Positioning assembly for heart stent metal mold processing machine tool

A metal mold and machine tool technology, which is applied in the field of positioning assemblies for heart stent metal mold machining machine tools, can solve the problems of accumulation of angle errors, low production extrusion efficiency of annular molds, and mold error deformation, and achieves the effect of increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

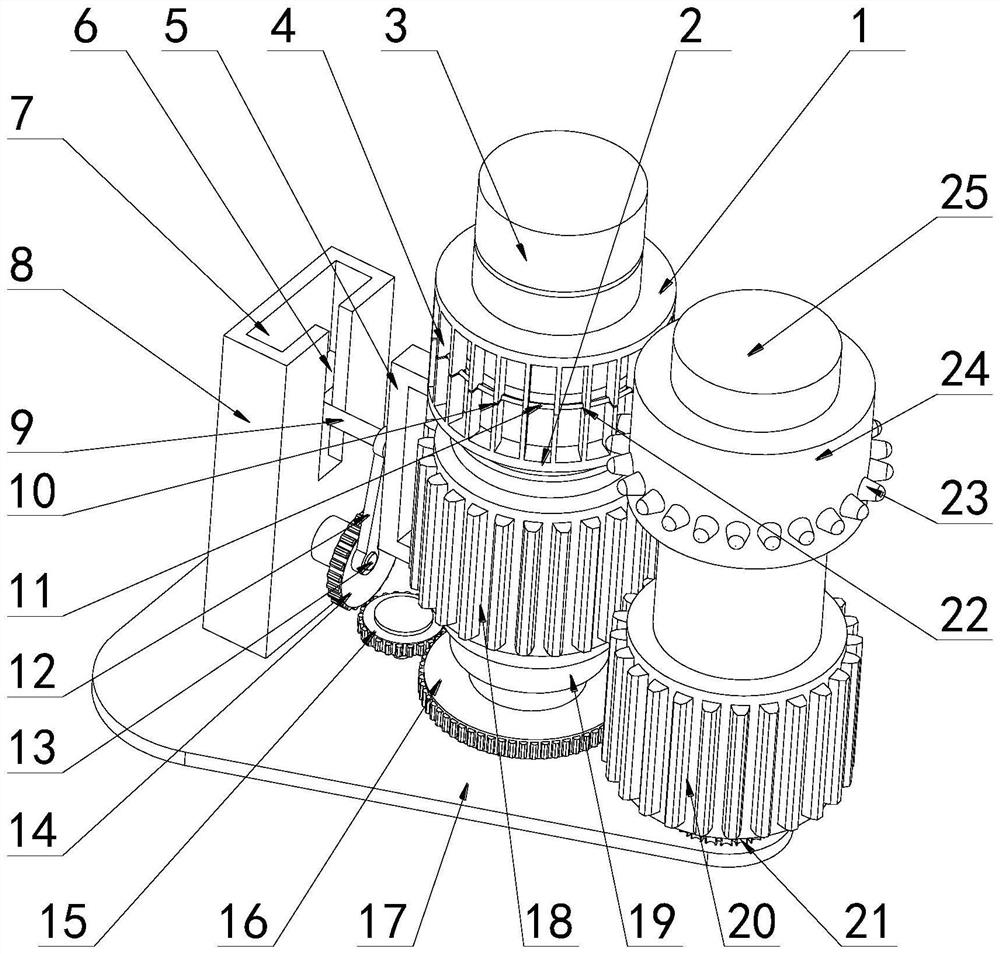

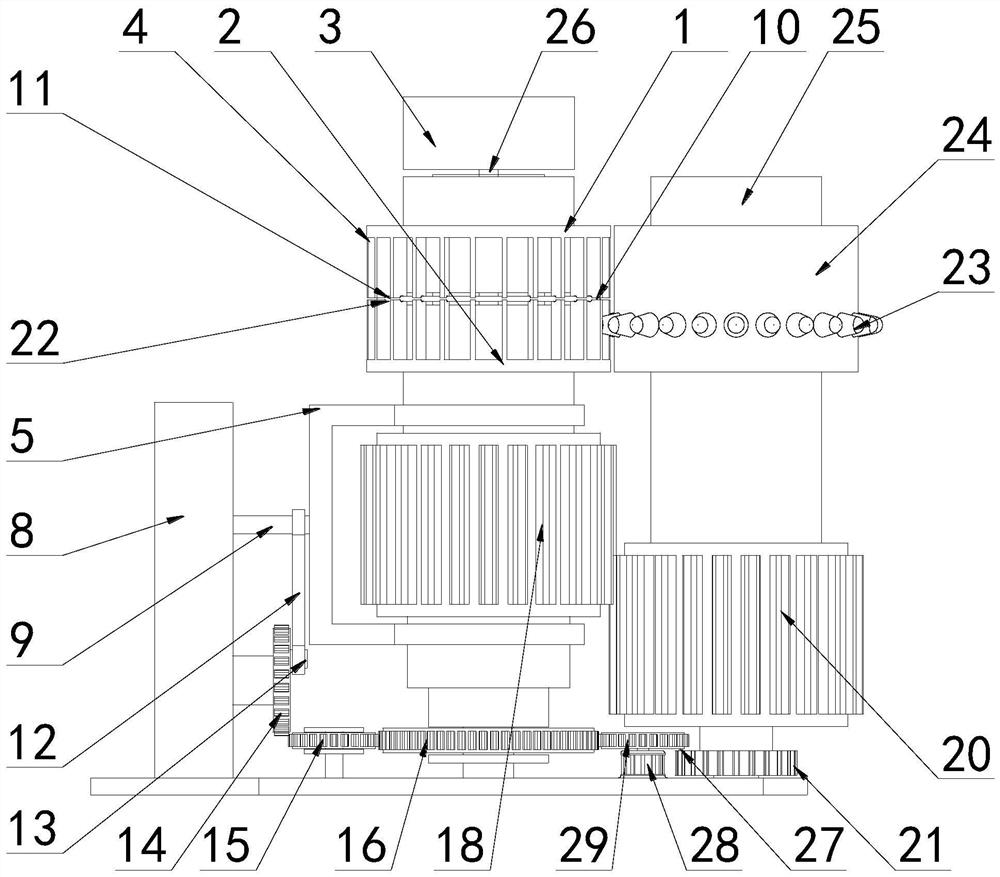

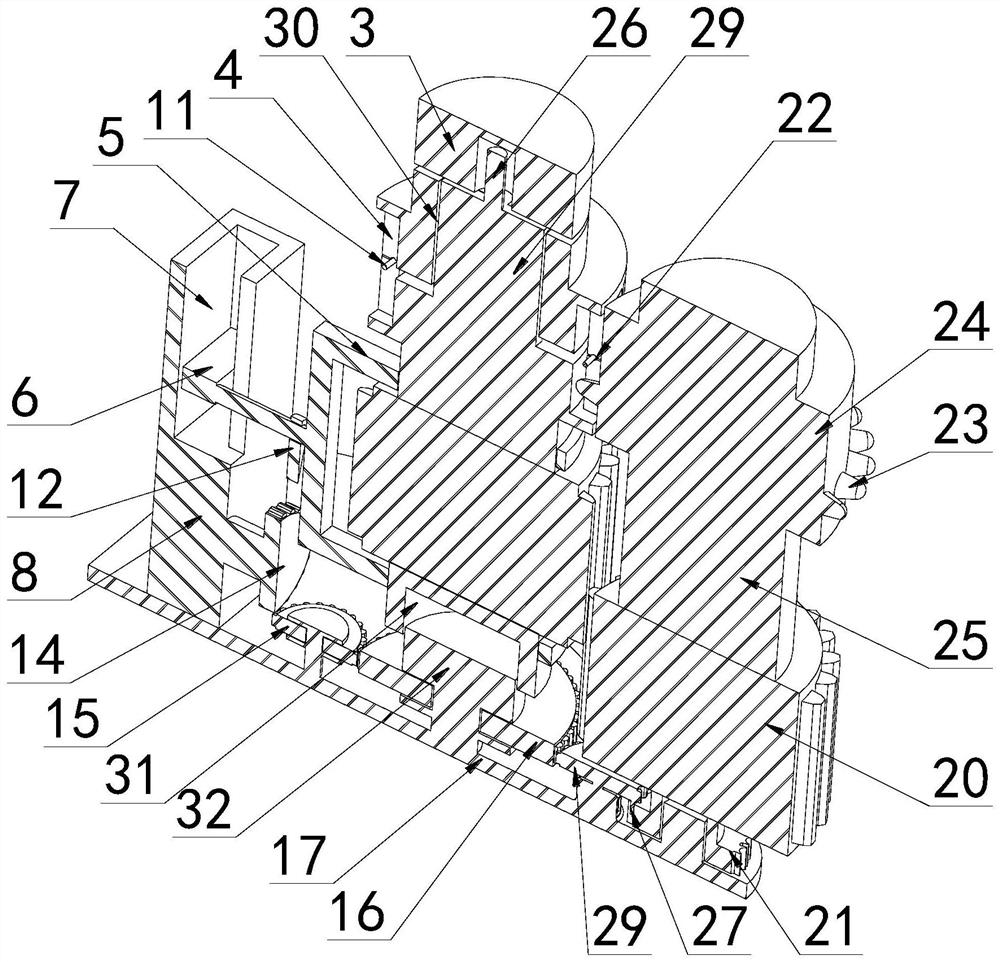

[0034] Example 1, please refer to Figure 1-6, the present invention provides a technical solution: a positioning assembly for a heart stent metal mold processing machine tool, including a base plate 17, a drive pair 28 fixed above the base plate 17, and a vertical frame 8, and the base plate 17 is rotatably connected by a rotating shaft There are a first horizontal transmission gear plate 15, a second horizontal transmission gear plate 16 and an intermittent gear 21, a first gear transmission roller 18 and a second gear transmission roller 20 are arranged above the base plate 17, and the upper and lower sides of the first gear transmission roller 18 Both run through and rotate the limit sleeve 19, and the sleeve frame 5 is fixed between the two limit sleeves 19, and the top of the first gear transmission roller 18 is fixed with the fixed ring 2, and the upper end of the fixed ring 2 is abutted with the collar 1, and the collar 1 and the fixed ring 2 are provided with an annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com