Pipe fitting bending device

A pipe bending and pipe fitting technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of manual bending, low bending efficiency, time-consuming and labor-intensive problems, and achieve controllable bending angle and high bending efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

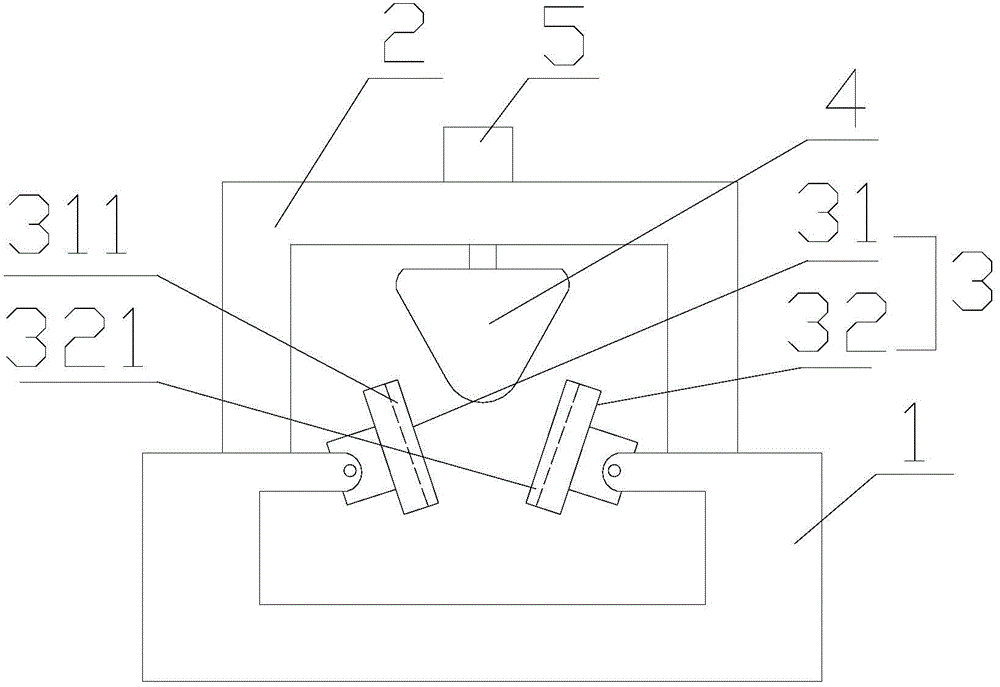

[0012] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a pipe bending device proposed by the present invention.

[0013] refer to figure 1 , the present invention proposes a pipe fitting bending device, comprising: a base 1, a mounting frame 2, a die 3, a punch 4, a driving device 5, a first fixing member and a second fixing member;

[0014] The die 3 includes a first die 31 and a second die 32, the first die 31 and the second die 32 are oppositely arranged and respectively rotated and connected to the base 1, and formed between the first die 31 and the second die 32 The bending space for bending pipe fittings, the first die 31 and the second die 32 are respectively provided with a first die pipe fitting groove 311 and a second die pipe fitting groove 321 along their length direction for clamping and positioning The first fixture at the first end of the pipe is slidably installed in the first die pipe groove 311, and the second fixture for clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com