Large high-pressure oil pump cam box assembly

A high-pressure oil pump and cam box technology, which is applied to engine components, fuel injection pumps, machines/engines, etc., to achieve the effect of improving firmness and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in more detail:

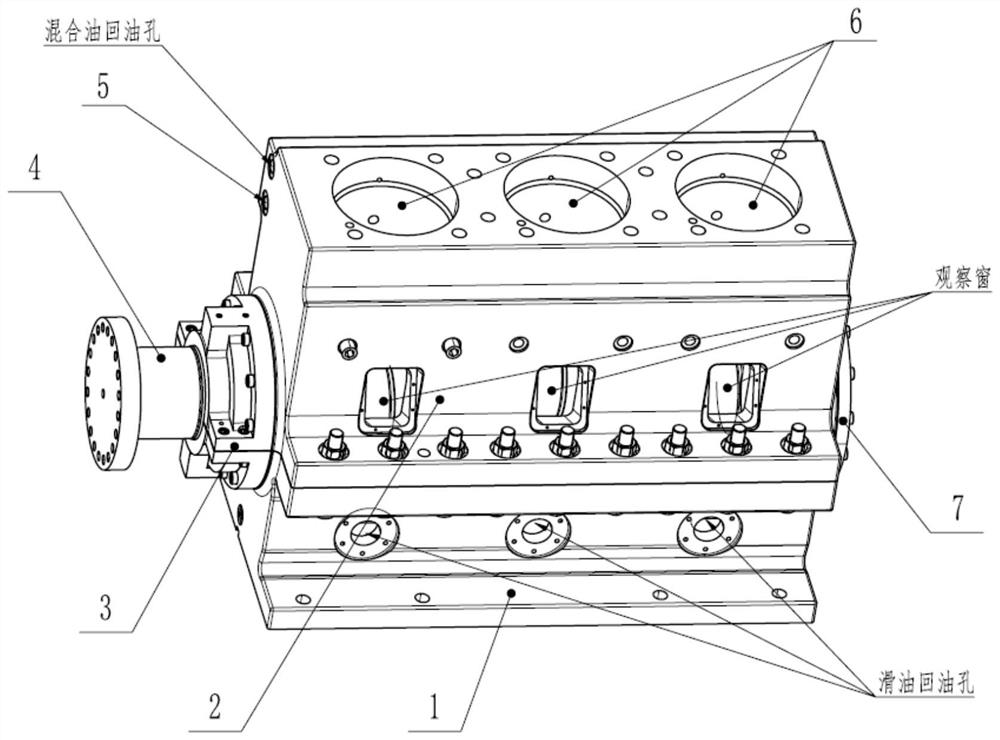

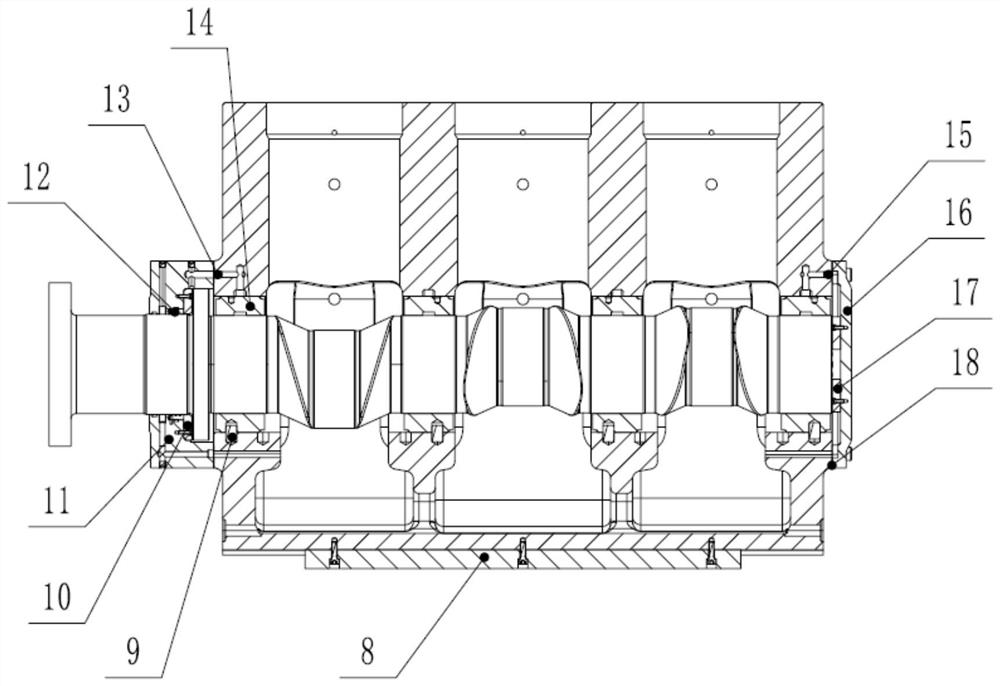

[0030] combine Figure 1-Figure 6 , this embodiment provides a cam box assembly for a low-speed single-unit high-pressure oil pump, which mainly includes a lower box body 1, an upper box body 2, a left end cover assembly 3, a camshaft 4, a right end cover assembly 7, and a bearing bush assembly 14 etc.

[0031] The overall volume of the cam box is very large, and it is difficult to cast it as a whole, so the box adopts a split design, which is divided into a lower box 1 and an upper box 2.

[0032] The upper box body 2 is provided with three independently arranged middle holes as the high-pressure oil pump installation holes 6, and a set of low-speed unit high-pressure oil pumps can be assembled in each of the high-pressure oil pump installation holes.

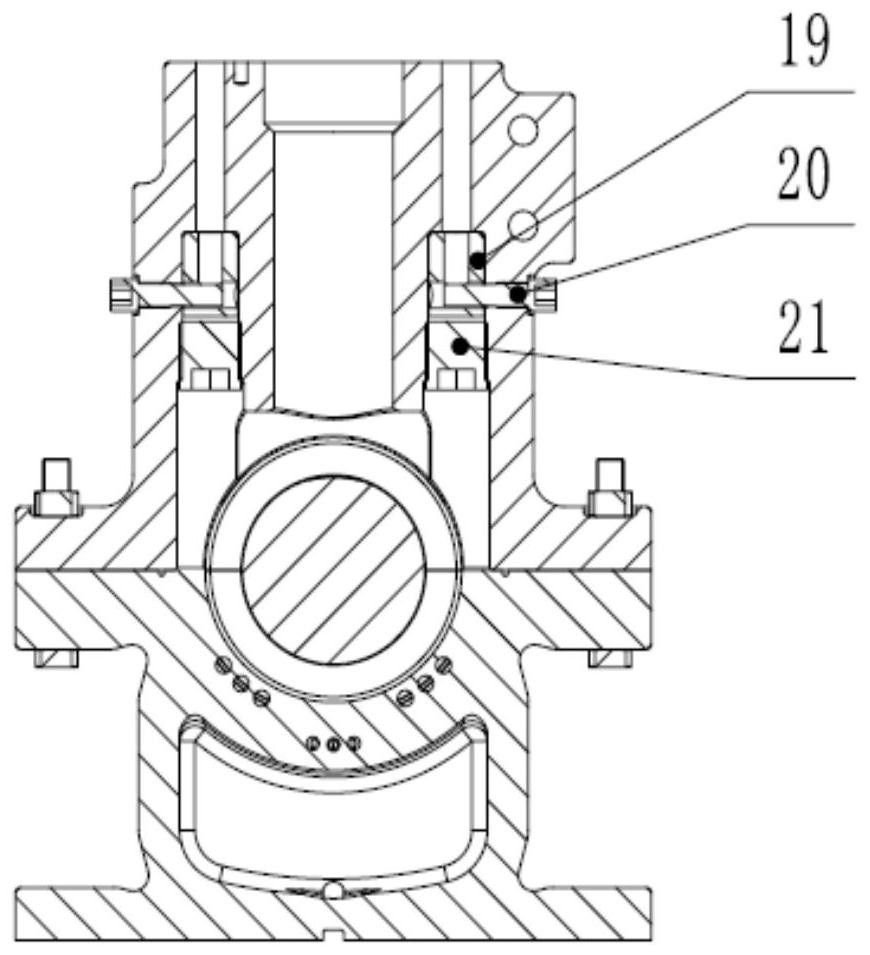

[0033] see image 3 , in order to install the high-pressure oil pump, considering that cast iron is brittle and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com