Processing technology for preventing flexible board of rigid-flexible board from being bent and broken

A soft-rigid combination board and processing technology technology, which is applied in the direction of circuit bendable/stretchable parts, printed circuit parts, electrical components, etc. Effects of bending stress, improved quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A processing technology for preventing the bending and fracture of the soft board of the soft-hard board, comprising the following steps:

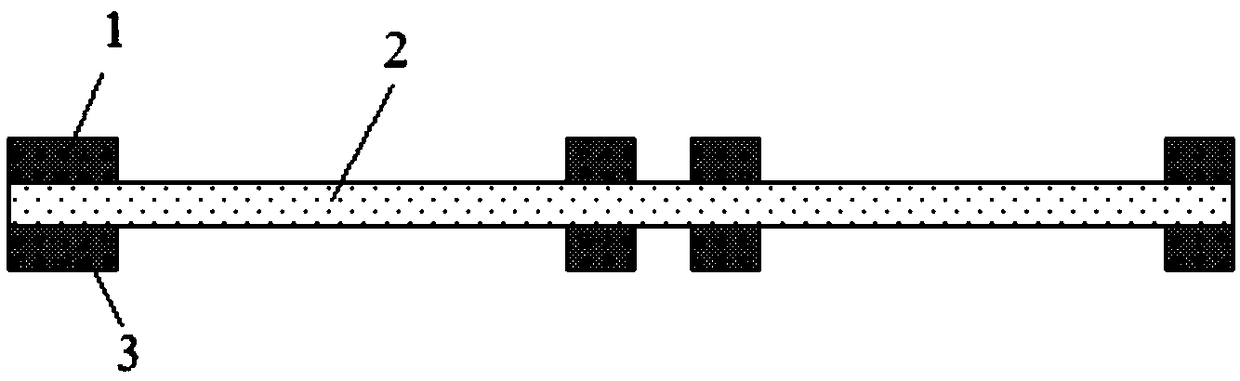

[0029] (1) if figure 1 As shown, prepare the flexible board substrate, the model of the flexible board substrate is 0.002″H / H OZ, and the supplier is Kunshan Xinyang Electronic Materials Co., Ltd.; the flexible board layer substrate includes an upper copper surface 1, an insulating layer 2, a lower copper surface 3, and make circuits on the upper copper surface 1 and the lower copper surface 3 respectively;

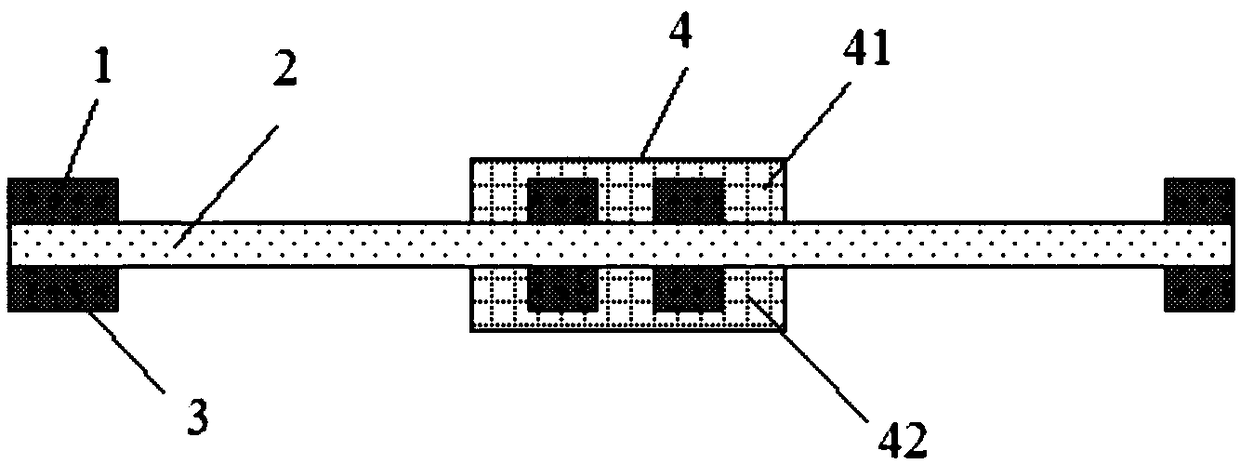

[0030] (2) Make the cover film 4 for protecting the circuit of the flexible board, including the upper cover film 41 and the lower cover film 42, the model is FGA0525, and the supplier is Kuntaihong Electronic Materials Co., Ltd.; the size of the cover film 4 is bent than the flexible board The area is 1.27mm larger;

[0031] (3) if figure 2 As shown in , attach the prepared cover film to the soft board layer;...

Embodiment 2

[0039] Embodiment 2: A processing technology for preventing the bending and fracture of the soft board of the soft-hard board, comprising the following steps:

[0040] (1) if figure 1 As shown, prepare the flexible board substrate, the model of the flexible board substrate is 0.002″H / H OZ, and the supplier is Kunshan Xinyang Electronic Materials Co., Ltd.; the flexible board layer substrate includes an upper copper surface 1, an insulating layer 2, a lower copper surface 3, and make circuits on the upper copper surface 1 and the lower copper surface 3 respectively;

[0041] (2) Make the cover film 4 for protecting the circuit of the flexible board, including the upper cover film 41 and the lower cover film 42, the model is FGA0525, and the supplier is Kuntaihong Electronic Materials Co., Ltd.; the size of the cover film 4 is bent than the flexible board 1.5mm larger area;

[0042] (3) if figure 2 As shown in , attach the prepared cover film to the soft board layer;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com