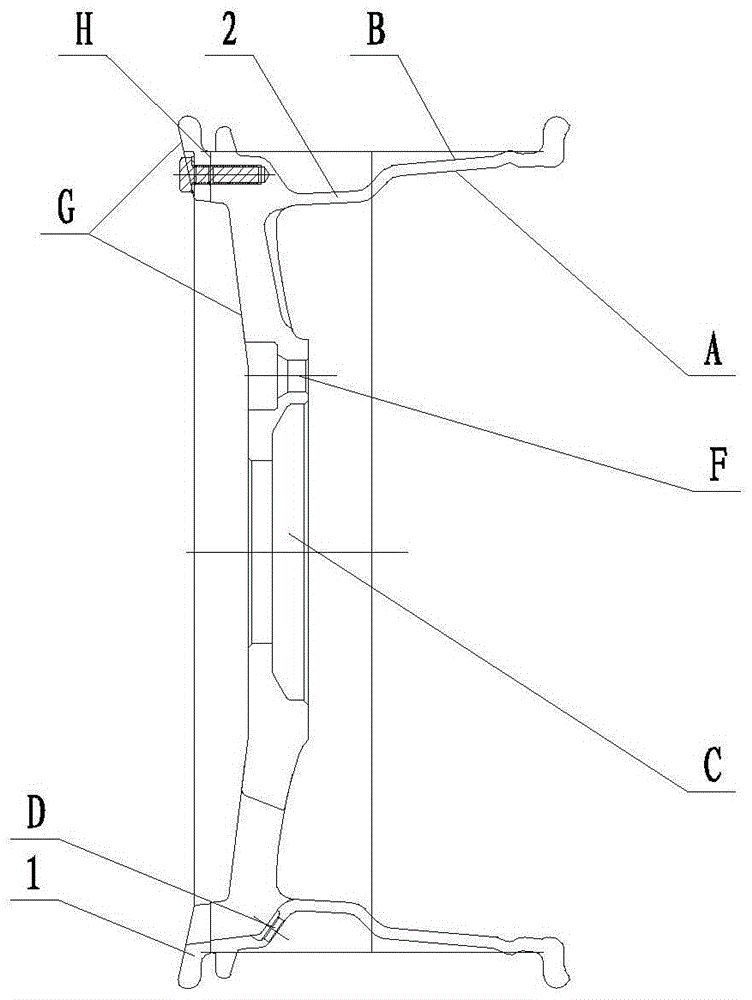

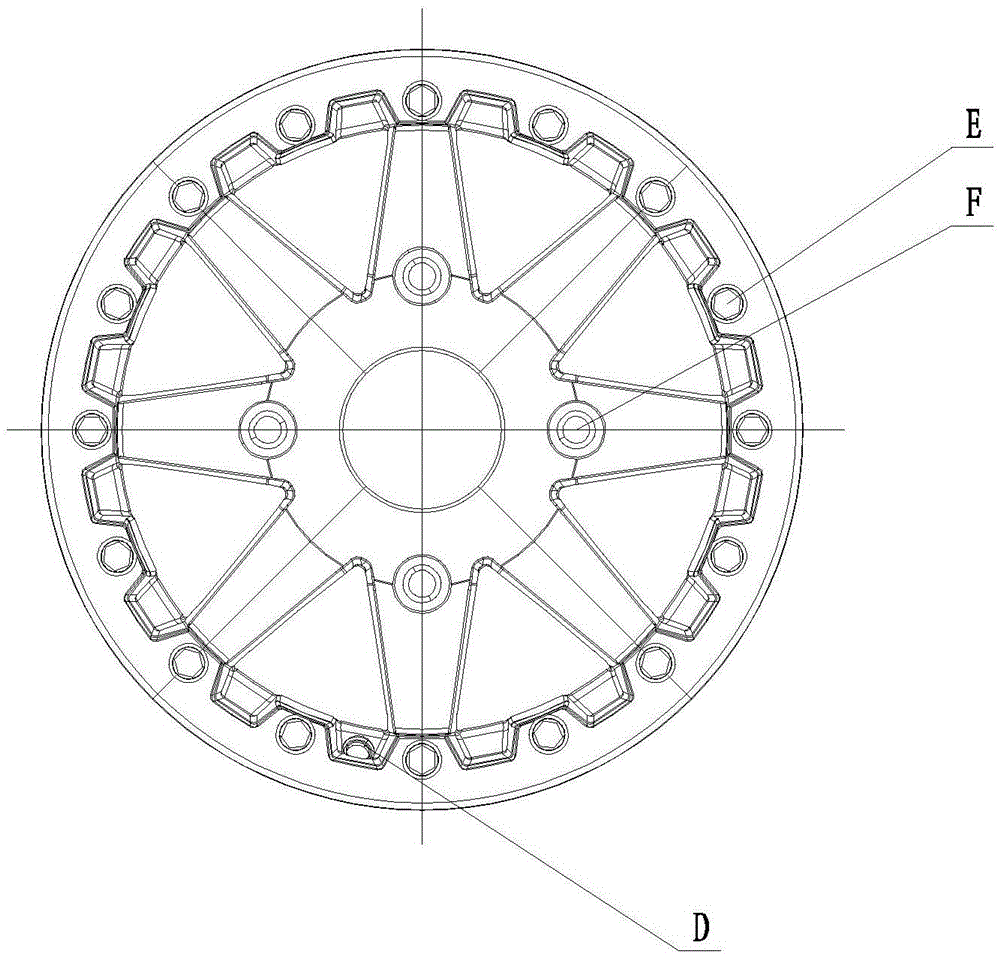

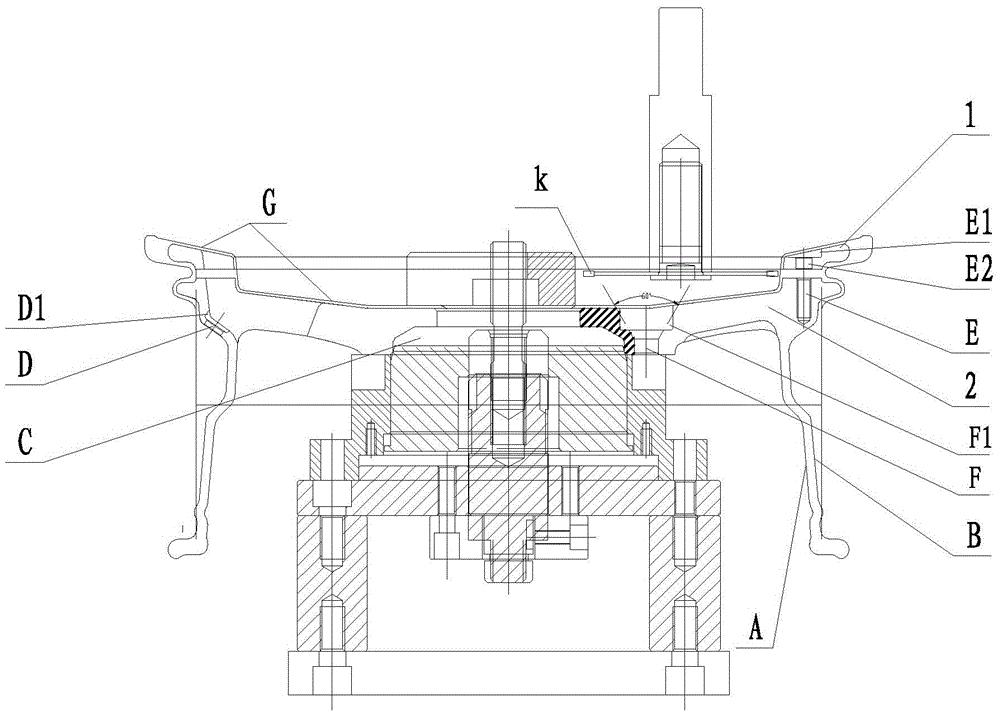

Processing Technology of One-piece Aluminum Wheel Hub and Lock Ring

A processing technology, an integrated technology, applied in the field of wheel manufacturing, can solve the problems of inability to cut, the lock ring is thrown off, and the production cost of the lock ring is very expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A processing technique for an integrated aluminum wheel hub and a lock ring, comprising the following process steps:

[0022] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 720°C, the time is 2 hours, and the temperature of the heat preservation room is 800°C;

[0023] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 700°C, the time is 30 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 5°C. The cooling time is 120 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 250 seconds;

[0024] (3) Heat treatment: first solid solution treat the one-piece blank at 535°C for 6.5 hours, put it in 60°C water for 3 minutes within 30 seconds after solution treatmen...

Embodiment 2

[0031] Embodiment 2: A processing technology for an integrated aluminum wheel hub and a lock ring, including the following process steps:

[0032] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 740°C, the time is 1 hour, and the temperature of the heat preservation room is 950°C;

[0033] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 720°C, the time is 20 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 15°C. The cooling time is 150 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 320 seconds;

[0034] (3) Heat treatment: first solid solution treat the one-piece blank at 545°C for 5.5 hours, put it in 90°C water for 5 minutes within 30 seconds after solution treatmen...

Embodiment 3

[0041] Embodiment 3: A processing technology for an integrated aluminum wheel hub and a lock ring, including the following process steps:

[0042] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 730°C, the time is 1.5 hours, and the temperature of the heat preservation room is 900°C;

[0043] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 710°C, the time is 25 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 10°C. The cooling time is 130 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 300 seconds;

[0044] (3) Heat treatment: first solid solution treat the one-piece blank at 540°C for 6 hours, put it in 80°C water for 4 minutes within 30 seconds after solution treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com