Structure for oil pipe bundle heat shrinkage

A technology for heating structure and tubing, applied in the direction of parts of bundling machinery, etc., can solve the problems of uneven heating, axial bending of tubing, low heat shrinking efficiency, etc., to improve product competitiveness, eliminate bending stress, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

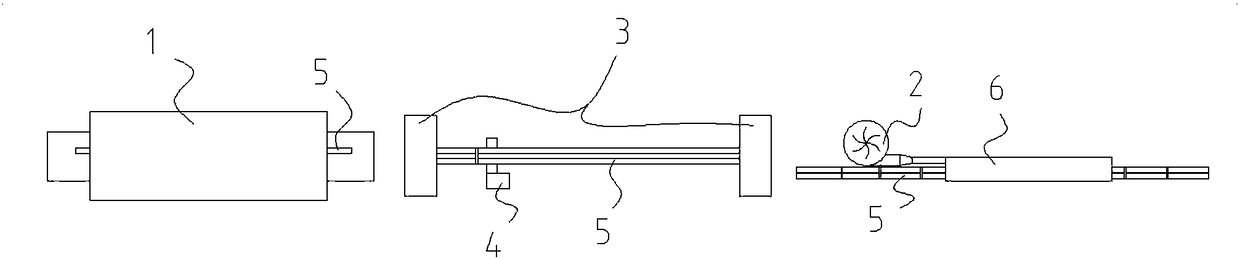

[0015] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0016] figure 1 It is a structural diagram of an embodiment of a heat-shrinkable structure for oil tube bundles in the present invention. Such as figure 1 As shown, the structure for heat-shrinking the oil tube bundle provided in this embodiment includes: heat-shrinking heating equipment 1 , blowing device 2 , straightening device 3 and binding device 4 .

[0017] Specifically, the heat-shrinking heating equipment 1 includes a transport table and a heating structure. The transport table is a roller structure, and a heating structure is arranged above and below the transport table to ensure uniform heating of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com