Processing technology of integrated aluminum wheel hub and lock ring

A processing technology, integrated technology, applied in the field of wheel manufacturing, can solve problems such as normal production, high cost of lock ring production, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

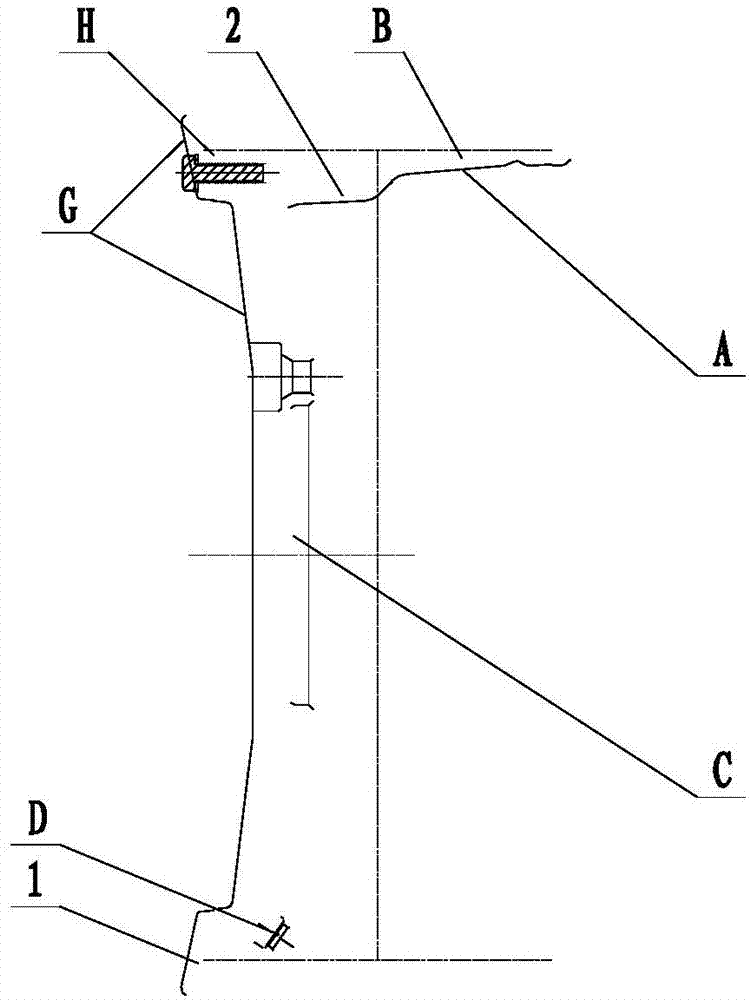

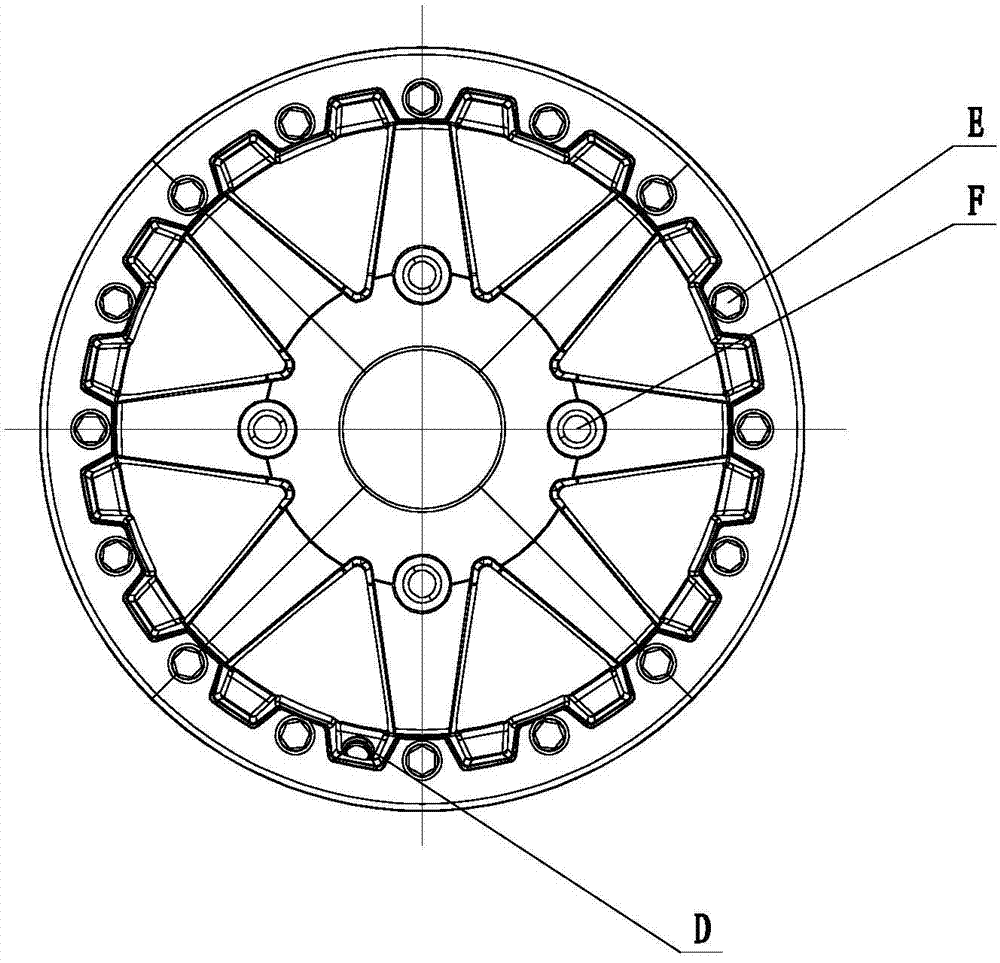

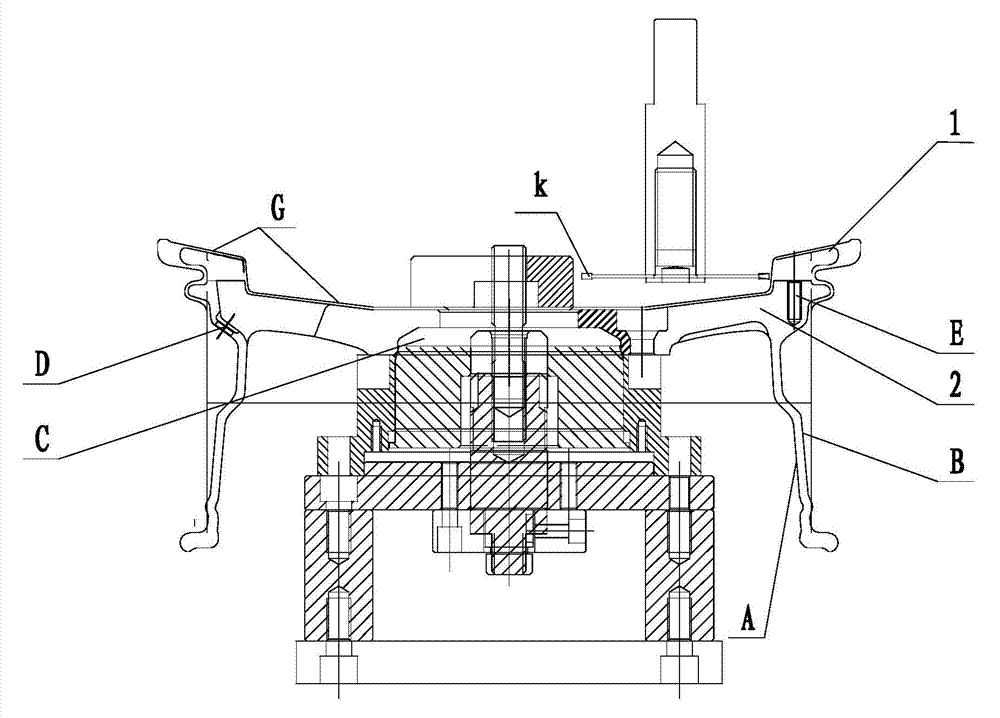

[0021] Embodiment 1: A processing technique for an integrated aluminum wheel hub and a lock ring, comprising the following process steps:

[0022] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 720°C, the time is 2 hours, and the temperature of the heat preservation room is 800°C;

[0023] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 700°C, the time is 30 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 5°C. The cooling time is 120 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 250 seconds;

[0024] (3) Heat treatment: first solid solution treat the one-piece blank at 535°C for 6.5 hours, put it in 60°C water for 3 minutes within 30 seconds after solution treatmen...

Embodiment 2

[0031] Embodiment 2: A processing technology for an integrated aluminum wheel hub and a lock ring, including the following process steps:

[0032] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 740°C, the time is 1 hour, and the temperature of the heat preservation room is 950°C;

[0033] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 720°C, the time is 20 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 15°C. The cooling time is 150 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 320 seconds;

[0034] (3) Heat treatment: first solid solution treat the one-piece blank at 545°C for 5.5 hours, put it in 90°C water for 5 minutes within 30 seconds after solution treatmen...

Embodiment 3

[0041] Embodiment 3: A processing technology for an integrated aluminum wheel hub and a lock ring, including the following process steps:

[0042] (1) Melting: A356.2 aluminum alloy ingots are smelted to obtain molten aluminum, which is stored in a heat preservation room; the melting temperature is 730°C, the time is 1.5 hours, and the temperature of the heat preservation room is 900°C;

[0043] (2) After refining and degassing the molten aluminum, cast it into a heated metal mold to obtain an integrated blank; the casting temperature is 710°C, the time is 25 seconds, the cooling method is water mist cooling or air cooling, and the cooling temperature is 10°C. The cooling time is 130 seconds; demoulding after natural cooling, the total time from casting to demoulding of the integrated blank is 300 seconds;

[0044] (3) Heat treatment: first solid solution treat the one-piece blank at 540°C for 6 hours, put it in 80°C water for 4 minutes within 30 seconds after solution treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com