Longitudinal electromagnetic stirring device for electromagnetic induction holding furnace

An electromagnetic induction and electromagnetic stirring technology, which is applied in the direction of stirring devices, furnace control devices, furnaces, etc., can solve the problems that it is difficult to overcome the stirring effect of molten aluminum, difficult to control product quality, and unable to control the uniformity of metal alloy components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

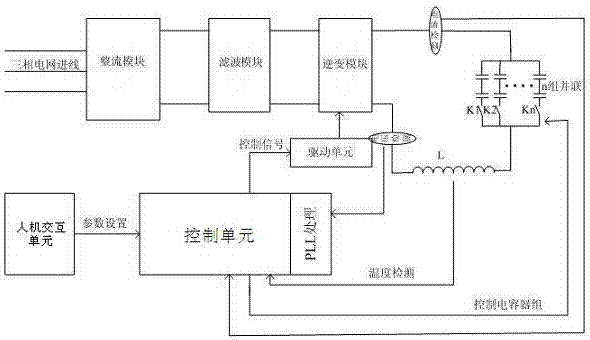

[0015] The electromagnetic induction holding furnace of this embodiment can change the three-phase power frequency alternating current into a high frequency of 10-20KHZ or a low frequency single-phase alternating current of 0.8-3.5HZ through the rectification module, the filter module and the inverter module, and the output terminal of the inverter module It is connected with the electromagnetic induction coil of the electromagnetic induction holding furnace, and the automatic switching parallel capacitor bank connected in series with the electromagnetic induction coil; there is also a control unit connected with the automatic switching parallel capacitor bank control line to control its capacitor input number, resulting in different resonant frequencies , so that the electromagnetic induction holding furnace has a high-frequency heating operation mode and a low-frequency stirring operation mode; the control unit drives the inverter module through the drive unit and controls t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com