Trailer axle tube steel and its processing method

A processing method and section steel technology, applied in metal rolling and other directions, can solve the problems of low utilization rate of steel, easy formation of bending stress, complicated production process, etc., and achieve the effect of increasing strength, eliminating bending stress and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

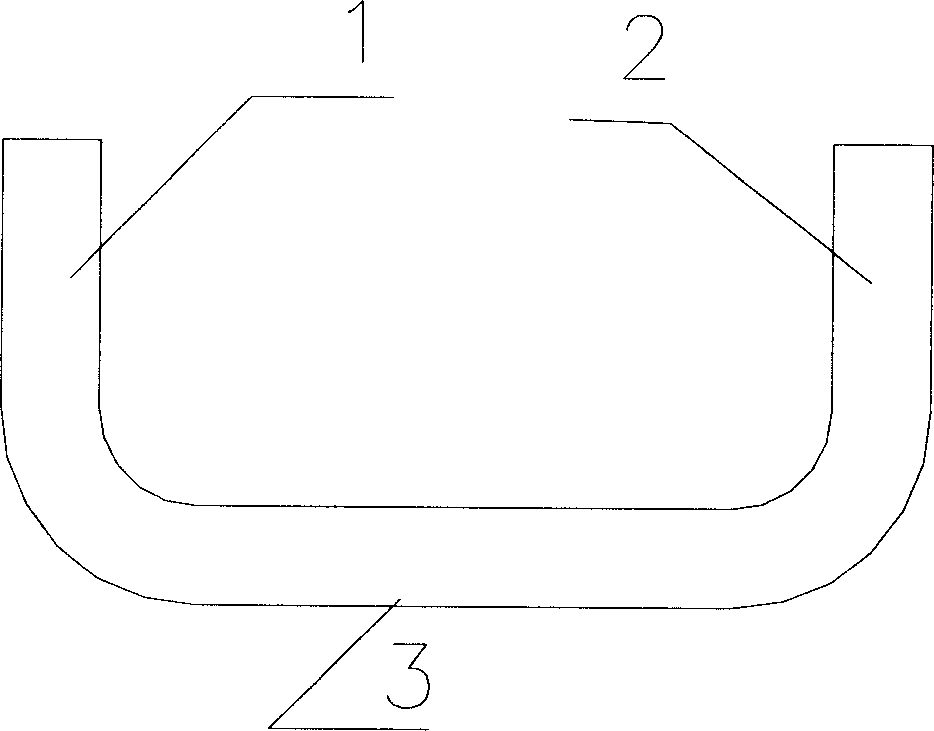

[0013] Example 1 as figure 1 As shown, it is a special-shaped channel steel, the wall thickness of flanges 1, 2 and web 3 is equal, the height of the flange is 1 / 2 of the length of the web, and the flange of the channel steel is straight.

Embodiment 2

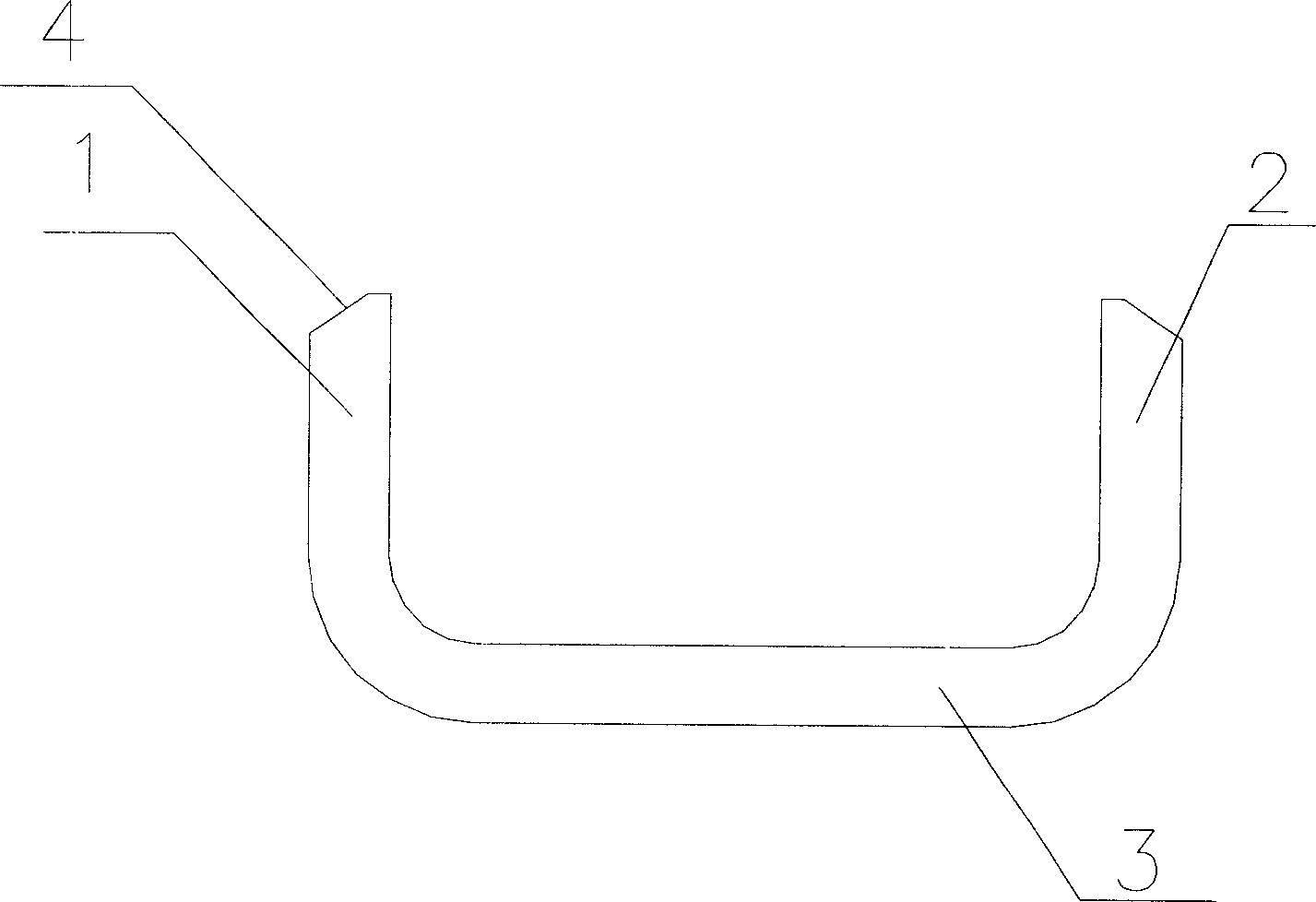

[0014] Example 2 as figure 2 As shown, it is special-shaped channel steel with external bevel angle, the wall thickness of flange 1, 2 and web plate 3 is equal, the flange height is half of the length of the web plate, and the top outer side of the flange has an external bevel angle 4, so The outer bevel is smoothly transitioned to the top surface at 1 / 10 of the upper outer surface of the channel steel flange, and the angle of the outer bevel 4 is 20-40 degrees.

[0015] When the two-shaped steel is butted and used to make the axle tube of the trailer, there is no need to cut the welding incision, which reduces the processing procedure, effectively saves metal materials, and improves work efficiency.

[0016] The dimensions of the above two types of steel are:

[0017] Example 1: 150×75×16 for the production of 13-15t trailer axle tubes

[0018] Example 2 150×75×16×28 for the production of 13-15t trailer axle tubes

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com