Motor coil middle head cushion paper forming discharging device

A motor and coil technology, which is applied in the field of head pad paper forming and blanking equipment in the motor coil, can solve the problems of reducing work efficiency, increasing labor intensity, affecting bandaging, etc., and achieves the goal of improving work efficiency, reducing labor intensity, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

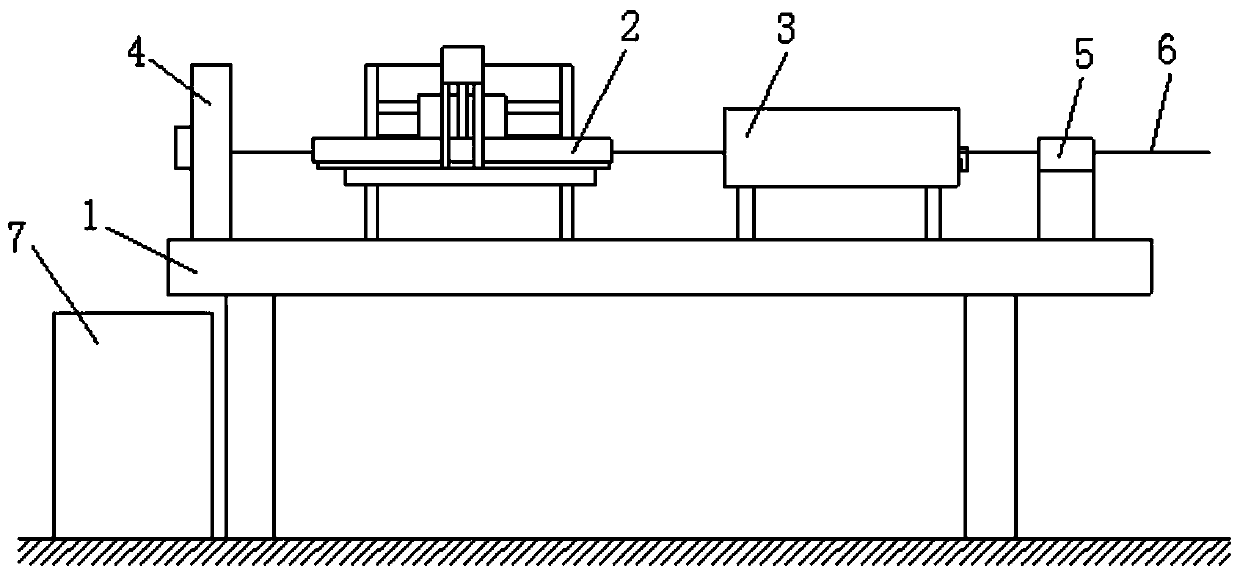

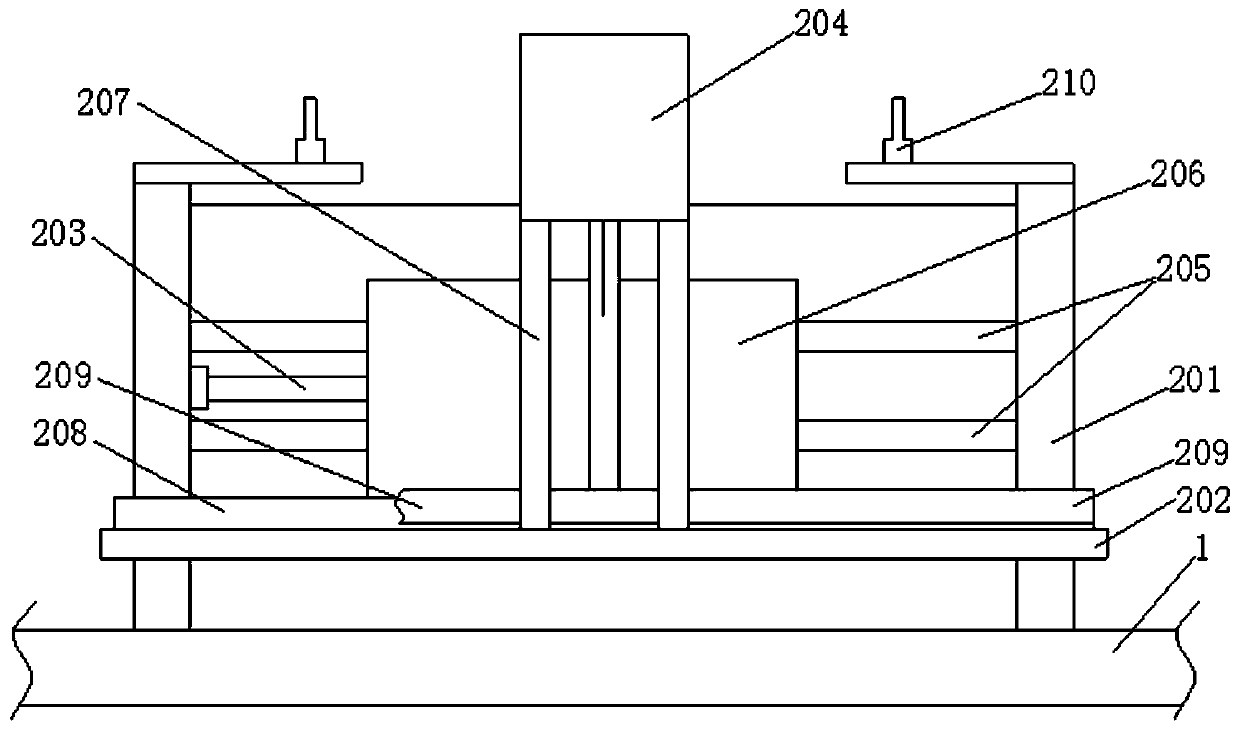

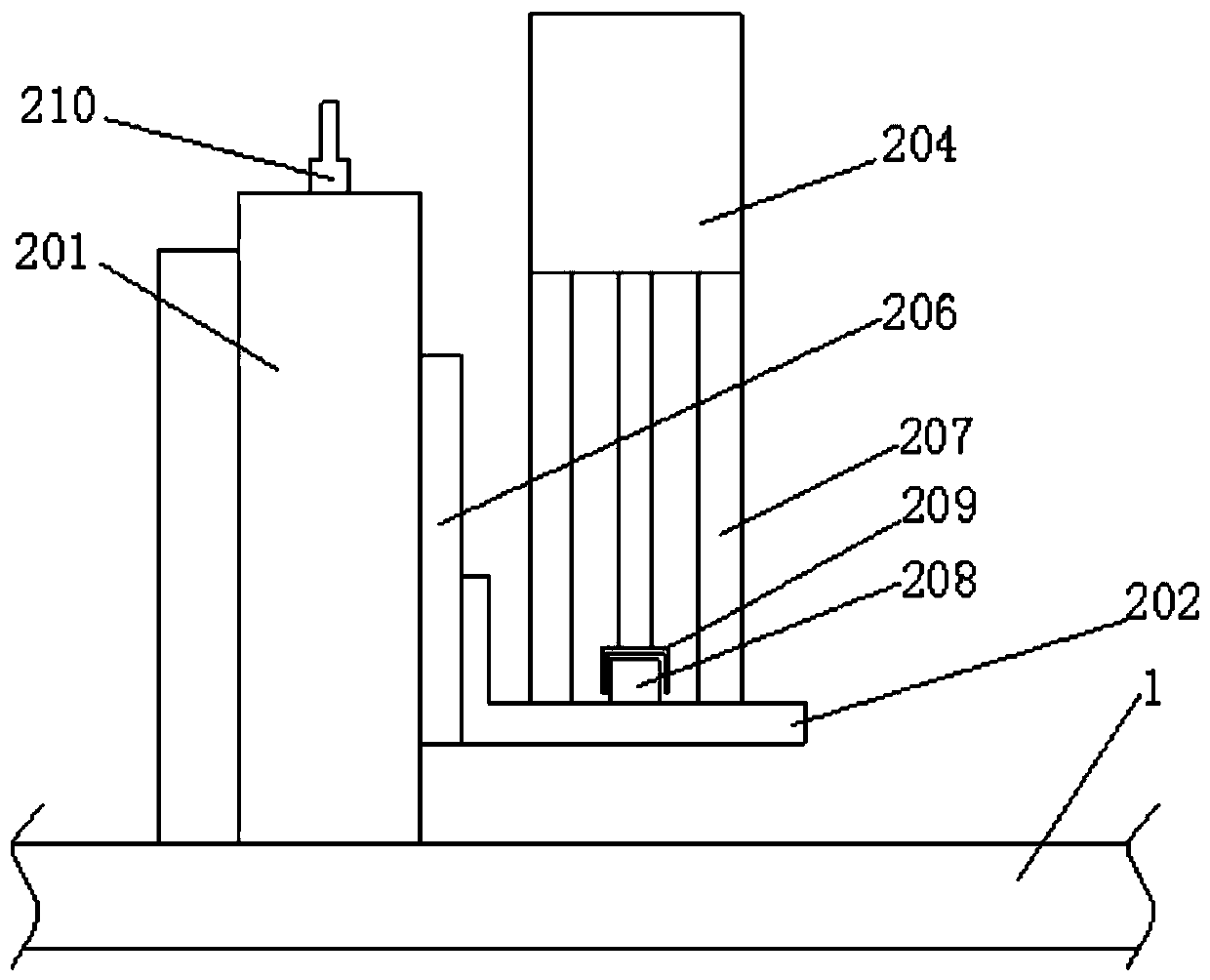

[0038] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 , in the figure, 1-support, 2-feeding mechanism, 3-forming mechanism, 4-cutting mechanism, 5-auxiliary limit device, 6-pad paper, 7-storage box;

[0039] 201-feeding bracket, 202-feeding bottom plate, 203-feeding cylinder, 204-pressing cylinder, 205-cylindrical guide rail, 206-slider, 207-pressing bracket, 208-strip rectangular protrusion, 209- Compression plate, 210-limit sensor;

[0040] 301-molding shell, 302-heating device, 303-outer mold, 304-mold core, 305-elbow, 306-rectangular through hole;

[0041] 401-cutting vertical plate, 402-cutting cylinder, 403-cutting knife, 404-slide, 405-n type through hole;

[0042] 501-bar block, 502-bar hole.

[0043] The forming and blanking equipment for the head pad paper in the motor coil, including the support 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com