Conductive part for connecting batteries, battery connecting method and battery pack

A technology of conductive parts and connection methods, which is applied in the connection of electrical parts, battery pack parts, connections, etc., can solve the problems of large bending stress and torsional stress, short service life of connecting pieces, bending deformation of connecting pieces, etc., to eliminate bending Stress and torsional stress, extended service life, and the effect of strong stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

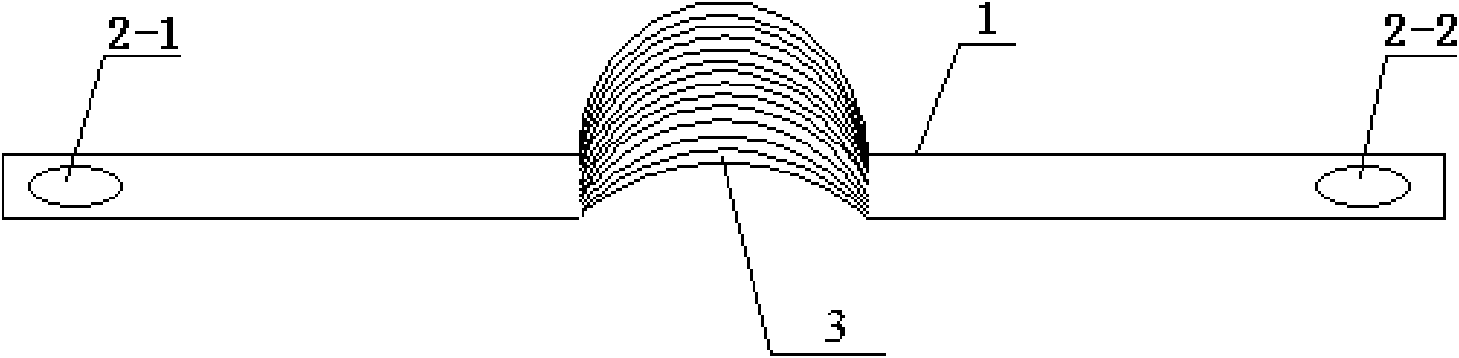

[0016] refer to figure 1 , the conductive part 1 of the present embodiment comprises 20 sheets of metal sheets 3, the thickness of the metal sheets 3 is 0.05mm, the two ends of these metal sheets are formed by pressure welding (i.e. as a whole), the middle part is a free arch, and the two ends of the conductive parts A through hole 2-1, 2-2 is opened respectively.

[0017] The experiment found that under the same test conditions of the battery extrusion operation, the above-mentioned conductive parts did not break, and the battery operated normally, while the connecting pieces of ordinary conductive parts were completely broken, and the battery could no longer work normally.

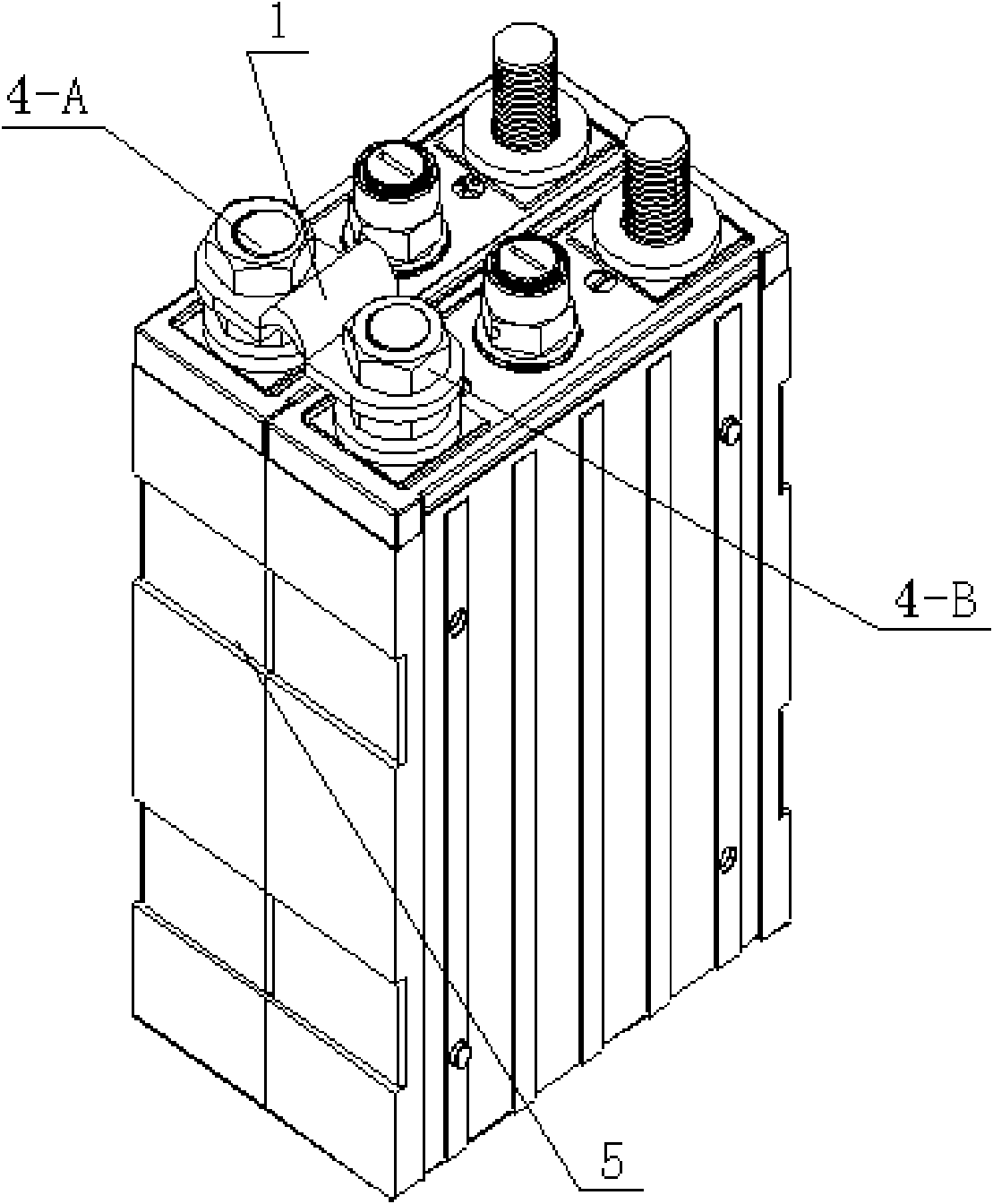

[0018] refer to figure 2 , using as figure 1 The shown conductive member 1 connects the positive and negative poles between the two batteries 4-A and 4-B to form a battery pack 5 .

Embodiment 2

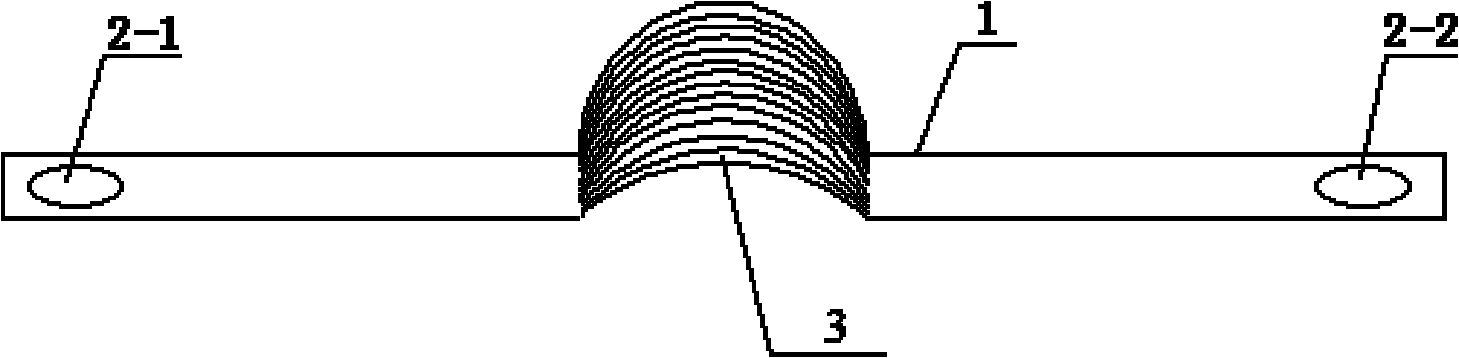

[0020] The conductive component 1 in this embodiment includes 10 pieces of thin metal sheets 3 with a thickness of 0.3 mm. The rest are the same as embodiment 1.

[0021] The experiment found that under the same test conditions of the battery extrusion operation, the above-mentioned conductive parts did not break, and the battery operated normally, while the connecting pieces of ordinary conductive parts were completely broken, and the battery could no longer work normally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com