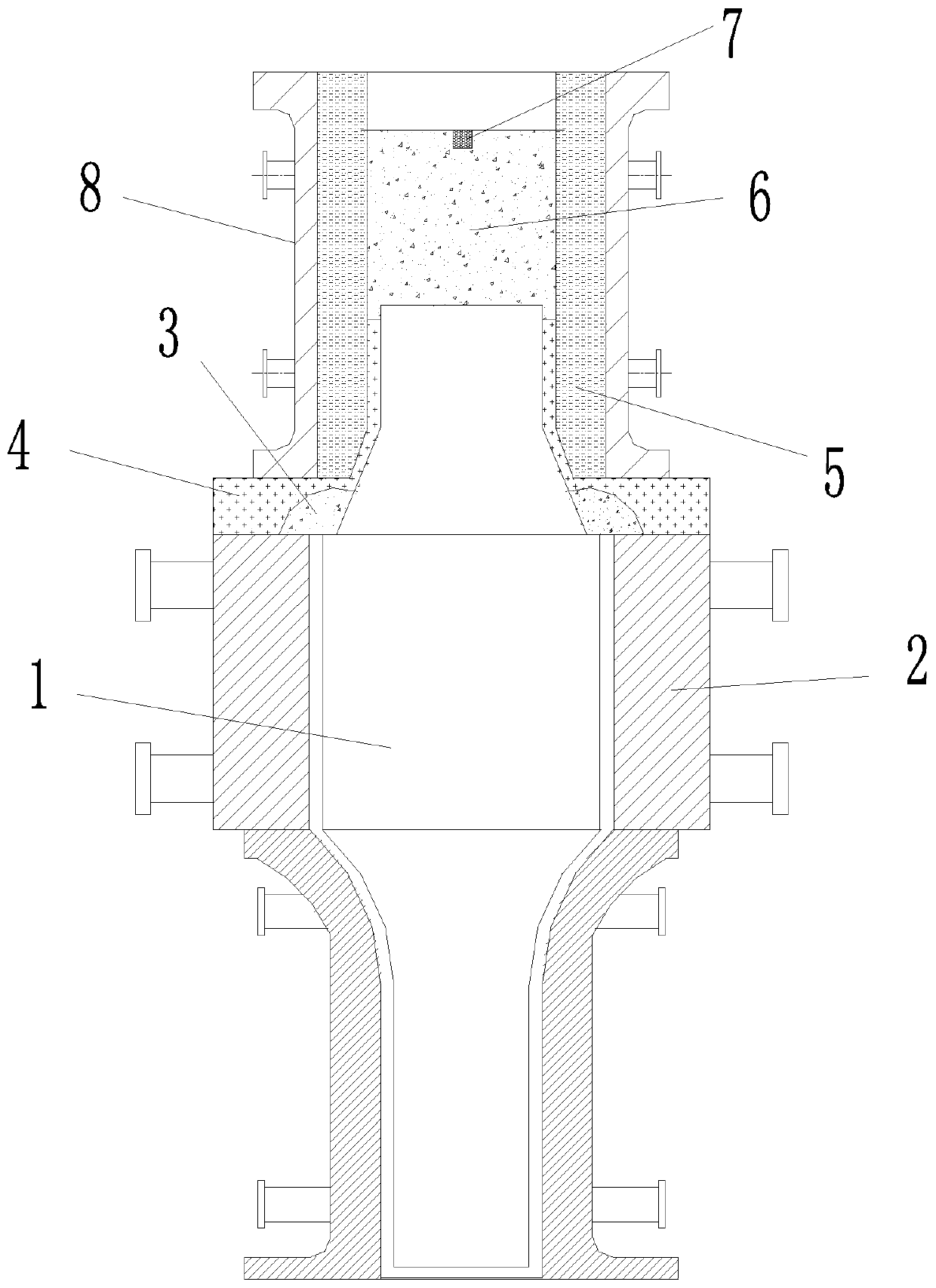

Cast steel roller thermal connection device and using method thereof

A cast steel roll and roll technology are applied in the field of cast steel roll heat splicing devices, which can solve the problems of inappropriate roll casting size, low strength of welded joints, insufficient loss size, etc., and achieve the same performance, low cost, and dense finished product structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S1. Preheat the rolls to be connected to 280°C and then clean the plane of the rolls to be connected;

[0047] S2. Clamp and fix the end of the roll to be connected with a fixing piece, then fix the mold at the position to be connected to form a cavity to be connected, fill the cavity to be connected with dry sand, and lay horizontally on the upper layer of the dry sand Water glass 70 sand and blow carbon dioxide to harden;

[0048] S3. Fill the thermal bonding material into the cavity to be connected, and set the ignition material in the thermal bonding material, wherein the component content of the thermal bonding material is: 18 grams of aluminum powder, 60 grams of iron oxide powder, 8 grams of Sodium nitrate, 5 grams of lime, 8 grams of fluorite; the composition content of the ignition material is 3 grams of aluminum powder and 6 grams of sodium nitrate.

[0049] S4. Ignite the ignition material and perform the ignition operation. After the thermal bonding reactio...

Embodiment 2

[0051] Using the same method as in Example 1, the difference is that the preheating temperature of the roll to be joined is 260° C., and the temperature of the molten steel is 1450° C., to obtain a new roll A2 after thermal bonding.

Embodiment 3

[0053] Using the same method as in Example 1, the difference is that the preheating temperature of the rolls to be joined is 300° C., and the temperature of molten steel is 1520° C. to obtain a new roll A3 after thermal bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com