Lamination preparation process of curved-surface double-glass photovoltaic module

A double-glass photovoltaic and preparation technology, which is applied in lamination, lamination devices, photovoltaic power generation, etc., can solve the problem of high production cost of curved double-glass photovoltaic modules, and achieve the effect of preventing relative sliding and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

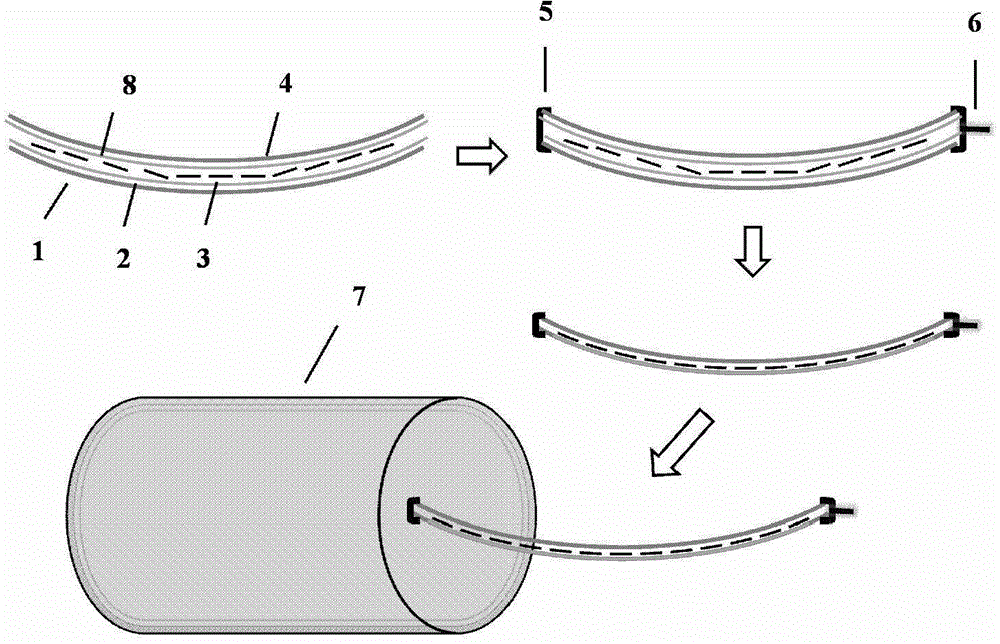

[0031] A lamination preparation process for curved double-glass photovoltaic modules,

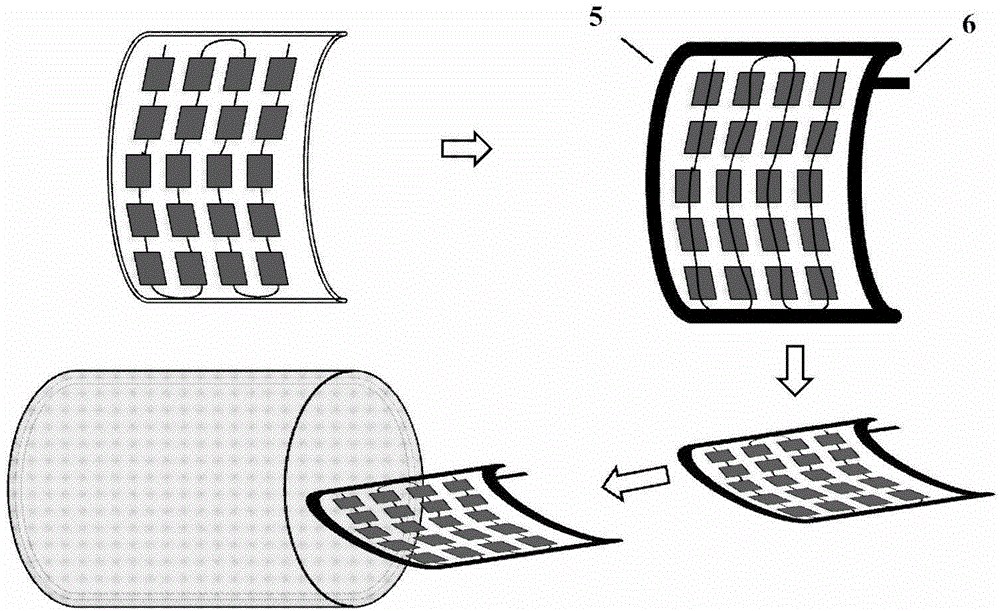

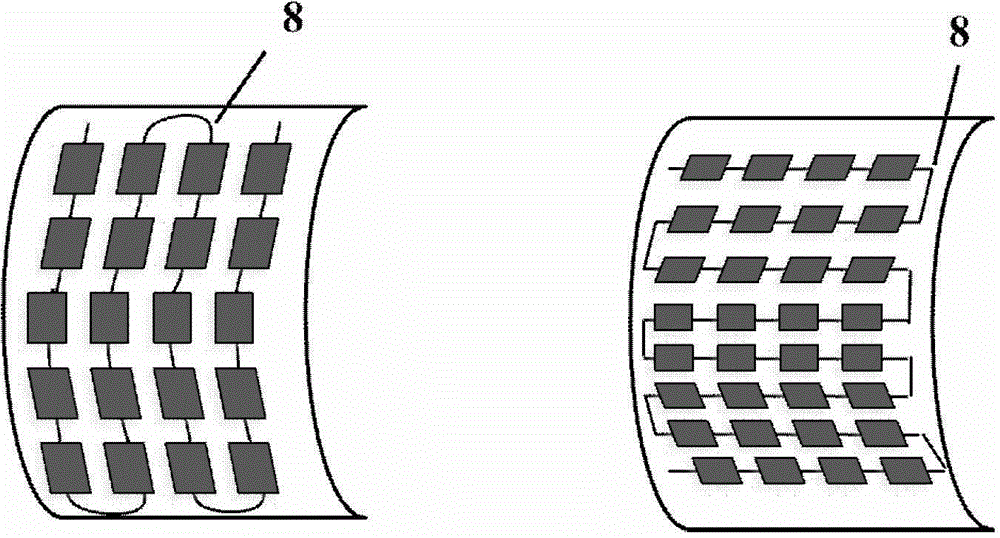

[0032] First, cover a layer of bonding material 2 on the panel curved glass 1, place solar cells 3 on the bonding material 2, then cover a layer of bonding material 8 on the solar cells 3, and then cover the back panel curved glass 4 After aligning the edges of the panel curved glass 1 and the back panel curved glass 4, put a vacuum rubber ring 5 around it, so that the solar cell 3 and the two layers of bonding material are placed between the panel curved glass 1, the back panel curved glass 4 and the In the closed space enclosed by the vacuum rubber ring 5, the closed space is evacuated, and under the action of the external atmospheric pressure, the panel curved glass 1 and the back panel curved glass 4 compact the solar cells and bonding materials therebetween, Prevent relative sliding to obtain the component to be packaged; put the component to be packaged into the autoclave laminator 7 ...

Embodiment 2

[0034] A lamination preparation process for curved double-glass photovoltaic modules,

[0035] First, cover a layer of bonding material 2 on the back panel curved glass 4, place solar cells 3 on the bonding material 2, then cover a layer of bonding material 8 on the solar cells 3, and then cover the panel curved glass 1 ; After aligning the edges of the panel curved glass 1 with the back panel curved glass 4, put a vacuum rubber ring 5 around it, so that the solar cell 3 and the two layers of bonding material are placed between the panel curved glass 1, the back panel curved glass 4 and the In the closed space enclosed by the vacuum rubber ring 5, the closed space is evacuated, and under the action of the external atmospheric pressure, the panel curved glass 1 and the back panel curved glass 4 compact the solar cells and bonding materials therebetween, Prevent relative sliding to obtain the component to be packaged; put the component to be packaged into the autoclave laminator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com