Differential type vertical micro-force loading device and method

A loading device, differential technology, applied in the direction of measuring device, measuring force, force/torque/work measuring instrument calibration/test, etc. The effect of eliminating bending deformation and bending stress, improving force loading accuracy, and eliminating the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

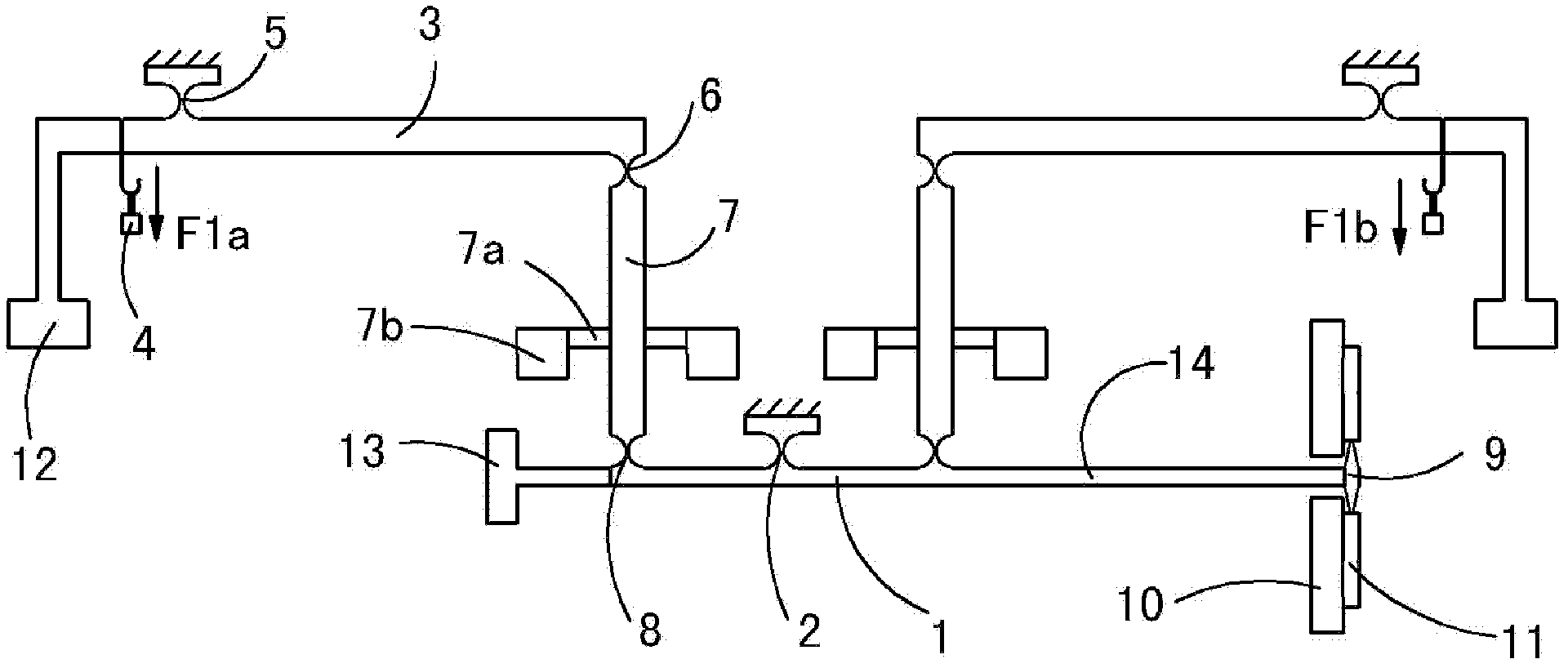

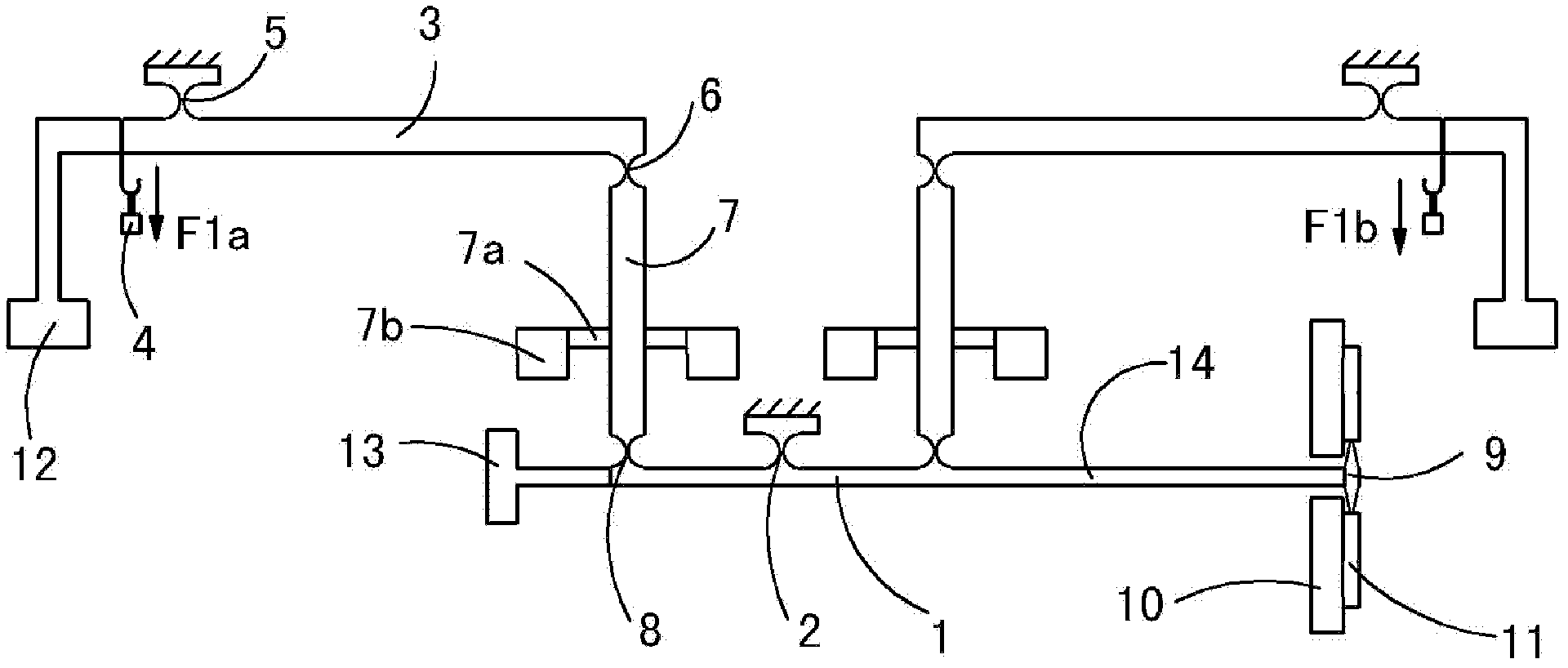

[0021] see figure 1 , the differential vertical micro-force loading device of this embodiment includes: a pair of primary levers 3, a secondary lever 1, a pair of transition bars 7, a pair of primary lever counterweights 12, a pair of cantilever arms 7a, a pair of Transition lever counterweight 7b and a secondary lever counterweight 13; in this embodiment, the secondary fulcrum 2 is set in the middle of the secondary lever 1 placed horizontally, with the secondary fulcrum 2 as the center, in the same vertical In the plane, a pair of first-level levers 3 are symmetrically located on both sides of the second-level fulcrum 2, and are connected to the second-level lever 1 through the transition rods 7 on their respective sides;

[0022] The first-level lever 3 is placed horizontally, the loading weight 4 is set at the outer end of the first-level lever as the input end, the first-level fulcrum 5 is located in the middle of the first-level lever 3, and the inner end of the first-le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com