Metal wire rod precision alignment cutting device and method

A technology for metal wires and cutting devices, applied in the field of precision straightening and cutting devices for metal wires, can solve problems such as the inability to meet the requirements of the precision parts industry, large truncated length errors, and beveled edges in the incision, achieving high promotion and application value, eliminating Bending stress, effect of small length tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

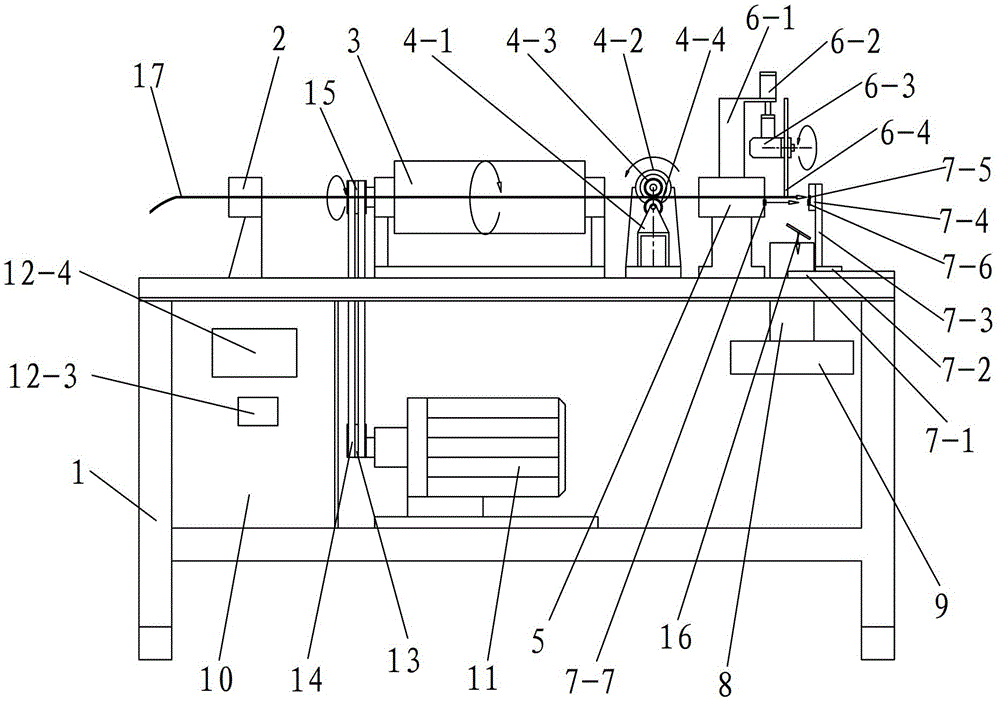

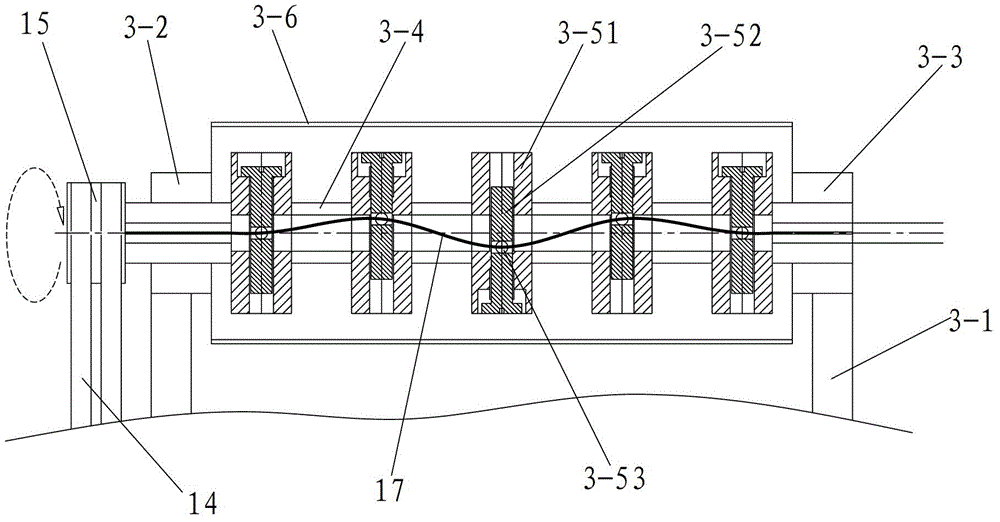

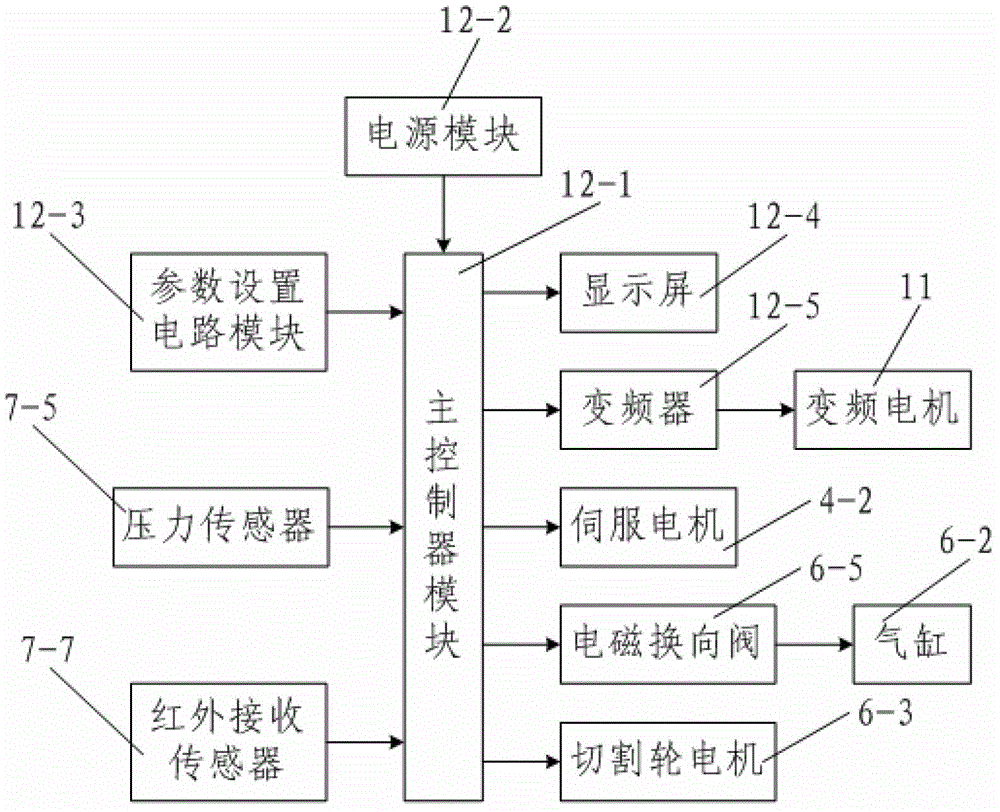

[0048] Such as figure 1 and figure 2 As shown, the metal wire precision straightening and cutting device described in the present invention includes a double-layer frame 1 provided with an upper layer placement plane and a lower layer placement plane. There are front-end guiding cylinder 2, rotary straightening cylinder 3, traction mechanism, rear-end guiding cylinder 5, cutting mechanism and mechanical sizing mechanism; Rotary straightening cylinder bearing 3-1 and the first bearing seat 3-2 and the second bearing housing 3-3 installed on the top of the rotating straightening cylinder bearing 3-1, the first bearing housing 3-2 and the second bearing A straightening guide cylinder 3-4 is installed on the seat 3-3, and a plurality of straightening modules and a protective cover 3 for covering a plurality of straightening modules are installed on the straightening guide cylinder 3-4 -6, the end of the straightening guide cylinder 3-4 is equipped with a first pulley 15; the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com