Skin anastomat nail pressing structure and skin anastomat thereof

A technology of staplers and staples, which is applied in the direction of surgical fixation nails, etc. It can solve the problems of missing staple feet, easy slippage of staples, and inability to anastomose, achieving the effects of reducing pain, reliable molding, and reducing surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

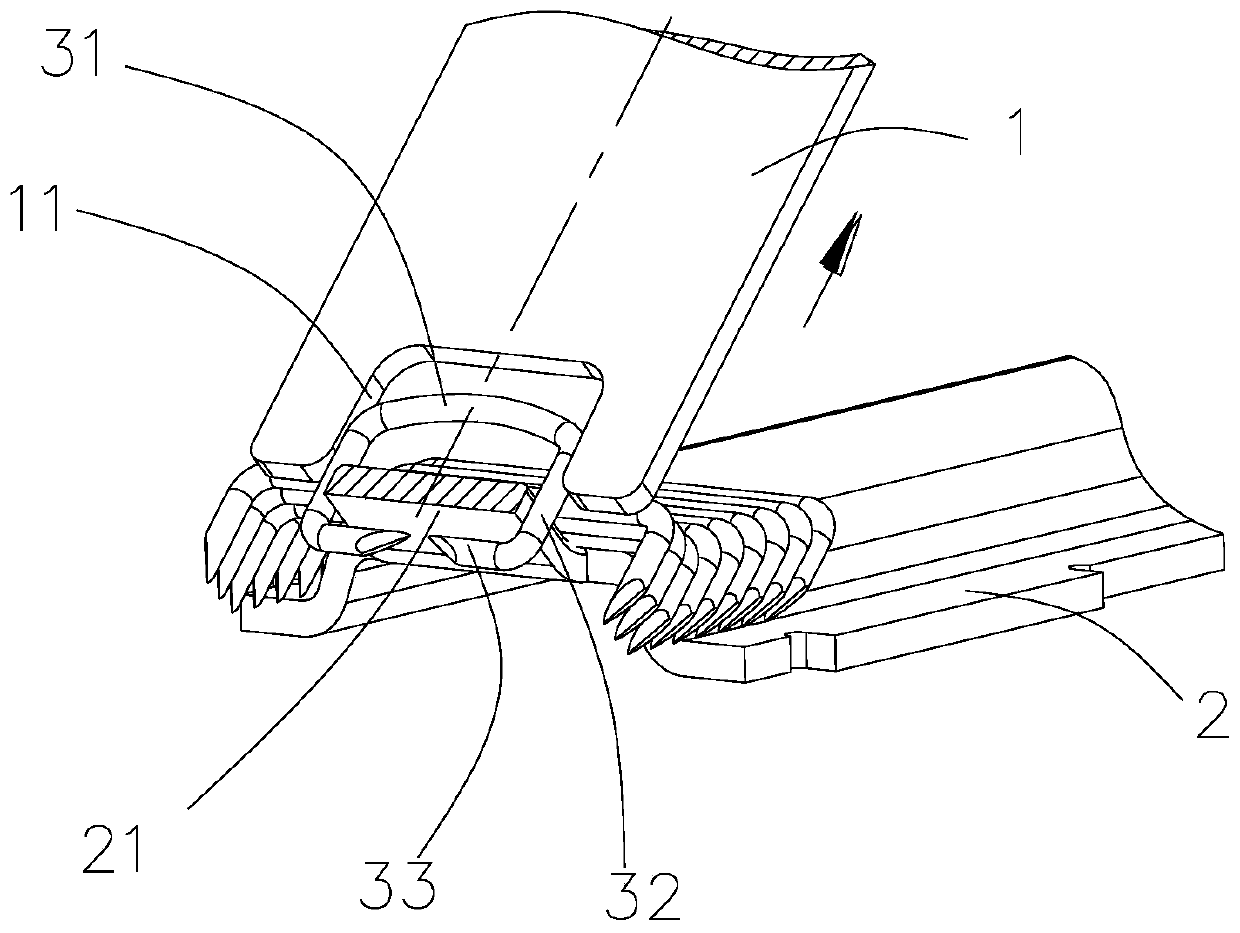

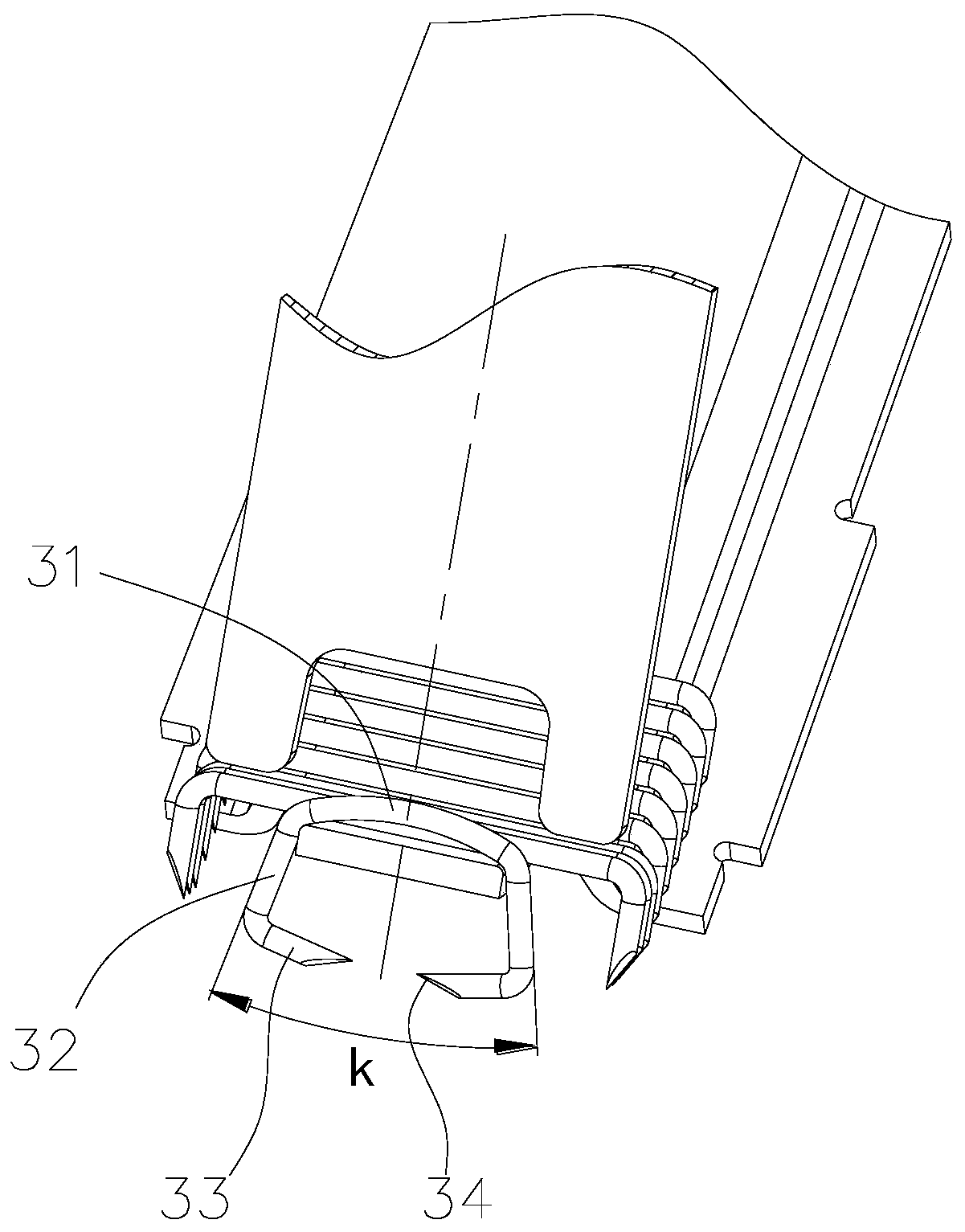

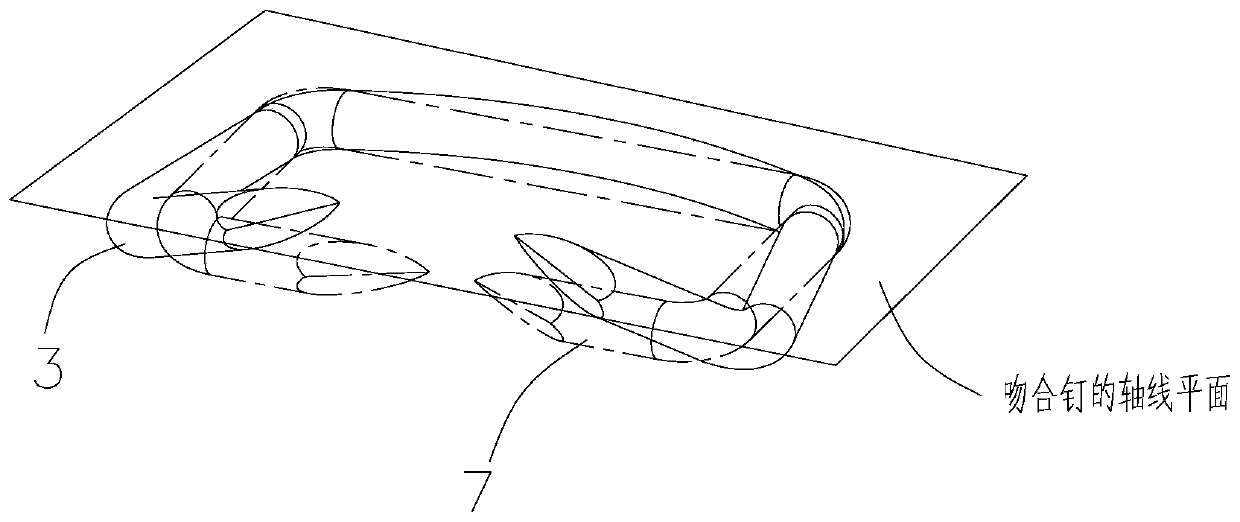

[0035] Such as Figure 4-10 As shown, a nail-pressing structure of a skin stapler includes a nail-pressing plate 4 and a nail seat 6. When operating the stapler, the direction of the arm is the rear end, and the forming end of the nail-pressing plate 4 is provided with a jaw 41 , the jaw 41 is in the shape of a bell mouth with a narrow bottom and a wide top, the opening angle of the jaw 41 is α, 0°<α<40°, and the inner sides of the jaw 41 are provided with inner profile molding surfaces 42, the end of the jaw 41 is provided with an end forming surface 43, and an arc forming surface 44 is provided between the inner profile forming surface 42 and the end forming surface 43, and an arc forming surface 44 is set on the end forming surface 43. There is a first V-shaped groove 431, and a second V-shaped groove 441 communicating with the first V-shaped groove 431 is opened on the arc forming surface 44. The bottom 45 of the jaw is provided with a pressing table 46, and the first V-sh...

Embodiment 2

[0042] Such as Figure 12 As shown, in this embodiment, the difference from Embodiment 1 is that both the first V-shaped groove 431 and the second V-shaped groove 441 are V-shaped grooves facing directly. The simplified embossing mold does not have a curved V-shaped groove, and it is obvious that the punch of such an embossing mold is easier to process and manufacture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com