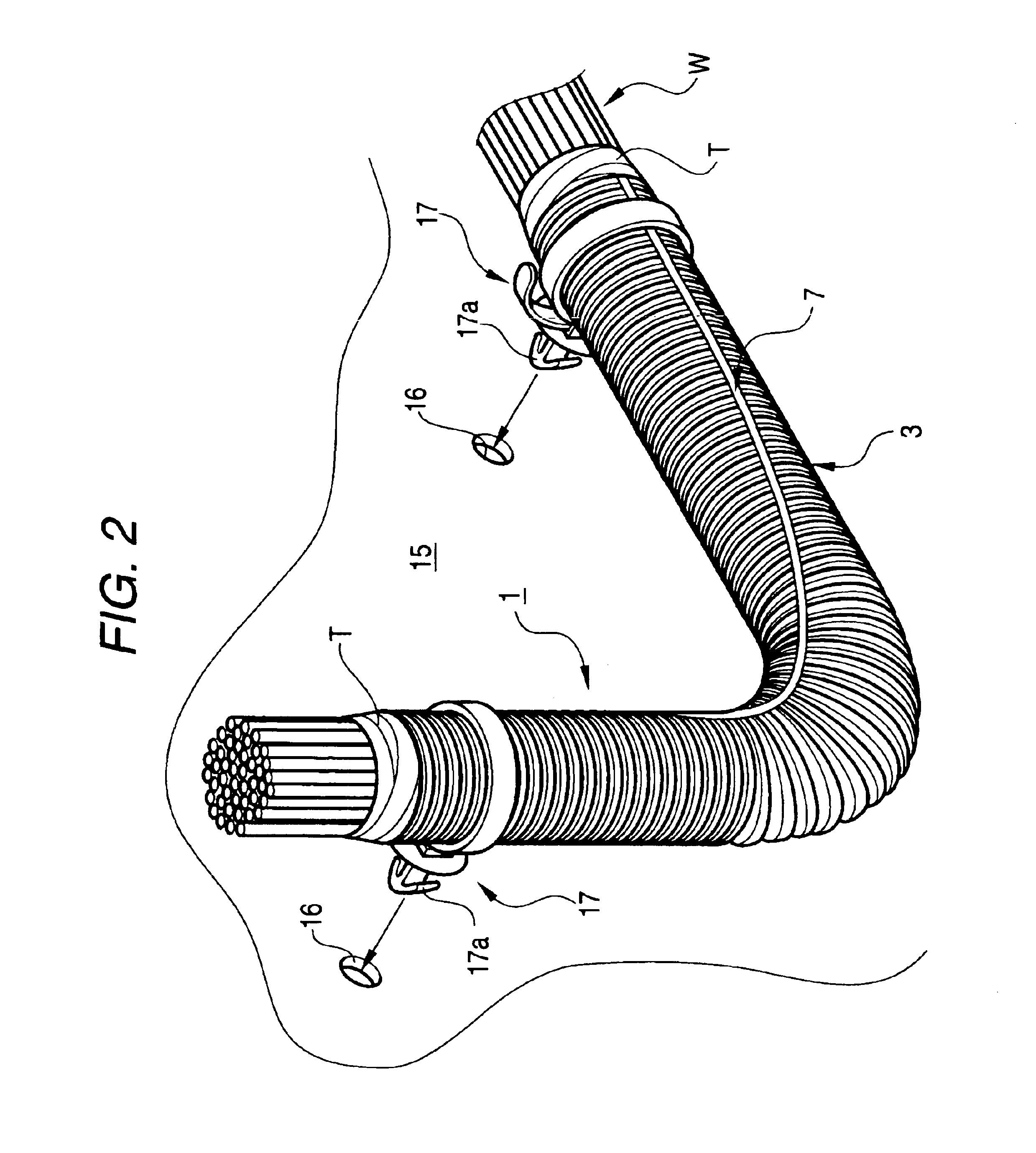

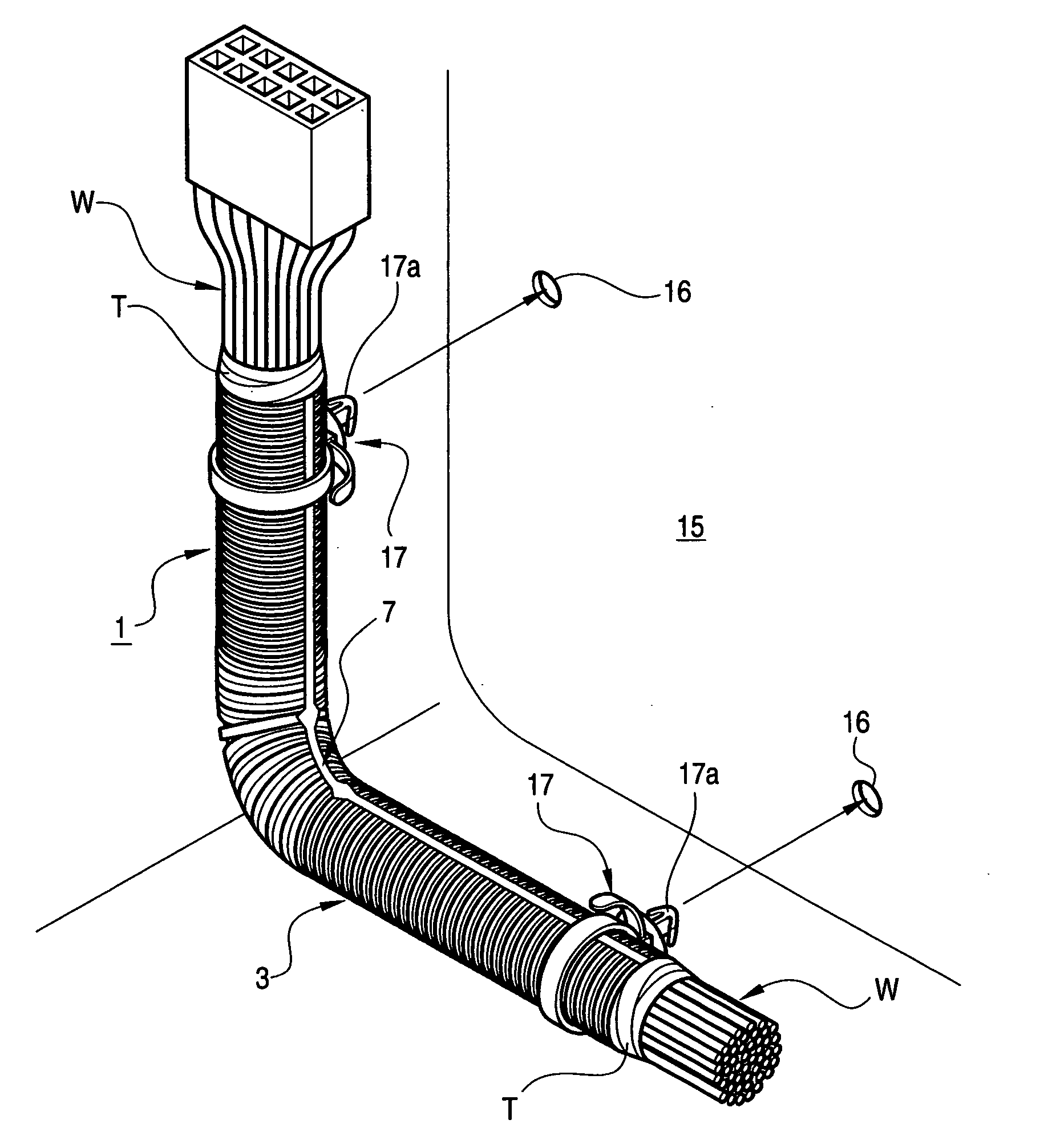

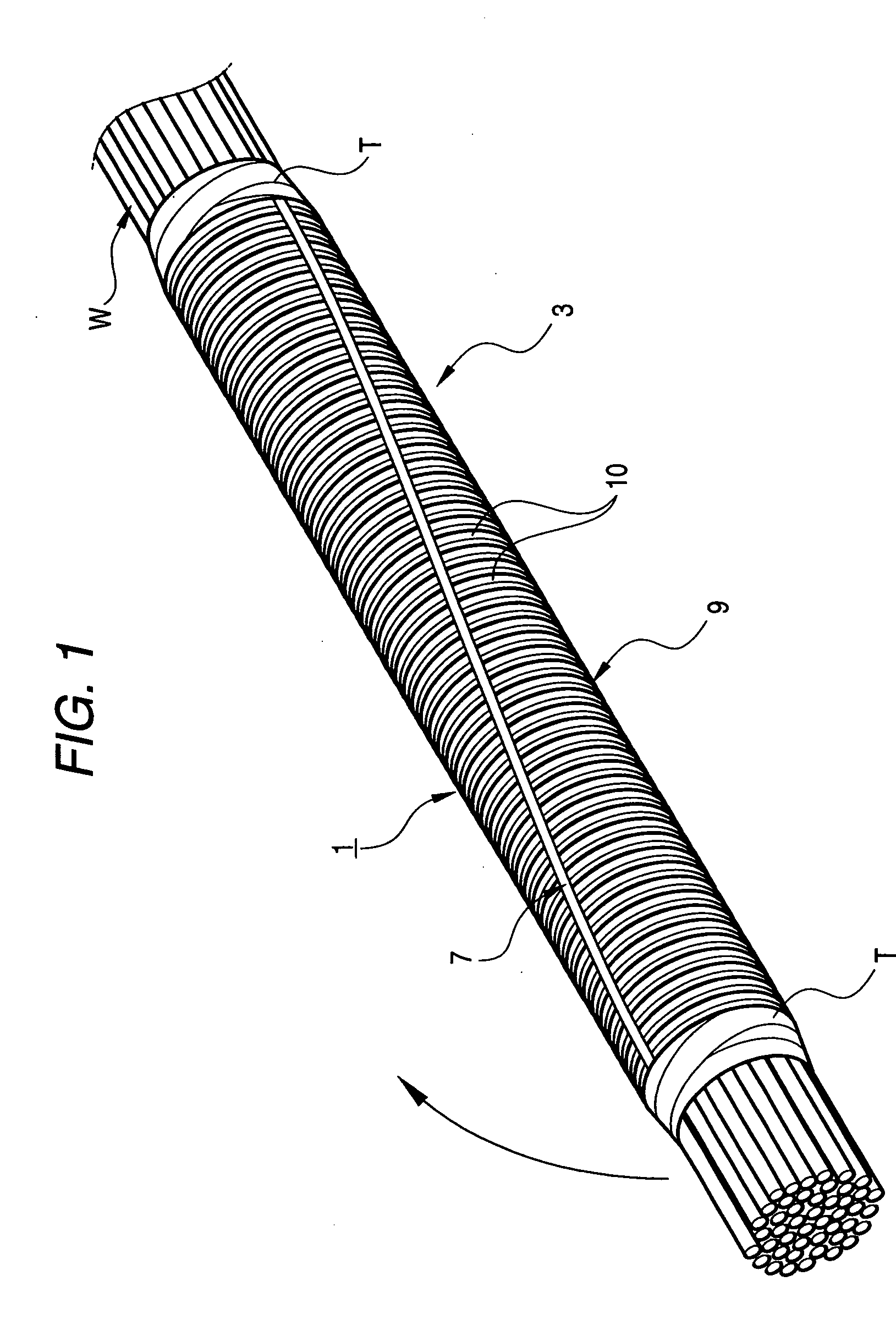

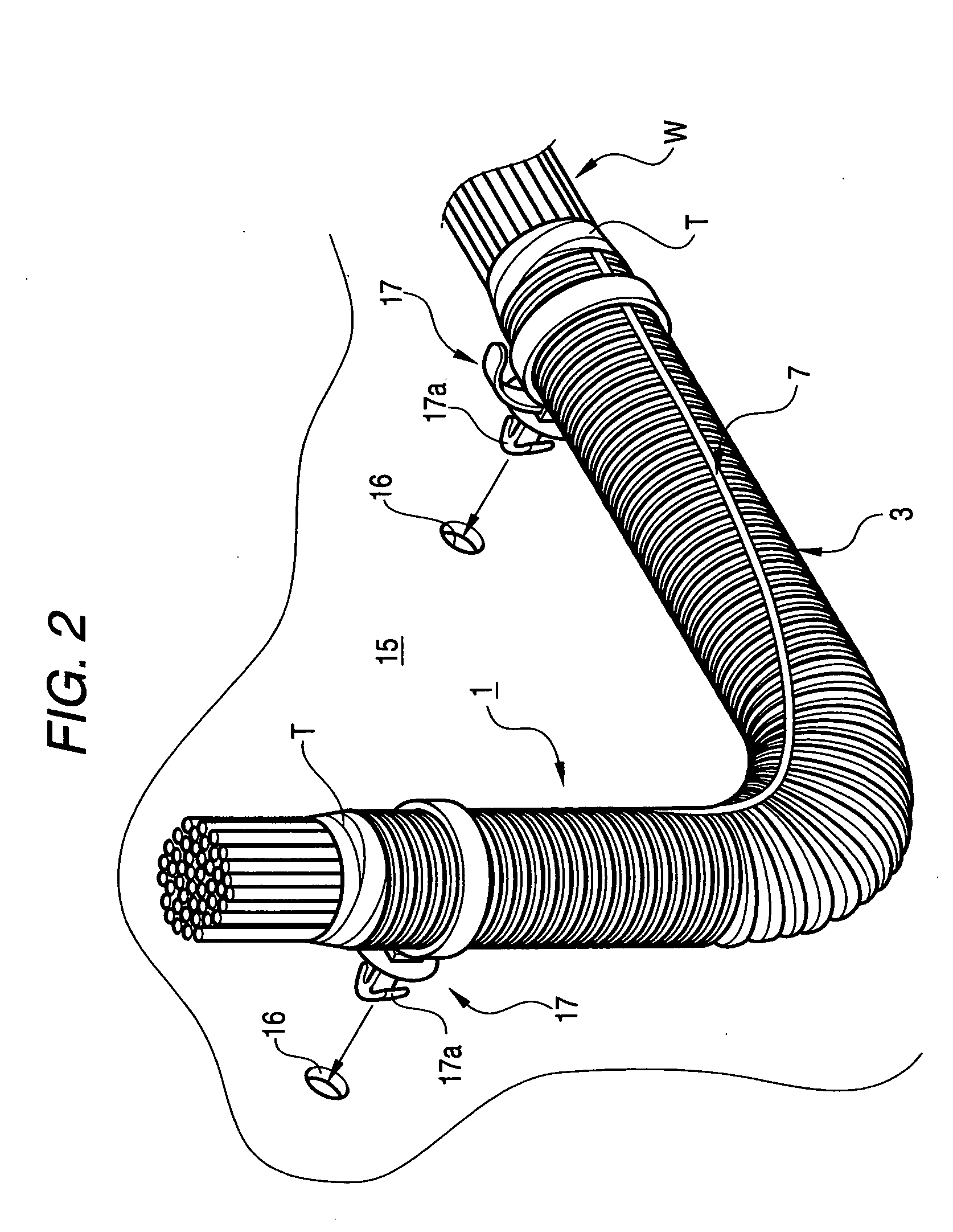

Corrugated tube-mounting structure

ActiveUS6948241B2Easy to bendRelieve bending stressLine/current collector detailsPipe supportsEngineeringRidge

A corrugated tube includes a tubular body, formed with a slit extending in an axial direction of the tubular body; a plurality of ridge portions, formed on an outer periphery of the tubular body and arranged side by side in the axial direction; and a lap portion, protruded from one of opposed end portions of the tubular body which are separated by the slit and extended toward an inner face of the other opposed end portion of the tubular body. A plurality of fixation members are provided on the outer periphery of the tubular body to fix the corrugated tube onto the panel body in a state that the tubular body is so twisted that the slit is spirally extended.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY +1

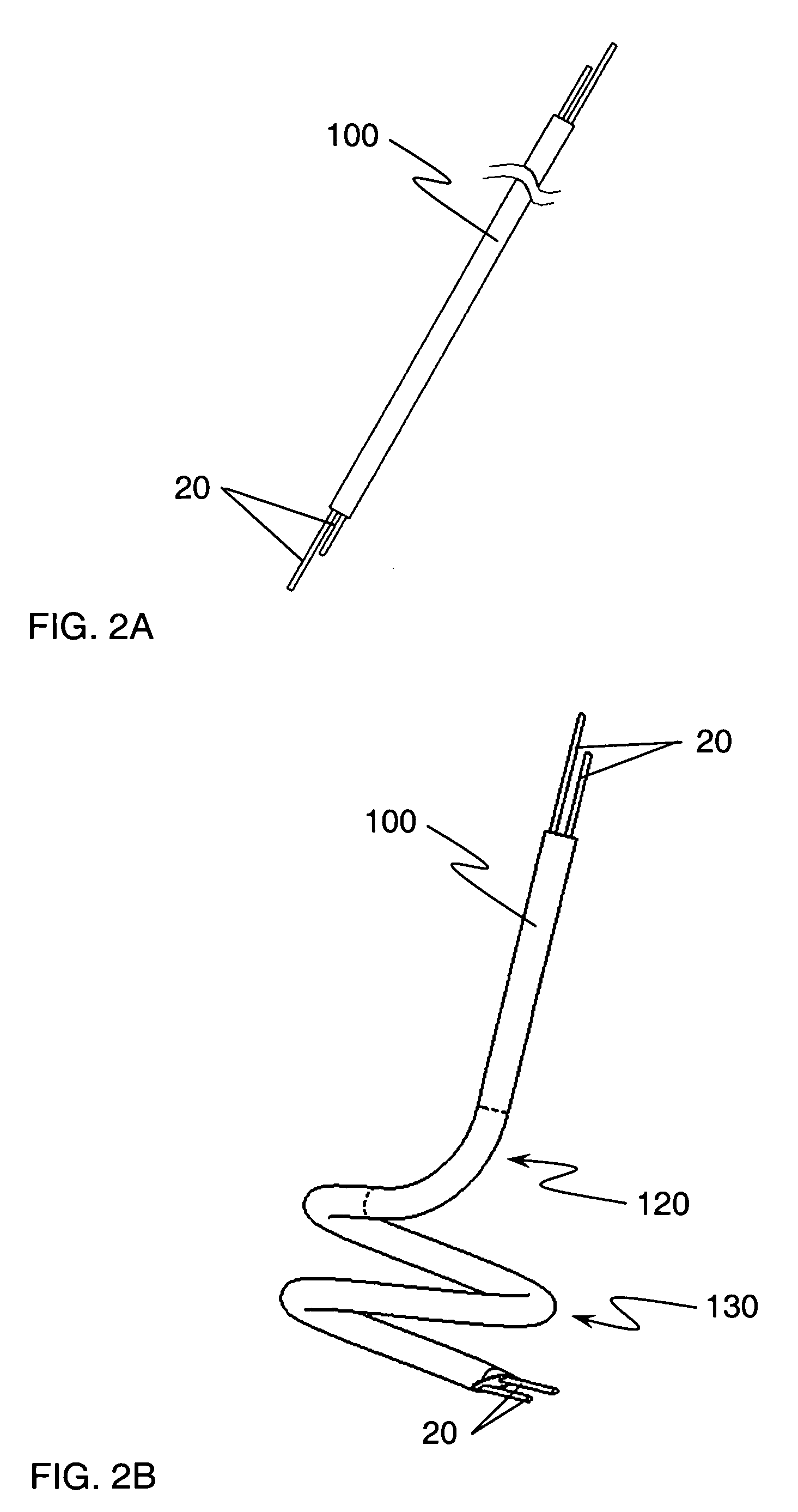

Curved needle assembly for subcutaneous light delivery

InactiveUS20080009749A1Easy to insertRule out the possibilityElectrocardiographySensorsCurve shapeBiomedical engineering

In this invention, a substantially straight needle containing one or more optical fibers is bent into a curved shape, typically including a helical portion, after the insertion of optical fibers into the needle. This curved needle, with its integral optical fibers, allows the subcutaneous delivery of light to a tissue-under-test. The preferred embodiment of this apparatus performs three functions: subcutaneous delivery of light to a tissue-under-test, attachment to the tissue-under-test, and subcutaneous electrical contact. In this invention the optical fibers are inserted into the needle prior to needle bending which prevents fiber breakage because the needle is not curved or in a helical form and therefore provides no resistance to the insertion of the fibers.

Owner:DELIANIDES THEODORE PHILIP +1

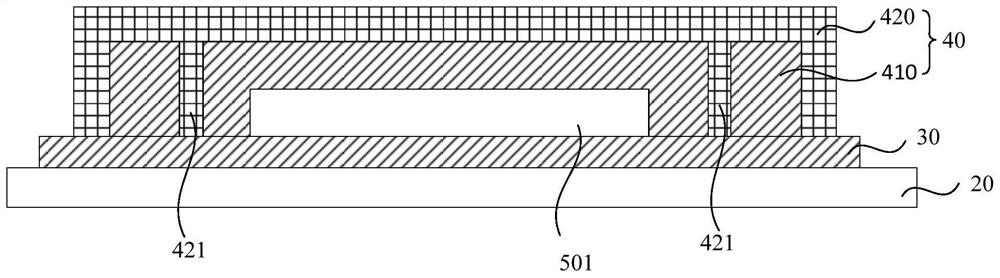

Display panel and display device

InactiveCN109065570ARelieve bending stressLow requirements for forming processFinal product manufactureSolid-state devicesDisplay deviceEngineering

The invention relates to a display panel, which is characterized in that the display panel comprises a flexible screen body, the flexible screen body comprises a display area and a non-display area; The non-display area comprises a bending area and an extension area arranged in sequence, and the extension area is not coplanar with the display area; An adhesive layer includes at least one flexiblefilm layer formed on a display surface of the flexible screen body, the flexible film layer extending out of the display region and supporting and covering the bent region and / or the extended region.The display panel and the attachment layer can be bent along with the bending area of the flexible screen body to alleviate the bending stress of the bending area of the flexible screen body. The adhesion layer completely covers the display area and bending area of the flexible screen. Compared with the traditional protective layer with smaller width, the forming process of the adhesion layer is required less. In addition, the adhesive layer extends out of the display area and completely covers the bending area, so that the adhesive force is large and it is not easy to fall off, so as to effectively improve the stability of the batch production. The invention also relates to a display device.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Financial self-service equipment

ActiveCN104616394AEliminate bendingRelieve bending stressCoin/paper handlersSelf-serviceMechanical engineering

Owner:GRG BAKING EQUIP CO LTD

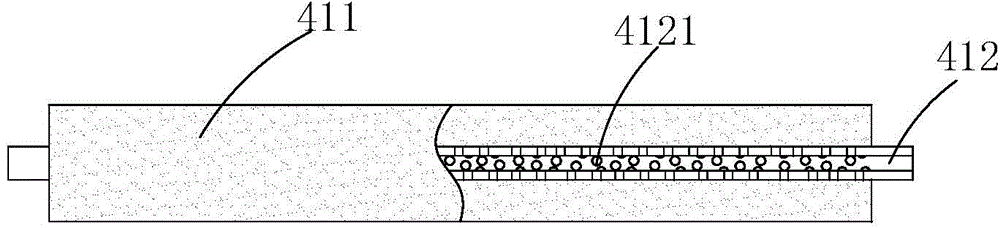

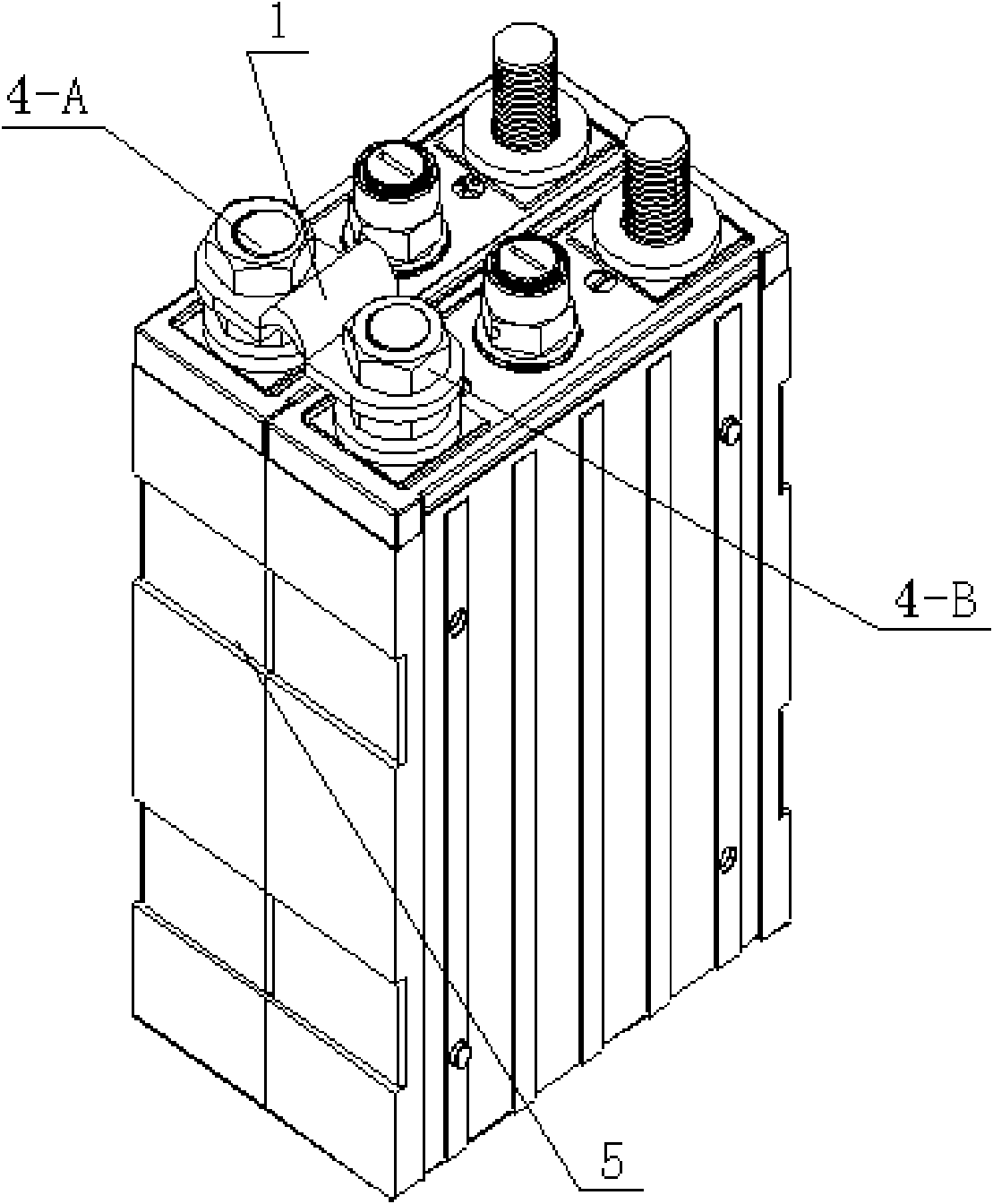

Conductive part for connecting batteries, battery connecting method and battery pack

InactiveCN101826608AImprove performanceRelieve bending stressElectric connection structural associationsCell component detailsMetal sheetBattery pack

The invention relates to a conductive part for connecting batteries, a battery connecting method and a battery pack. The conductive part comprises at least one metal sheet, the middle part of which takes on a free arch shape; the two ends of the metal sheet are provided with through holes; and the conductive part is respectively connected with a positive pole and a negative pole of the two batteries, so that the battery pack is formed. The conductive part can effectively eliminate the bending stress and the distorting stress between the batteries, prolongs the service life of a conductive connecting piece and improves the performance of the batteries.

Owner:湖南科霸汽车动力电池有限责任公司

Processing technology for preventing flexible board of rigid-flexible board from being bent and broken

InactiveCN108770185ARelieve bending stressAvoid bending and breakingCircuit bendability/stretchabilityPrinted circuit manufactureCopper foilEngineering

The invention relates to a processing technology for preventing a flexible board of a rigid-flexible board from being bent and broken. The processing technology is characterized by comprising the following steps of (1) preparing a flexible board layer substrate; (2) fabricating a coverage film for protecting a flexible board circuit, wherein the coverage film comprises an upper-layer coverage filmand a lower-layer coverage film, the size of the coverage film is larger than that of a flexible board bending region by at least 0.5 millimeter, and a single edge is needed to extend into a rigid board region by at least 0.25 millimeter; (3) attaching the fabricated coverage film onto a flexible board layer; (4) sequentially arranging an upper copper foil, a second upper prepreg, an upper rigidboard layer, a first upper prepreg, the flexible board layer substrate, a first lower prepreg, a lower rigid board layer, a second lower prepreg and a lower copper foil from top to bottom according toa sequence, and performing lamination; and (5) producing according to the required process flow, and completing production of a product. By the processing technology, the rigid-flexible board can beprevented from being bent and broken, and the quality and the reliability of the product are improved.

Owner:GULTECH WUXI ELECTRONICS CO LTD

Corrugated tube-mounting structure

InactiveUS20050247826A1Easy to bendRelieve bending stressPipe supportsMining devicesEngineeringRidge

Owner:YAZAKI CORP

Trailer axle tube steel and its processing method

InactiveCN1718292ARelieve bending stressAvoid deformationMetal rolling arrangementsManufacturing technologyMetallic materials

A U-shaped steel used for the tubular axle of trailer is disclosed. Its manufacture technology includes such steps as providing raw material, heating, rolling, cooling, and finishing. It can improve the structure and strength of tubular axle.

Owner:LAIWU IRON & STEEL GRP

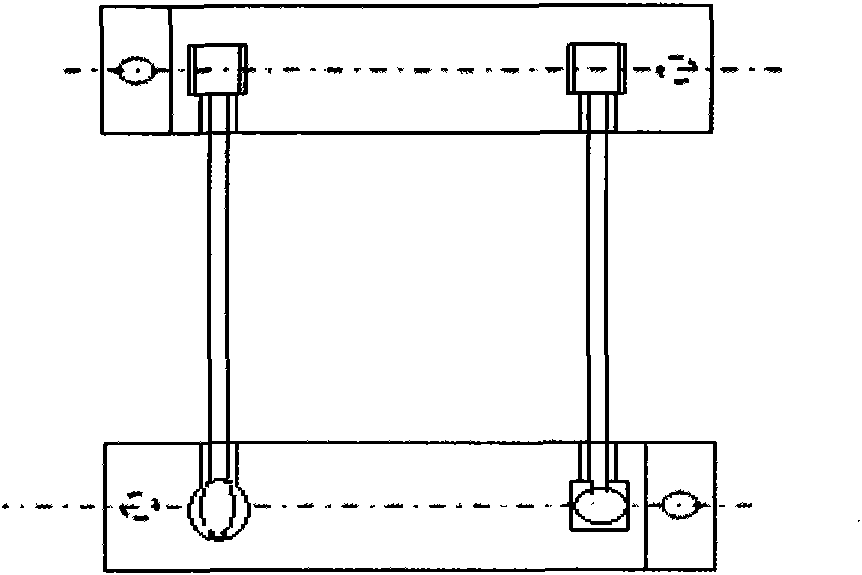

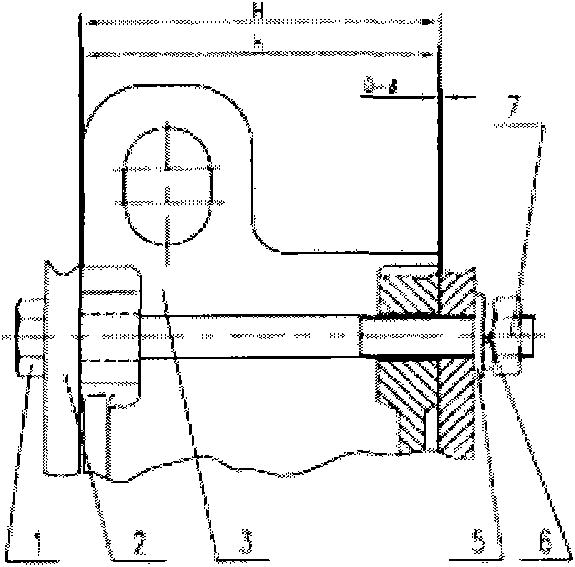

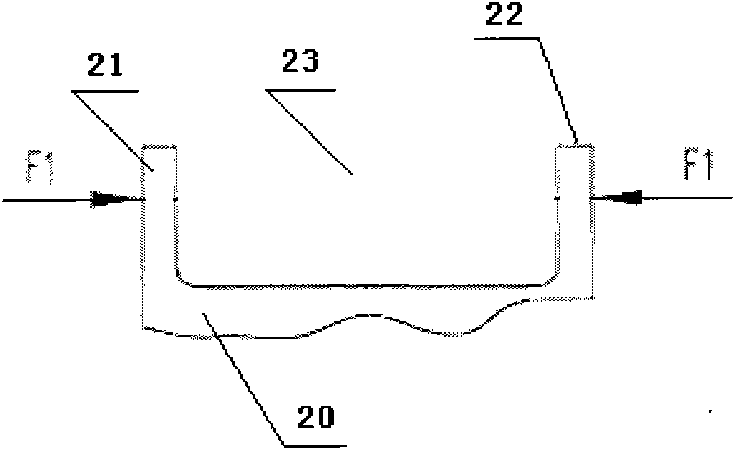

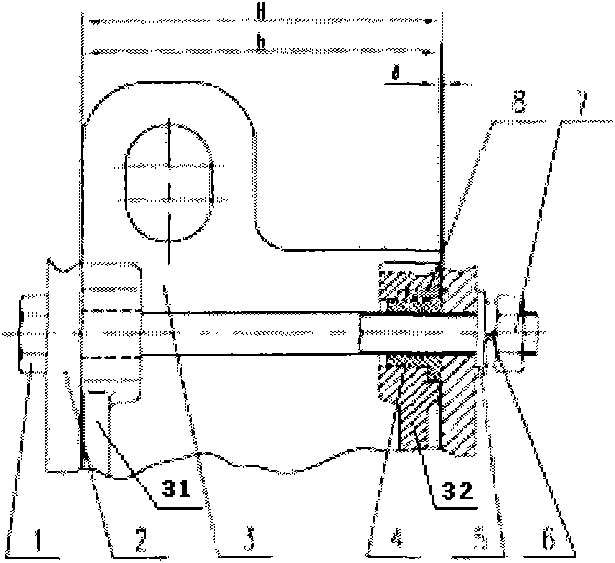

Snap ring-type force sensor

The invention relates to a snap ring-type force sensor. When pulling force or pressure force is detected, a T-shaped head of one end of an elastic body is connected with a T-shaped groove of a half ring in longitudinally-matched manner, and the other longitudinal elliptic end of the elastic body is connected with a round groove of the other half ring in a matched manner; and four resistance foil gauges are stuck on four sides of the elastic body of the sensor respectively, wherein four sides are parallel with an axes, two resistance foil gauges are stuck longitudinally while another two resistance foil gauges are stuck horizontally, directions of corresponding faces are the same and are on the same transversal surface, and the longitudinal position is h2+H2+(3-4)mm away from the top end of a rectangular head. When torque force is detected, one end of the elastic body is T-shaped and the other end of the elastic body is latitudinal elliptic; and two resistance foil gauges are stuck on two corresponding sides of the elastic body of the sensor respectively, wherein the two corresponding sides are at the depth of section, directions of the corresponding sides are the same and are on the same transversal surface, and the longitudinal position is h2+H2+(3-4)mm away from the top end of a rectangular head. The sensor can well transmit bending force generated by pulling force, pressing and torque, and is not affected by other deformation. Various functions of the sensor can be realized by using different elastic body combination.

Owner:SHANGHAI INST OF TECH

Air condition compressor fixing device and engine and automobile provided with same

The invention discloses an air condition compressor fixing device and an engine and an automobile provided with the same. The air condition compressor fixing device for the engine comprises a stand bar, a support, a fixed bolt for passing through the stand bar and the support, a nut suitable for threaded connection with the fixed bolt, and a mosaic loop which can be arranged in the support only by a way of slipping along the axial direction of the fixed bolt, wherein the mosaic loop is provided with internal threads suitable for threaded connected with a thread part of the fixed bolt. Therefore, the attachment strength of the threaded connection directly extrudes two sides of a protrusion of the support, and no bending stress is generated on the stand bar and the support; in addition, when a large gap exists between the stand bar and the support, the mosaic loop can slip to abut against a protrusion of the stand bar, so the requirement on matching precision is reduced.

Owner:BEIQI FOTON MOTOR CO LTD

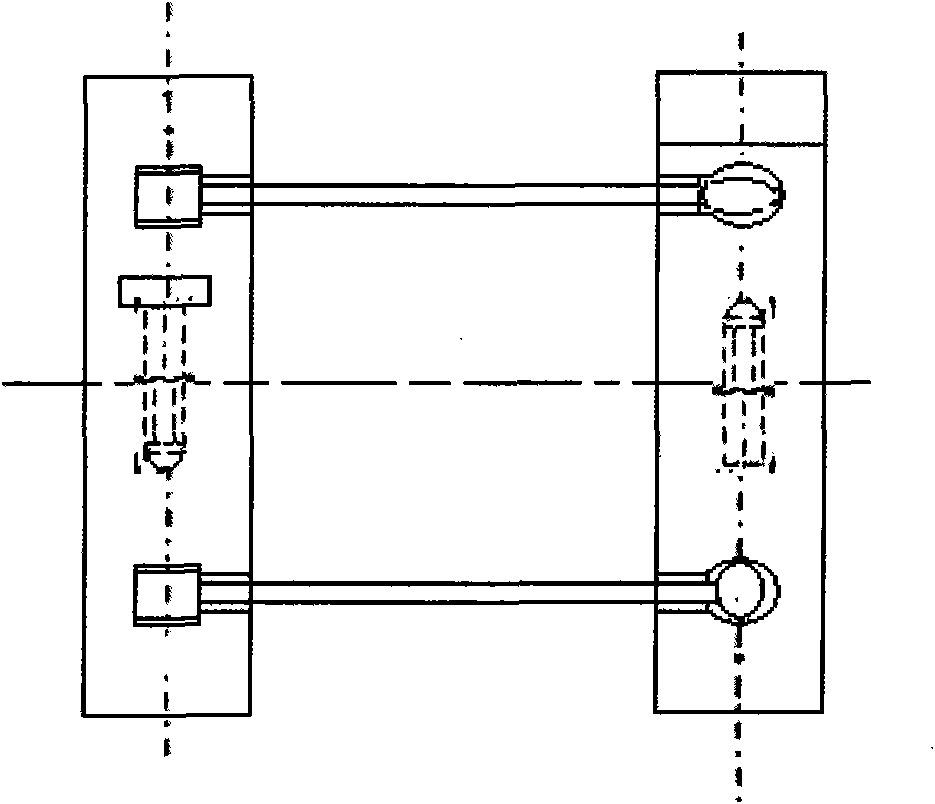

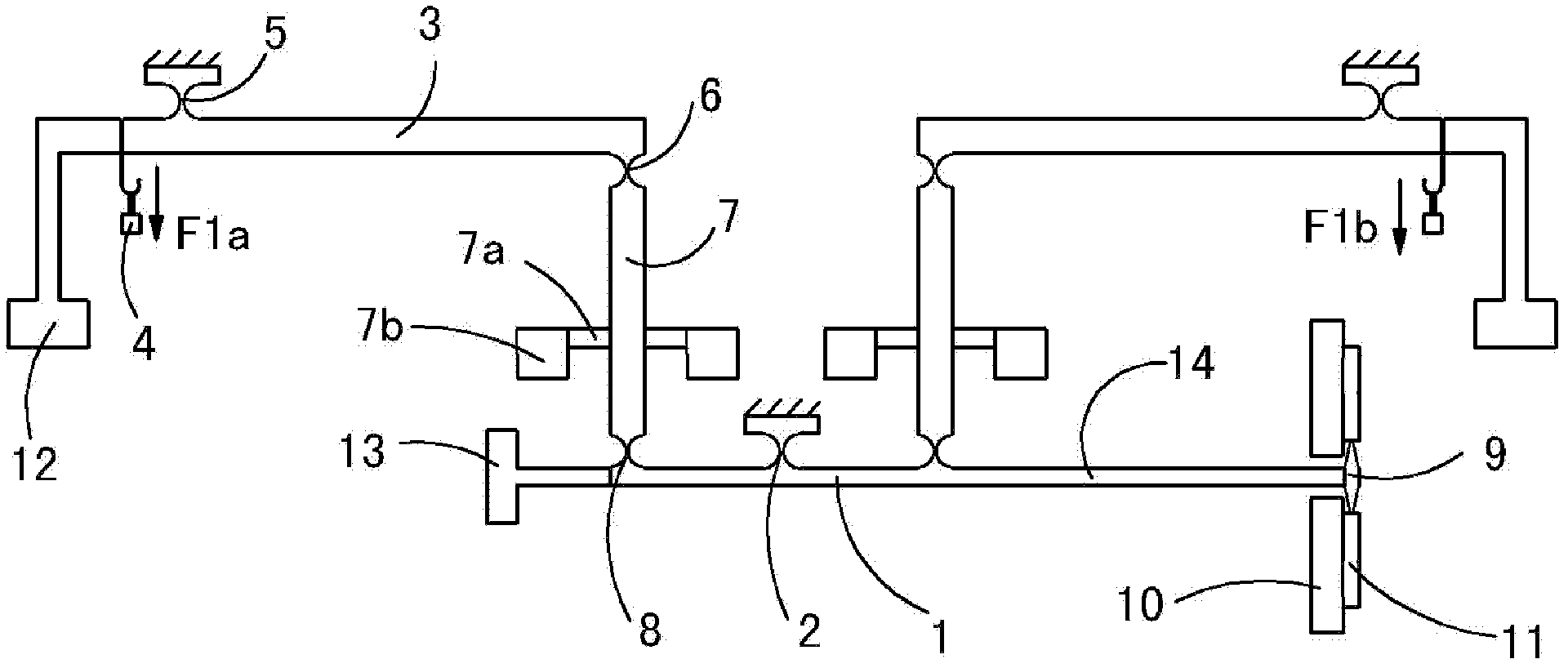

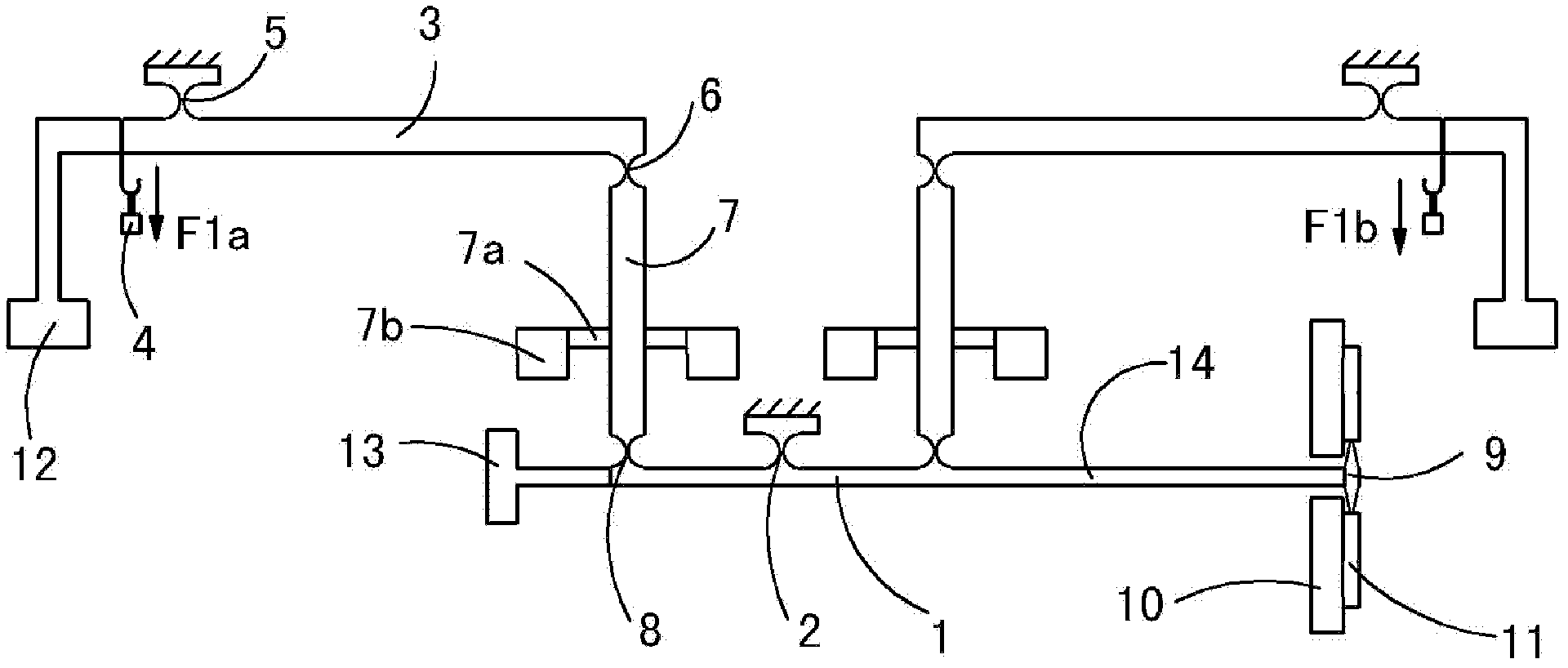

Differential type vertical micro-force loading device and method

InactiveCN102305687AEasy to operateReduce frictionForce measurementForce/torque/work measurement apparatus calibration/testingVertical planeMicroelectromechanical systems

The invention discloses a differential type vertical micro-force loading device and method, which is characterized in that a secondary pivot horizontally placed at the middle of a secondary lever, a pair of primary levers is symmetrically distributed at two sides of the secondary pivot in one vertical plane with the secondary pivot as a center, and the primary levers are respectively linked with the secondary lever by a transition lever at own side. The differential type vertical micro-force loading device and method can be used for calibrating micro-force sensors, microelectromechanical systems, and various micro-force detectors, and provides support for the force measuring system of the micro-force.

Owner:HEFEI UNIV OF TECH

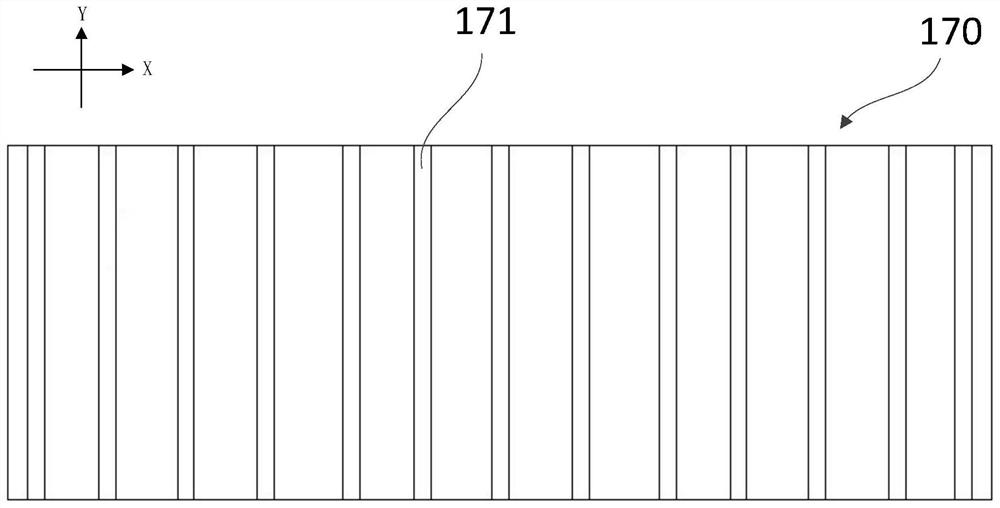

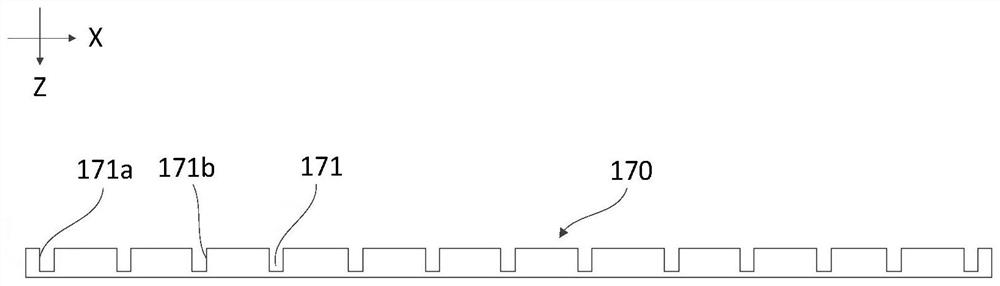

Flexible display module, display device and control method of flexible display module

PendingCN114220355AConforms to curl's needsImprove flatnessIdentification meansComputer hardwareDisplay device

The invention provides a flexible display module, a display device and a control method of the flexible display module, relates to the technical field of display, and is used for solving the technical problem that the flatness of the flexible display module is poor when the flexible display module is flattened for use. The flexible supporting plate is located on the side, away from the display side, of the flexible display panel, and a plurality of mounting grooves are formed in the surface, back to the flexible display panel, of the flexible supporting plate; the plurality of mounting grooves are arranged at intervals when the flexible display panel is in a flattened state; a variable magnetic structure is arranged in each mounting groove, and when the flexible display panel is flattened, any two adjacent variable magnetic structures repel each other.

Owner:HEFEI VISIONOX TECH CO LTD

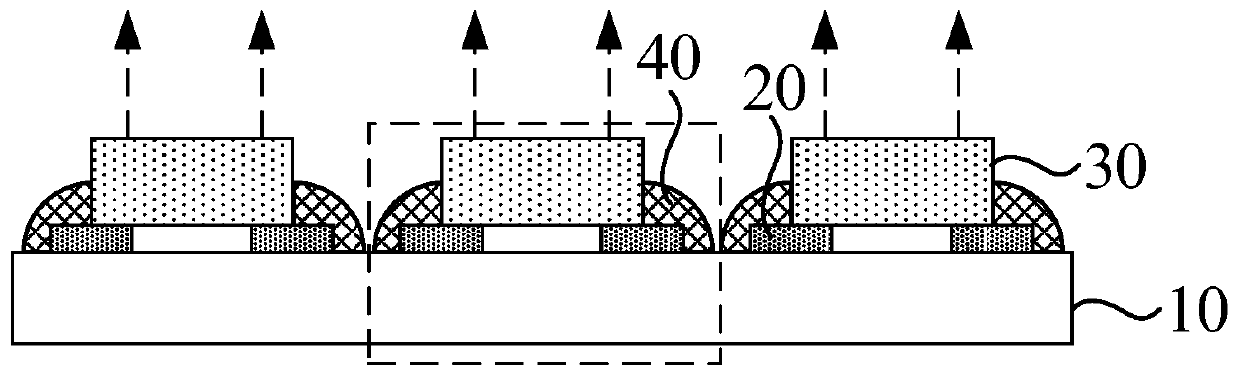

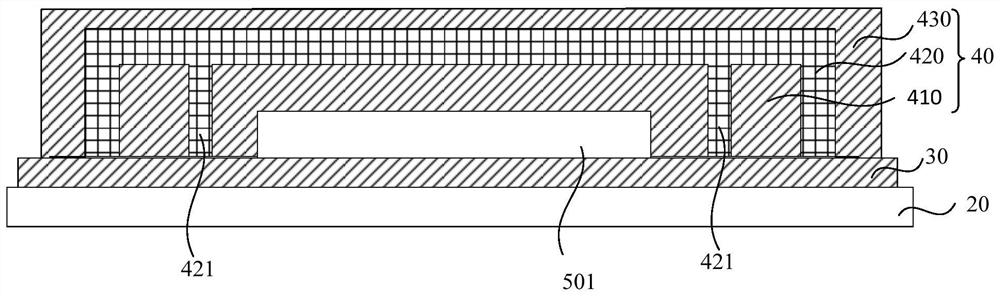

Light board, backlight module and curved display device

InactiveCN110297356AEasy accessSolve the problem of short circuitNon-linear opticsElectricityDisplay device

The embodiment of the invention discloses a light board, a backlight module and a curved display device. The light board comprises a substrate basal plate, multiple light sources and an insulation structure; multiple bonding pads are arranged on the substrate basal plate; each the bonding pad comprises a first part and a second part; the light sources are electrically connected with the substratebasal plate through the bonding pads; orthographic projection of the first part in the plane, where the substrate basal plate is, is positioned in corresponding orthographic projection of the light source in the plane, where the substrate basal plate is; and orthographic projection of the second part in the plane, where the substrate basal plate is, is positioned in orthographic projection of theinsulation structure in the plane, where the substrate basal plate is. According to the light board in the embodiment of the invention, the short-circuiting problem due to the fact that bonding pads of adjacent light sources are easily contacted when the light board is curved can be solved; mutual insulation among the bonding pads is ensured; simultaneously, the insulation structure can be used for relieving bending stress of the bonding pads; and breakage of the bonding pads when the light board is curved is prevented.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

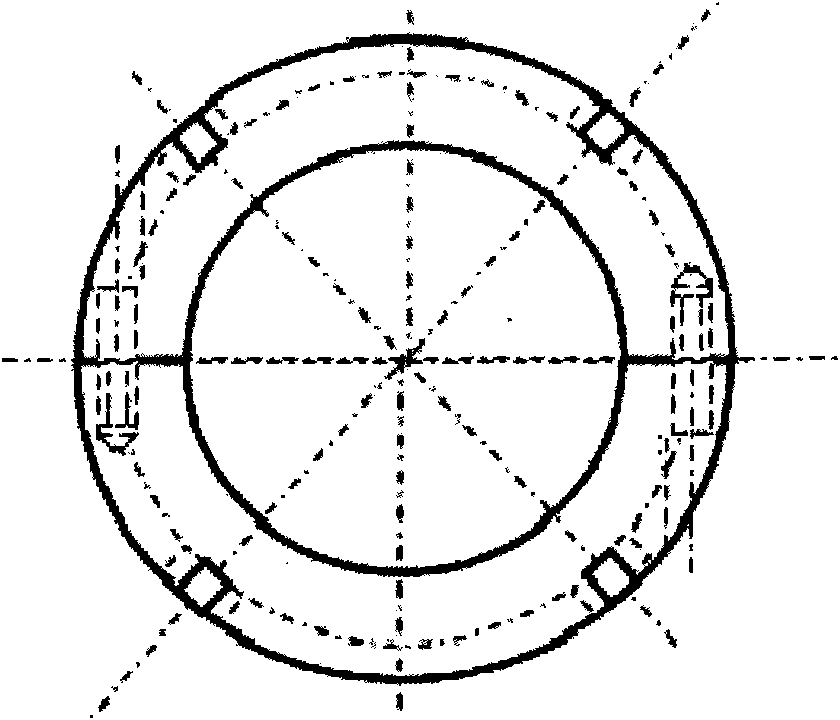

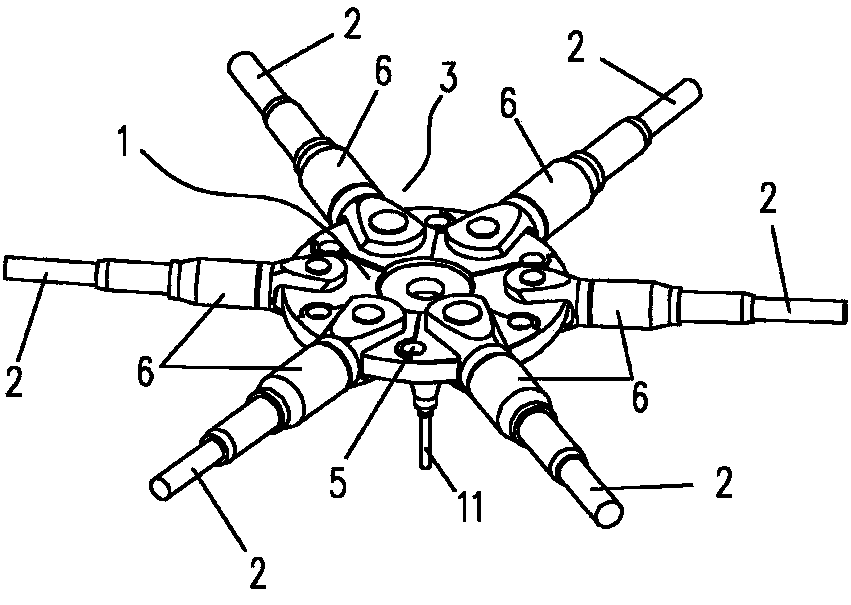

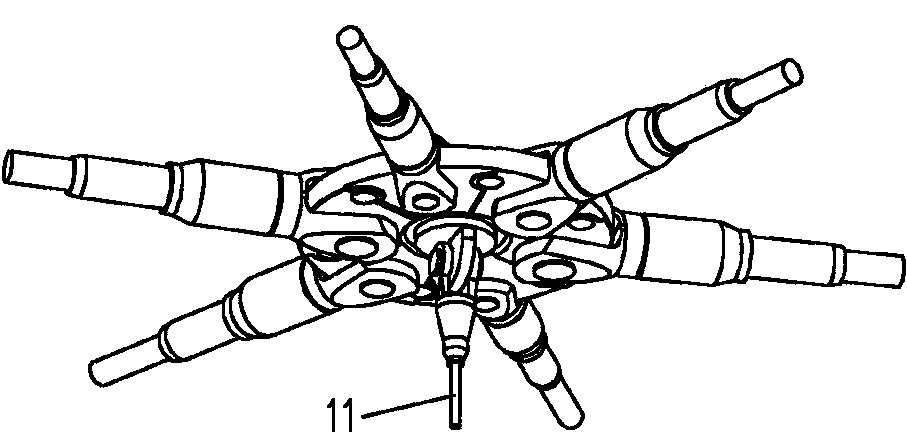

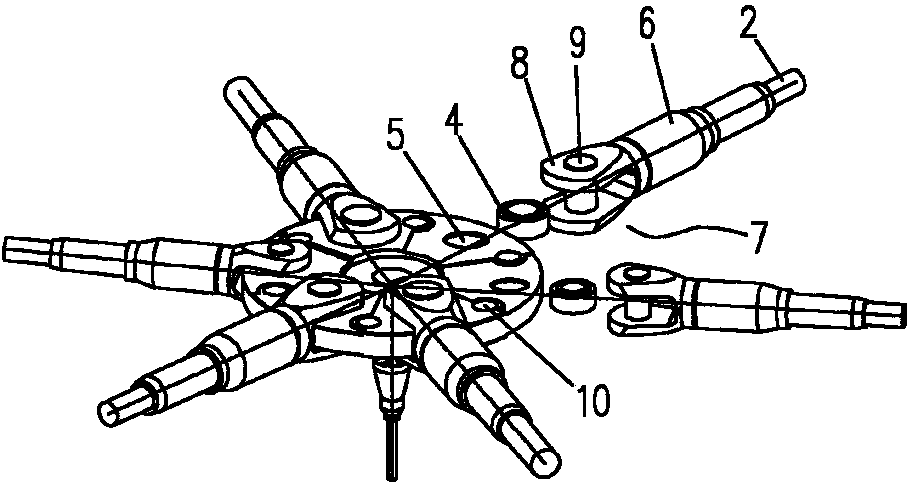

Large radio telescope with active displacement type cable net knot supporting structure

The invention discloses a large radio telescope with an active displacement type cable net knot supporting structure. The large radio telescope comprises a plurality of main cable knot discs, the main cable knot discs are connected through inhaul cables and are overall combined to form a spherical main cable net, joint bearings are arranged at the connecting positions of the inhaul cables and the main cable knot discs, and in the cable net displacement process, the inhaul cables carry out adaptive displacement through the joint bearings and the main cable knot discs to eliminate the additional bending stress of the connecting positions. The large radio telescope can effectively relieve the bending stress of a cable structure close to an anchorage device, and the overall reliability of the cable net structure is improved.

Owner:NAT ASTRONOMICAL OBSERVATORIES CHINESE ACAD OF SCI

RFID tag

InactiveUS20080204250A1Avoid stress concentrationAvoid disconnectionSolid-state devicesRecord carriers used with machinesEngineeringSealant

A RFID tag includes a base that extends in a predetermined longitudinal direction; an antenna for communication that is wired on the base; a circuit chip that is electrically connected to the antenna and conducts radio communication via the antenna; and a sealant that covers a top of the circuit chip and seals the circuit chip in cooperation with the base. A portion of the antenna that is exposed without being covered with the sealant extends in the width direction perpendicular to the longitudinal direction.

Owner:FUJITSU LTD +1

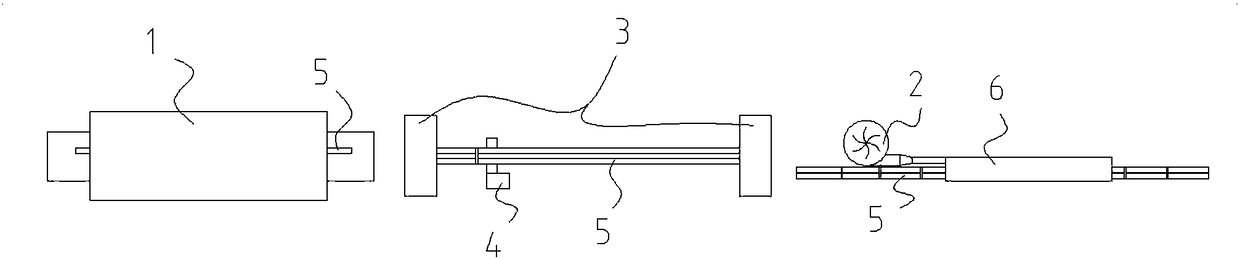

Structure for oil pipe bundle heat shrinkage

PendingCN108262897ARelieve bending stressStrong penetrating powerBundling machine detailsMaterial resourcesCutting oil

The invention provides a structure for oil pipe bundle heat shrinkage, and belongs to the technical field of oil pipe bundling. The structure for oil pipe bundle heat shrinkage comprises heat shrinkage heating equipment, a straightening device, a bundling device and an air blowing device. Cut oil pipes pass through the heat shrinkage heating equipment firstly, and corresponding stress is removed;meanwhile, the straightening device and the bundling device are adopted for bundling the multiple oil pipes in a grouping manner, and the oil pipes are kept perfectly straight; then, the air blowing device is used for blowing a heat shrinkage pipe to achieve the expansion state, and the grouped oil pipes can conveniently penetrate the heat shrinkage pipe; and through the heat shrinkage heating equipment, the heat shrinkage pipe wraps the exteriors of the oil pipes, efficiency is high, cost is low, manpower and material resources are saved, and operation is convenient.

Owner:SHANGHAI FANUC ROBOTICS

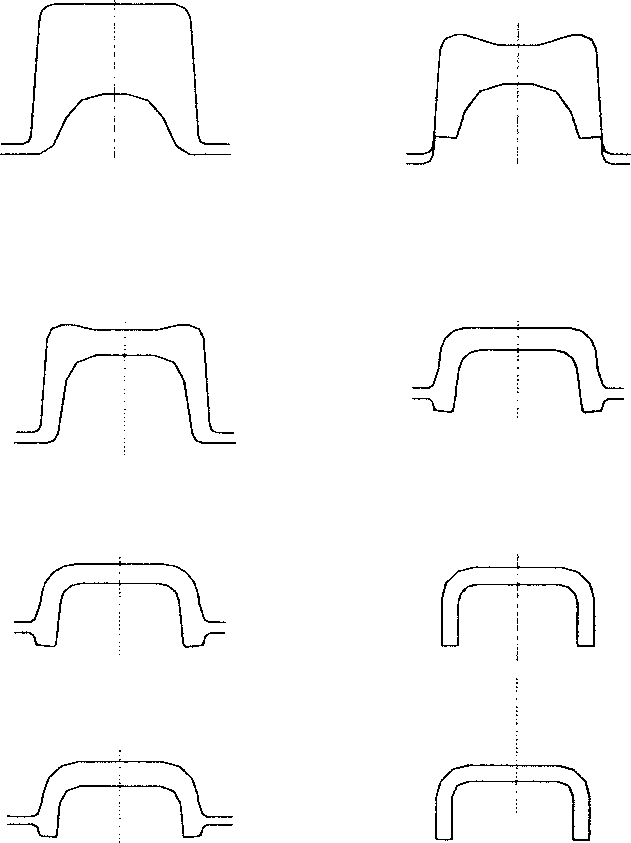

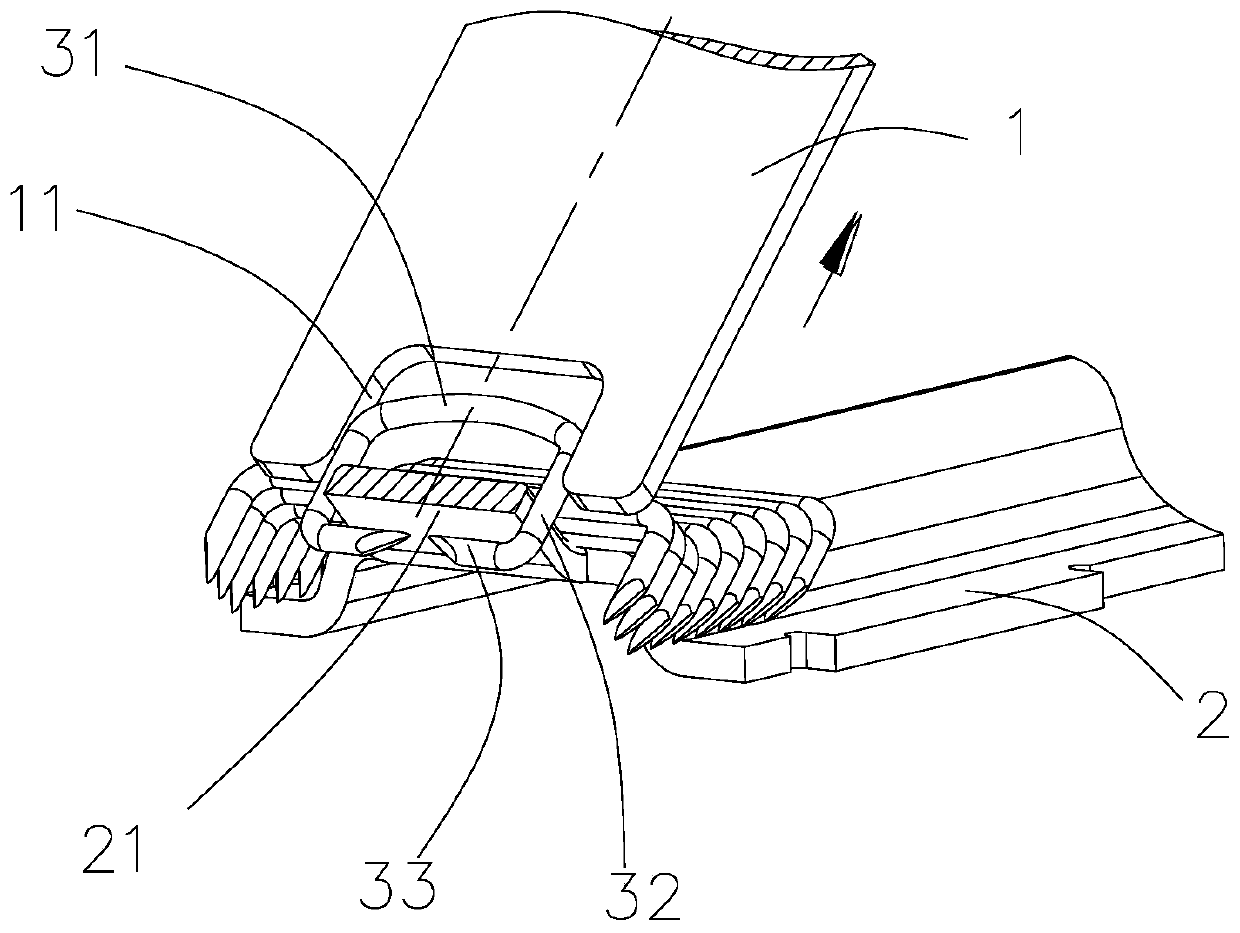

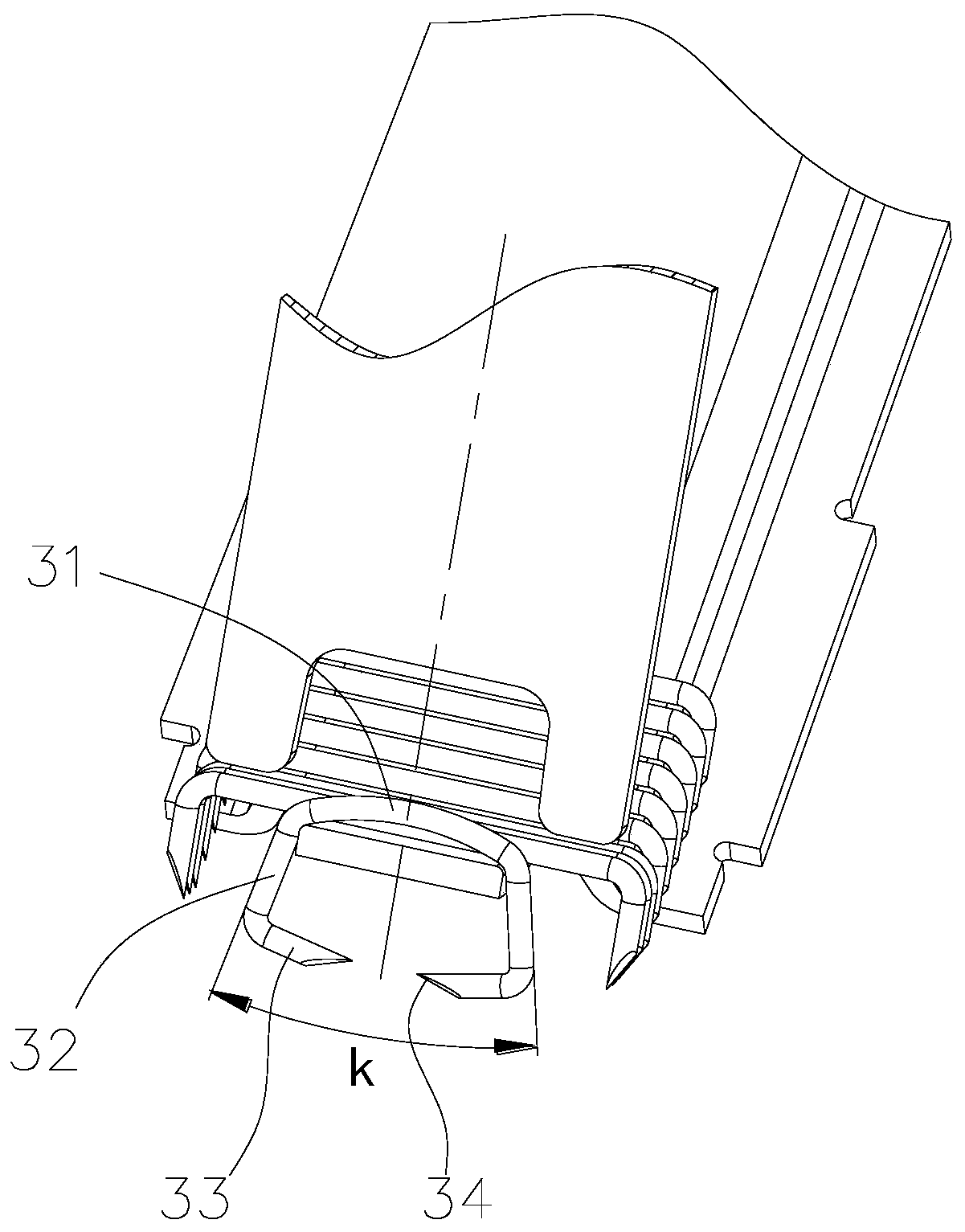

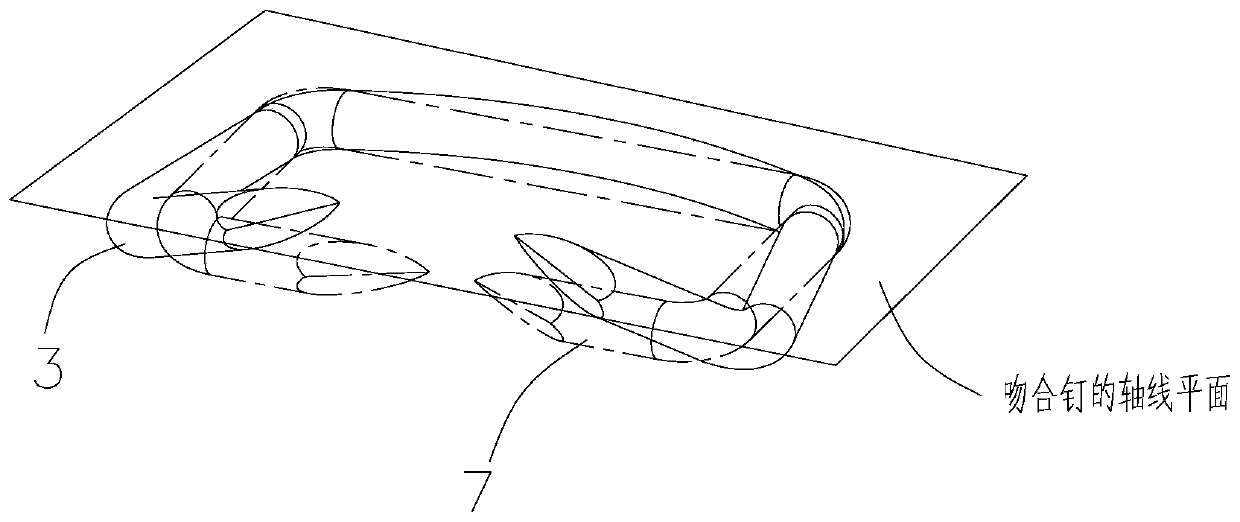

Skin anastomat nail pressing structure and skin anastomat thereof

PendingCN110338865AIncrease cold work hardening strengthReduce surface roughness valueSurgical staplesBiomedical engineeringTongue part

The invention particularly relates to a skin anastomat nail pressing structure. The structure comprises a nail pressing plate, a nail seat and a stopper, a jaw is formed in a forming end of the nail pressing plate and is in a bell mouth shape with a wide upper side and a narrow lower side, inner stopping forming surfaces are arranged on both sides of the inside of the jaw, the end part of the jawis provided with end forming surfaces, and arc forming surfaces are disposed between the inner stopping forming surfaces and the end forming surfaces; first V-shaped grooves are formed in the end forming surfaces, second V-shaped grooves communicated with the first V-shaped grooves are formed in the arc forming surfaces, and the bottom of the jaw is provided with pressing tables; the front end ofthe nail seat is provided with a nail seat tongue part, anastomotic nails are arrayed on the nail seat, the jaw of the nail pressing plate is moved close to or away from the nail seat tongue part, andwhen the jaw cooperates with the nail seat tongue part and the anastomotic nails are formed in the jaw, the pressing tables are in contact with nail beams of the anastomotic nails. The stopper includes a stopper fixing part and a stopper head part, a door hole slidingly matched with the stopper head part is formed in the bottom of the jaw, the pressing tables are located on the two sides of the door hole, and the stopper head part is located above the nail seat tongue part.

Owner:CHANGZHOU KANGDI MEDICAL STAPLER

Display panel and display device

ActiveCN109671725ARelieve bending stressAvoid breakingSolid-state devicesSemiconductor devicesDisplay device

The invention provides a display panel and a display device. The display panel comprises a display region and a non-display region located at one side of the display region, wherein the non-display region comprises a first wiring region which cannot be bent, a second wiring region which can be bent and a third wiring region which cannot be bent; the first wiring region is adjacent to the display region; the second wiring region is located at one side, far away from the display region, of the first wiring region; the third wiring region is located at one side, far away from the display region,of the second wiring region; the display panel comprises a first substrate and a second substrate, which are arranged oppositely; the first substrate and the second substrate extend into the non-display region; the area of the second substrate in the second wiring region is smaller than the area of the first substrate in the second wiring region. According to the display panel provided by the invention, the second substrate which extends into the non-display region can be used for alleviating bending stress on metal wiring in the first wiring region, the second wiring region and the third wiring region, and the pulling stress on the packaging of the first substrate and the second substrate at a crossed part of the display region and the first wiring region can be alleviated.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

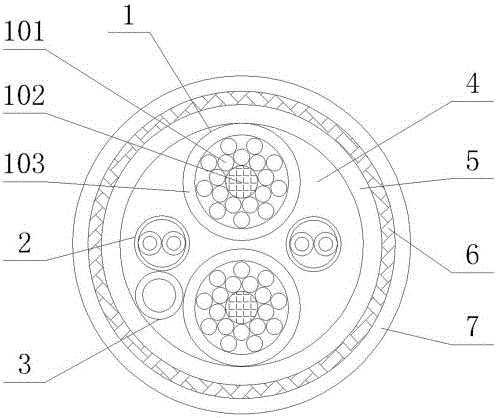

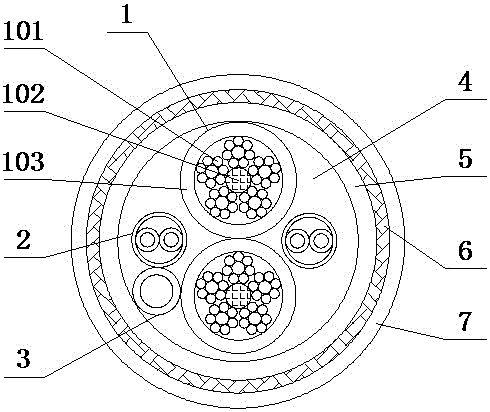

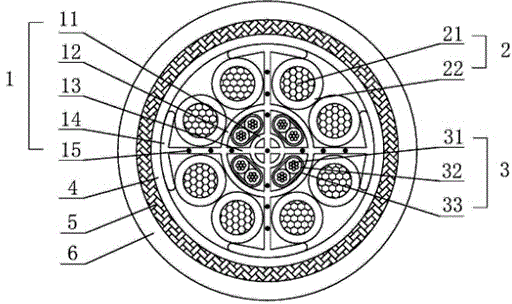

Cable for electric vehicle charging pile and manufacturing method thereof

InactiveCN106328276AGood flexibilityReduce extrusion and deformationInsulated cablesPower cablesPolyesterCopper wire

The invention discloses a cable for an electric vehicle charging pile. The cable comprises a cable core and an outer sheath, the cable core is formed by twisting of charging wire cores, signal wire cores, and a grounding protection wire core, the periphery of the cable core is wrapped by a filling layer, the periphery of the filling layer is wrapped by a polyester tape slipping layer, the periphery of the polyester tape slipping layer is wrapped by a stainless steel wire braided layer, the periphery of the stainless steel wire braided layer is extruded by the outer sheath, and a plurality of copper wire conductors and a rope core are twisted in a winding manner and then extruded by an insulating layer to form each charging wire core. According to the cable for the electric vehicle charging pile, the flexibility is high, the tension and the bending resistance are good, green environmental protection is realized, and the service lifetime is long.

Owner:江苏江扬特种电缆有限公司

Display panel, preparation method thereof and display device

PendingCN112542557ABuffer stress reliefIncreased cushioning stressSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention discloses a display panel, a preparation method thereof and a display device. The display panel comprises a substrate, a first water vapor barrier layer, an OLED devicelayer and a second water vapor barrier layer, wherein the second water vapor barrier layer comprises a first inorganic layer and a buffer stress layer which are stacked, the buffer stress layer is located on the side, which is away from the substrate, of the first inorganic layer, the first inorganic layer and the first water vapor barrier layer wrap the OLED device layer, the buffer stress layerand the first water vapor barrier layer wrap the OLED device layer, the buffer stress layer comprises a buffer part, and the buffer part is embedded into the first inorganic layer. According to the technical scheme provided by the embodiment of the invention, the light-emitting unit is wrapped by the first water vapor barrier layer and the second water vapor barrier layer to form a double-layer sealed packaging structure, the packaging effect of the OLED device layer can be improved, and the bending stress of the first inorganic layer can be reduced by embedding the buffer part into the firstinorganic layer, so that the bending capability of the display panel is improved.

Owner:HEFEI VISIONOX TECH CO LTD

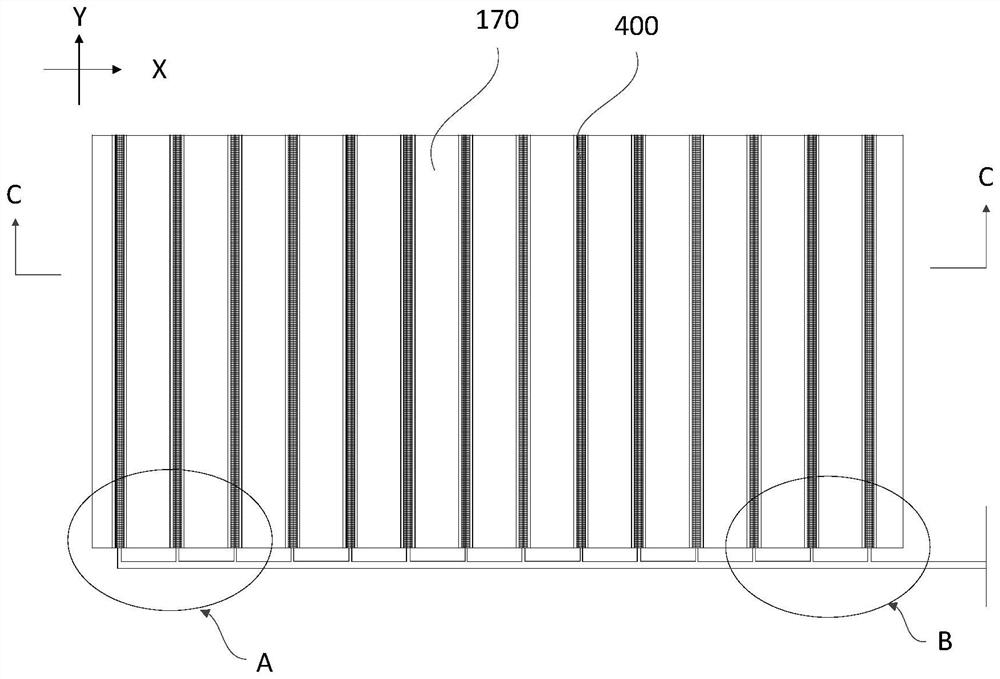

Flexible display panel and manufacturing method therefor

PendingUS20220036771A1Reduce metal stressIncrease flexibilityStatic indicating devicesPhotomechanical apparatusEngineeringStructural engineering

A flexible display panel and a manufacturing method therefor. The flexible display panel comprises an organic insulating layer and a metal layer disposed on the organic insulating layer, and is divided into a display region located in the middle, a binding region located outside the display region, and a bending region located between the display region and the binding region. The organic insulating layer is provided with a plurality of protrusions in the bending region so that the surface of the organic insulating layer is uneven in the bending region. The metal layer comprises a plurality of metal wires penetrating the bending region, and each metal wire covers a part the protrusions of the organic insulating so that the surface the metal wire is also uneven along with the organic insulating layer. During the bending of the flexible display panel, the protrusions would release part of stress.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Straight high-bending resistance strength cable

InactiveCN105609181AImprove bending and extrusion resistanceImprove extrusion resistanceInsulated cablesInsulated conductorsCross-linkEngineering

The invention discloses a straight high-bending resistance strength cable, which comprises a cable center, a second coating layer, a cross linked protective layer and a sheath layer, wherein the cable center internally comprises an elastic support frame; the elastic support frame is composed of an inner cylinder, an outer cylinder and multiple supporting plates radially arranged along the cable center; one end of each supporting plate is located in the inner cylinder and the other end passes out of the inner cylinder and the outer cylinder; the arc-shaped protective piece located at the tail end of the outer side of the outer cylinder of the supporting plate abuts against the inner wall of the second coating layer in a matched mode; multiple wires are vertically arranged between any two adjacent supporting plates and located at the outer side of the outer cylinder and are close to the supporting plates at two sides, the outer wall of the outer cylinder and the inner wall of the arc-shaped protective piece; multiple groups of signal line pairs are respectively vertically arranged between any two adjacent supporting plates and located between the inner cylinder and the outer cylinder; and the cable core is sequentially coated by the coating layer, the cross linked protective layer and the sheath layer. The straight high-bending resistance strength cable is an-extrusion, bending-resisting and simple and stable in structure.

Owner:郑四珍

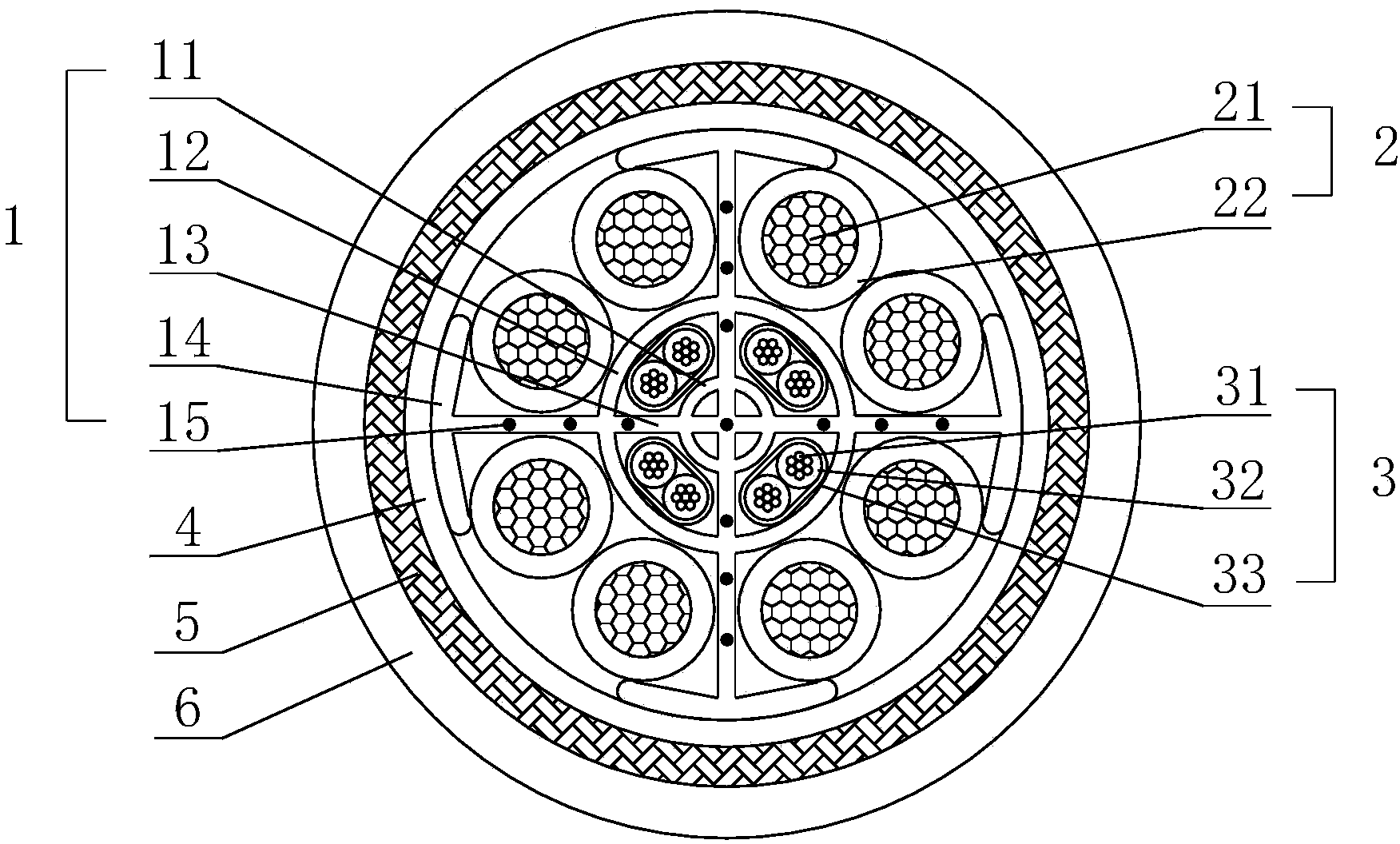

Extruding-resistant and bending-resistant complex cable

InactiveCN104123985ARelieve bending stressReduced risk of core breakageFlexible cablesFlexible conductorsSignal linesEngineering

The invention discloses an extruding-resistant and bending-resistant complex cable. The extruding-resistant and bending-resistant complex cable comprises a cable core, a second wrapping layer, a metal woven protection layer and a jacket layer, wherein an elastic support frame is arranged in the cable core, and consists of an inner barrel, an outer barrel and a plurality of support plates which are distributed along the radial direction of the cable core; one end of each support plate is positioned in the inner barrel, and the other end of each support plate passes through the inner barrel and the outer barrel; an arc-shaped protection part of each support plate positioned at the tail end of the outer side of the outer barrel is pressed against the inner wall of the second wrapping layer; a plurality of leads are longitudinally arranged between any two adjacent support plates, are positioned on the outer side of the outer barrel, and stick close to the support plates on both sides, the outer wall of the outer barrel and the inner walls of the arc-shaped protection parts; a plurality of groups of signal lines are longitudinally arranged between any two adjacent support plates, and are positioned between the inner barrel and the outer barrel; the core layer is coated with the wrapping layer, the metal woven protection layer and the jacket layer in sequence. The extruding-resistant and bending-resistant complex cable is resistant to extruding and bending, and is simple and stable in structure.

Owner:ANHUI FUXING CABLE GRP

Storage box

ActiveCN101037146AImprove convenienceReduce the burden onPaper/cardboardRigid containersEngineeringMechanical engineering

Owner:FUJIFILM BUSINESS INNOVATION CORP +1

Metal wire rod precision alignment cutting device and method

Owner:JINDUICHENG MOLYBDENUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com