Cable for electric vehicle charging pile and manufacturing method thereof

A technology of electric vehicles and charging piles, which is applied in the direction of cable/conductor manufacturing, power cables, insulated cables, etc., can solve problems such as bending and dragging, and achieve the effects of reducing friction, improving bending performance, and easing bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

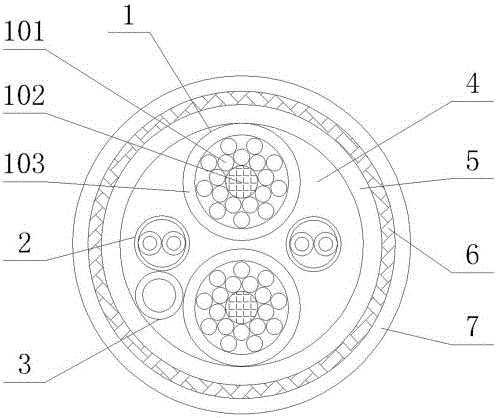

[0017] Embodiment 1: as figure 1 As shown, the cable for electric vehicle charging pile includes a cable core and an outer sheath 7. The cable core is jointly twisted into a cable by a pair of charging core 1, signal core 2 and grounding protection core 3. The cable core The outer circumference is wrapped with a filling layer 4, and the outer circumference of the filling layer 4 is wrapped with a polyester tape sliding layer 5, and the outer circumference of the polyester belt sliding layer 5 is covered with a stainless steel wire braided layer 6, and the stainless steel wire braided layer 6 An outer sheath 7 is extruded on the outer periphery of the charging wire core 1, and an insulating layer 103 is extruded on the outside after several copper wire conductors 101 are twisted around the rope core 102.

[0018] As a further improvement, the rope core 102 is a hemp core dipped in lubricating oil, the filling layer 4 is a glass fiber filling rope, the insulation layer 103 is ma...

Embodiment 2

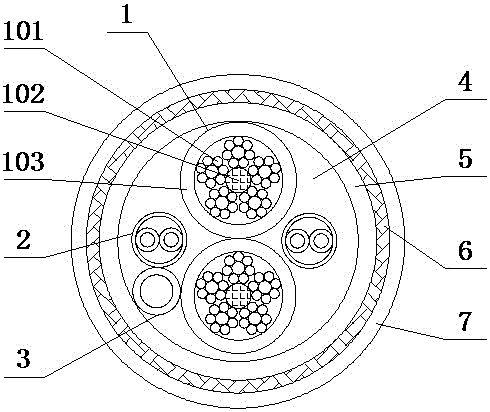

[0025] Embodiment 2: as figure 2 As shown, the cable for electric vehicle charging pile includes a cable core and an outer sheath 7. The cable core is jointly twisted into a cable by a pair of charging core 1, signal core 2 and grounding protection core 3. The cable core The outer circumference is wrapped with a filling layer 4, and the outer circumference of the filling layer 4 is wrapped with a polyester tape sliding layer 5, and the outer circumference of the polyester belt sliding layer 5 is covered with a stainless steel wire braided layer 6, and the stainless steel wire braided layer 6 The outer periphery of the cable is extruded with an outer sheath 7, and the charging wire core 1 is composed of several copper wire conductors 101 first twisted into a single-strand wire, and then several single-strand wires are twisted around the rope core 102 and then an outer extruded insulation layer 103 is formed. .

[0026] As a further improvement, the rope core 102 is a hemp cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com