Corrugated tube-mounting structure

a corrugated tube and tube-mounting technology, which is applied in the direction of machine supports, other domestic objects, mechanical apparatus, etc., can solve the problems of affecting the operation of inserting, affecting the insulating sheath of the wire harness, and requiring a lot of time and labor for taping operation, so as to achieve convenient bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

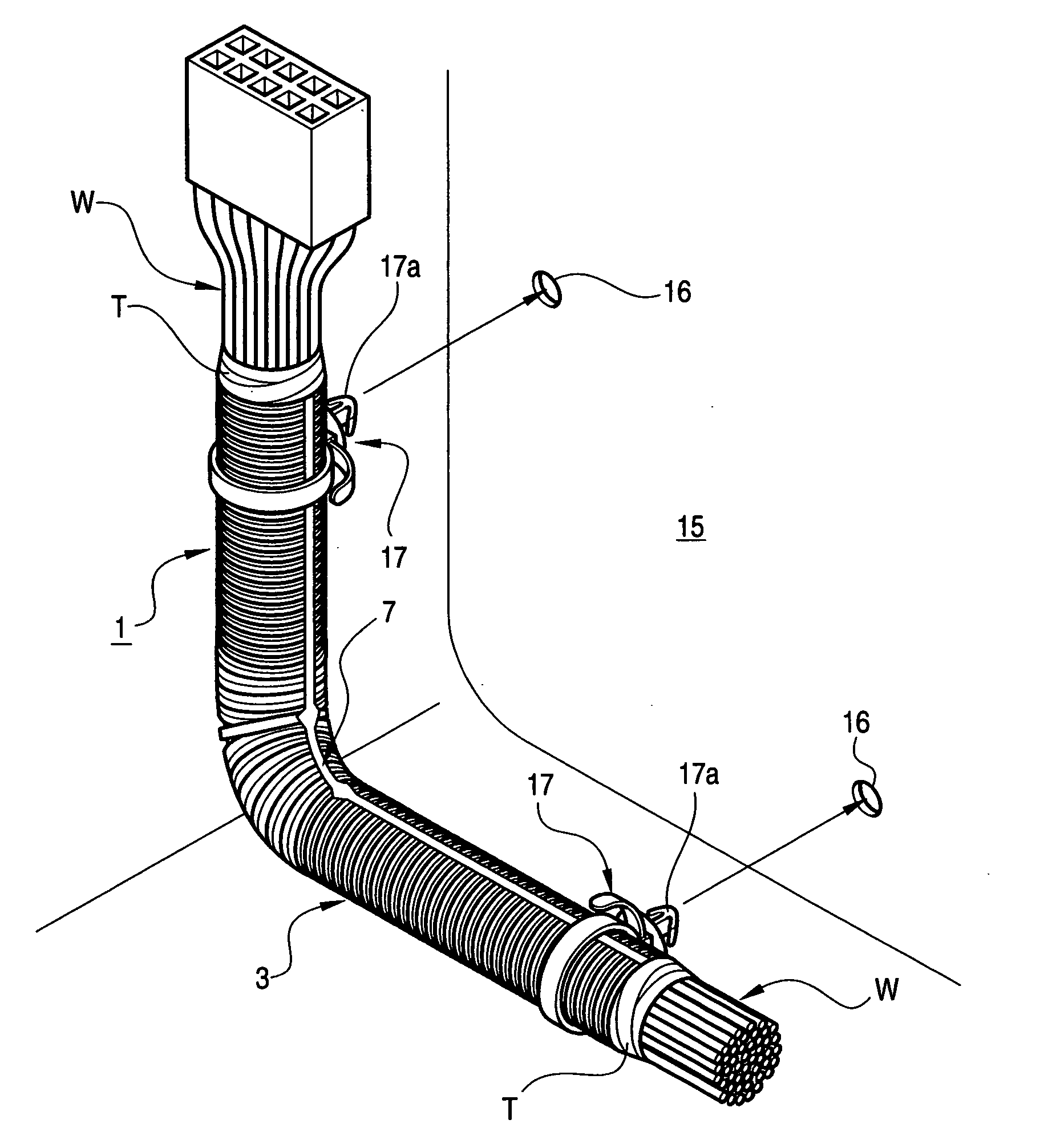

[0055] A corrugated tube 1, used in a mounting structure is fixed to a predetermined portion of a wire harness W by adhesive tapes T or the like wound respectively on opposite end portions thereof, as shown in FIG. 1. At this time, a tubular body 3 is beforehand fixed to the wire harness W, passing therethrough, in such a manner that this tubular body 3 is twisted about an axis thereof relative to the wire harness W.

[0056] Namely, the tubular body 3 is twisted about the axis thereof, so that a lap portion 8 extends spirally along an outer peripheral face of the tubular body 3. In this embodiment, although the tubular body 3 is twisted about the axis thereof through an angle of about 90 degrees, this twisting angle can be suitably changed in accordance with the overall length of the tubular body 3 and so on.

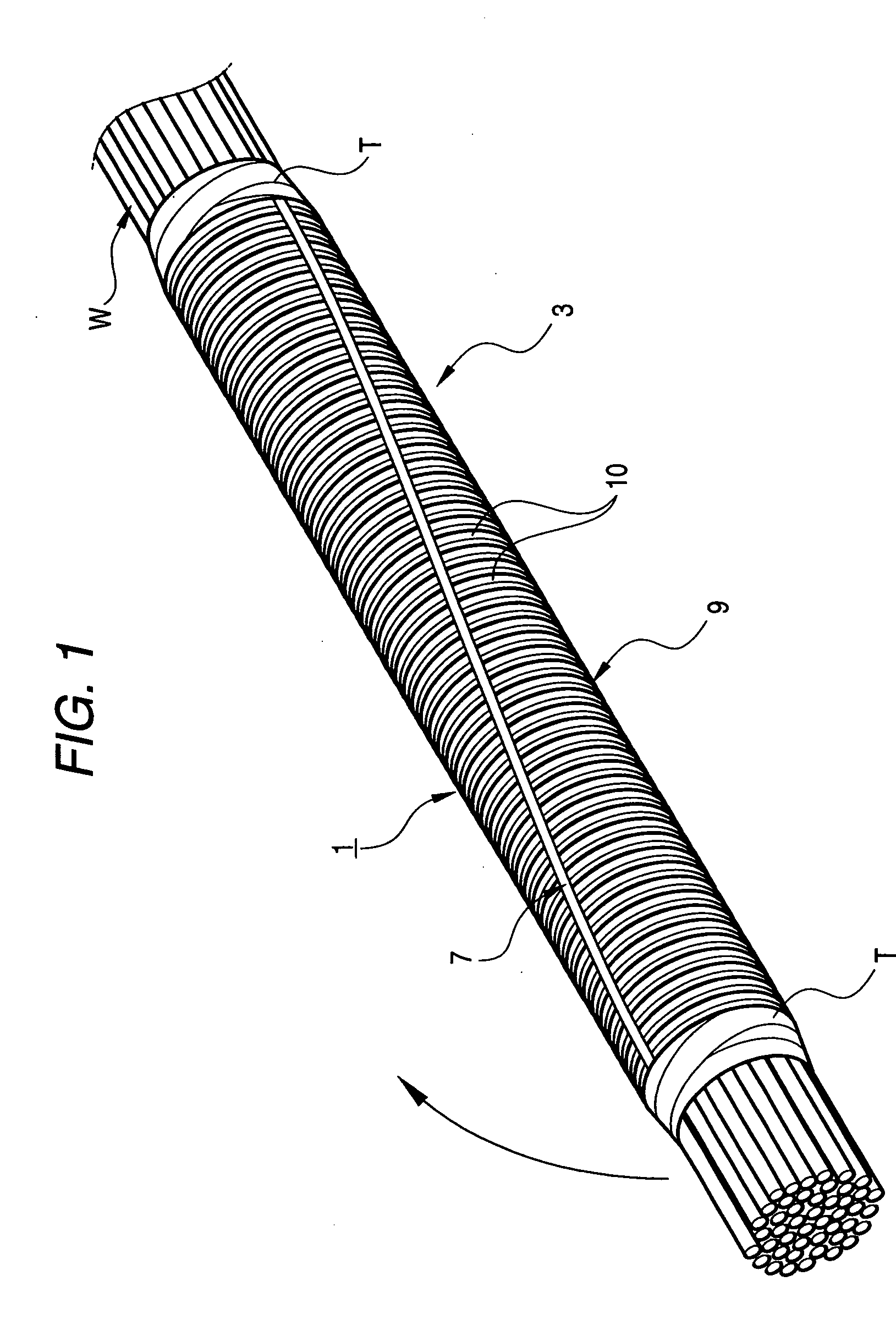

[0057] As shown in FIG. 2, the corrugated tube 1, together with the wire harness W, is fixed to a vehicle body panel 15 of a vehicle, for example, by inserting clip portions 17a...

second embodiment

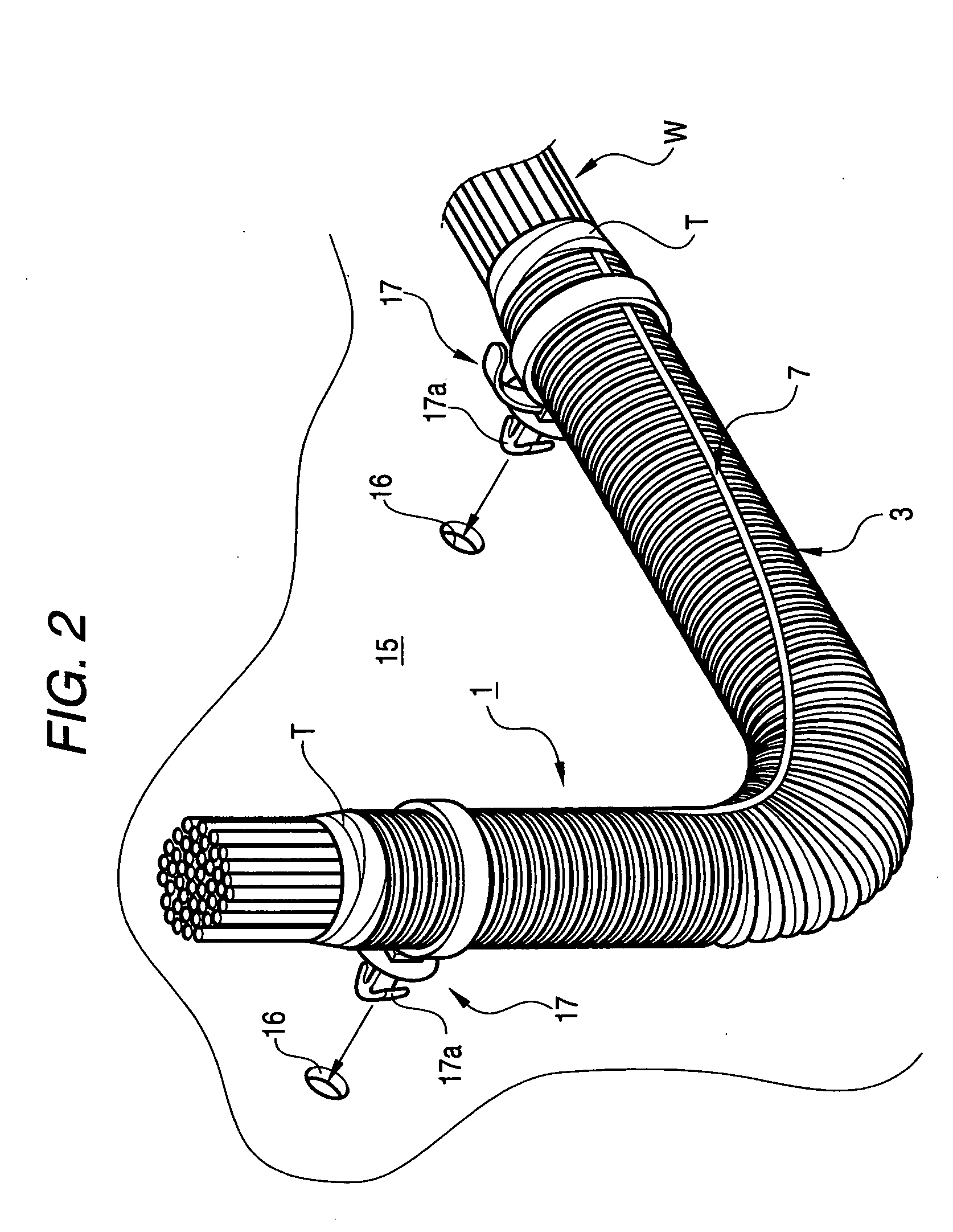

[0060] A corrugated tube 1, used in a mounting structure is fixed to a predetermined portion of a wire harness W by adhesive tapes T or the like wound respectively on opposite end portions thereof, as shown in FIG. 3.

[0061] At this time, a tubular body 3 need only to be fixed to the wire harness W, passing therethrough, in such a manner that the opposite end portions of this tubular body 3 are fixed straight to the wire harness W as is the case with the tubular body 3 of FIG. 11, and therefore the operation for fixing the tubular body 3 to the wire harness W is easy.

[0062] Then, a pair of band clips (clamp members) 21 and 31 are fastened respectively on those portions of the outer peripheral face of the tubular body 3 disposed near respectively to the opposite ends of this tubular body 3.

[0063] As shown in FIG. 4, the band clip 21 is integrally molded of an insulative resin material, and includes a winding bland 24 for being wound on the outer peripheral face of the tubular body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| flexibility | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com