Self-pressing mechanism based on multi-stage pressure control system of air cylinder

A technology of this pressure mechanism and pressure control, applied in the field of automation, can solve the problems of powerless sensor detection, inconvenient operation, and difficult observation, etc., and achieve the effects of easy production efficiency, good control and adjustment, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: the concrete structure of the present invention is as follows:

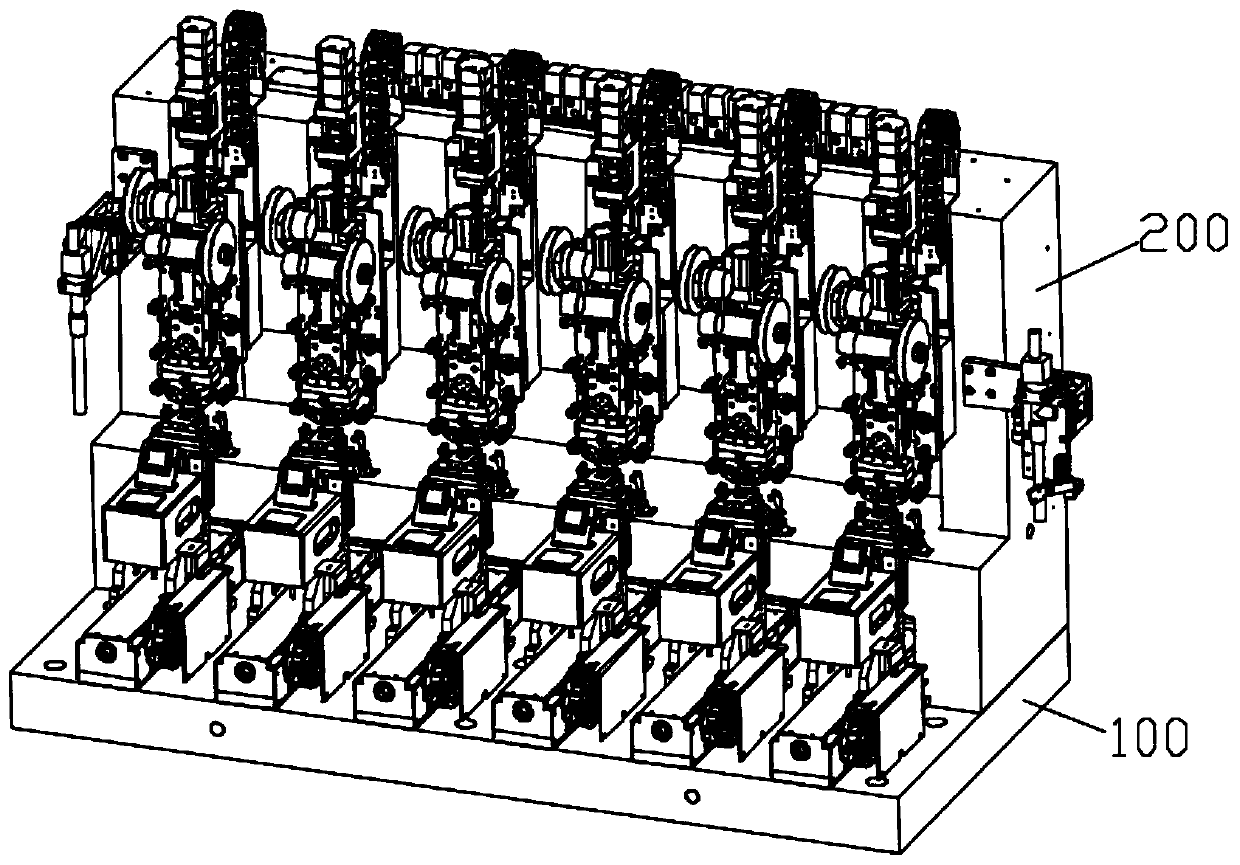

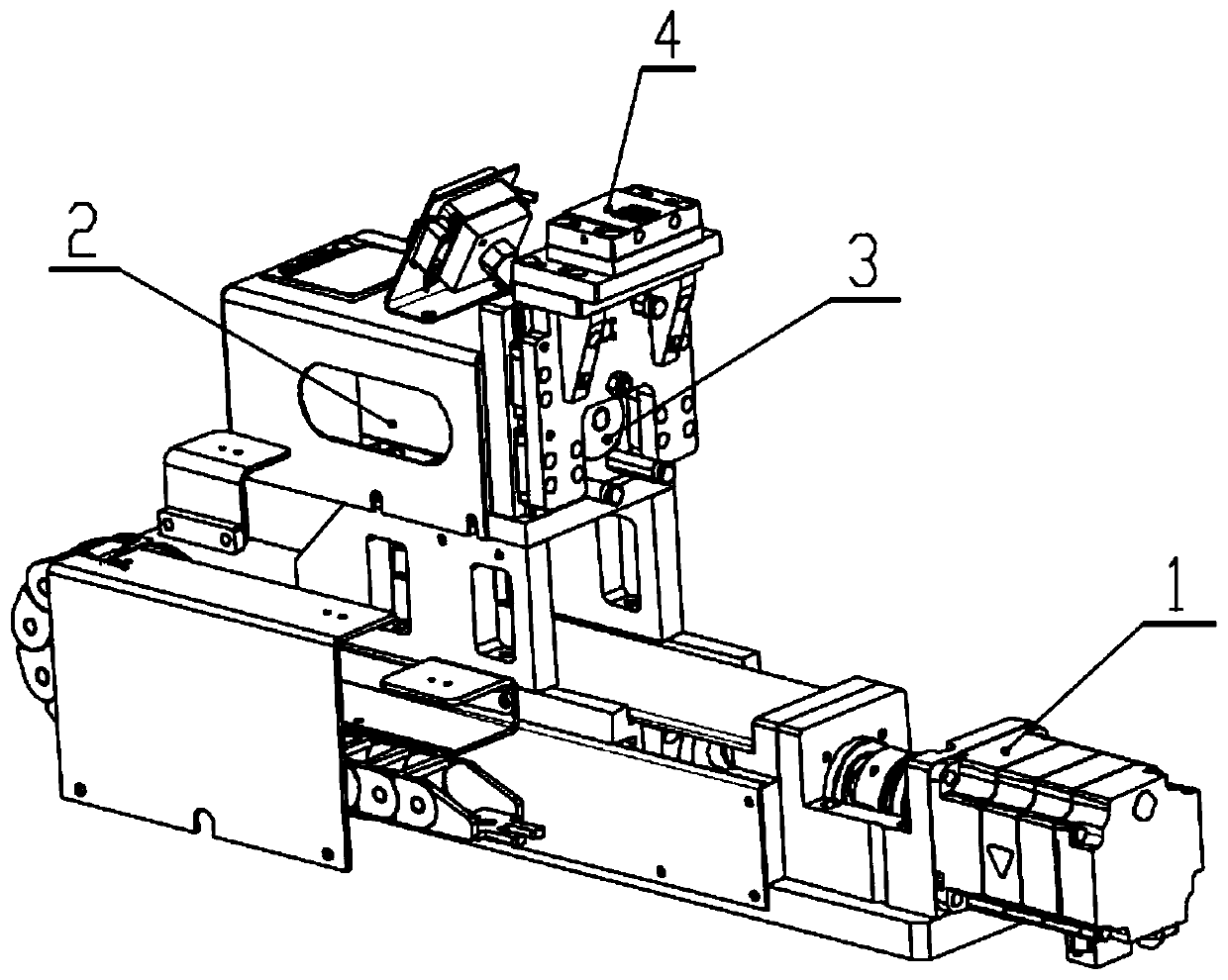

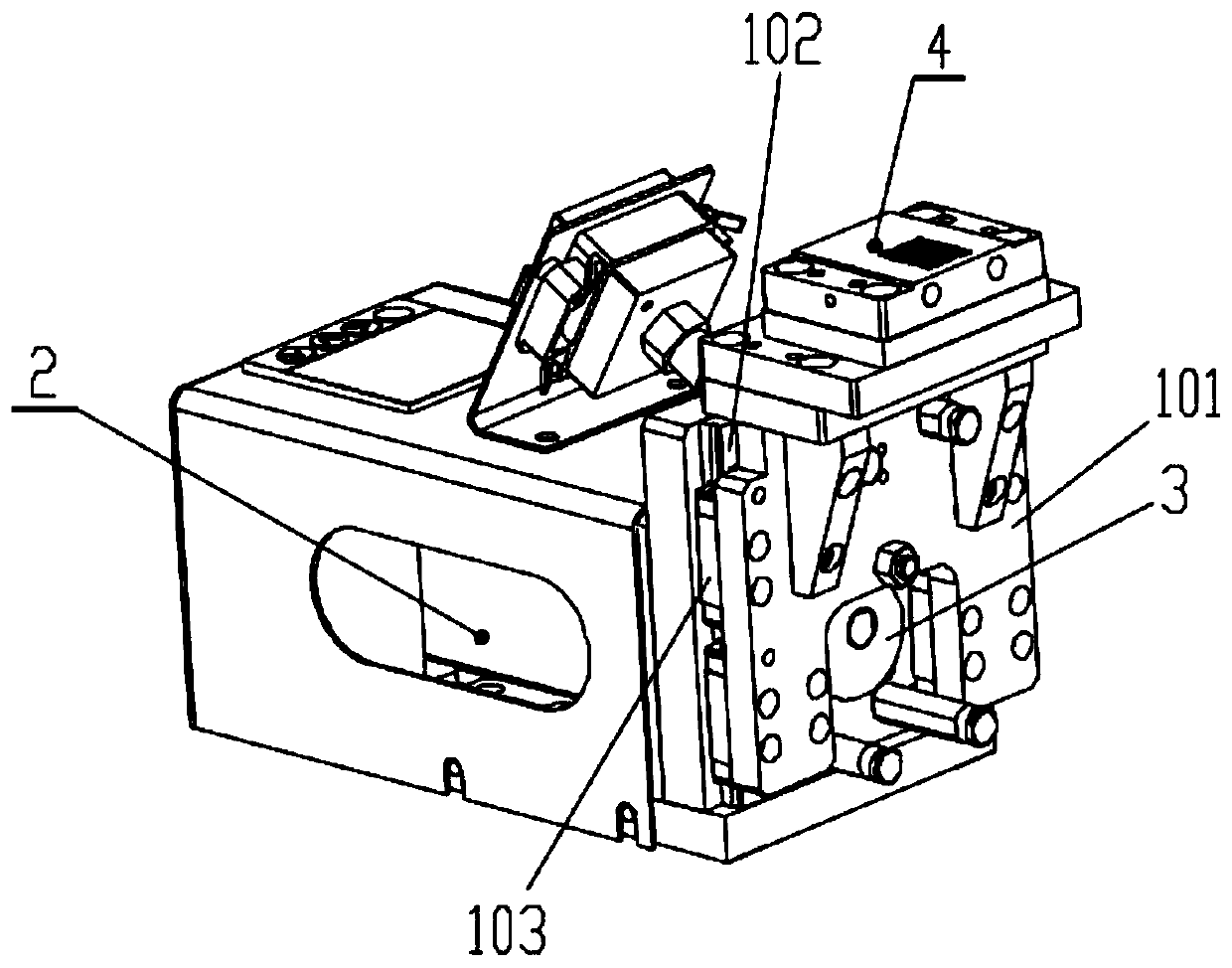

[0046] Please refer to the attached Figure 1-8 , a local pressure mechanism based on a multi-stage pressure control system of a cylinder of the present invention includes an installation assembly and a plurality of groups of local pressure mechanism units installed side by side on the installation assembly, and the installation assembly includes an installation base plate 100 and a The installation vertical plate 200 with a stepped installation position on one side of the upper plate surface of the installation base plate, the installation seat composed of the installation base plate 100 and the installation vertical plate 200 can be installed with at least one local pressure mechanism unit, and the local pressure mechanism unit includes:

[0047]The present pressing platform assembly installed on the mounting base plate 100 includes a platform plate 4 for carrying products, a first Z-axis m...

Embodiment 2

[0075] like Figure 1-8 As shown, the product to be pressed is placed on the platform plate 4, the platform plate 4 opens the vacuum to suck the product, and transports the product to the bottom of the upper indenter through the Y-axis drive mechanism 1, the Y-axis drive mechanism 1 and the first Z The shaft drive mechanism automatically adjusts the position and height of the product.

[0076] Adjust the platform plate 4 to be parallel to the end face of the lower indenter 7. According to the requirements of the temperature and force required by the product, the pulse heating system automatically adjusts the temperature of the upper indenter 18 and the lower indenter 7, and the upper indenter 18 is lowered. The pressure force is constantly detected by the pressure sensor 13, and the pressure sensor 13 constantly feeds back the force situation to the system, and the system automatically adjusts the force of the downward pressure to carry out the original pressure on the product...

Embodiment 3

[0078] The local pressing mechanism based on the cylinder multi-stage pressure control system of the present invention uses the pressure sensor 13 to constantly detect the force exerted on the product when the upper indenter 18 is pressed down, and the stroke control is composed of a servo motor screw and a cylinder, which is convenient for the upper indenter to lower the product. Compression enables stroke and force control. The buffer material feeding structure and buffer material receiving structure are placed above, and the structure is simple. The structure of the guide wheel is used to place the buffer belt above the pressing part of the product. , the upper indenter 18 acts as a buffer for the product when it is pressed down.

[0079] The lower indenter fixing block 6 for installing the lower indenter 7 and the upper indenter fixing block 16 for installing the upper indenter 18 are both made of brass and gold-plated, and the material of the lower indenter 7 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com