Patents

Literature

201results about How to "Position unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

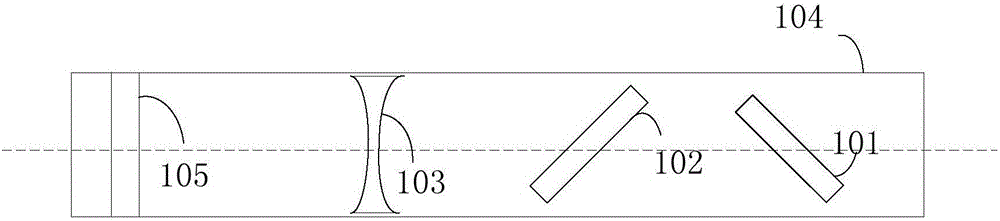

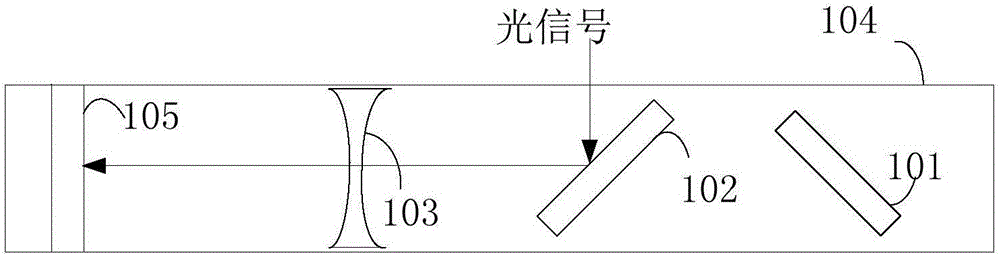

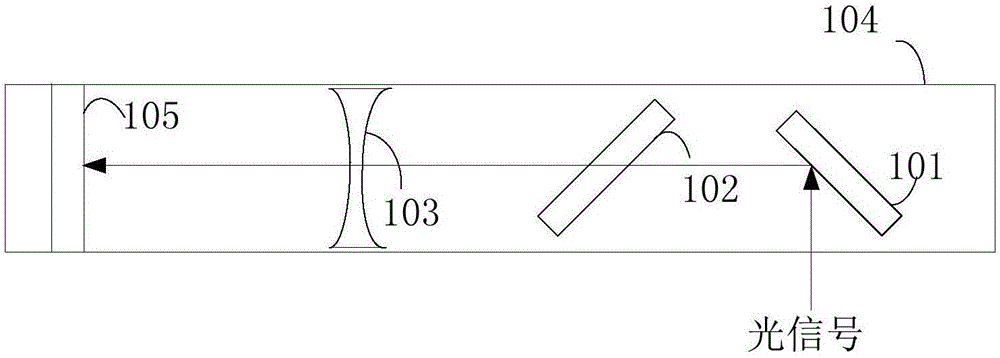

Camera module and terminal device

ActiveCN106550181ASmall footprintSmall sizeTelevision system detailsMirrorsOptical axisTerminal equipment

The invention discloses a camera module and a terminal device, and belongs to the technical field of electronics. The camera module comprises a rotatable reflector, a lens group, a shell and an image sensor; the shell comprises a first surface and a second surface; a first mirror surface of the rotatable reflector is a reflecting surface, and a part of the first mirror surface located in a first reflecting area is a first sub mirror surface; when the rotatable reflector is located at a first position, the first mirror surface reflects a first light signal, an image is generated after the reflected first light signal is transmitted along a straight line where an optical axis is located, when the rotatable reflector is located at a second position, the first mirror surface reflects a second light signal, and an image is generated after the reflected second light signal is transmitted along the straight line where the optical axis is located. According to the camera module provided by the embodiment of the invention, the function of double-channel shooting is realized by using just one rotatable reflector, thereby reducing the number of reflectors, shortening the size and saving the occupied space.

Owner:HUAWEI MACHINERY

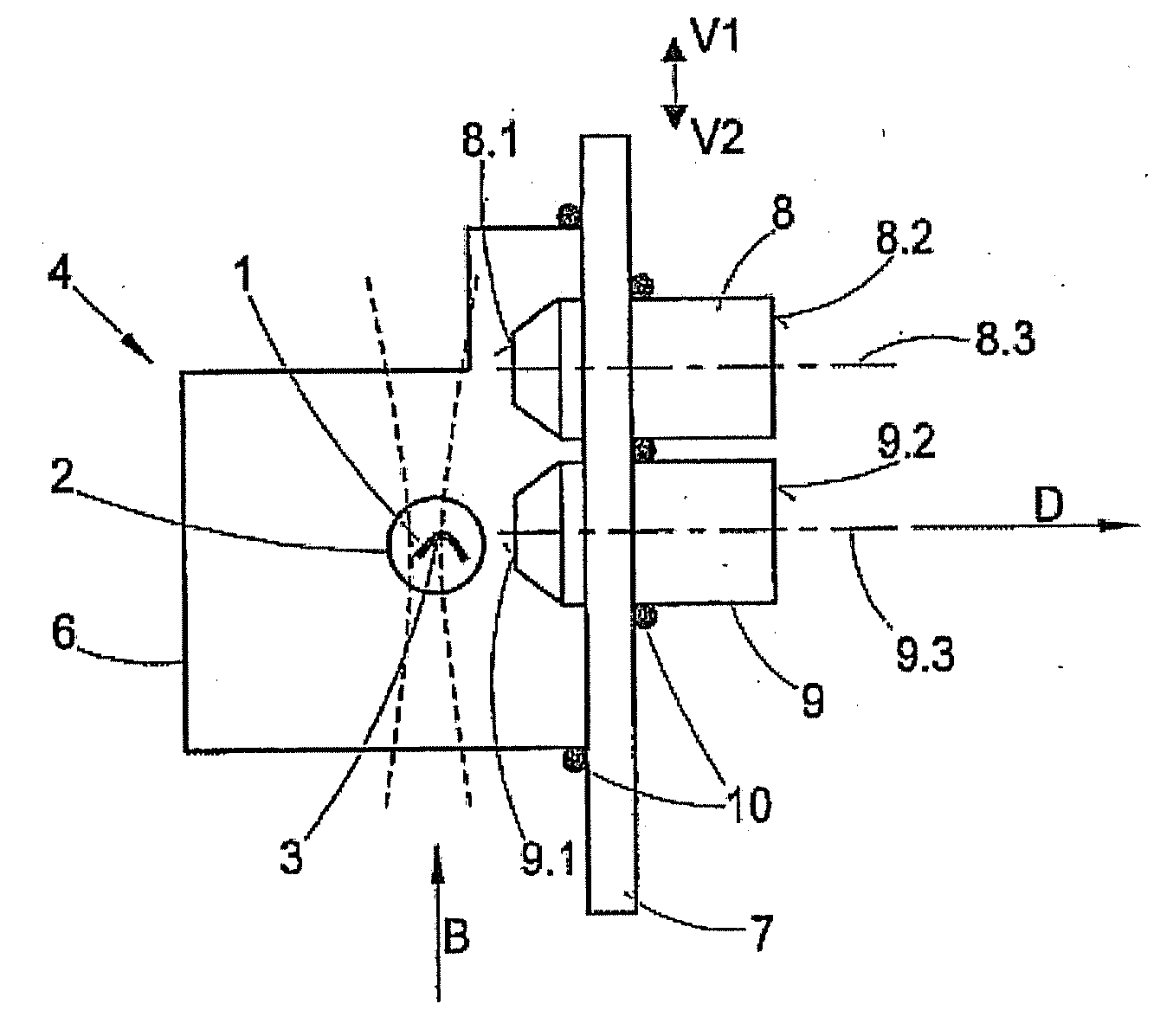

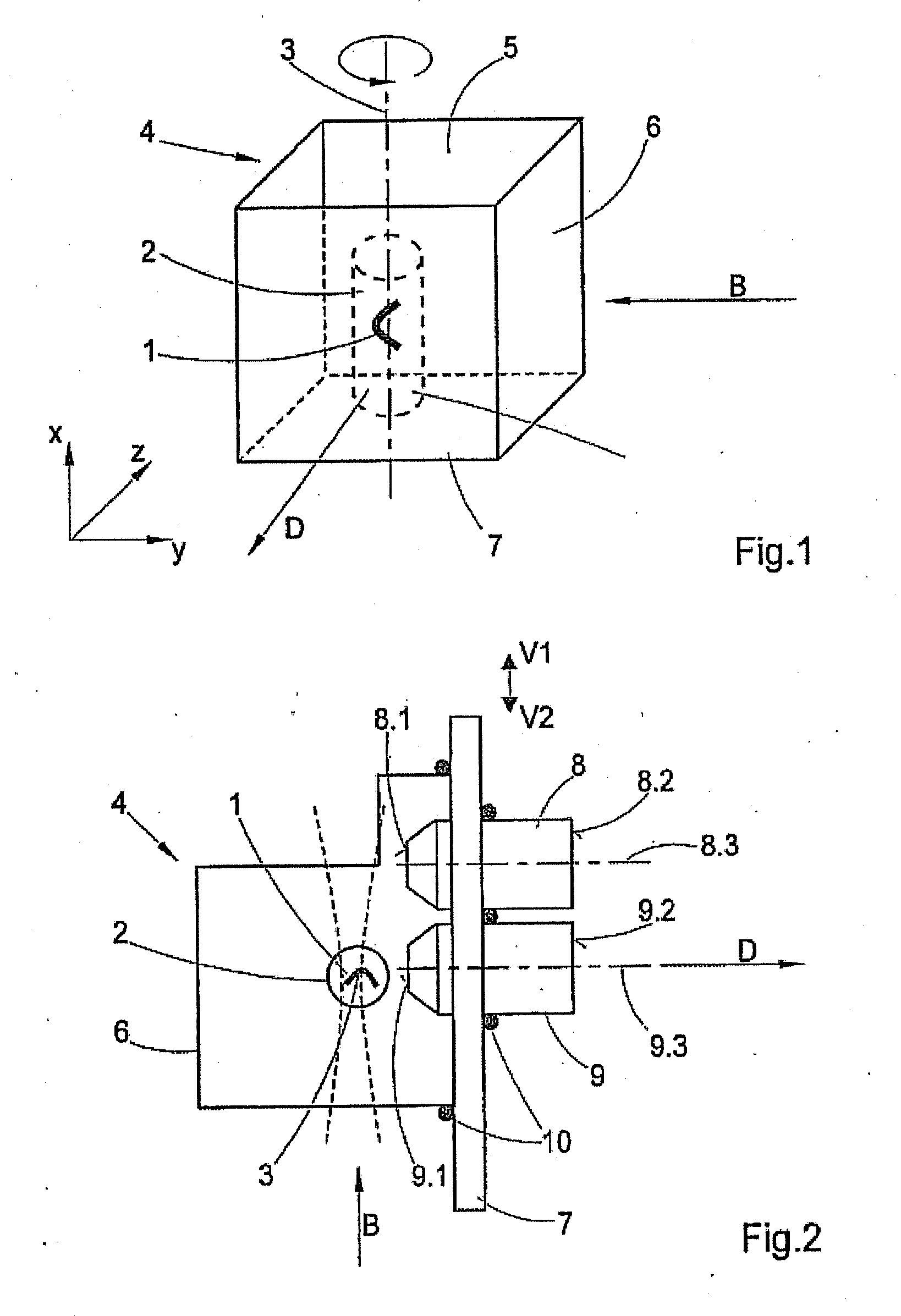

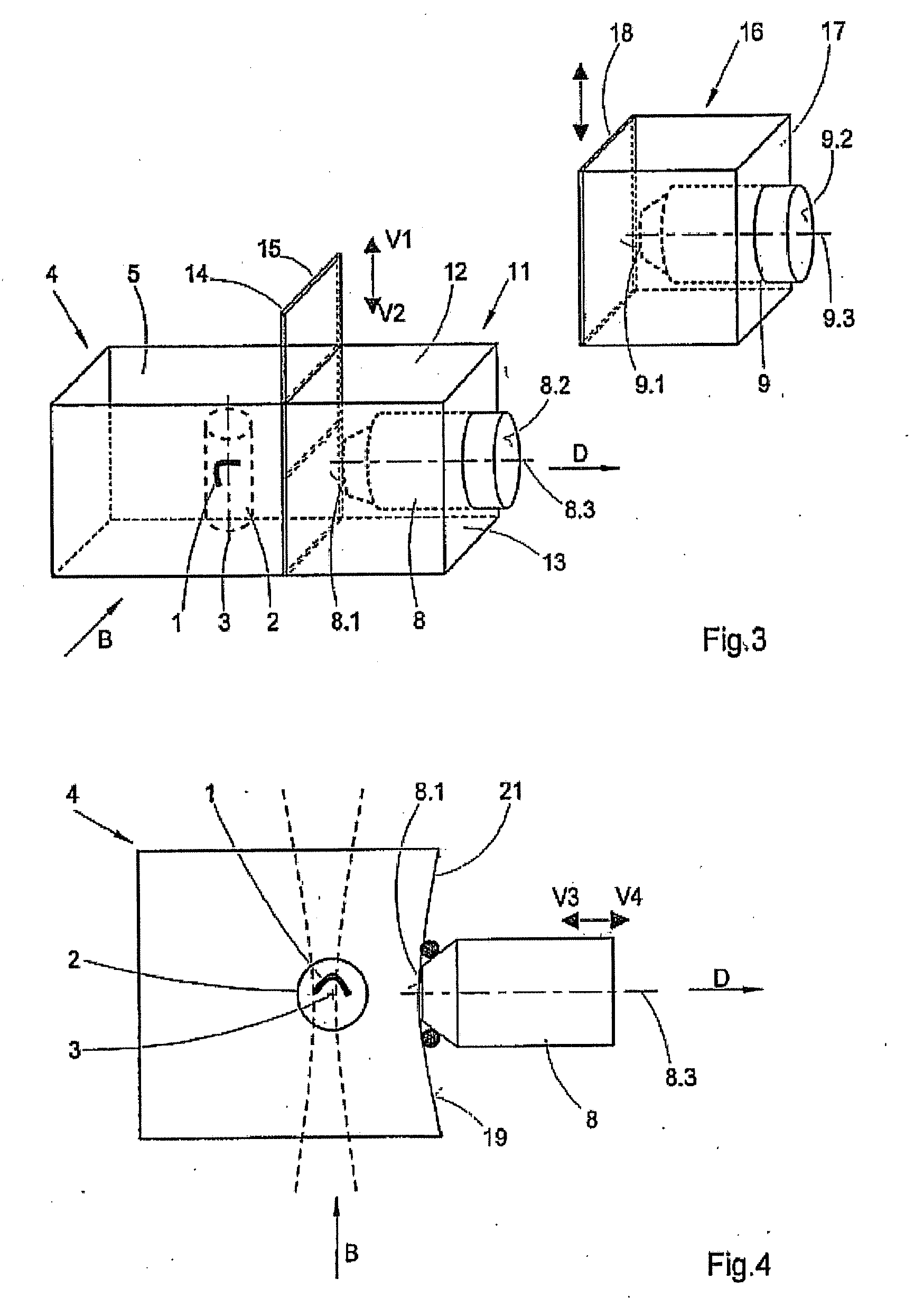

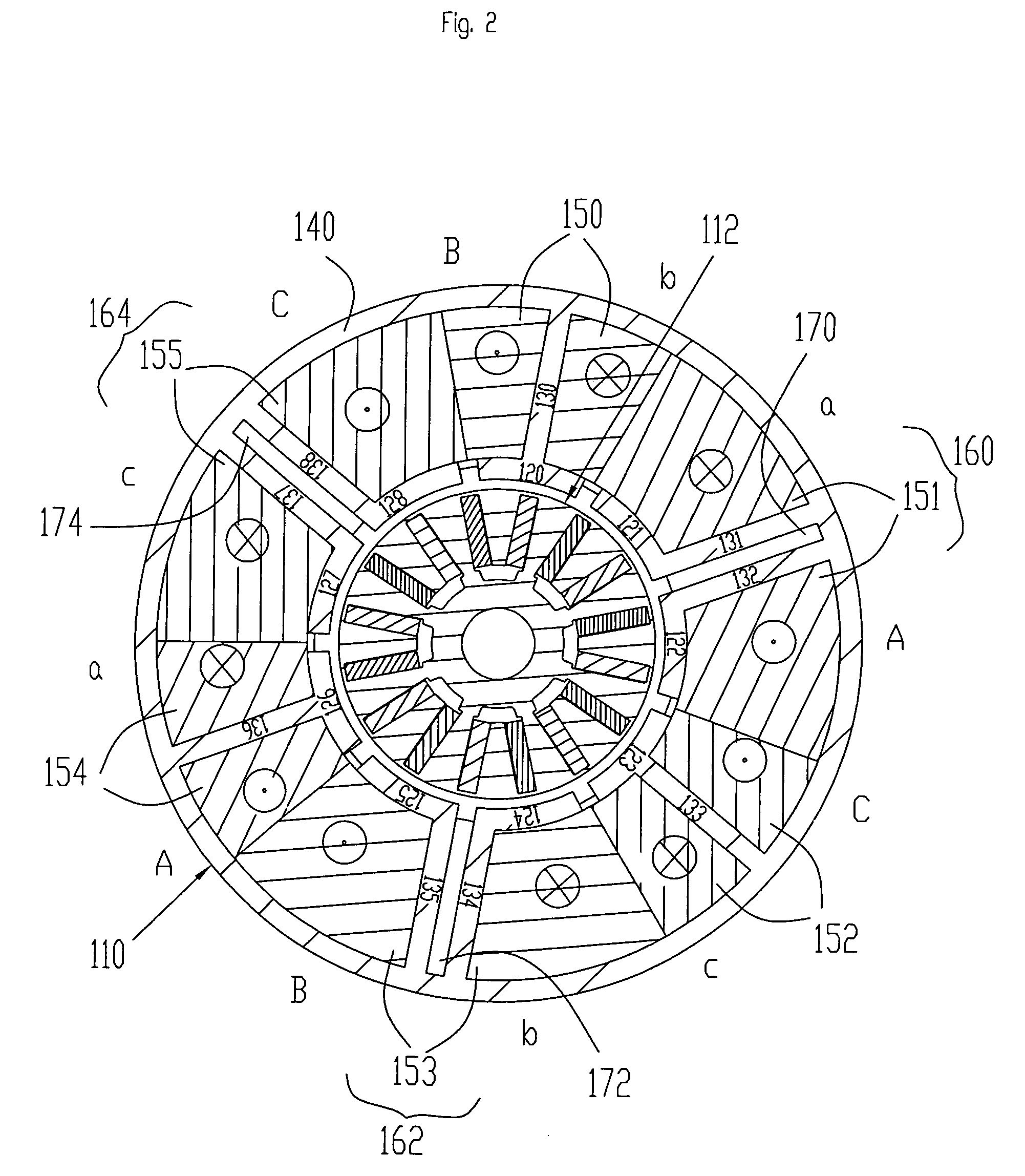

Objective replacement device for microscopes

ActiveUS20100134881A1Easy to changeShort timeMaterial analysis by optical meansMicroscopesLight beamGravitation

The invention relates to an objective replacement device for a microscope, wherein the sample is located in a sample chamber and surrounded by an immersion medium within the sample chamber, means for positioning and aligning the sample relative to the focus of an objective being present, wherein the detection beam path is aligned horizontally, which is to say perpendicular to the direction of action of gravity. For an objective replacement device for a microscope of the type described above, according to the invention a device is provided for exchanging the objective, at the focus of which the sample is positioned and aligned, with at least another objective, the position and alignment of the sample within the sample chamber remaining the same.

Owner:CARL ZEISS MICROSCOPY GMBH

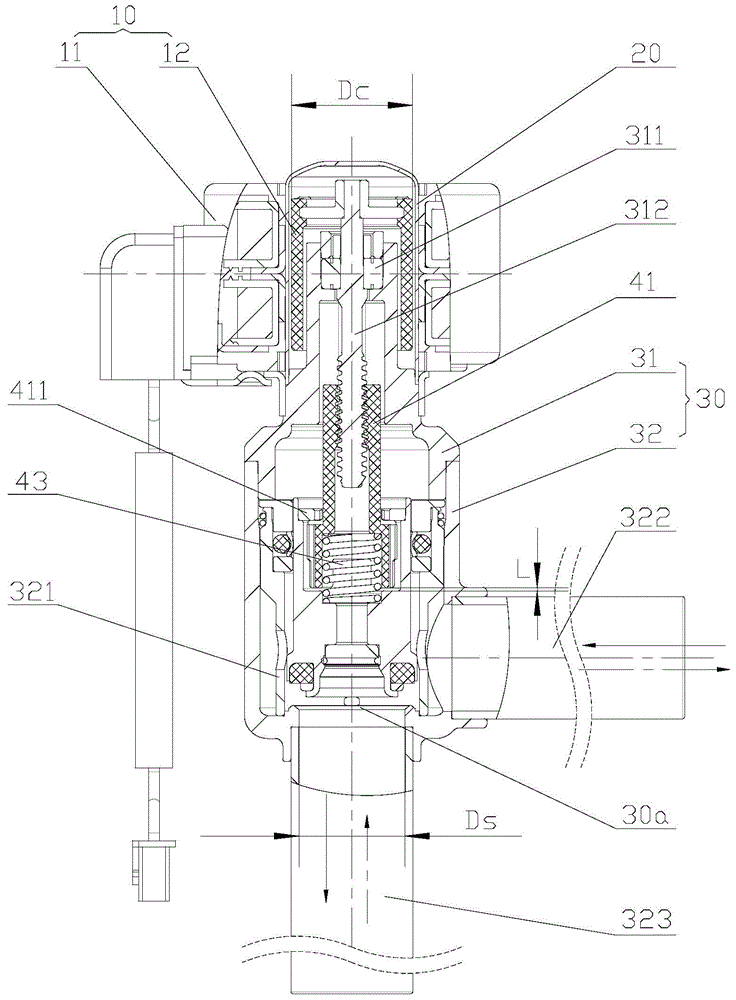

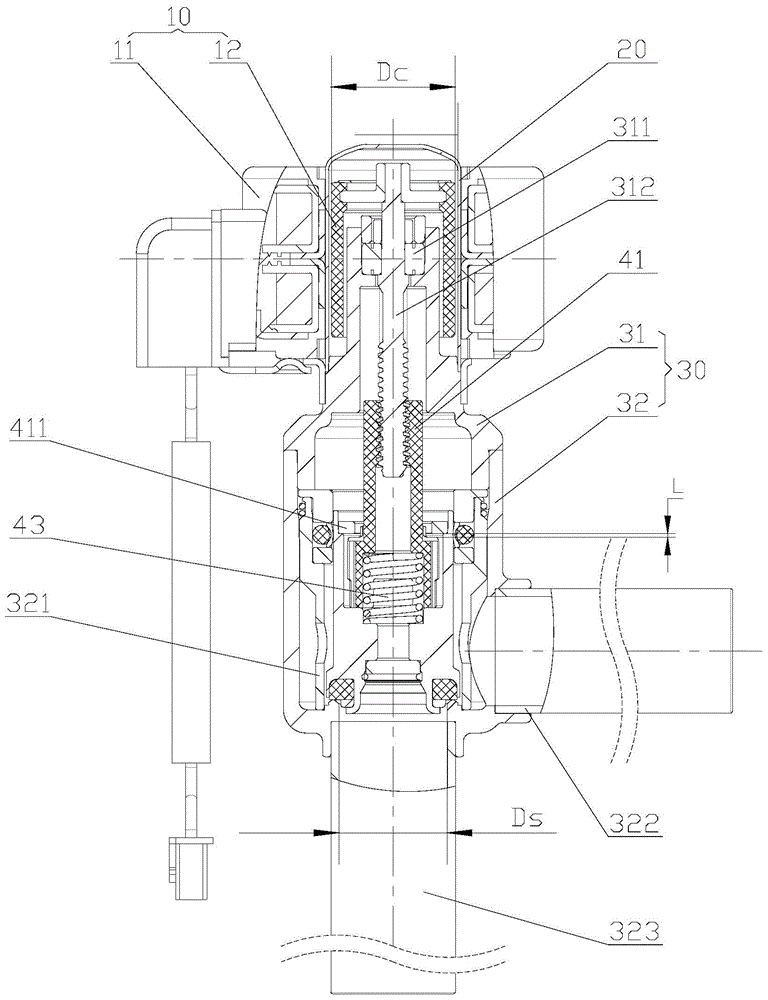

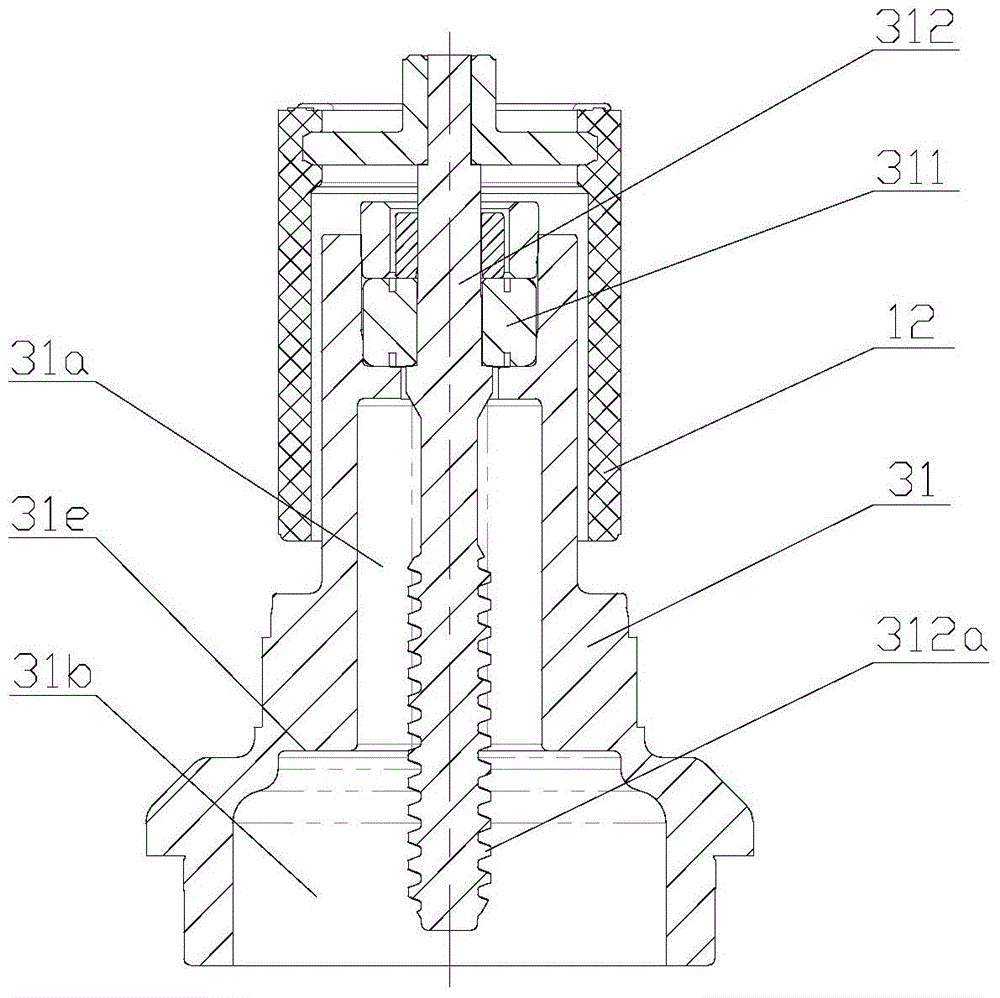

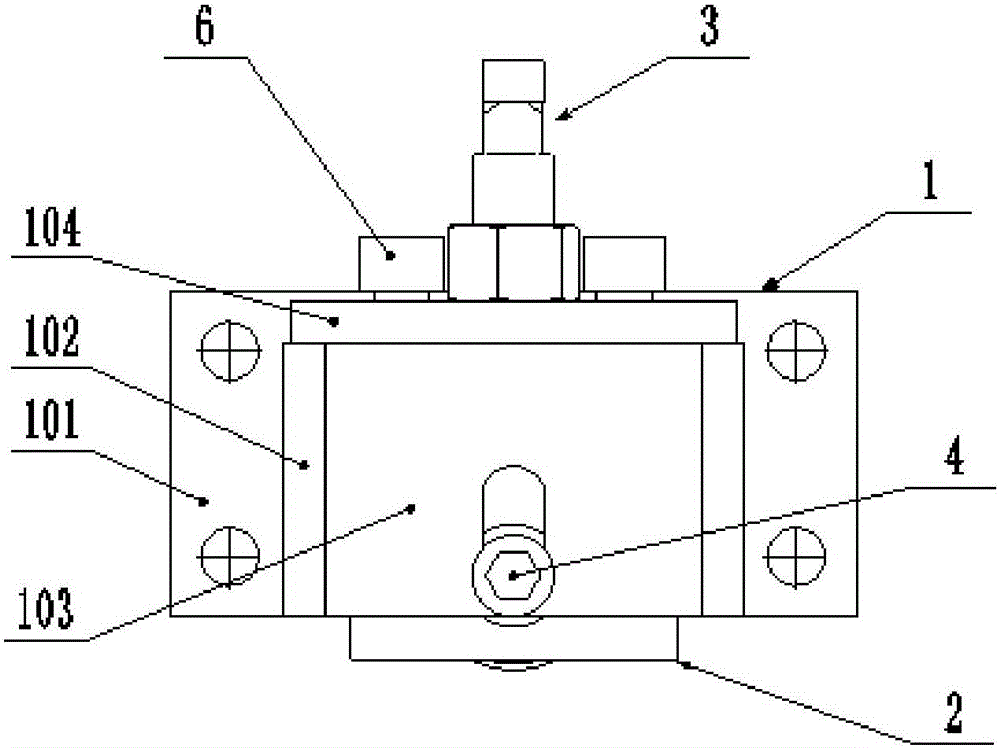

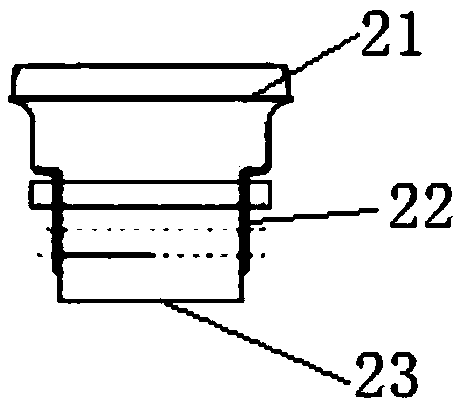

Direct acting electric valve

InactiveCN104791497APosition unchangedPrevent leakageOperating means/releasing devices for valvesLift valveScrew threadVALVE PORT

The invention discloses a direct acting electric valve. The direct acting electric valve comprises a valve base having a valve cavity, a motor arranged at the upper end of the valve base, and a lead screw, wherein a rotor of the motor is relatively fixed with the axial position of the valve base; the upper end of the lead screw is fixedly connected with the rotor; the lead screw is connected with a nut in a thread fit manner; the nut is connected with a valve core; the valve core is driven by the nut to axially move to open or close a valve port formed in the valve base; a spring is arranged between the nut and the valve core; the valve core is located in a total closing state; the valve core is tightly sealed with the valve port under the effect of the spring; and the lower end of the nut is bonded with the valve core. Through the design, when the failure of the axial locking force transferred to the nut and the valve core by the motor through the lead screw due to the slippage of transmission threads of the lead screw and the nut caused by vibration or other factors is generated, the valve core can be tightly pressed on the valve port through the elastic force of the spring to prevent leakage.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

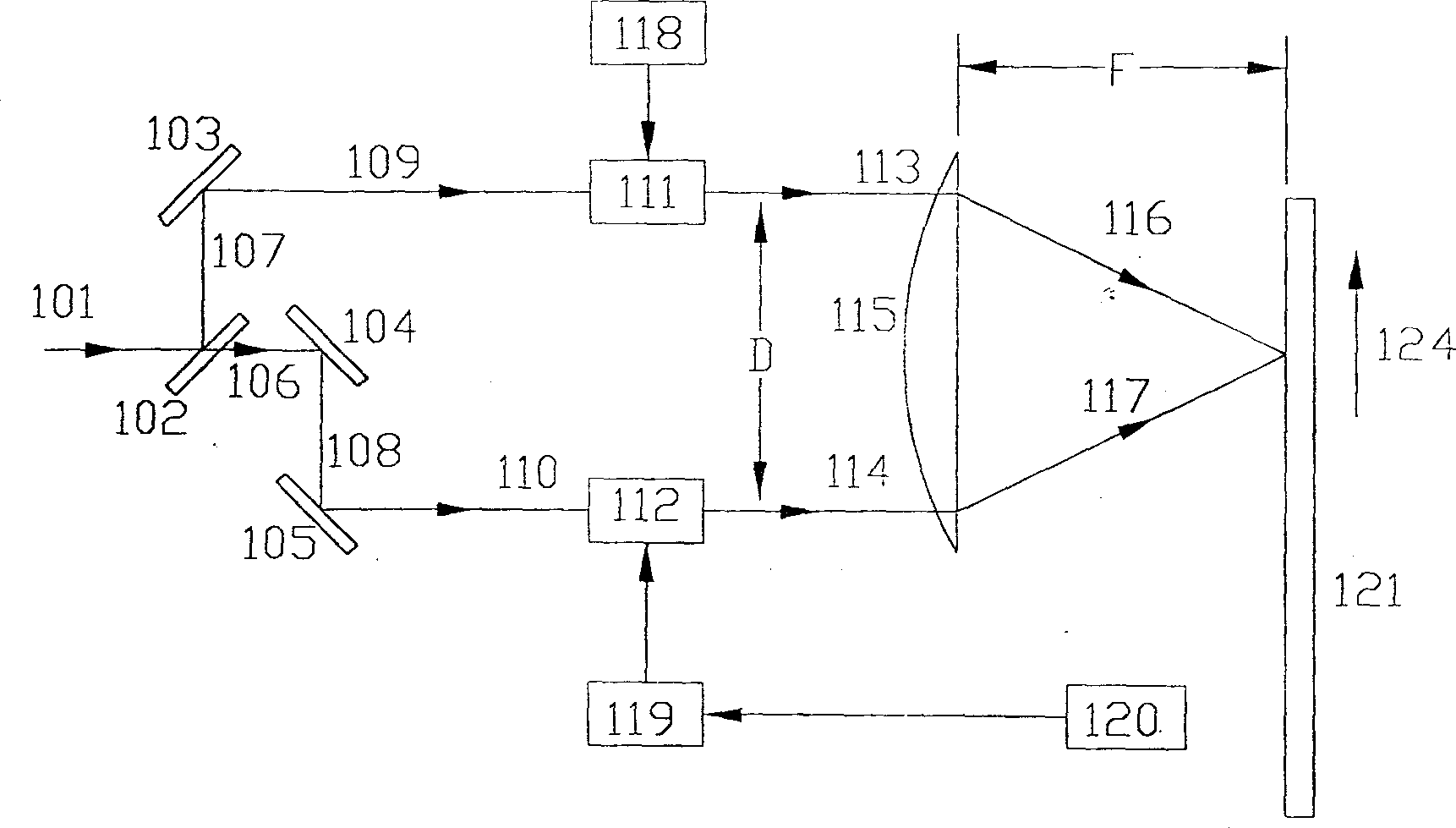

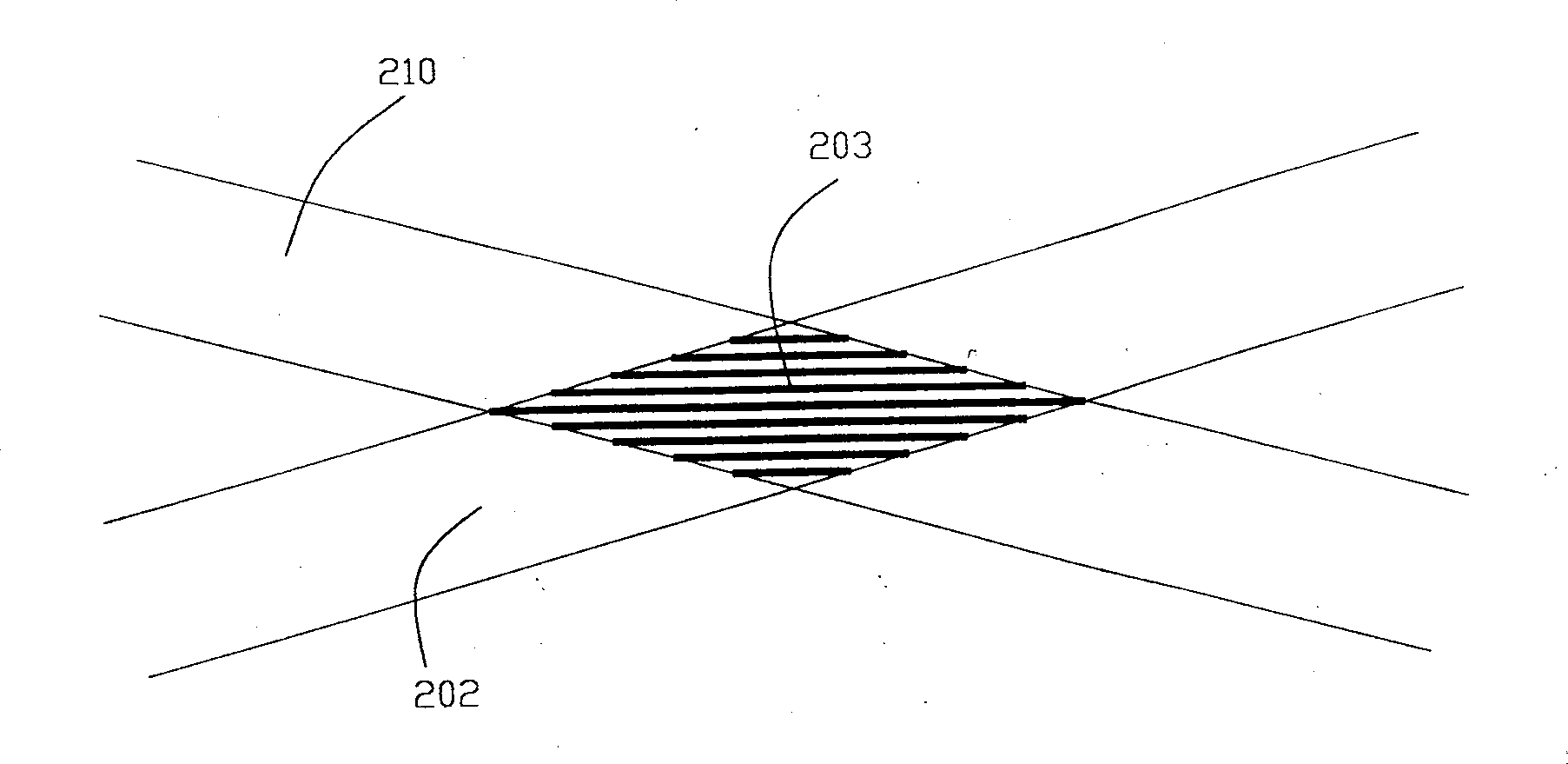

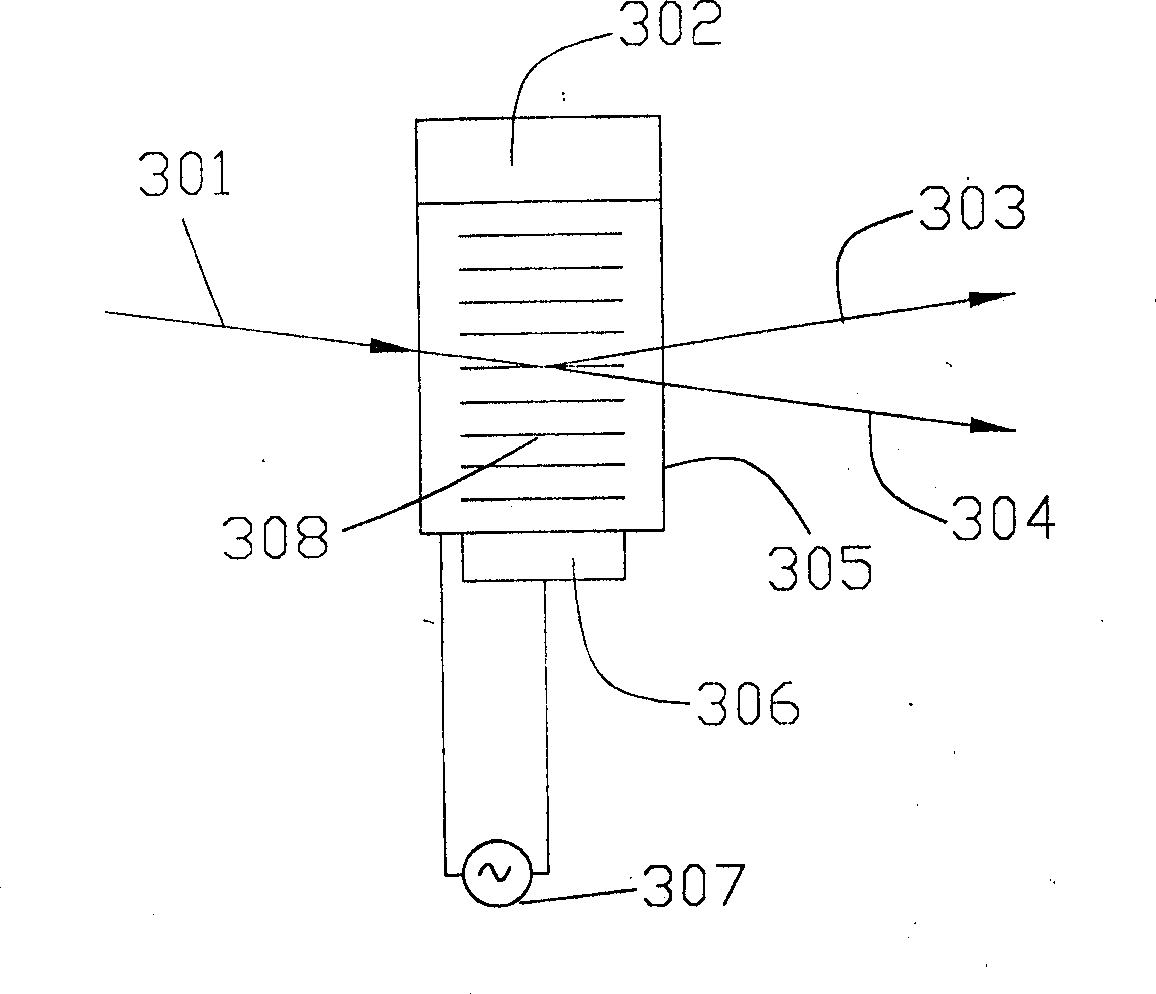

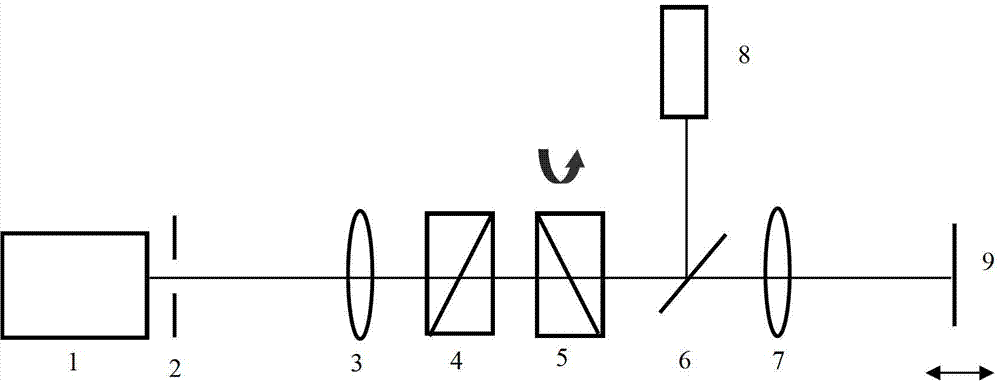

Grating fabricating equipment and process

InactiveCN1371001APosition unchangedLinearDiffraction gratingsOptical light guidesPhase gratingFiber gratings

The present invention relates to the equipment and process for fabricating low-cost precise grating, especially of diffraction grating and various waveguide grating including fiber Bragg grating, andcan generate continuous grating structure and write required fringes directly to fiber or planar waveguide to form Bragg grating, and may be used in fabricating various gratings. Technologically, thepresent invention includes separate frequency shift of two laser beams with equal or near strength, convergence of the laser beams to generate interference fringes, and graving photosensitive medium with the interference fringes while shifting the interference fringers. The present invention can solve the problems of chirp, toe cutting, phase shift and long grating write in grating fabrication.

Owner:李恩林

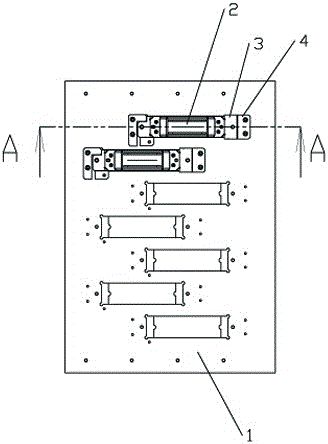

Circuit board welding clamp

InactiveCN101758356APosition unchangedSimple structureWelding/cutting auxillary devicesAuxillary welding devicesLinear motionPush pull

The invention relates to a circuit board welding clamp which comprises a first support, a first clamping block arranged on the first support, a second clamping block oppositely arranged with the first clamping block, a push-pull rod and a driving mechanism for driving the push-pull rod to carry out linear motion, wherein the first clamping block and the first support form a cylindrical motion pair; one end of the push-pull rod is arranged on the driving mechanism, and the second clamping block is arranged at the other end of the push-pull rod, and the other end of the push-pull rod and the second clamping block form a cylindrical motion pair. The circuit board welding clamp has simple structure and convenient operation, accurately positions a plurality of circuit boards by utilizing the first clamping block and the second clamping block and simultaneously can carry out multi-surface welding. The positions among the plurality of circuit boards can be kept unchanged in the whole welding process, thereby improving the production efficiency and the improving the welding accuracy.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

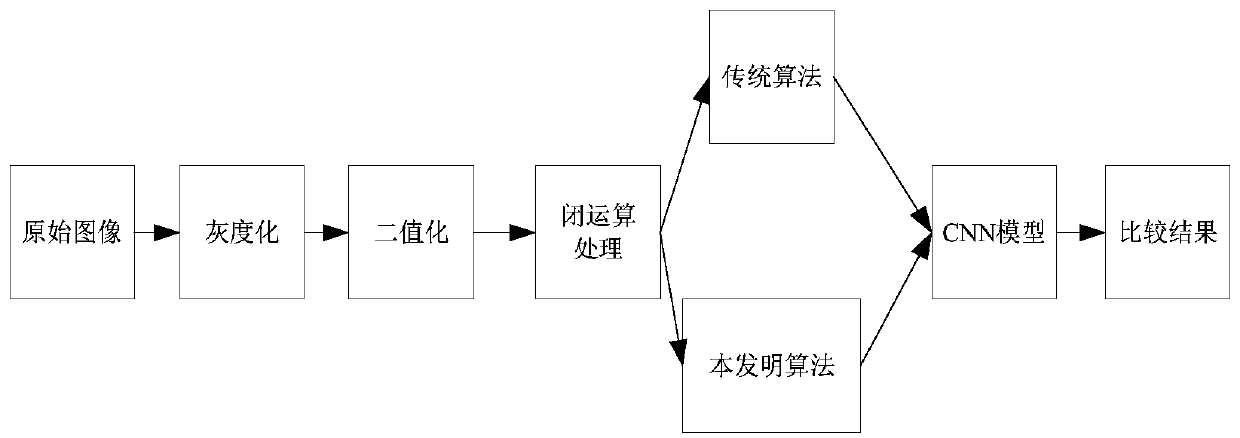

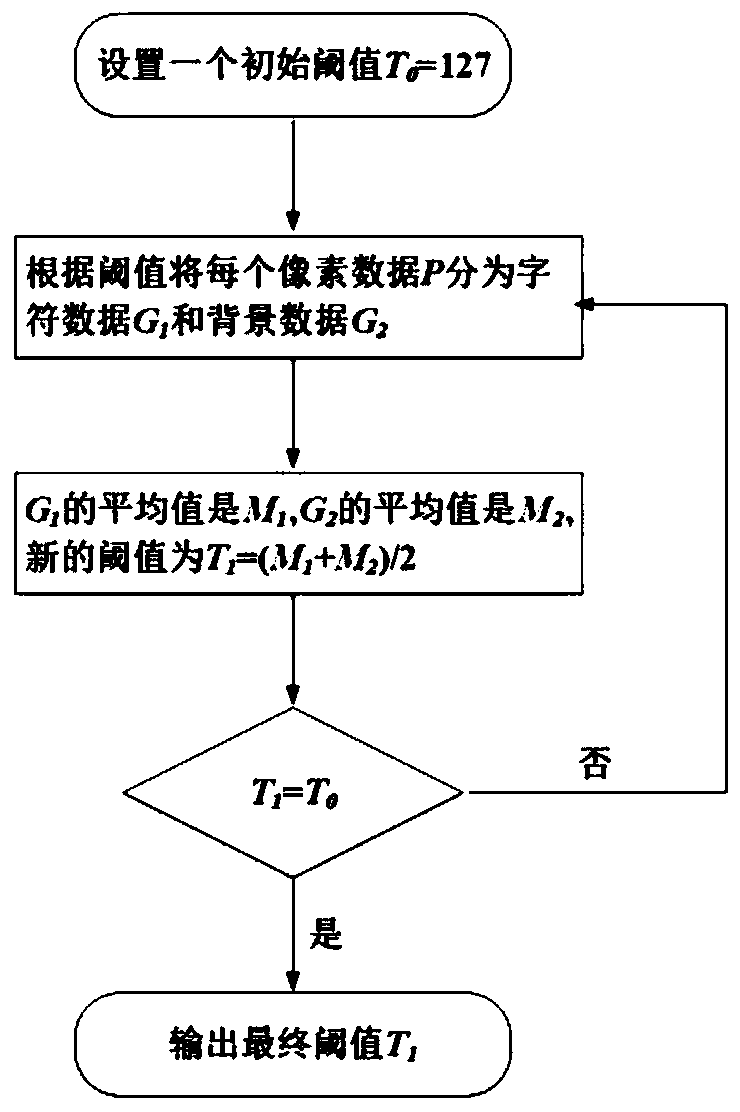

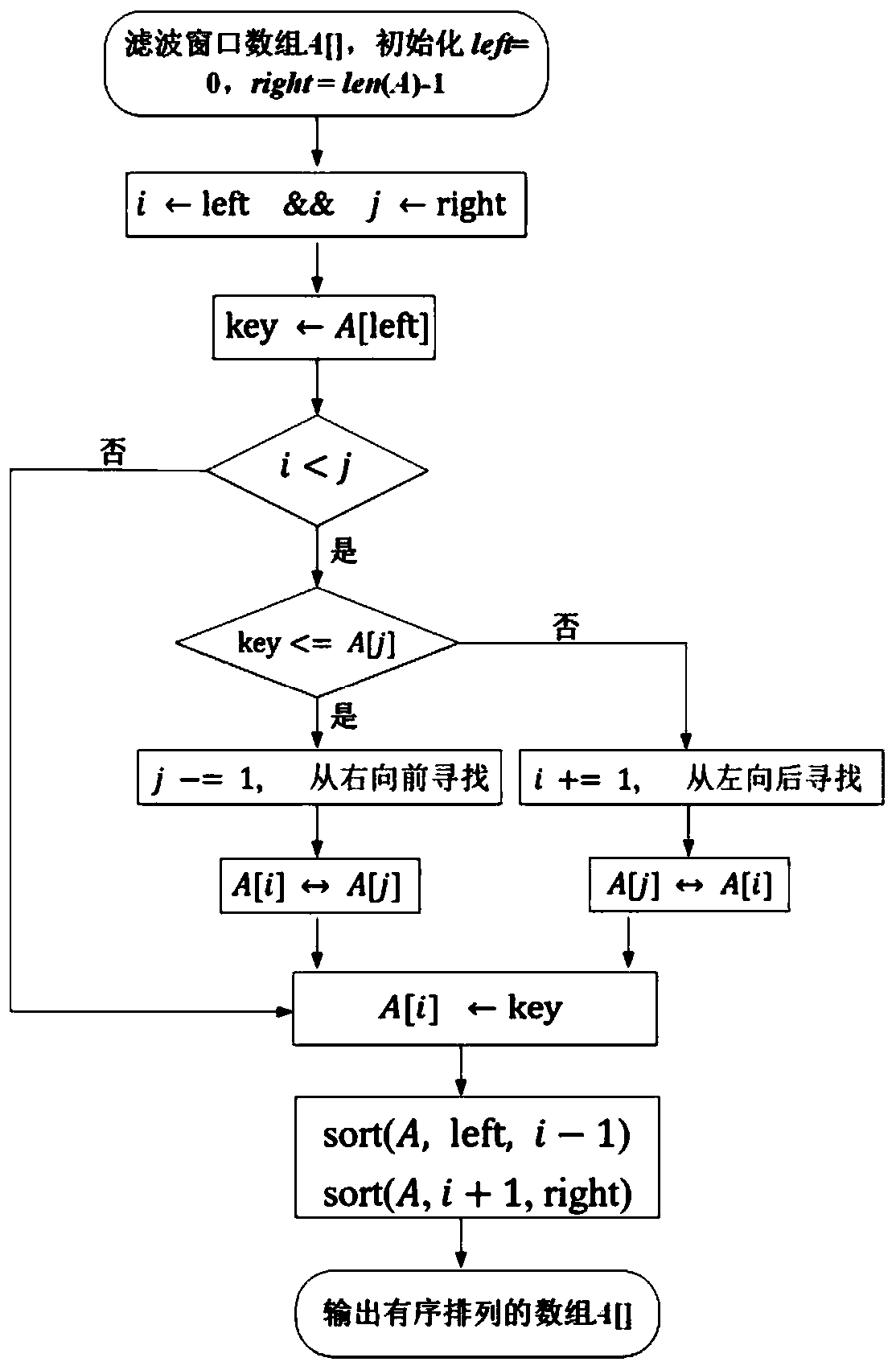

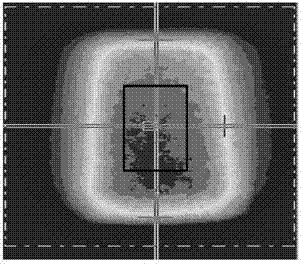

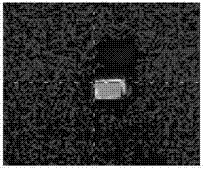

Self-adaptive median filtering denoising method applied to image processing

The invention discloses a self-adaptive median filtering denoising method applied to image processing, which comprises the following steps of: firstly preprocessing an image, and then, (1) sorting data in a filtering window by adopting a divide-and-conquer sorting strategy; And (2) adaptively adjusting the size of a filtering window by combining the noise density. The adaptive median filtering denoising method applied to image processing is high in denoising efficiency and easy to implement.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Laser damage testing device for optical thin film

InactiveCN102778426APosition unchangedSame sizeWeather/light/corrosion resistanceBeam splitterOptical thin film

The invention discloses a laser damage testing device for an optical thin film. The laser damage testing device comprises an optical power energy measurement instrument, wherein an aperture, a first lens, an optical attenuator, a sampling beam splitter and a focusing lens are arranged between a laser device and a coated lens to be tested in sequence; the aperture is arranged on the front focal plane of the first lens, and the coated lens to be tested is arranged on the rear focal plane of the focusing lens; and the incident transmission light of the sampling beam splitter enters the focusing lens, and the reflection light enters the optical power energy measurement instrument. According to the laser damage testing device, the infinite microscopic imaging mode is adopted, the uniform radiation on an image plane is obtained, the wide-range adjustable optical attenuation is realized, the needed spot size can be easily obtained, and the test requirement of high-power excimer laser system on film damage is met.

Owner:NORTHWEST INST OF NUCLEAR TECH

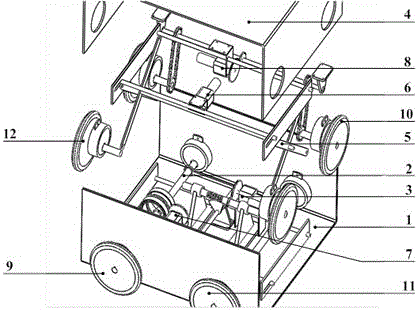

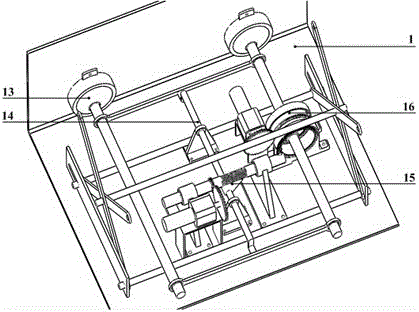

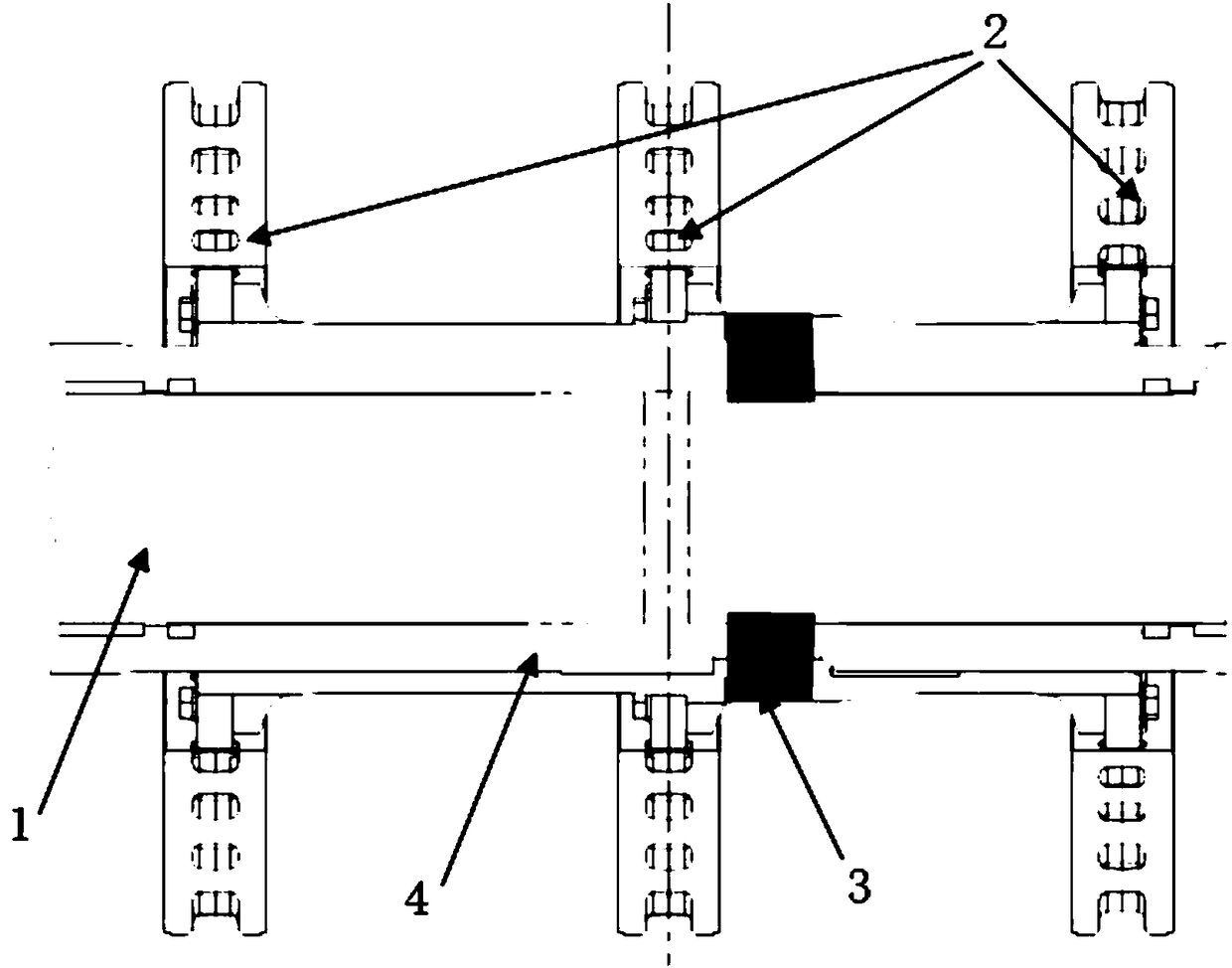

Variable-structure mobile robot capable of making orthogonal bidirectional movement and control method of variable-structure mobile robot

ActiveCN106003039AEnhanced mobilityIncrease flexibilityProgramme-controlled manipulatorDrive wheelEngineering

The invention discloses a variable-structure mobile robot capable of making orthogonal bidirectional movement and a control method of the variable-structure mobile robot. The variable-structure mobile robot capable of making orthogonal bidirectional movement comprises a chassis, a separation type variable-position driving mechanism, a variable-position motor, an integral variable-position driving mechanism, a variable-position electric push rod, a driving wheel motor A, a driving wheel motor B, a driving wheel A, a driving wheel B, a follower wheel A, a follower wheel B, a control device and a guiding sensor. The separation type variable-position driving mechanism is installed on the chassis, and the position, relative to the chassis, of the axis of the driving wheel A is changed while the position of the driving wheel motor A is kept unchanged. The integral variable-position driving mechanism is installed on a top cover, and the position, relative to the chassis, of the axis of the driving wheel B is changed by changing the height of the top cover. The axis of the driving wheel A is orthogonal with the driving wheel B, and the lowest position of the axis of the driving wheel A is the same as that of the driving wheel B. Orthogonal bidirectional movement of the mobile robot is achieved by changing the driving wheels making contact with the ground, the movement direction can be freely switched between orthogonal directions in the same plane, and the movement maneuverability and flexibility of the mobile robot are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

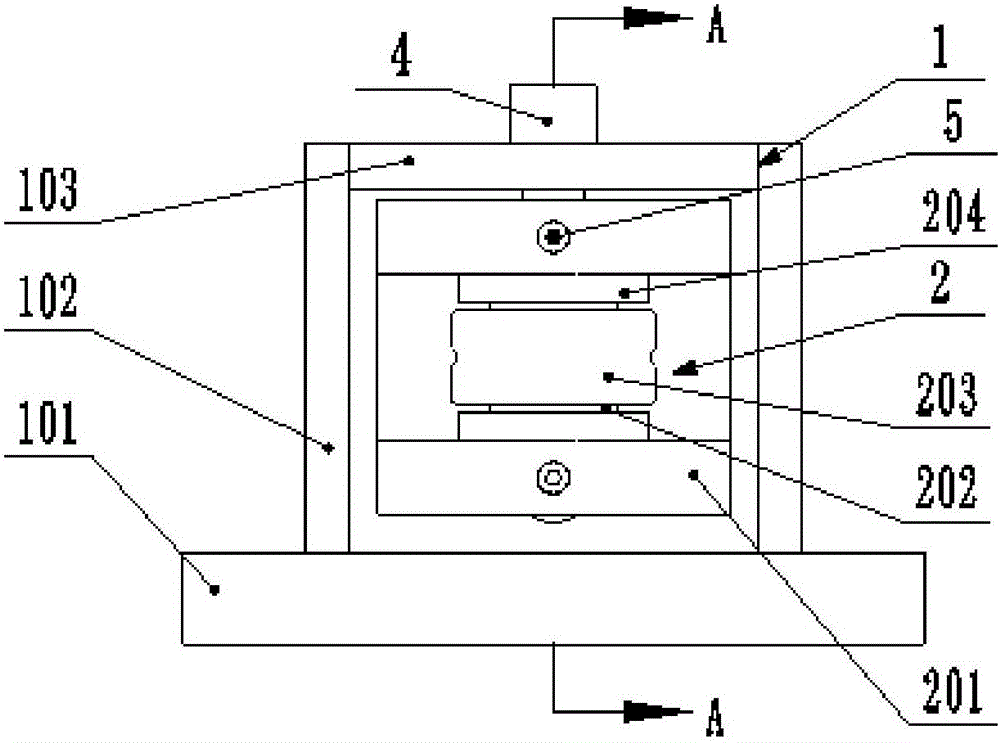

Bi-directional rotary handle and vehicle with same

InactiveCN101898611AGuaranteed clockwise reset in placePosition unchangedCycle control systemsMotorcyclesEngineeringElectric vehicle

The invention discloses a bi-directional rotary handle which comprises a rotary handle seat 1, a rotary handle 2 and a Hall inductive element 4. The rotary handle is provided with magnetic steel 5; the bi-directional rotary handle is characterized in that a middle rotating component 6 is arranged between the rotary handle seat and the rotary handle; a backward return spring 7 is arranged between the middle rotating component and the rotary handle seat, one end of the backward return spring is connected with a rotary handle 30, and the other end of the backward return spring is connected with a middle rotating component 31; and a forward return spring 8 is arranged between the middle rotating component and the rotary handle, one end of the forward return spring is connected with a middle rotating component 32, and the other end of the forward return spring is connected with the rotary handle. The invention further discloses electric vehicles with the bi-directional rotary handle. By adopting the technical scheme, the electric vehicle can be more conveniently operated and controlled and the comfort level of a cyclist can be enhanced, thus really achieving arbitrary operation and control environment.

Owner:何伟斌

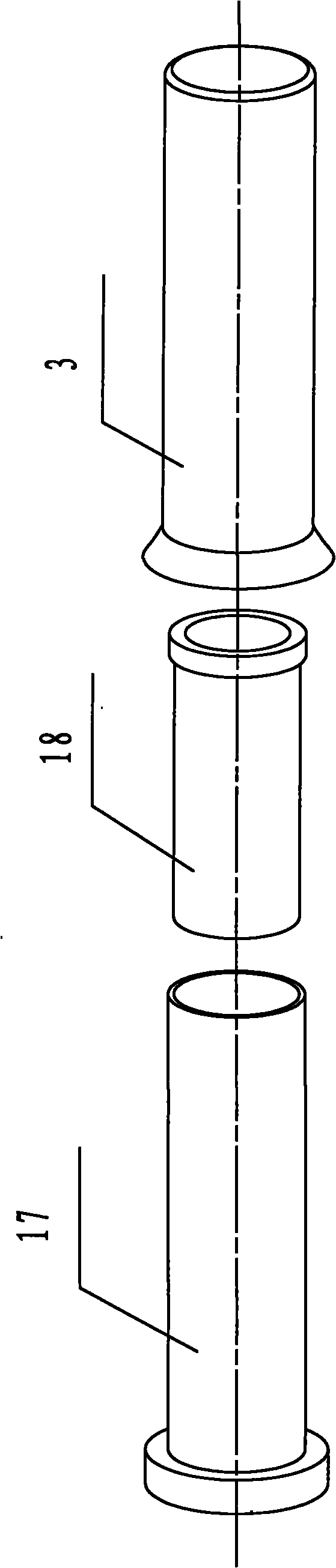

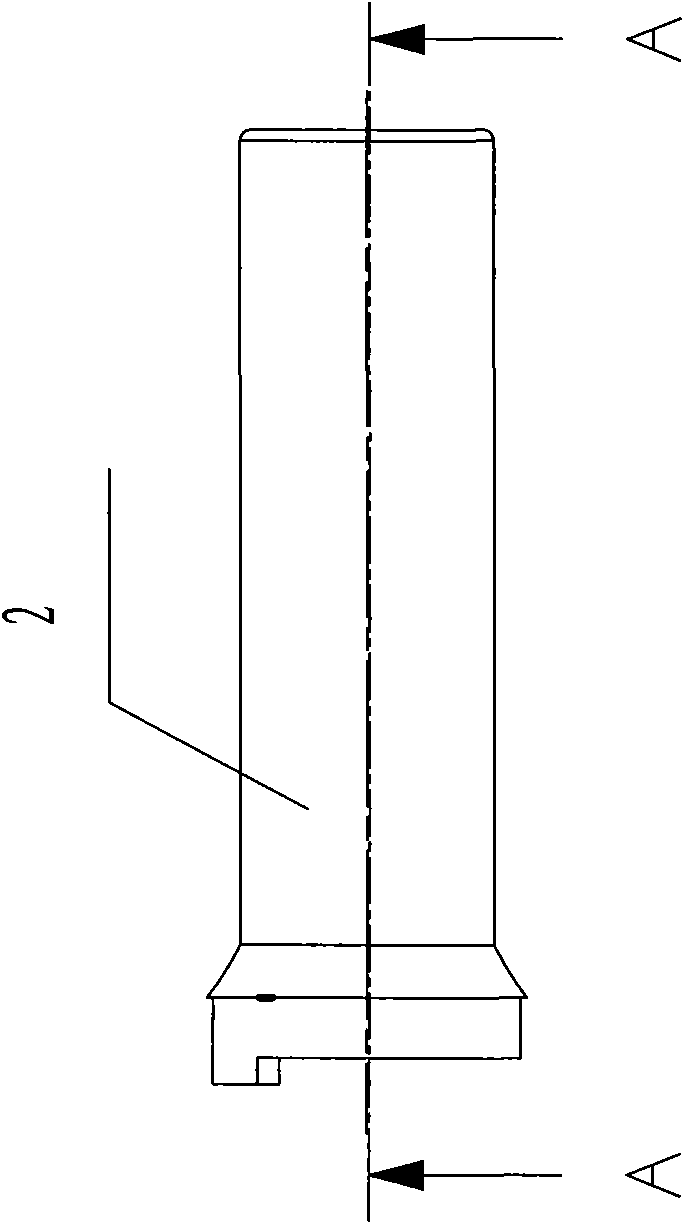

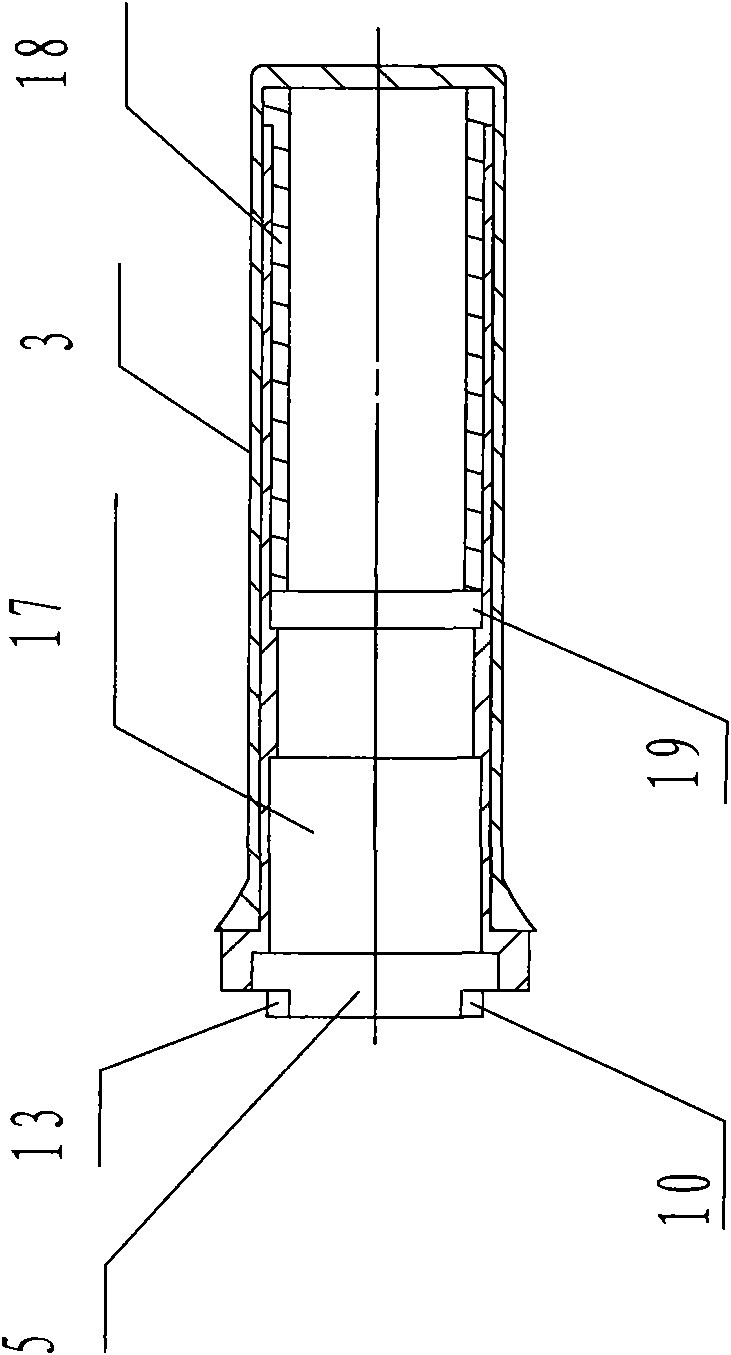

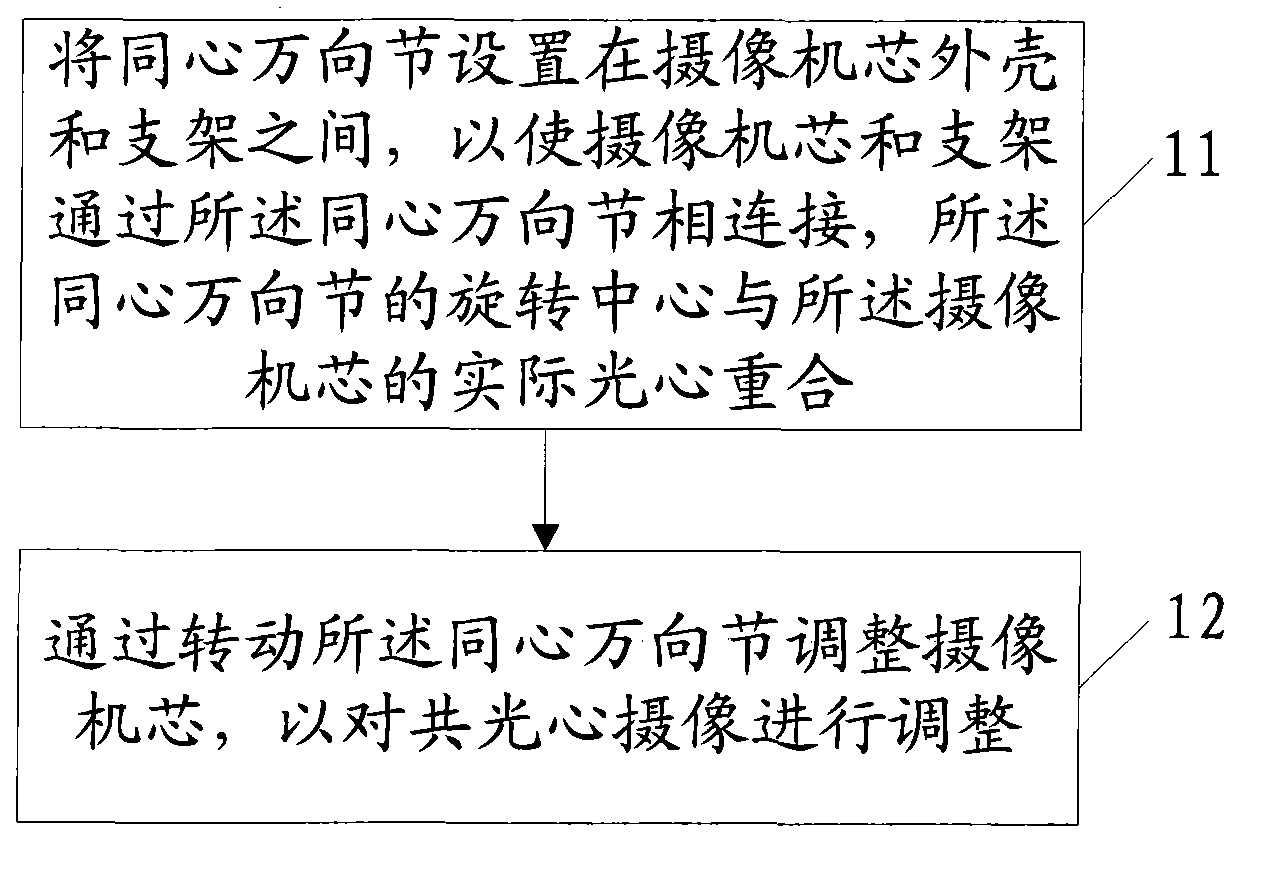

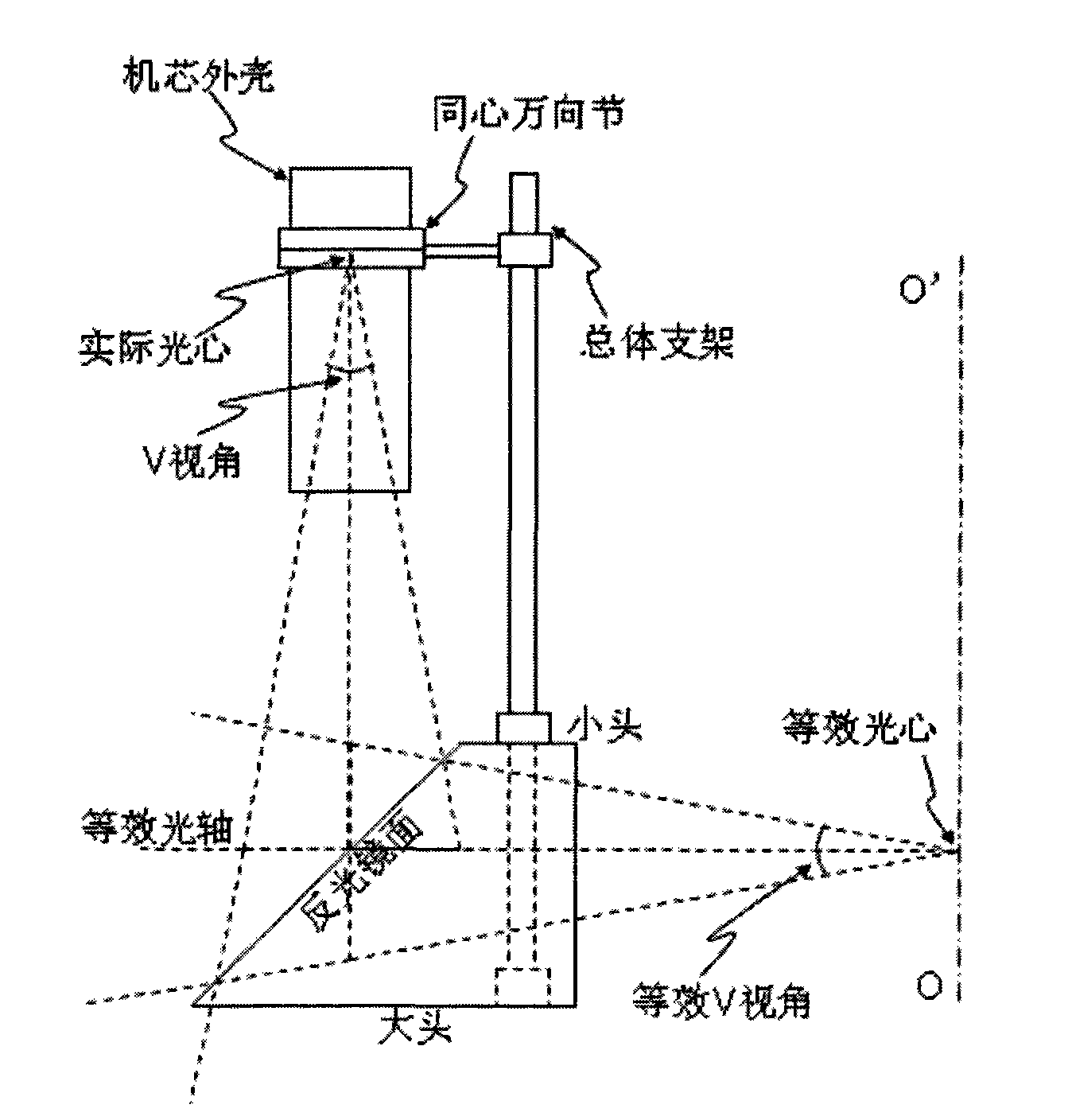

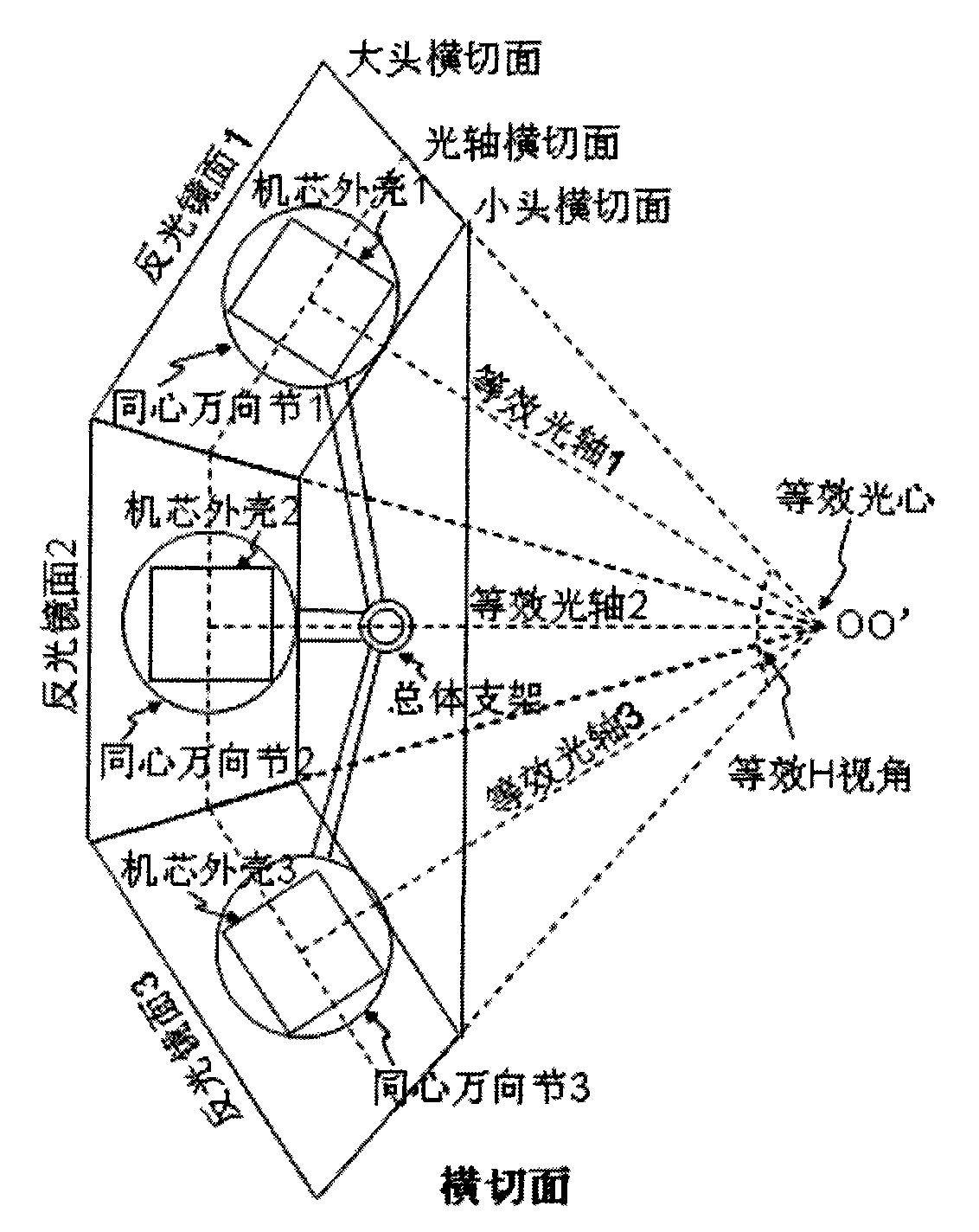

Adjusting method in co-optical-center videography and co-optical-center camera system

InactiveCN101783883APosition unchangedEasy to adjustTelevision system detailsColor television detailsUniversal jointVideo processing

The embodiment of the invention discloses an adjusting method in co-optical-center videography and a co-optical-center camera system, relating to a video-processing technology. The adjusting method can finely adjust the shooting direction of a video camera to align visual angle edges of the video camera and adjust the shooting direction of a Sensor while ensuring that the optical center of the video camera keeps a constant position and is easy to adjust and convenient to operate, and the adopted equipment has small size and low system cost. The adjusting method in co-optical-center videography, which is provided by the invention, comprises the following steps of: arranging a homocentric universal joint between an outer shell of a video camera core and a bracket so that the video camera core and the bracket are connected by the homocentric universal joint, wherein the rotating center of the homocentric universal joint coincides with the practical optical center of the video camera core; and adjusting the video camera core by rotating the homocentric universal joint so as to adjust co-optical-center videography. The embodiment of the invention is suitable for co-optical-center videography occasions.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

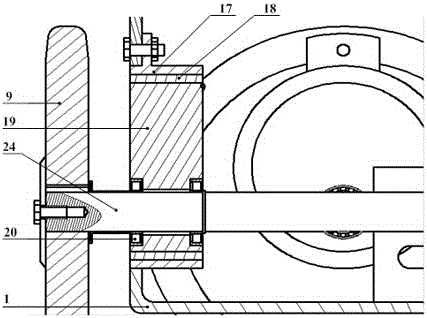

Axle-mounted brake device for gauge-changeable wheel set

ActiveCN108407845ARealize the braking effectAchieve circumferential positioningSelf-applying brakesVehicle brakeVehicle braking

The invention relates to the technical field of rail vehicle braking and discloses an axle-mounted brake device for a gauge-changeable wheel set. The axle-mounted brake device for the gauge-changeablewheel set comprises a transitional sleeve, a locating mechanism and a plurality of axle-mounted brake discs; the plurality of axle-mounted brake discs are fixed on the transitional sleeve at intervals; the transitional sleeve is connected with an axle of the gauge-changeable wheel set through a spline in a matched manner; and the locating mechanism is used for connecting the transitional sleeve with the axle so as to axially locate the transitional sleeve relative to the axle. According to the axle-mounted brake device for the gauge-changeable wheel set, by improving the connection modes between the axle-mounted brake discs and the axle, the relative positions of a brake clamp and the axle-mounted brake discs can be kept invariable during changing the gauge so that braking effects at different gauges are realized.

Owner:CRRC QINGDAO SIFANG CO LTD

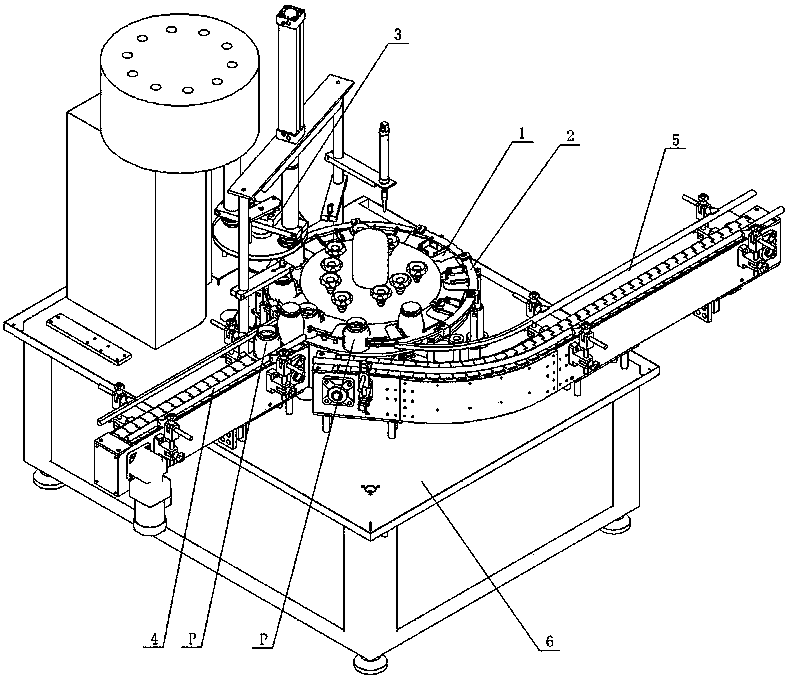

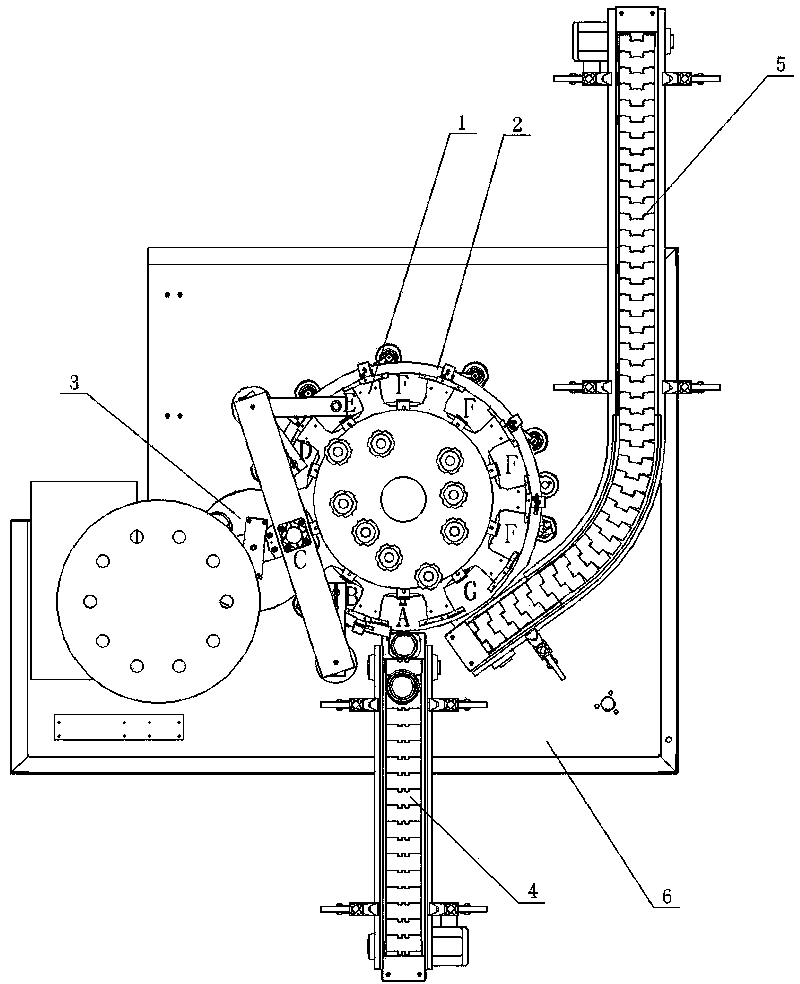

Bottling machine

The invention discloses a bottling machine. The bottling machine is characterized by comprising a rotating disc mechanism, a guardrail mechanism, a feeding mechanism, a bottle inlet mechanism and a bottle outlet mechanism. The rotating disc mechanism comprises a rotating disc driven by a motor to do indexing rotation. The rotating disc is provided with a bottle inlet station, a packing station, a spare station and a bottle outlet station. Each station rotation disc comprises a bottle containing cavity used for storing bottles, each bottle containing cavity is of a semi-surrounded shape with an outward opening and is formed by enclosure of an inner plate, a left plate and a right plate, the radial position of the inner plates can be adjusted, and the horizontal positions of the left plate and the right plate can be adjusted. The openings of the bottle containing cavities of the stations except for the bottle inlet station and the bottle outlet station are guarded by a guardrail of the guardrail mechanism, and the radial position of the guardrail can be adjusted. The bottle inlet mechanism corresponds to the bottle inlet station, the feeding mechanism corresponds to the packing station, and the bottle outlet mechanism corresponds to the bottle outlet station. The bottling machine is used for automatic production of bottled products and has the advantages of being suitable for bottles of various sizes and shapes and high in generality.

Owner:RUIAN RUIZHI MACHINERY

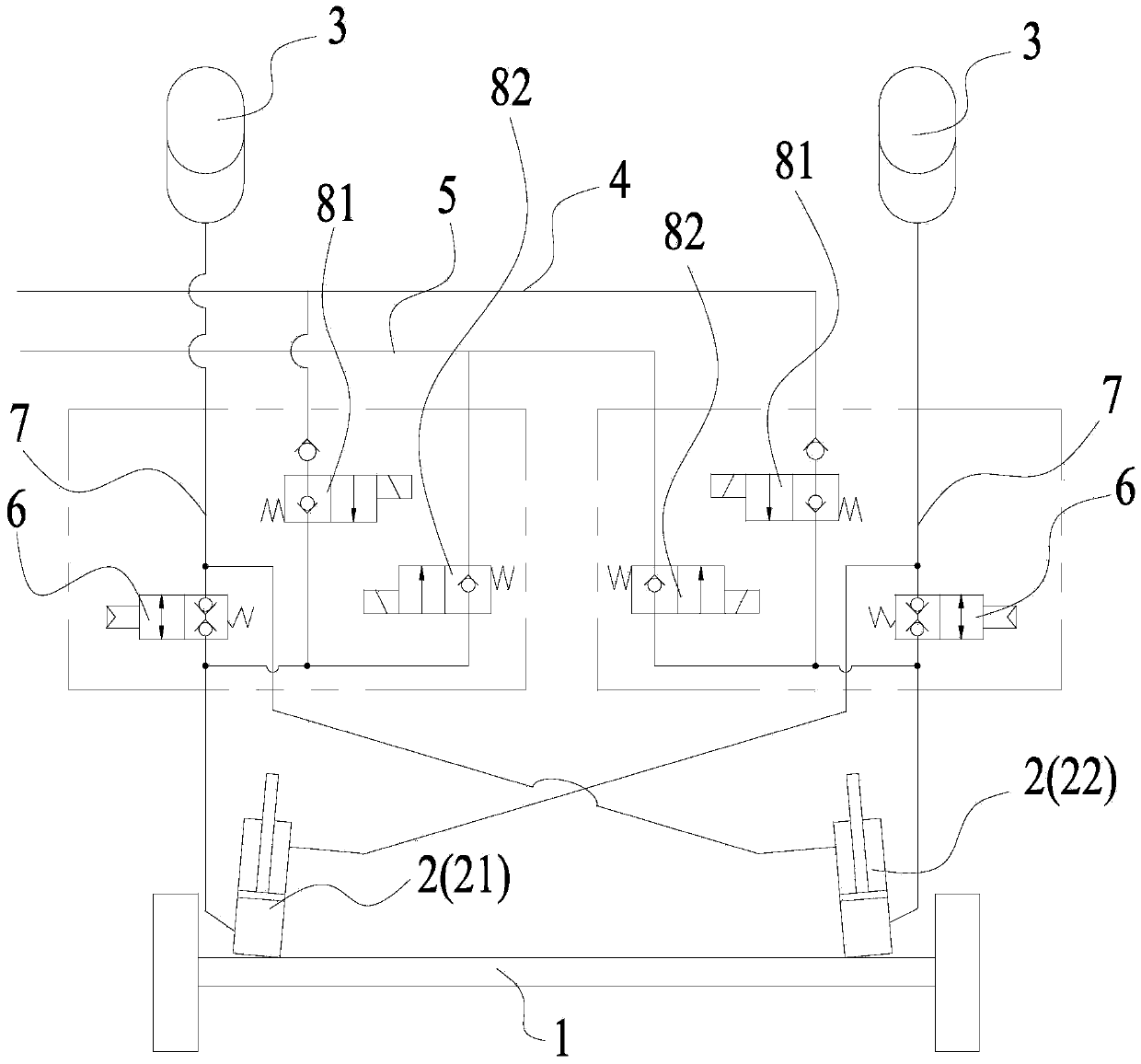

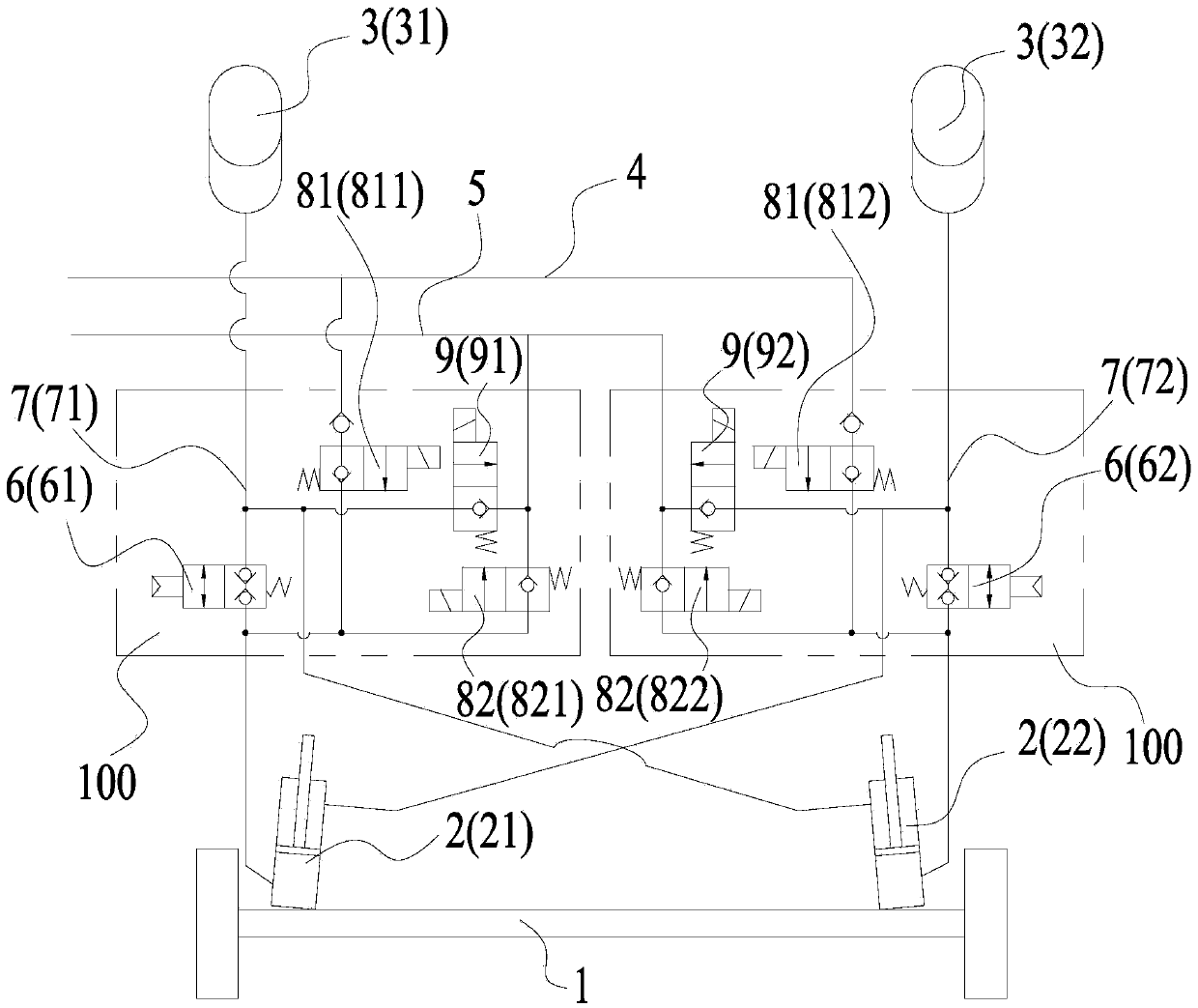

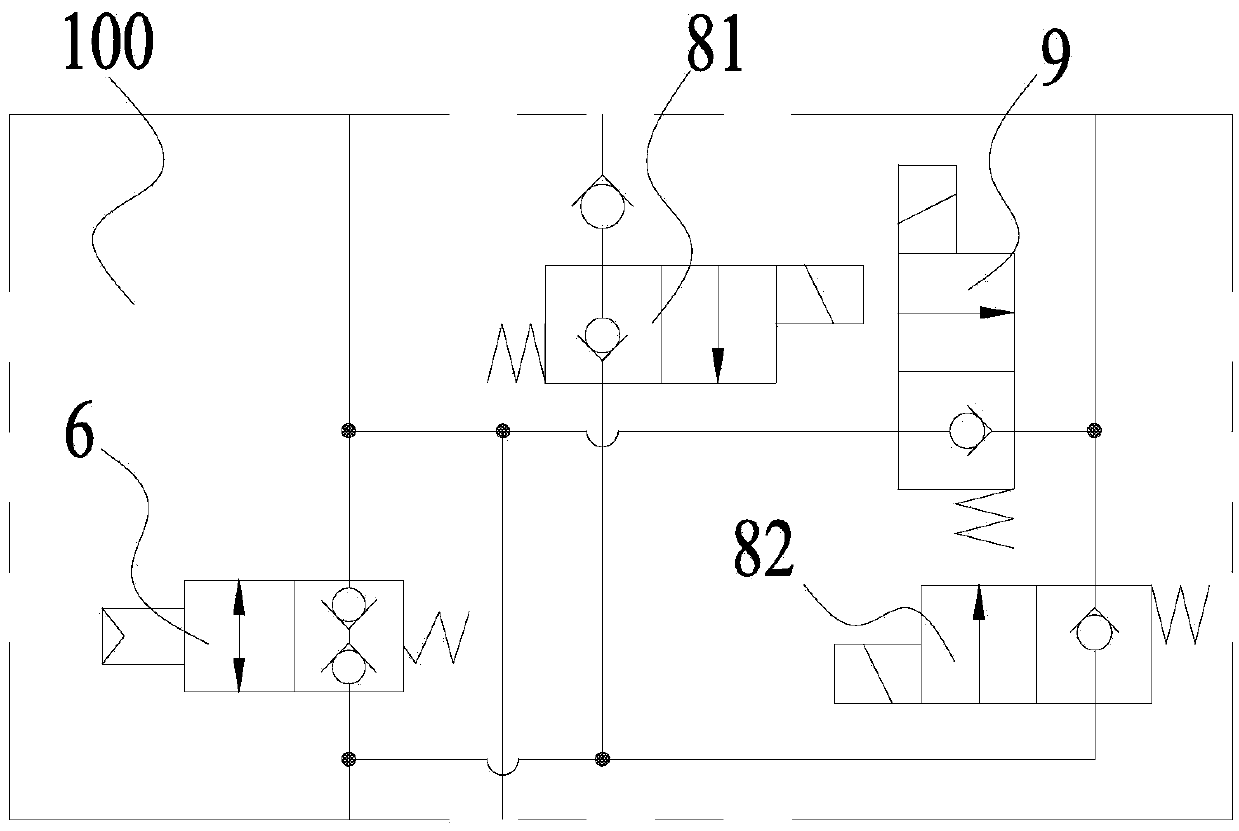

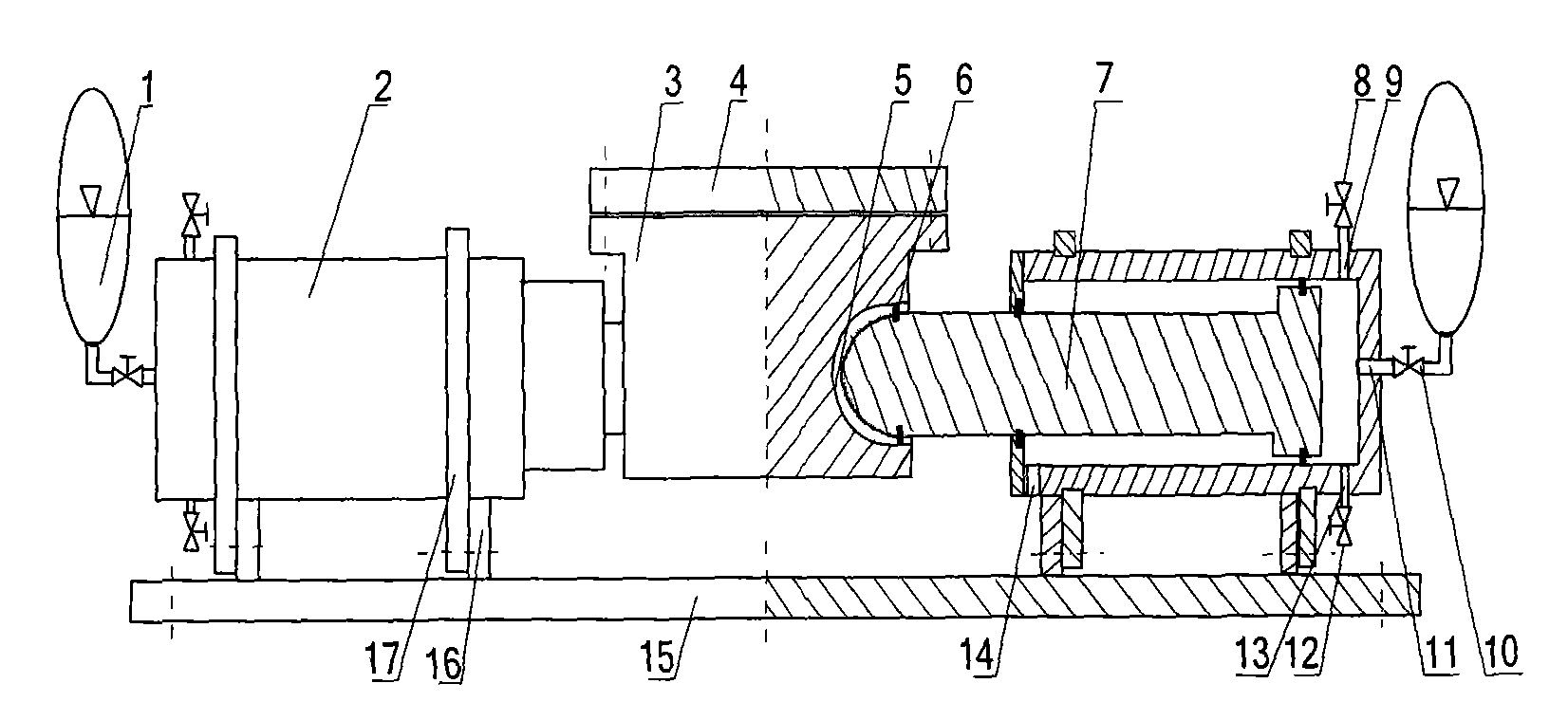

Suspension valve group, hydro-pneumatic suspension control system, hydro-pneumatic suspension control method, and vehicle

ActiveCN105365521AAchieve liftEasy to operateInterconnection systemsResilient suspensionsHydropneumatic suspensionControl system

The invention relates to the field of vehicle engineering, and discloses a suspension valve group, a hydro-pneumatic suspension control system, a hydro-pneumatic suspension control method, and a vehicle. The hydro-pneumatic suspension control system comprises suspension cylinders (2) which are symmetrically arranged, a left accumulator (31) and a right accumulator (32), and an oil feeding pipe (4) and an oil returning pipe (5). The oil cavities of the left accumulator (31) and the right accumulator (32) are respectively communicated with the rod chambers of the suspension cylinders at the opposite sides, and can be selectively communicated with the rodless chambers of the suspension cylinders (21) at the same sides so as to selectively switch a hydro-pneumatic suspension to a rigid or flexible state. The rodless chambers of the suspension cylinders (2) can be selectively communicated with the oil feeding pipe (4) or the oil returning pipe (5). When the hydro-pneumatic suspension is selectively switched to the rigid state, the rod chamber of at least one suspension cylinder (2) can be selectively communicated with the oil returning pipe (5). By adopting the hydro-pneumatic suspension control system and the hydro-pneumatic suspension control method of the invention, lifting operation can be implemented in the rigid state.

Owner:ZOOMLION HEAVY IND CO LTD

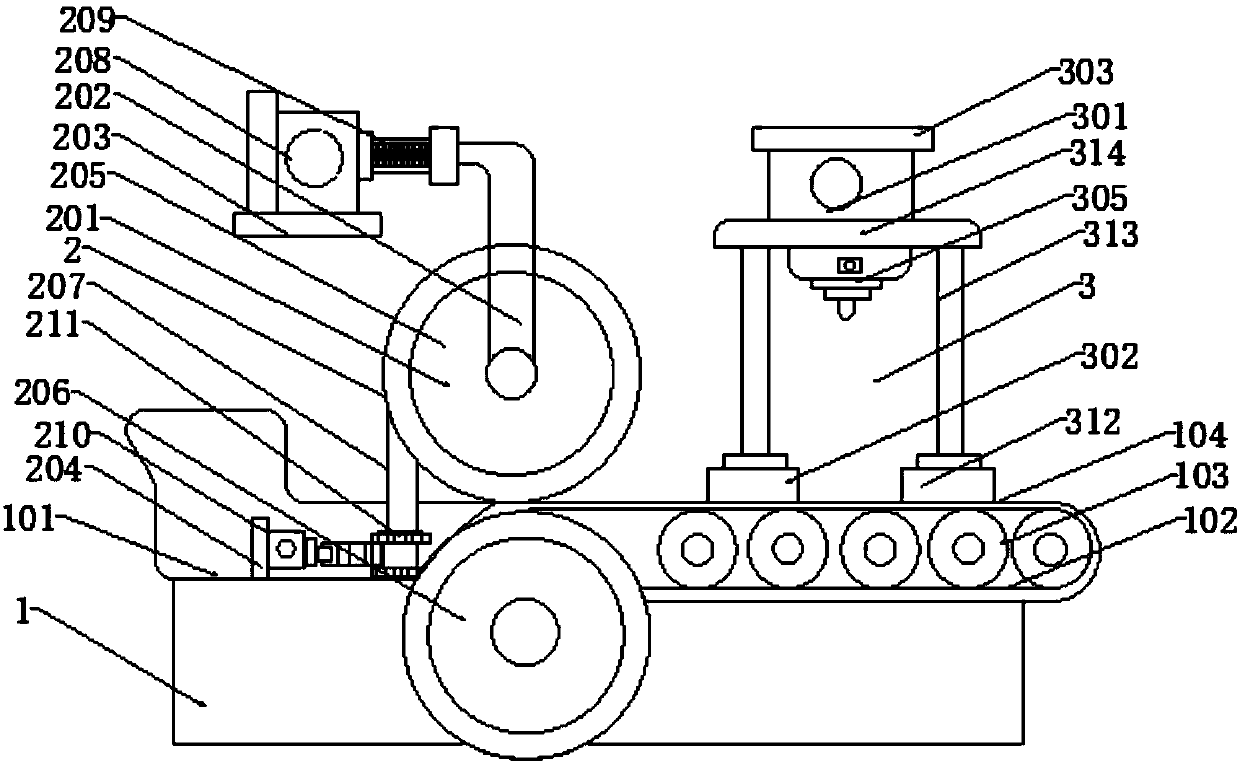

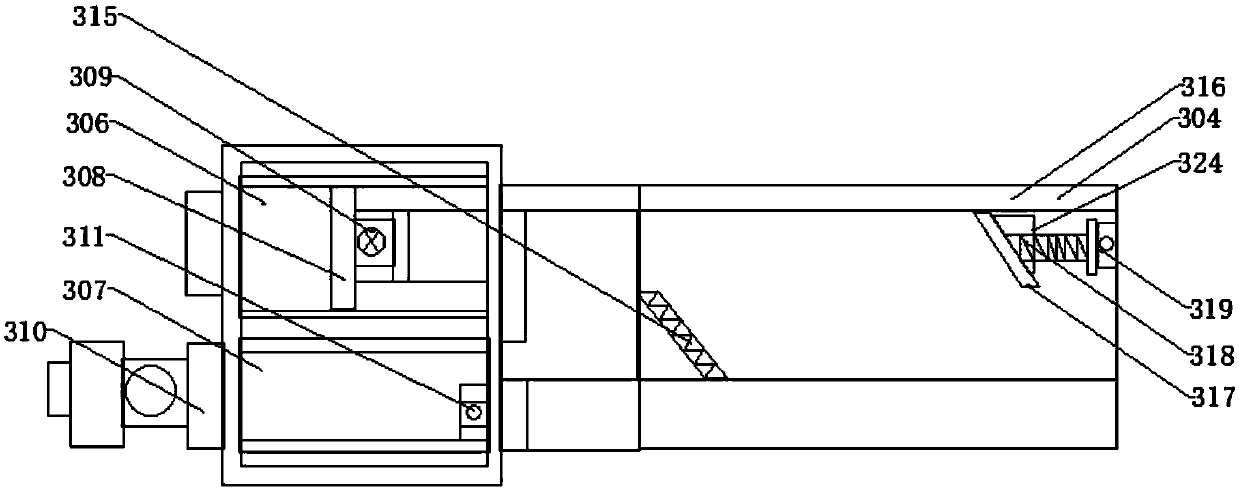

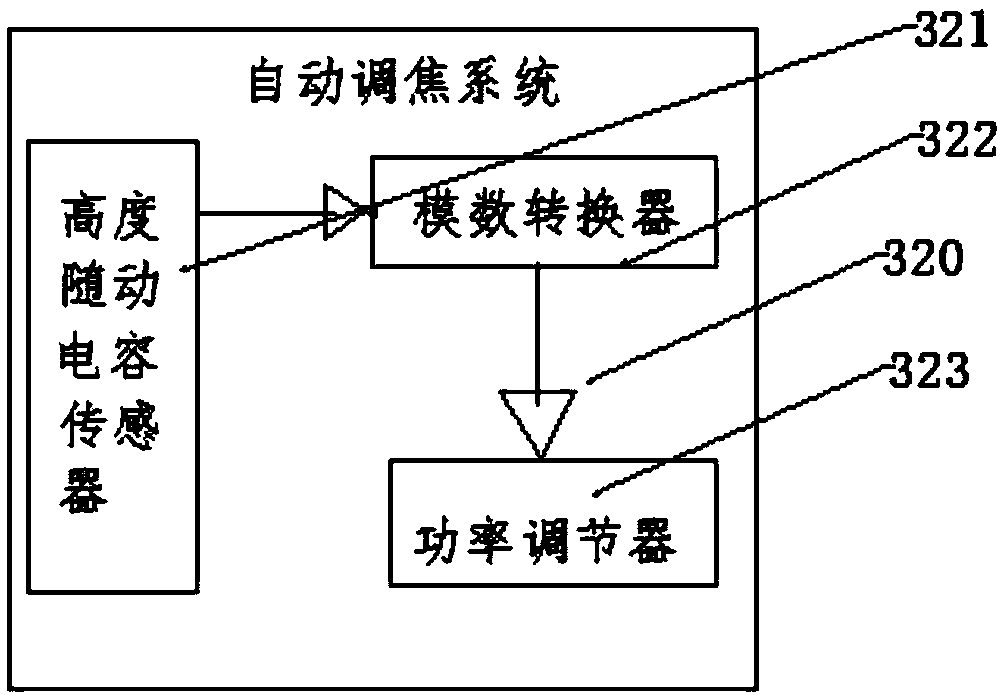

Calendering and directional cutting integrated equipment for automobile plates

ActiveCN108672949ARealization of automatic calenderingAchieve regulationLaser beam welding apparatusLight guideLaser cutting

The invention discloses calendering and directional cutting integrated equipment for automobile plates. The equipment comprises an automatic feeding mechanism, an automatic calendering mechanism and adirectional cutting mechanism. The automatic calendering mechanism comprises a hedging calendering roller, a curved bar connection shaft is connected with the center of a roller shaft of the hedgingcalendering roller in a penetrating mode, the other end of the curved bar connection shaft is connected with a pressing roller adjusting system, the side edge of the hedging calendering roller is further provided with a roller drum position adjusting device, the directional cutting device comprises a laser cutting system and an omni-directional supporting mechanism, the laser cutting system comprises a laser generator used for producing cutting laser light, a laser beam outlet of the laser generator is connected with a sealed light guide pipe used for stably transmitting light, and an output port of the sealed light guide pipe is connected with a laser cutting head. Calendering stretching and directional cutting operation for the automobile plates can be achieved, the good automatic adjusting function is achieved, the requirements of different plates are met, machining precision is high, and cutting in complex shapes can be achieved.

Owner:芜湖众梦电子科技有限公司

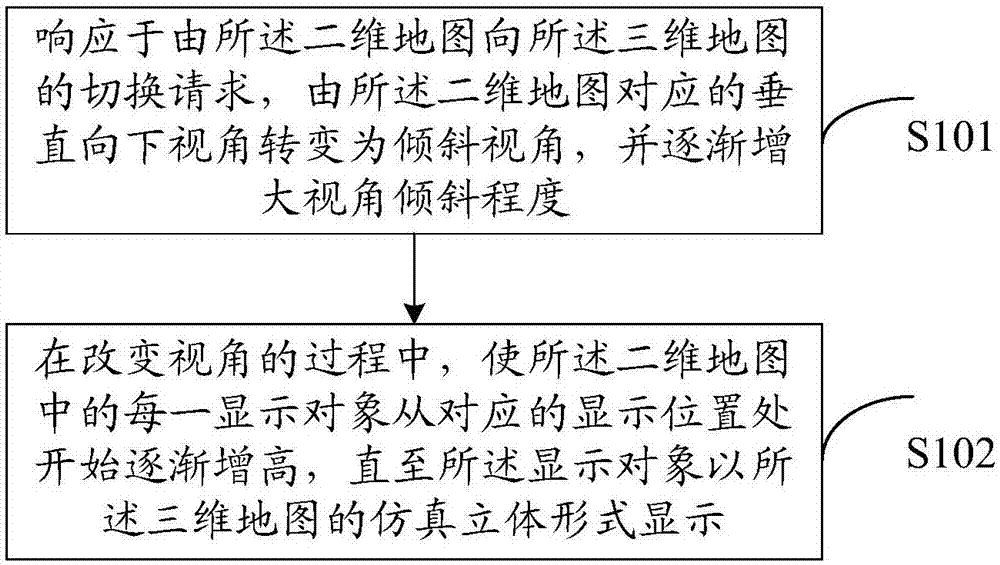

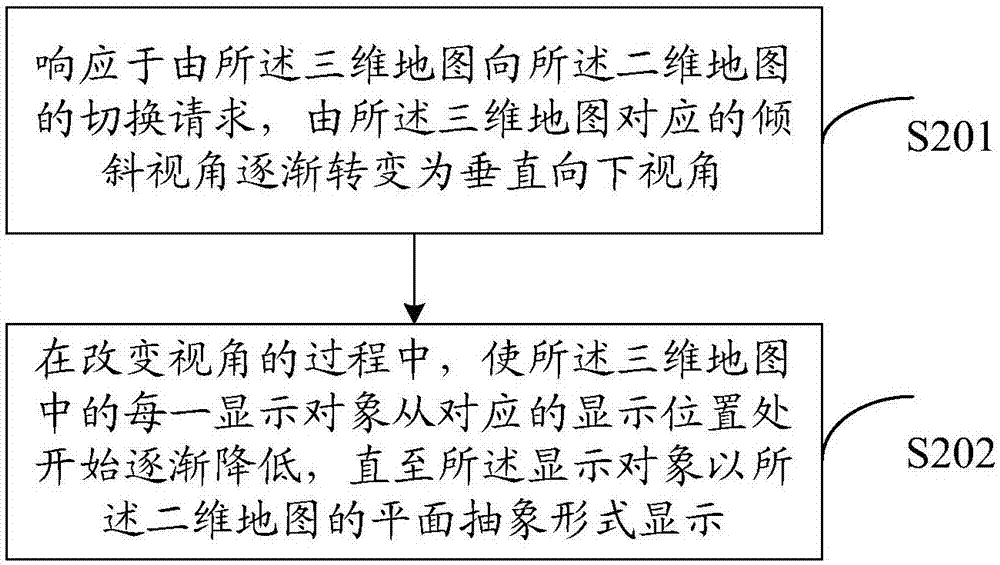

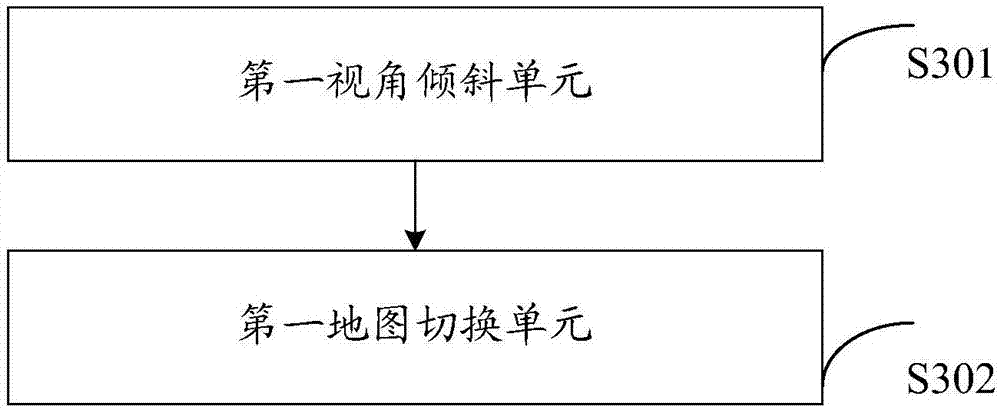

Method and device of switching between two-dimensional map and three-dimensional map

ActiveCN107491522AAchieve a natural transitionIncrease the slopeGeometric image transformationGeographical information databasesAngle of viewComputer science

The invention discloses a method and device for switching between a two-dimensional map and a three-dimensional map. By responding to the switching request of the two-dimensional map to the three-dimensional map, a vertical downward viewing angle corresponding to the two-dimensional map is converted to a tilt viewing angle, the tilt extent of the viewing angle is gradually increased, meanwhile in the process of changing the viewing angle, each display object in the two-dimensional map starts to increase gradually from the corresponding display position, until each display object is shown as a simulation stereoscopic form of the three-dimensional map. Thus, in the map switching process, the viewing angle of the map is gradually changed, meanwhile each display object in the map grows gradually higher at the original position and gradually transits to the stereoscopic simulation form corresponding to the three-dimensional map, and the gradual transformation process of map manifestation form achieves the natural transition from the two-dimensional map to the three-dimensional map.

Owner:城市生活(北京)信息有限公司

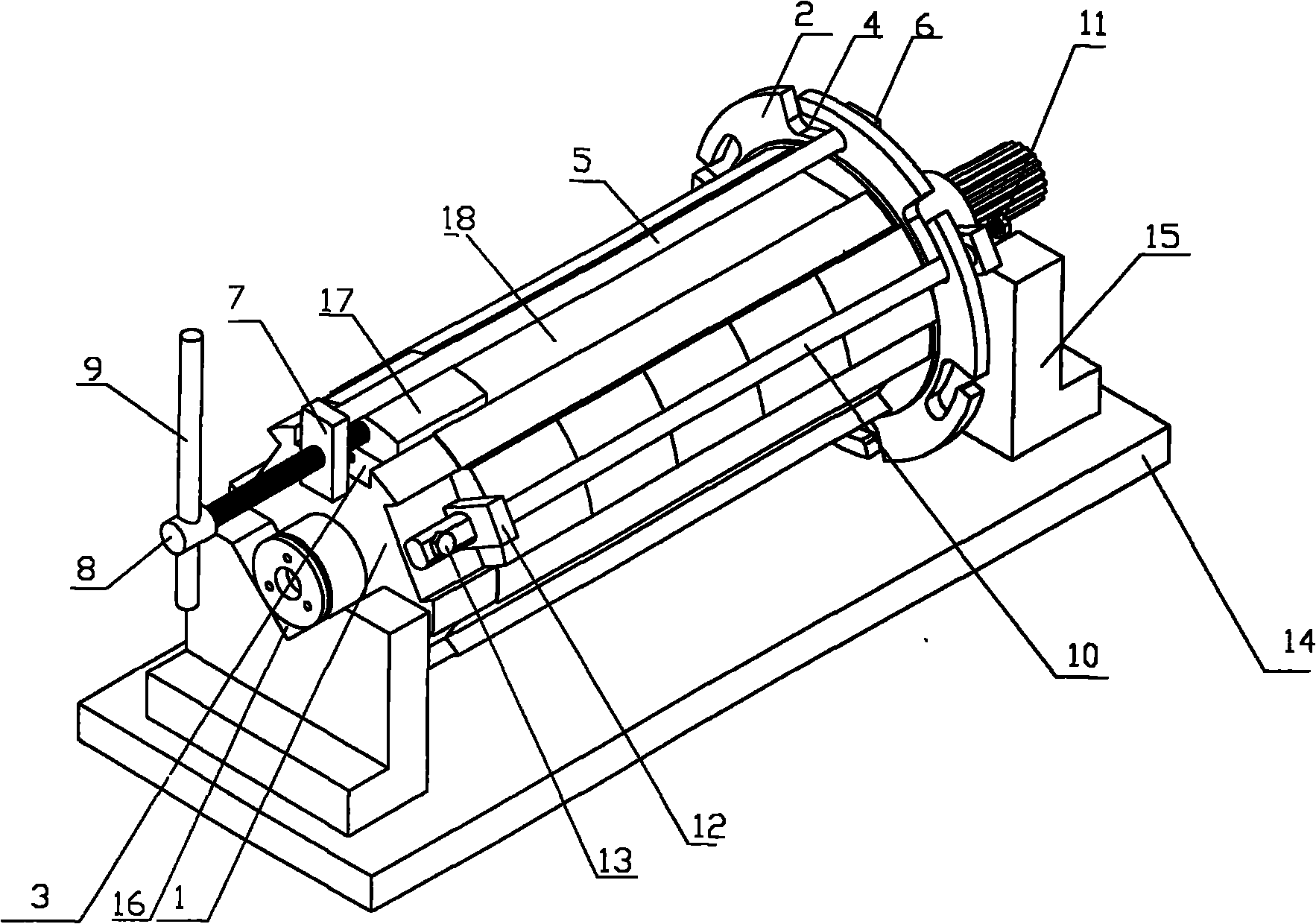

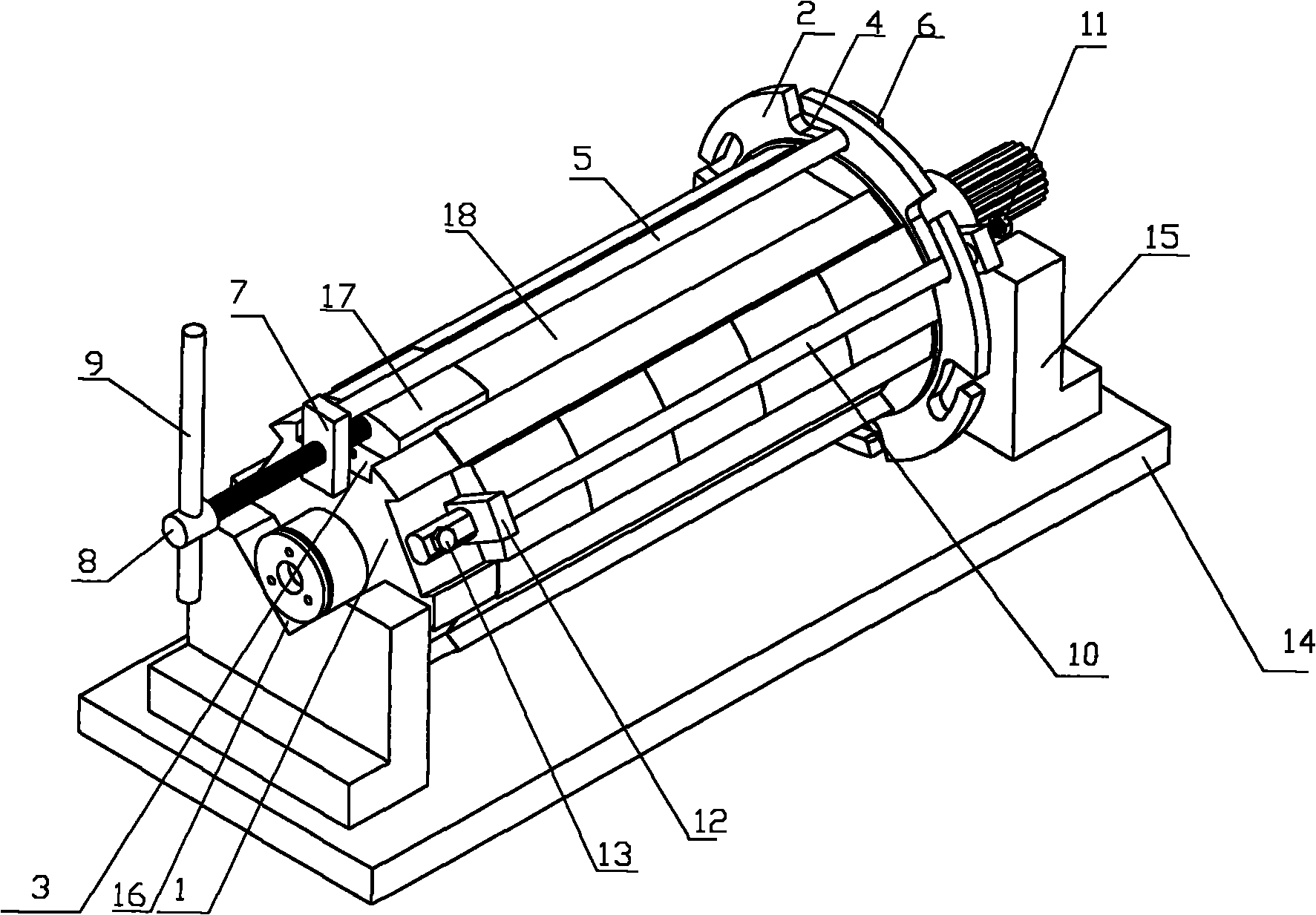

Insertion device for magnetic steel of permanent magnet motor

InactiveCN102025236AEasy to insertSolve the problem of difficult insertionManufacturing stator/rotor bodiesPermanent magnet motorInsertion device

The invention relates to the technical field of electromechanical manufacture, and provides an insertion device for the magnetic steel of a permanent magnet motor for the purpose of solving the technical problem when the magnetic steel of the permanent magnet motor is inserted. The insertion device for the magnetic steel of the permanent magnet motor comprises an annular guide disk and an annular fixed disk, wherein the disk periphery of the guide disk is provided with a plurality of notches corresponding to a motor rotor core groove; the disk periphery of the fixed disk is provided with a plurality of sliding slots corresponding to the motor rotor core groove; draw bars are arranged between the notches of the guide disk and the sliding slots of the fixed disk; one end of each draw bar is provided with an abutting head which is abutted against the outside of the fixed disk, and the other end of each draw bar is provided with an abutting block which is abutted against the guide disk; a screw hole is arranged on the abutting block; and a bolt passes through the screw hole on the abutting block by force. The insertion device for the magnetic steel of the permanent magnet motor has the advantages of simple structure and low manufacturing cost, is convenient to operate, and can effectively solve the problem that the magnetic steel of the rotor core can not be inserted easily.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

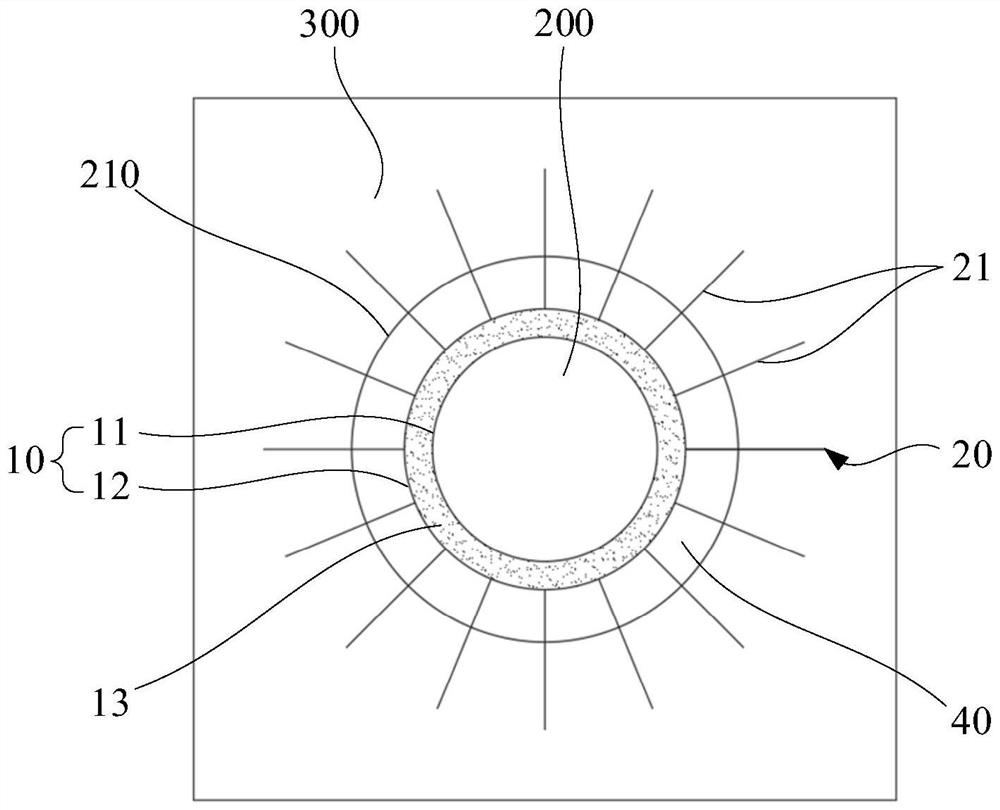

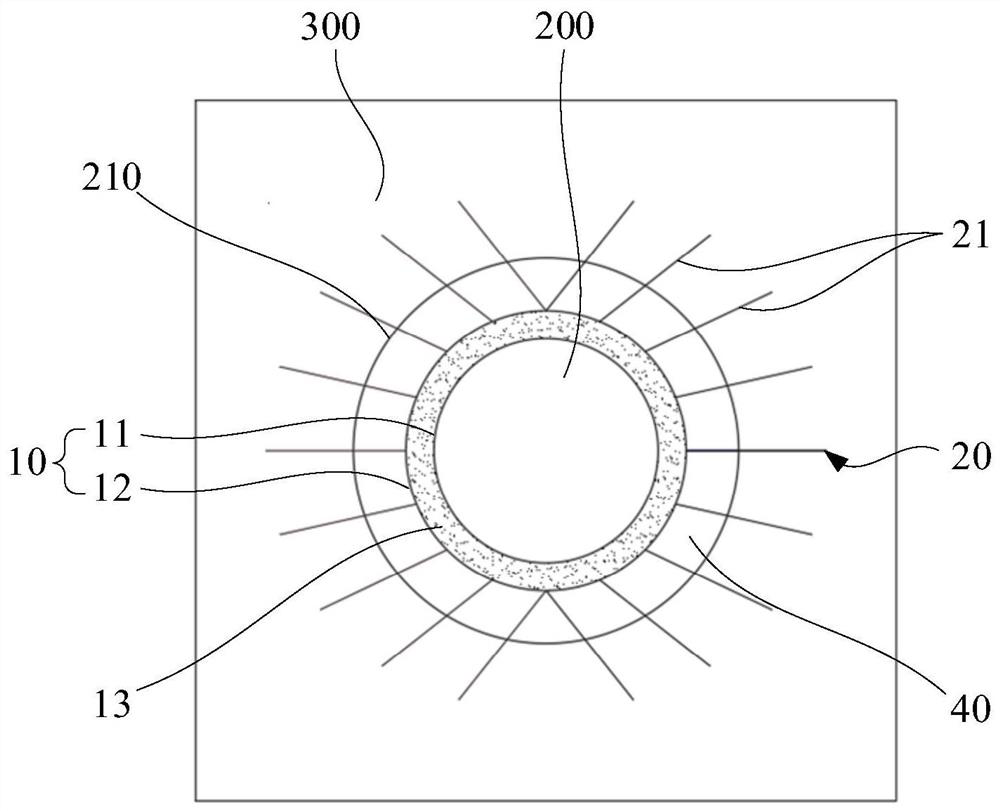

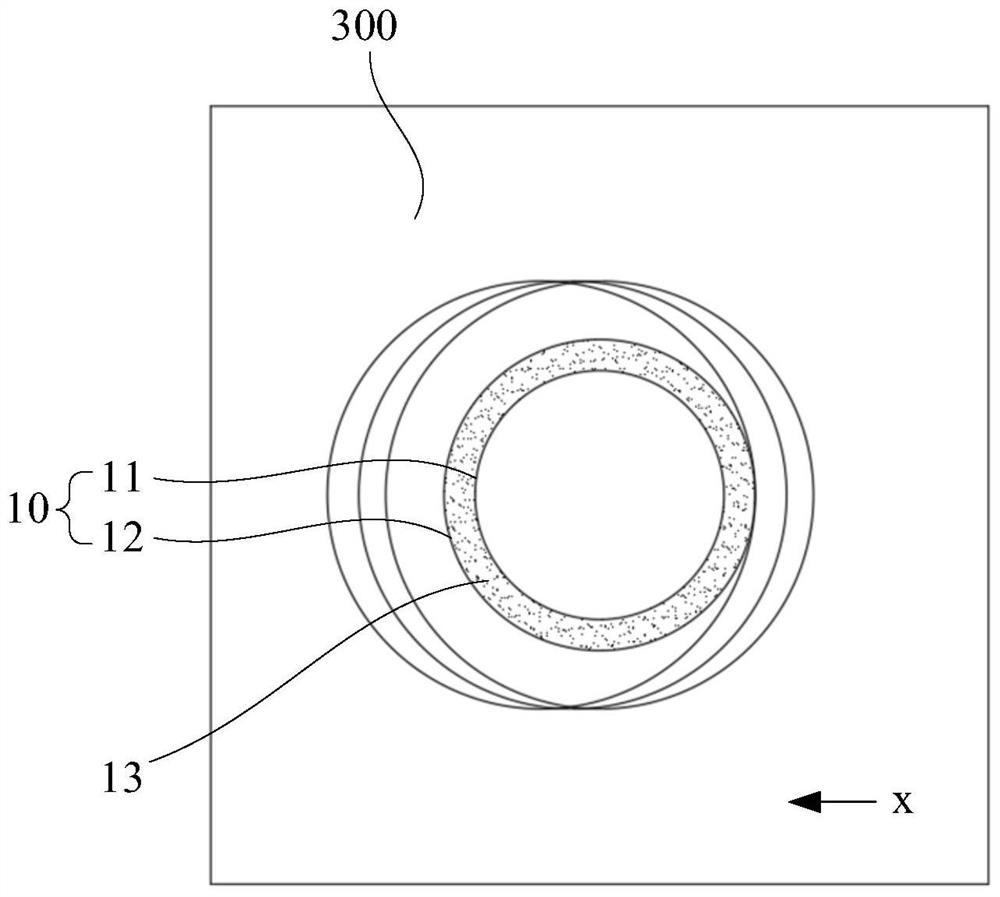

Supporting structure of active fault crossing tunnel and tunnel lining structure

PendingCN112096431AAvoid destructionImprove stress resistanceUnderground chambersTunnel liningArchitectural engineeringRock bolt

The invention discloses a supporting structure of a active fault crossing tunnel and a tunnel lining structure, and relates to the technical field of tunnel engineering. The supporting structure comprises a first support and a second support, the first support comprises a first pipeline arranged in the longitudinal direction of the tunnel and a second pipeline arranged outside the first pipeline in a sleeved, and concrete is filled between the first pipeline and the second pipeline, the second support comprises a plurality of first anchor rods radially arranged in the radial direction of the tunnel, one end of each first anchor rod is fixedly connected with the second pipeline, the other end of each first anchor rod extends to external surrounding rock, and a cavity is preset between the second pipeline and an excavation contour line of the tunnel in the radial direction of the tunnel. The supporting structure of the active fault crossing tunnel and the tunnel lining structure have good fault creep diastrophism damage resistance, and damage to the whole tunnel caused by fault creep can be effectively avoided.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

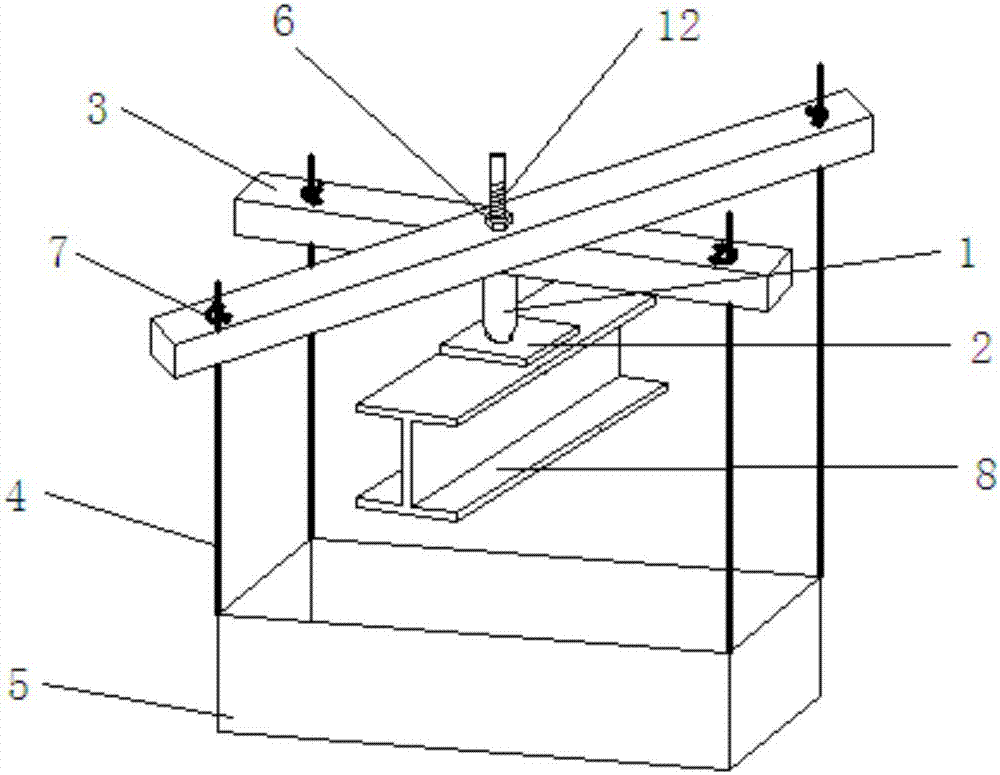

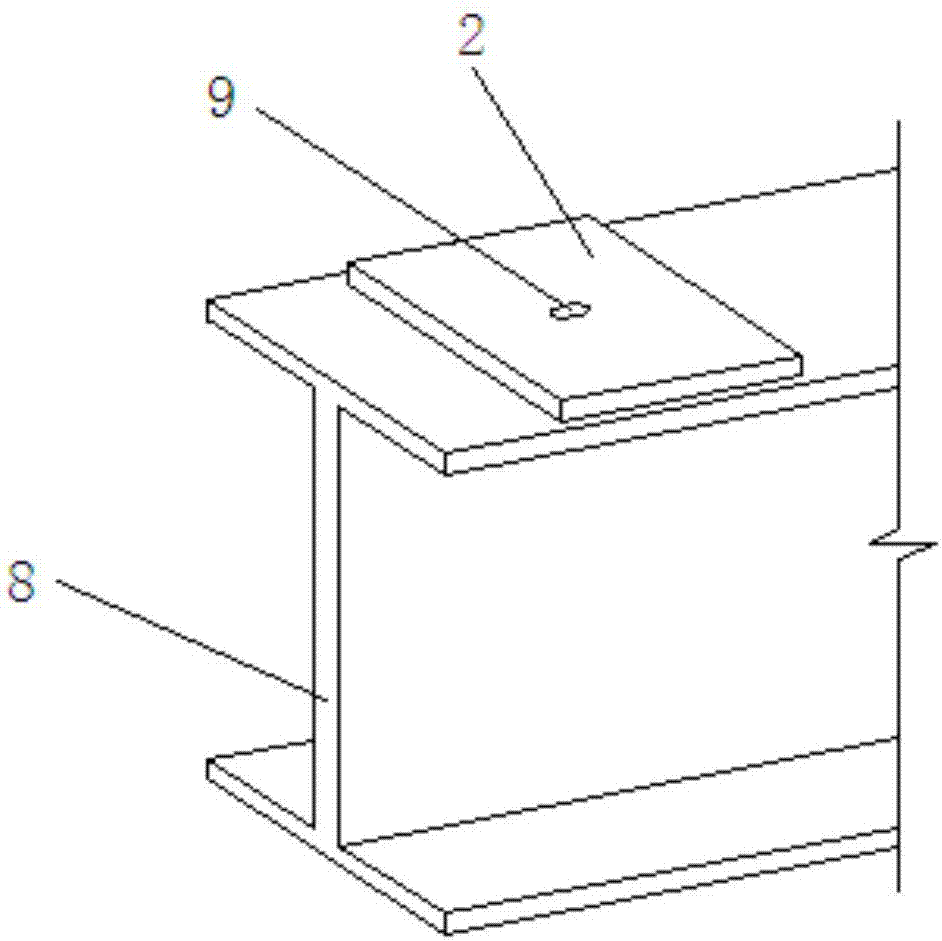

Assembled steel beam overall stability testing concentrated load loading device and method

PendingCN108007790AEasy to get materialsEasy to manufactureMaterial strength using tensile/compressive forcesReusabilityLap joint

The invention discloses an assembled steel beam overall stability testing concentrated load loading device and method. The method comprises a loading conical screw, a loading plate, square steel tubes, steel strands and loading tanks, wherein two square steel tubes are in mutual lap joint in a cross manner; the loading conical screw is inserted into a lap joint part of the two square steel tubes;threads are formed in the outer wall of the loading conical screw; the square steel tubes are locked by a screw nut screwed on the threads; the loading tanks are hung at four end parts of the square steel tubes through the steel strands respectively; a steel beam to be tested is fixedly connected below the loading plate; an end part of the loading conical screw penetrates through a through hole inthe loading plate and is in contact with the steel beam to be tested. The loading device is convenient in material obtaining, simple and easy to manufacture, high in reusability and high in assembling degree, a series of problems caused by welding in a conventional loading device are avoided, the loading conical screw is convenient to replace and simple to operate, loading directions and positions are not changed, the action area of a load is reduced to the maximum extent, and an ideal state that a concentrated load is loaded to an action point is approximately achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

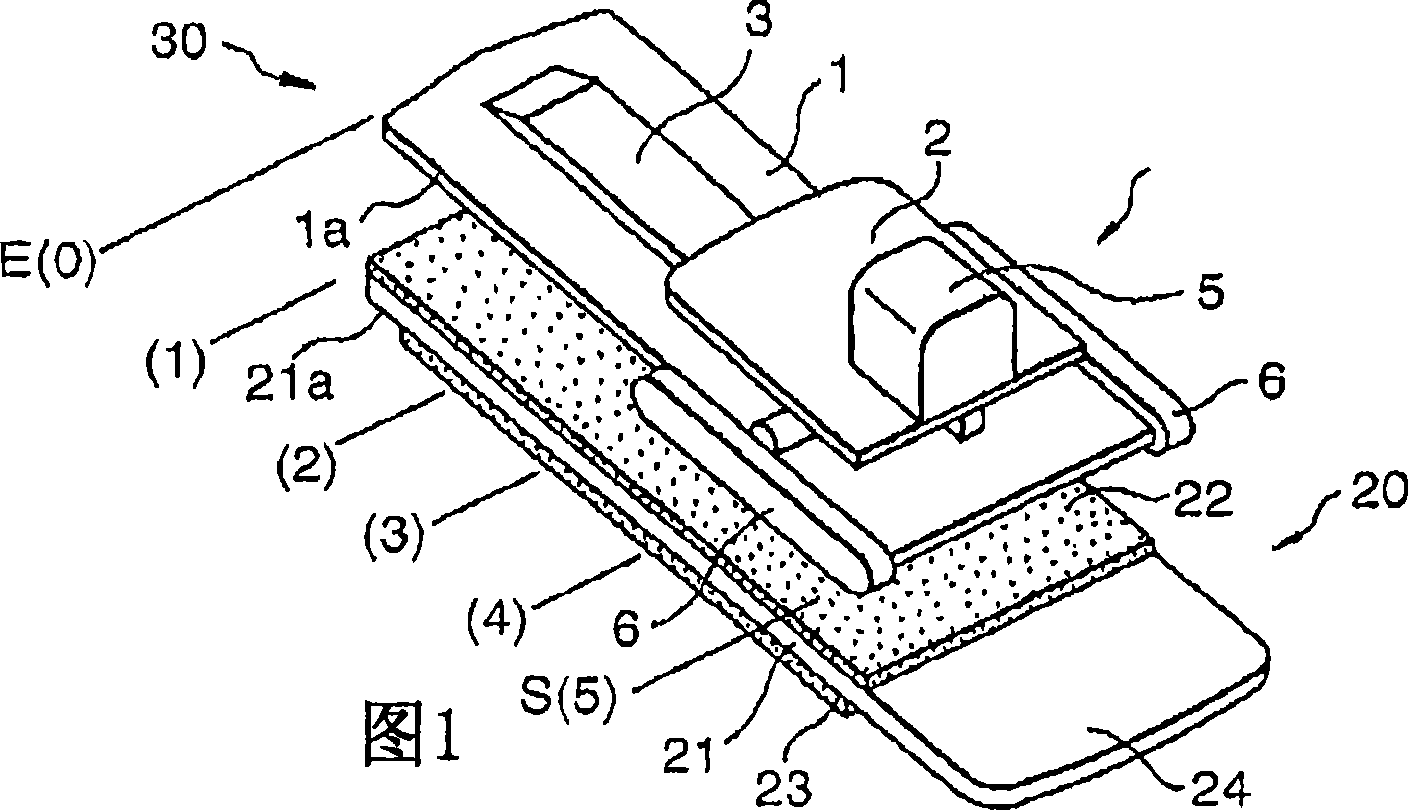

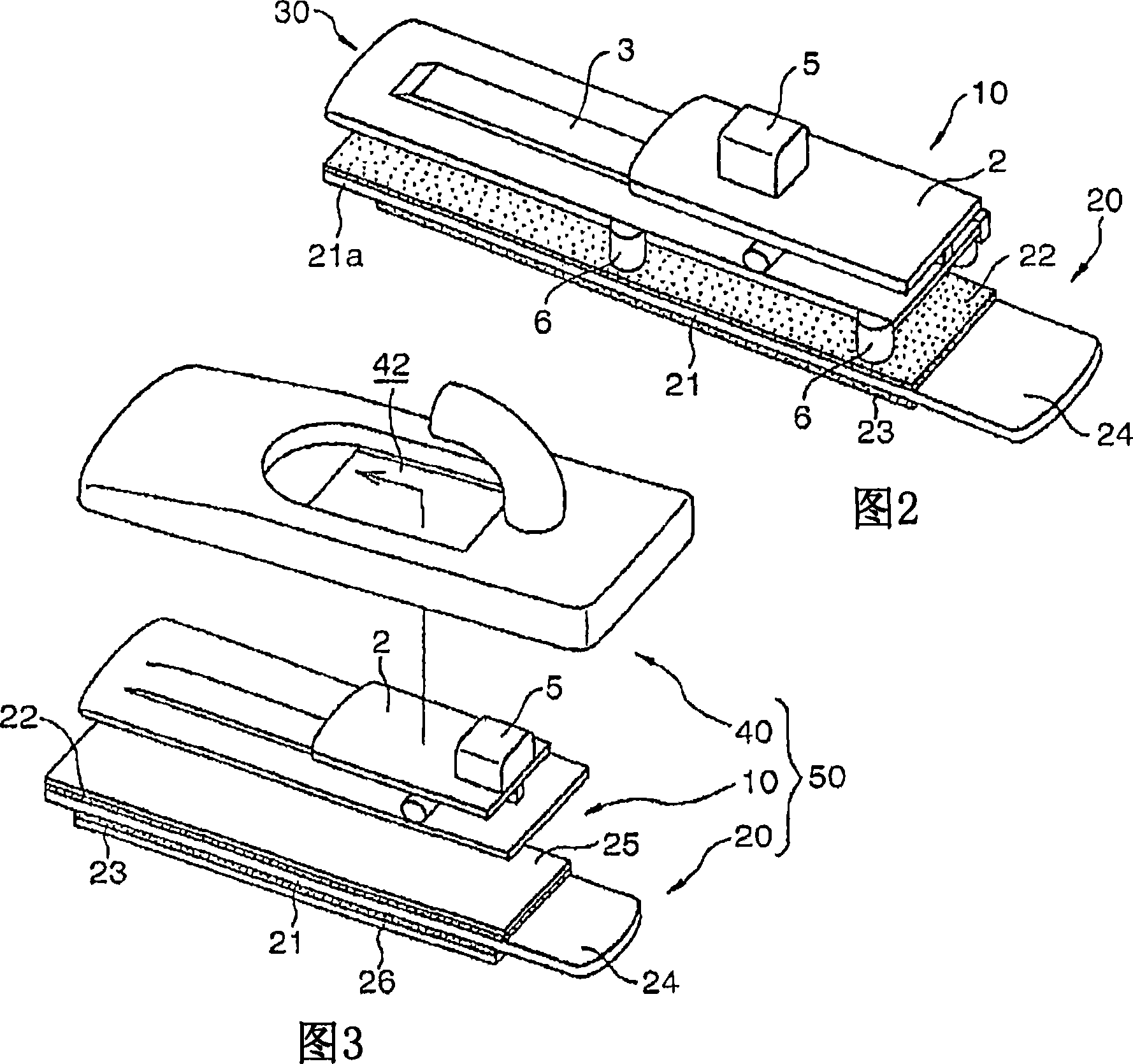

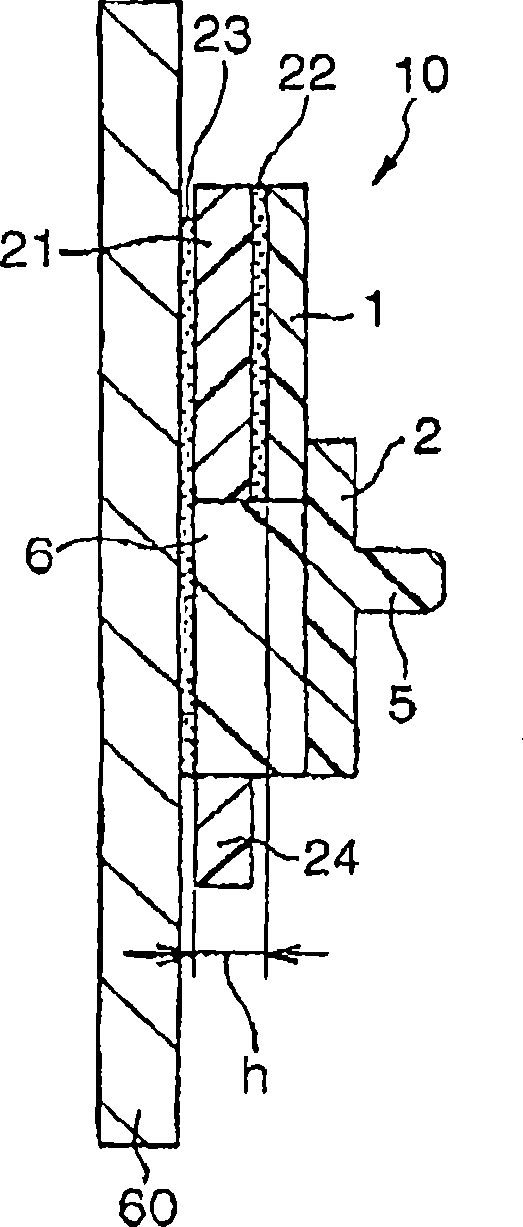

Article support structure and article attachment kit

InactiveCN101379156ACompactEasy to handlePicture framesFilm/foil adhesivesEngineeringMechanical engineering

To provide an article support structure used when attaching an article to an adherend with a stretch- releas'able adhesive tape in which components and the like do not fly off when releasing the adhesive tape from the adherend, the double -sided adhesive tape does not tear, and damage to high- sensitivity adherends can be effectively suppressed. An article support structure comprises a base plate which can be removably attached to an article, and a double -sided adhesive tape intervening between the base plate and an adherend, and having a stretchable base material and an adhesive layer. The base plate has a project ion- shaped gripping member, and at least one pair of spacer members disposed on both sides thereof which can form a gap between the surface of the adherend and the bottom surface of the base plate, and is configured so that the position of the gripping member and the position of the spacer members at least partly overlap in the length direction of the double-sided adhesive tape.

Owner:3M INNOVATIVE PROPERTIES CO

Vertical coating machine and vertical coating method

PendingCN109065938AEnsure consistencyImprove coating efficiencyPrimary cell manufactureAssembling battery machinesAgricultural engineeringEngineering

The invention provides a vertical coating machine and a vertical coating method, which relate to the technical field of battery manufacturing. A vertical coating machine comprises a frame, a first coating device and a second coating device arranged on the frame; An electric cell to be coated is upright on the frame, and an insulating film is arranged between the bottom surface of the electric cellto be coated and the rack; The first coating device can correspondingly wrap the front and rear sides of the insulating film on the front and rear surfaces of the cell to be coated; and the second coating device can correspondingly wrap the front and rear sides of the insulating film on the front and rear surfaces of the cell to be coated. The second coating device can correspondingly wrap the protruding edges of the front and rear side end portions of the insulating film on the left and right surfaces of the cell to be coated. A vertical coating method is based on the vertical coating machine. The invention solves the problems of low precision of horizontal coating method and the like in the prior art.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

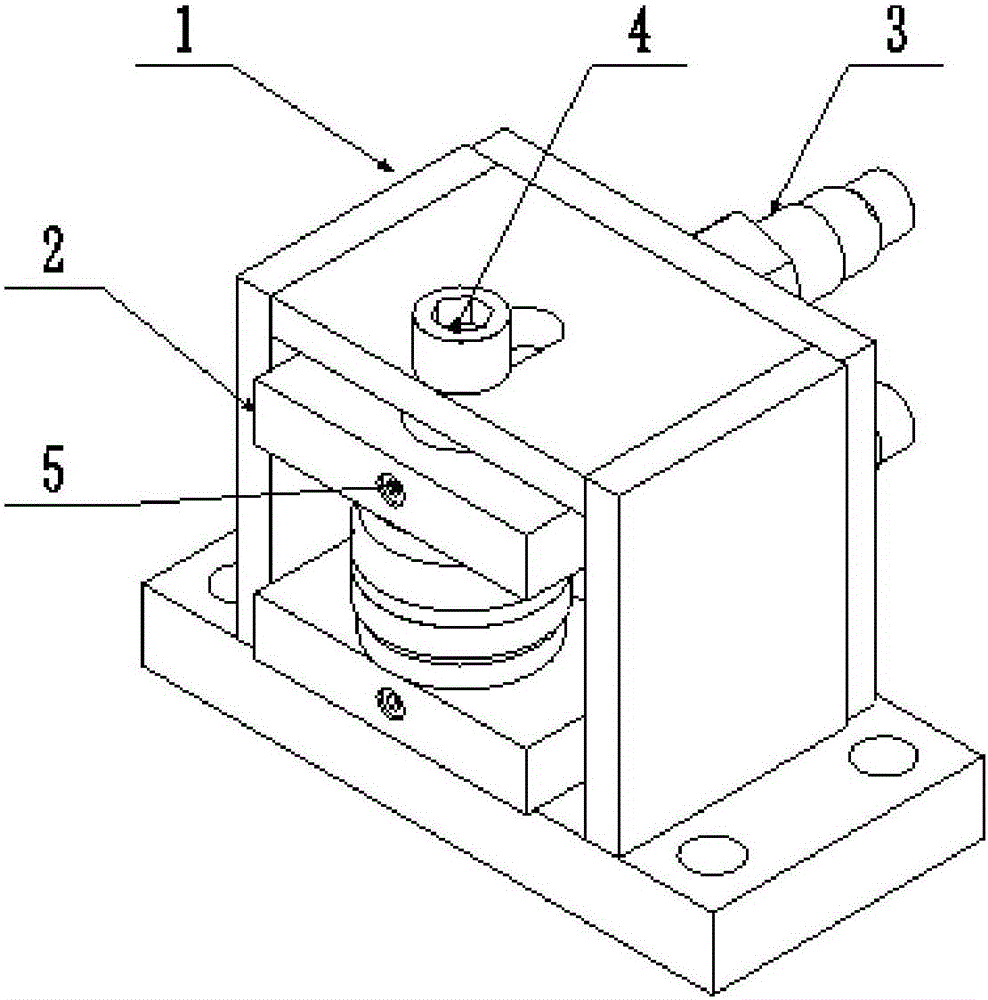

Hydraulic stopper used for weighing apparatus

InactiveCN101655389AImprove buffering effectEasy to assemble and disassembleWeighing relieving/arrestment mechanismsEngineeringAtmosphere

The present invention relates to a hydraulic stopper used for a weighting apparatus. The technical solution is as follows: the top ends of pistons (7) of two hydraulic piston cylinders are semi-spheres; two side end planes of a coupler (3) are symmetrically provided with hollow semi-spheres; the semi-spheres at the top ends of the pistons (7) of two hydraulic piston cylinders (2) are respectivelyinserted into the hollow semi-spheres at both sides of the coupler (3), and the two hydraulic piston cylinders (2) are respectively connected with the coupler (3). An oil inlet (9) above a rodless chamber of two hydraulic piston cylinders (2), an oil outlet (13) below the rodless chamber and an orifice (11) at the end of the rodless chamber are correspondingly equipped with an oil feeding stop valve (8), an oil discharging stop valve (12) and an orifice stop valve (10). The discharging ports (14) below the rod chamber of two hydraulic piston cylinders (2) are communicated with atmosphere. Twobag type energy accumulators (1) are respectively connected with the corresponding orifice stop valve (10). The hydraulic stopper of the invention has the characteristics of large buffer capacity, convenient disassembly and assembly, simple maintenance, high reliability and long service lifetime.

Owner:WUHAN UNIV OF SCI & TECH

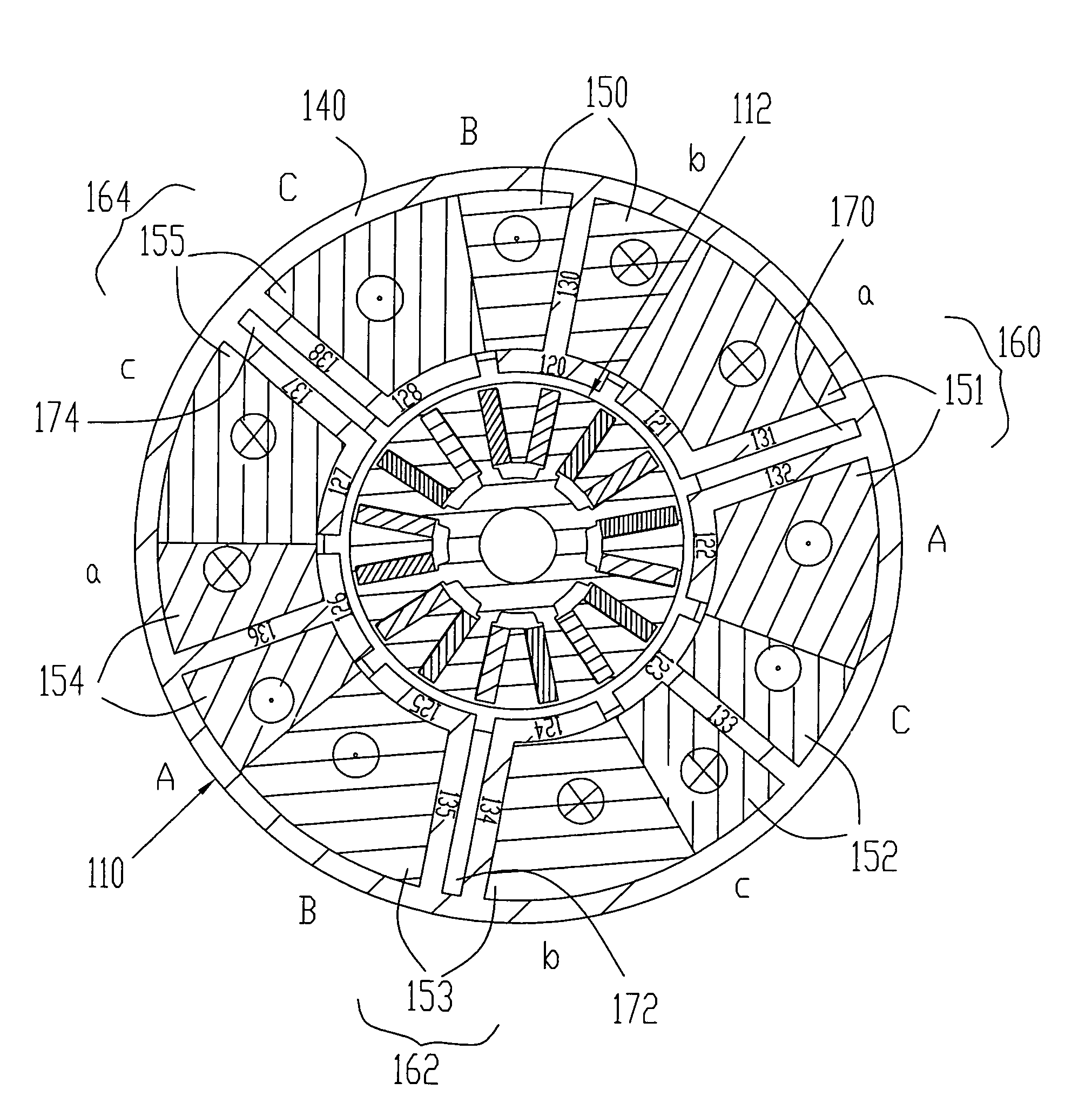

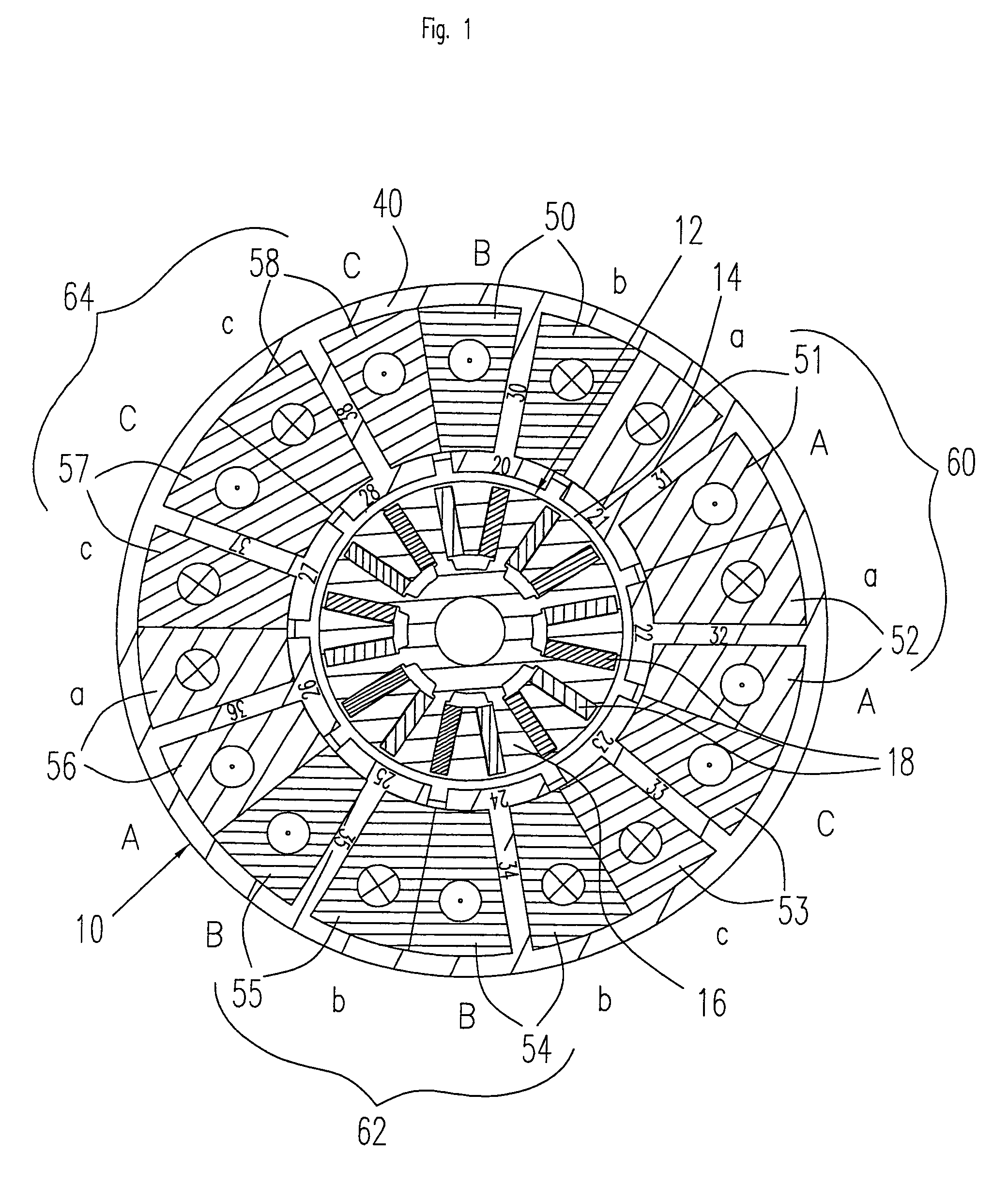

Brushless direct current motor

InactiveUS7132773B2Winding space availableImprove motor efficiencySynchronous generatorsWindingsConductor CoilDirect current

A direct current motor having a stator that has a plurality of radially arranged stator pole bridges to each of which one phase is allocated, at least one stator pole group being formed by at least two adjoining stator poles which are associated with the same phase, no winding sections being provided between the stator poles of the at least one stator pole group and the respective stator pole bridges of this stator pole group being disposed with a smaller spacing between each other than two adjoining stator pole bridges that are associated with different phases.

Owner:MINEBEA CO LTD

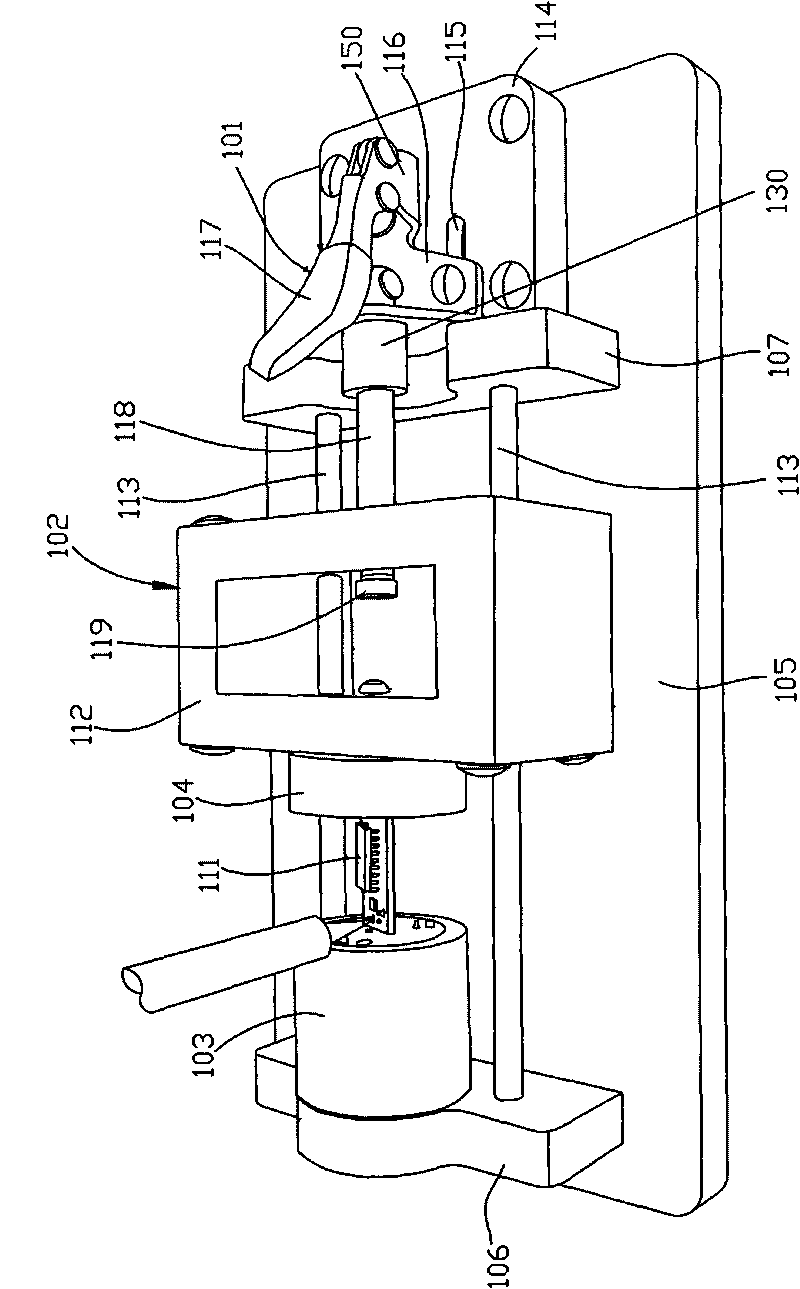

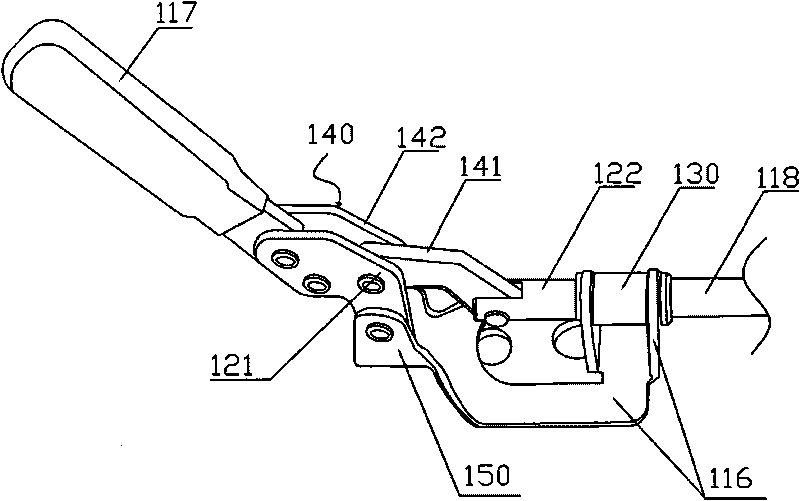

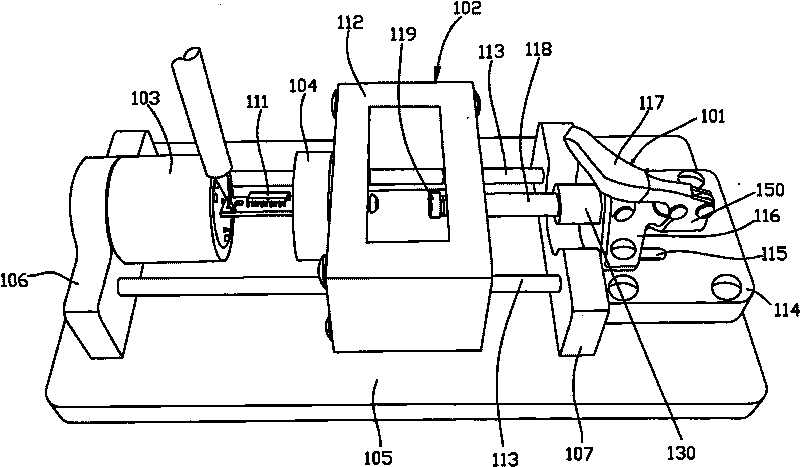

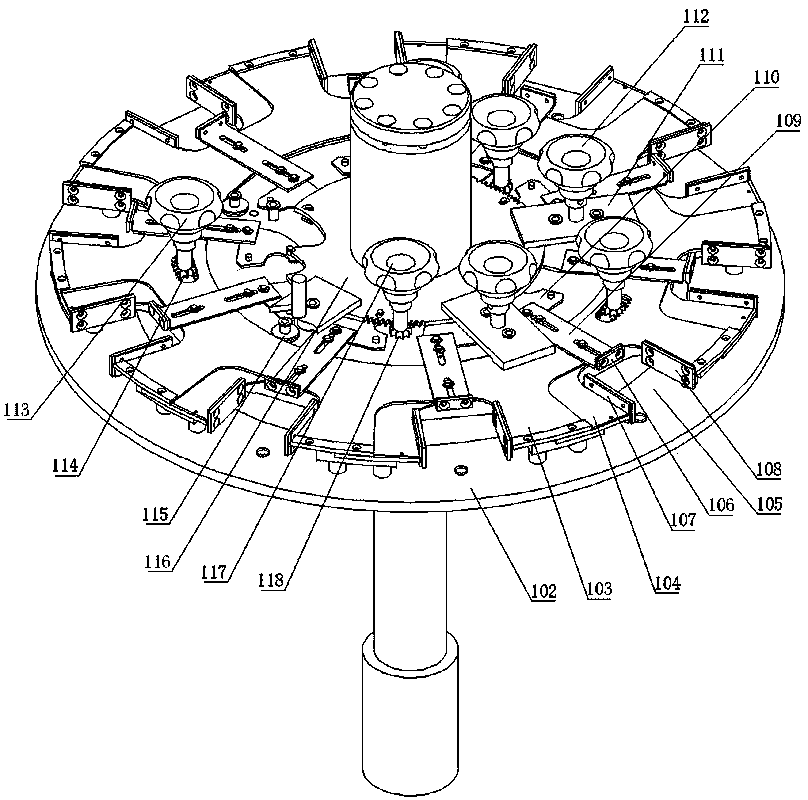

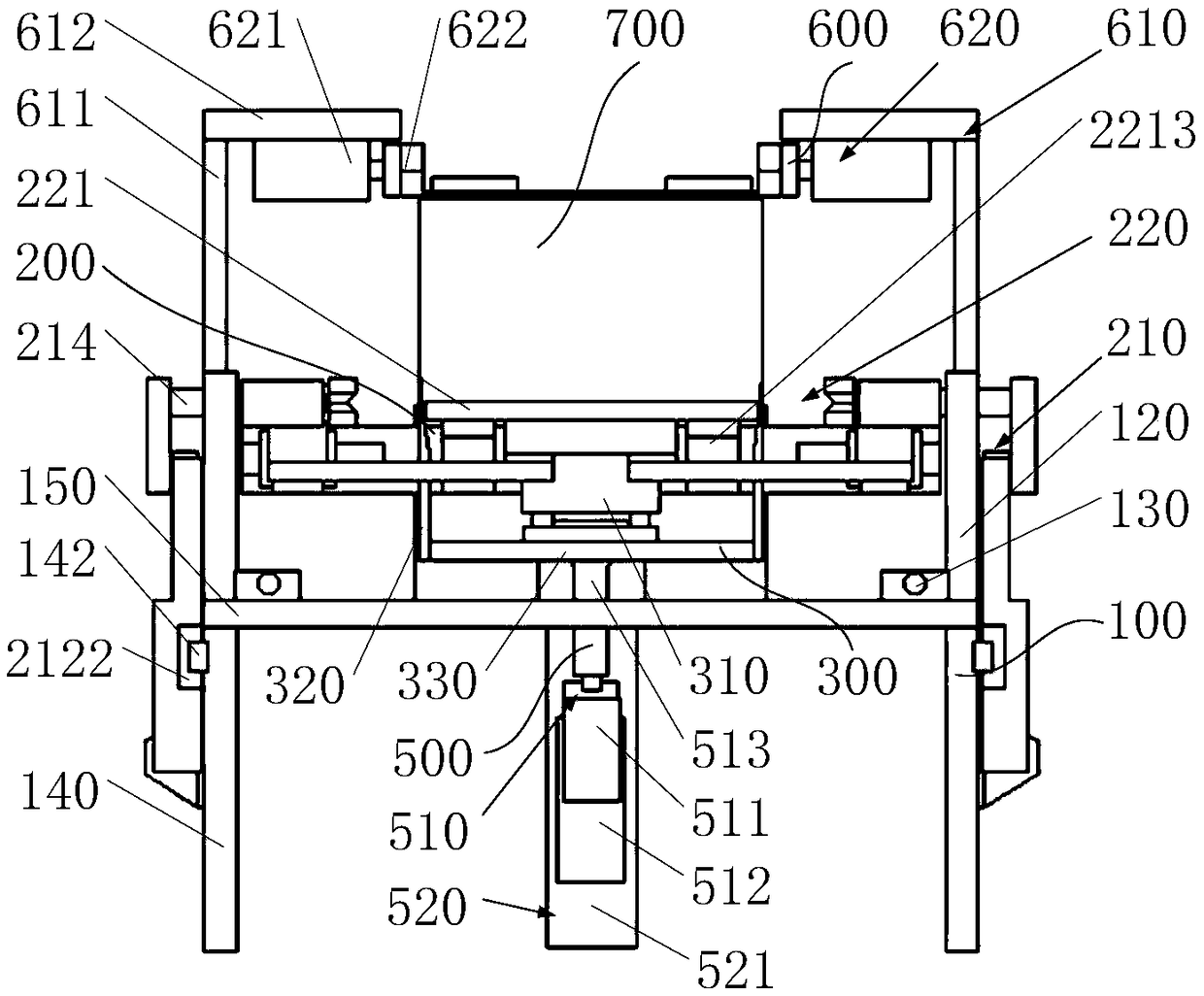

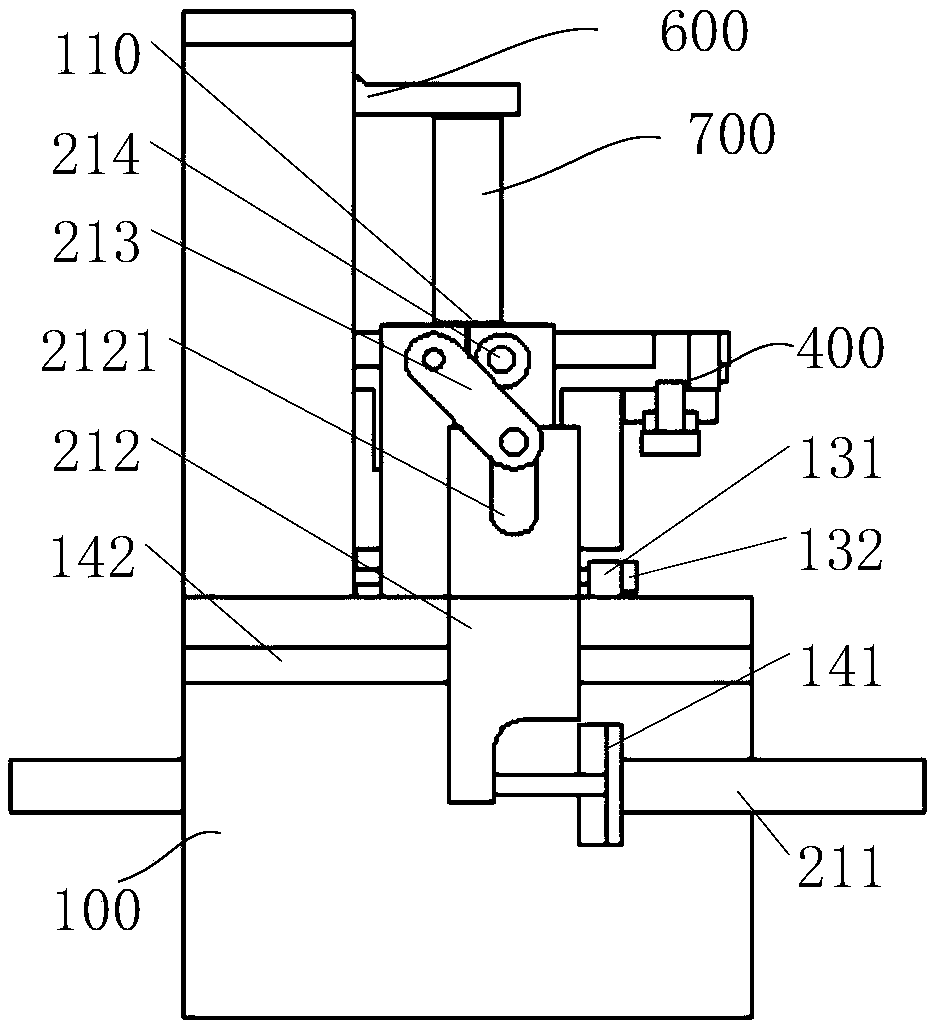

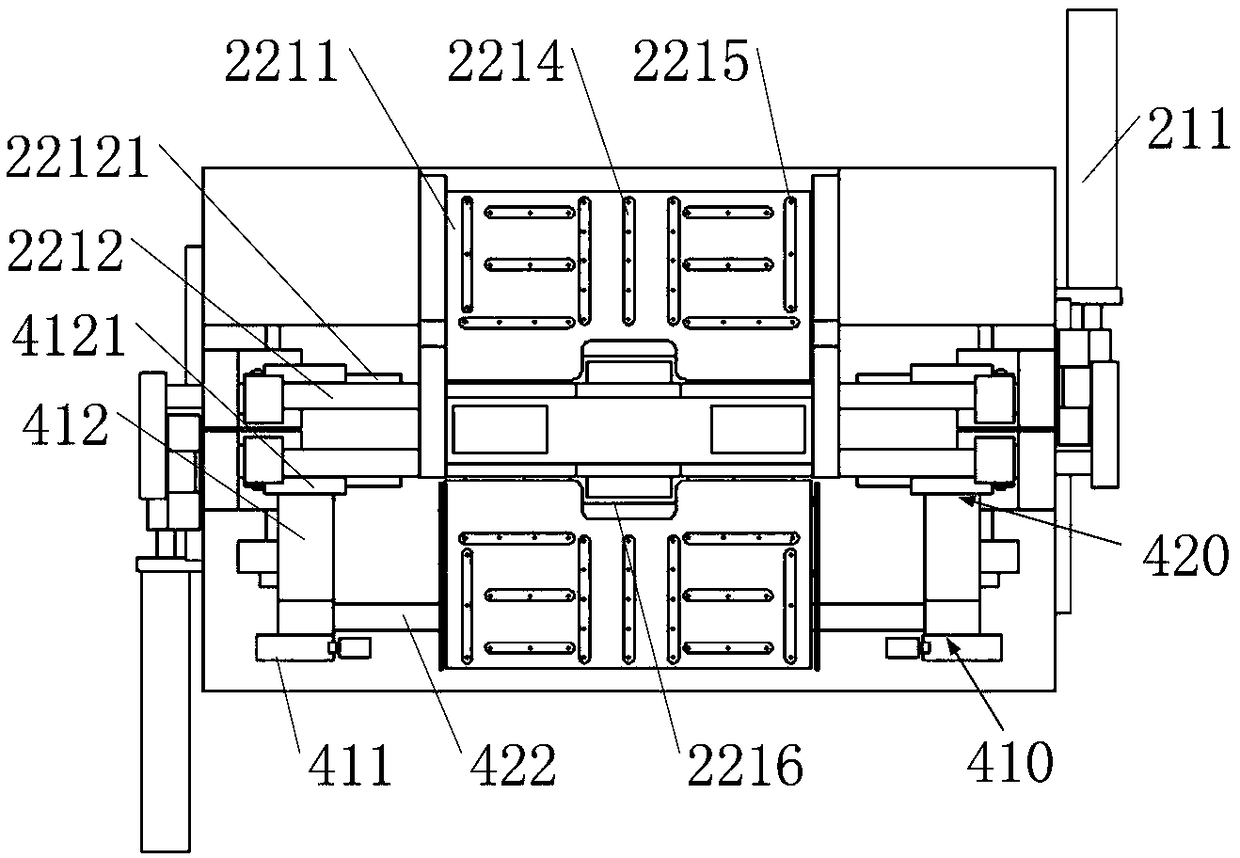

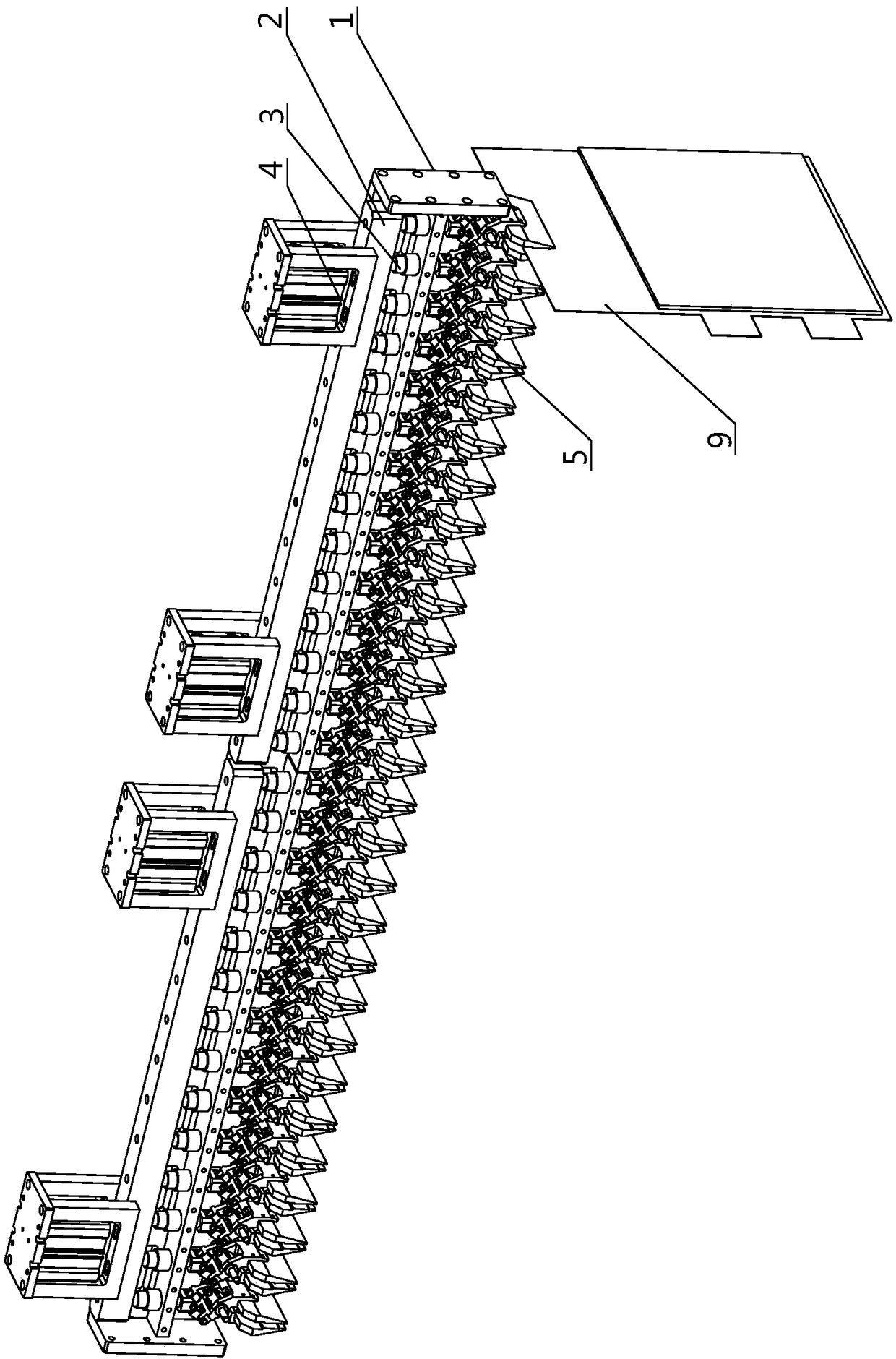

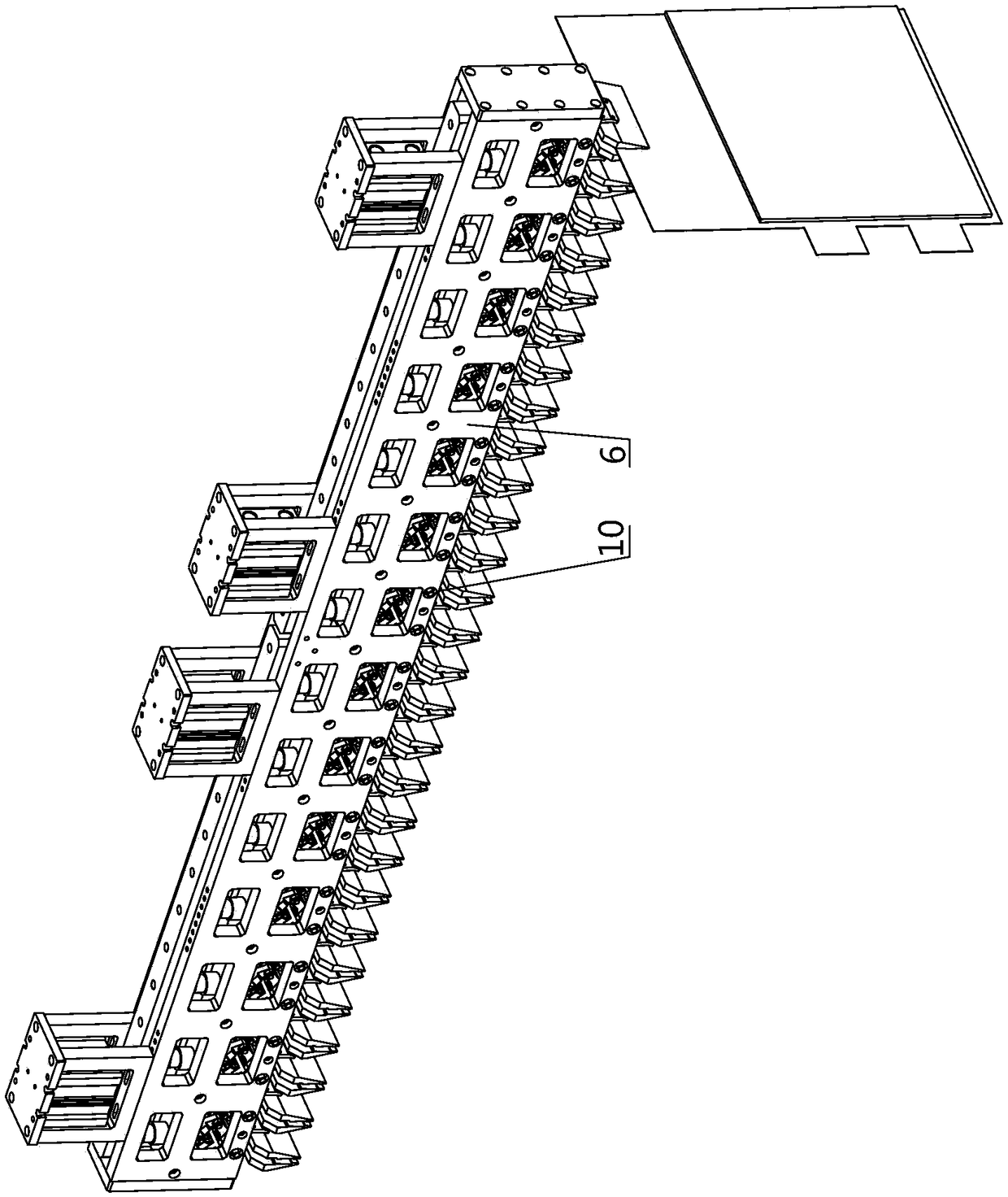

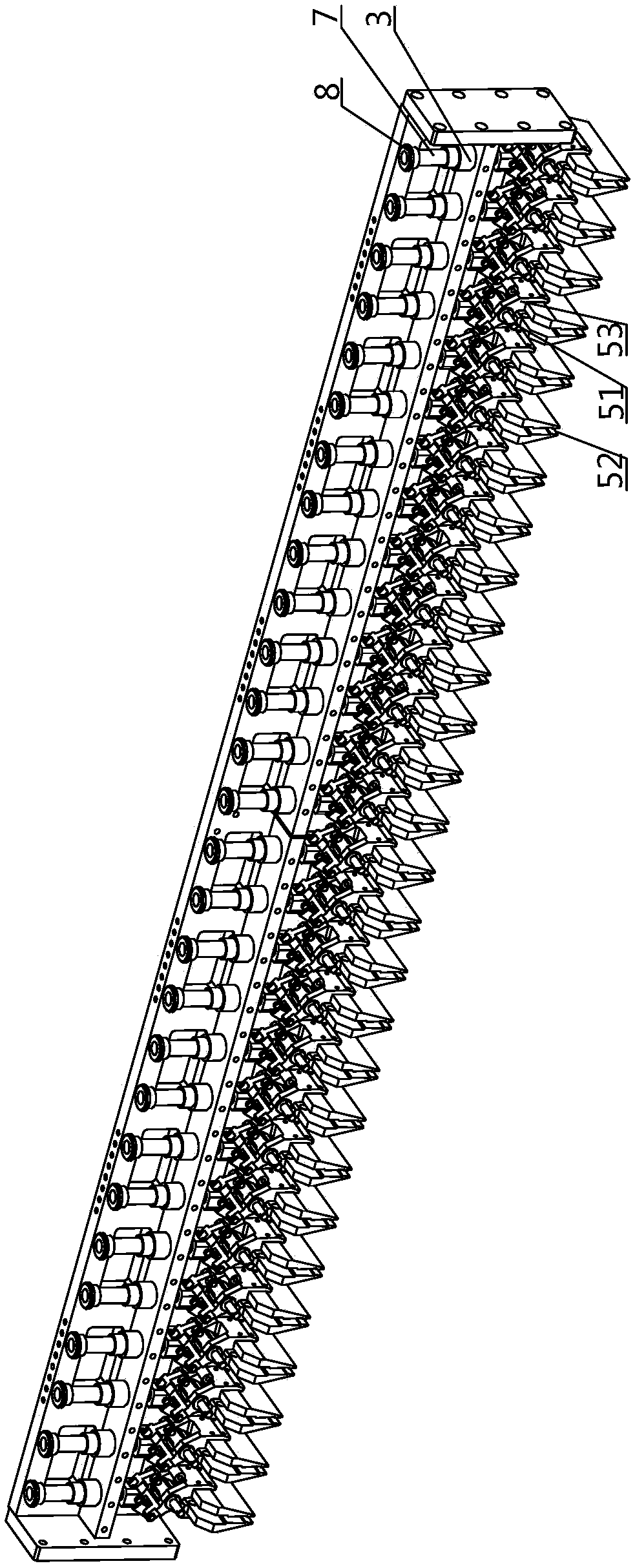

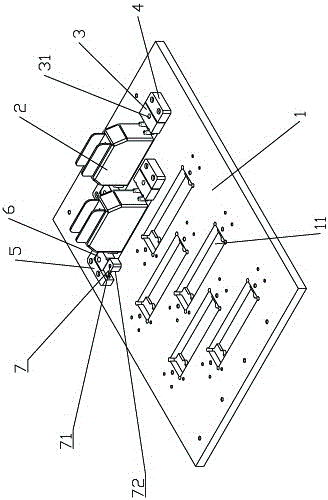

Opening and clamping device of lithium battery manipulator

The invention relates to an opening and clamping device of a lithium battery manipulator. The opening and clamping device comprises an opening and clamping pressing plate, opening and clamping blocks,a plurality of groups of clamping units and a clamp fixing plate. Cylinder units for realizing the pressing action of the opening and clamping pressing plate are arranged at the top of the opening and clamping pressing plate. Manipulator guide sleeves are arranged at the bottoms of the opening and clamping blocks. Clamping plates of the clamping units are fixed to the bottoms of corresponding material clamps, and the arc sections of the two material clamps of the same clamping unit are mutually staggered and fixed to a same rotating shaft. The clamping units enable the clamping plates to realize an expanded state or a tightened state through the pressing force transmitted by the corresponding opening and clamping blocks. The clamp fixing plate is provided with shaft positioning holes forfixing the distance between every two adjacent rotating shafts. The opening and clamping device of the lithium battery manipulator is favorable for controlling corresponding clamps to grab a battery cell up and down, the structure is simple and the grabbing mode is simple, a plurality of battery cells can enter into the next process with higher precision on the basis of keeping the same position distance, the detection steps are reduced, and the production efficiency is greatly improved.

Owner:SHENZHEN XINPU AUTOMATIC EQUIP CO LTD

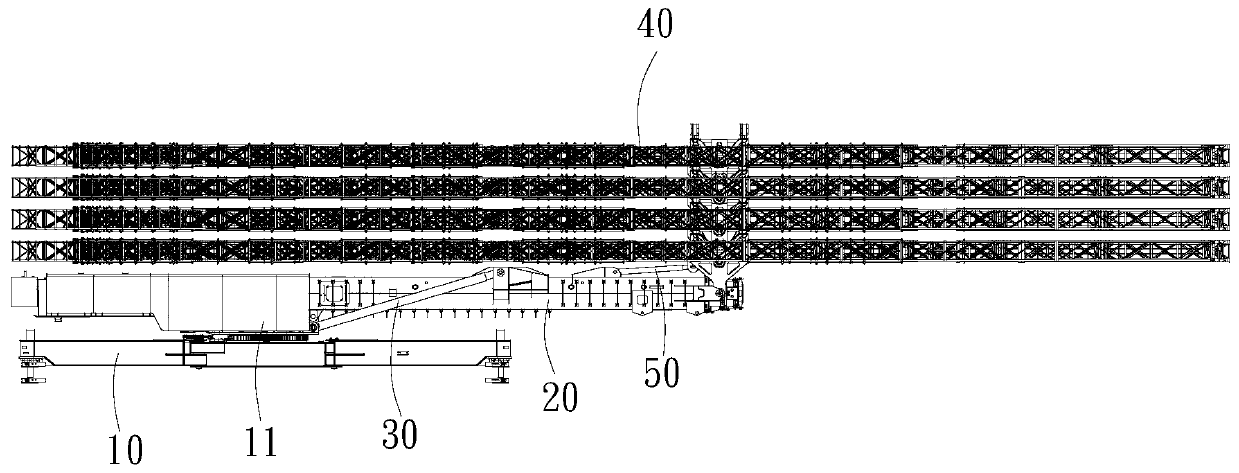

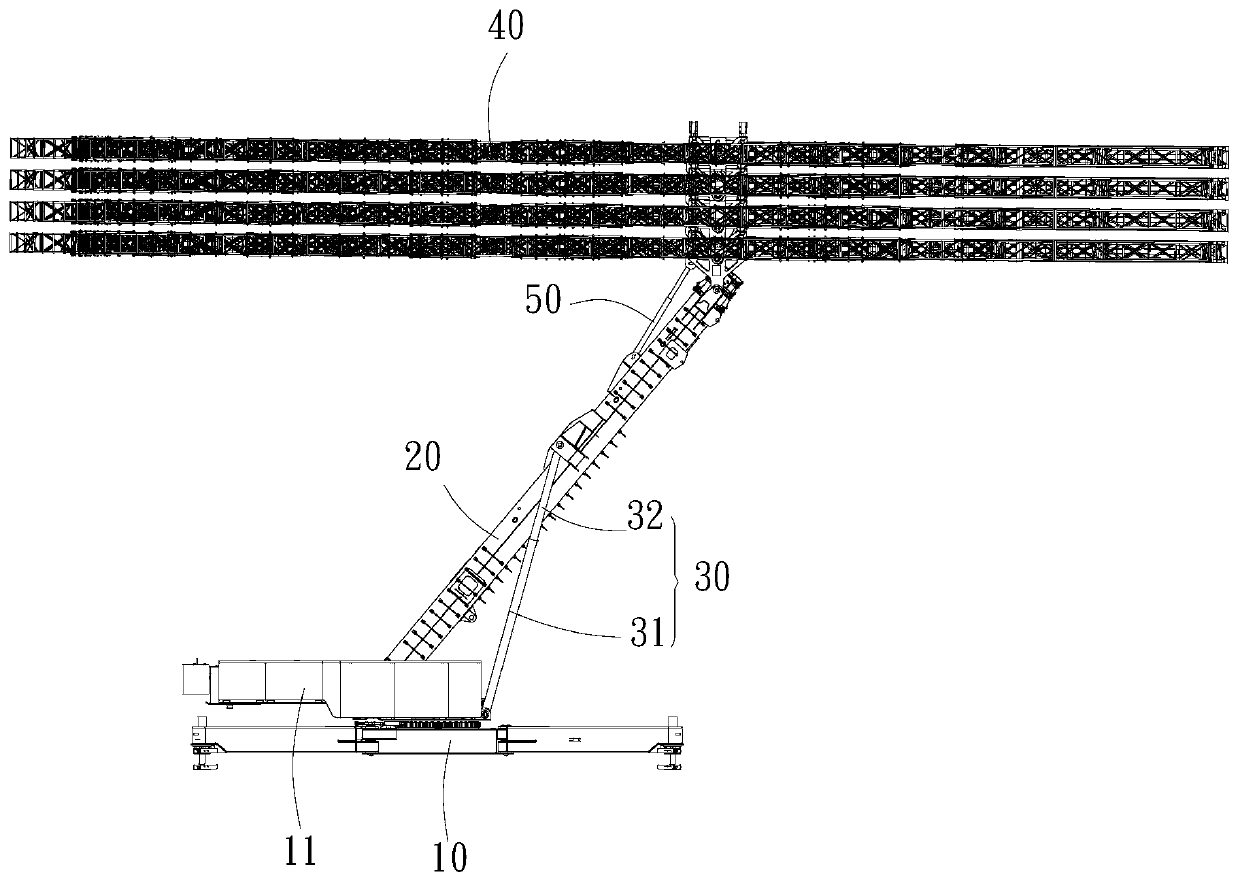

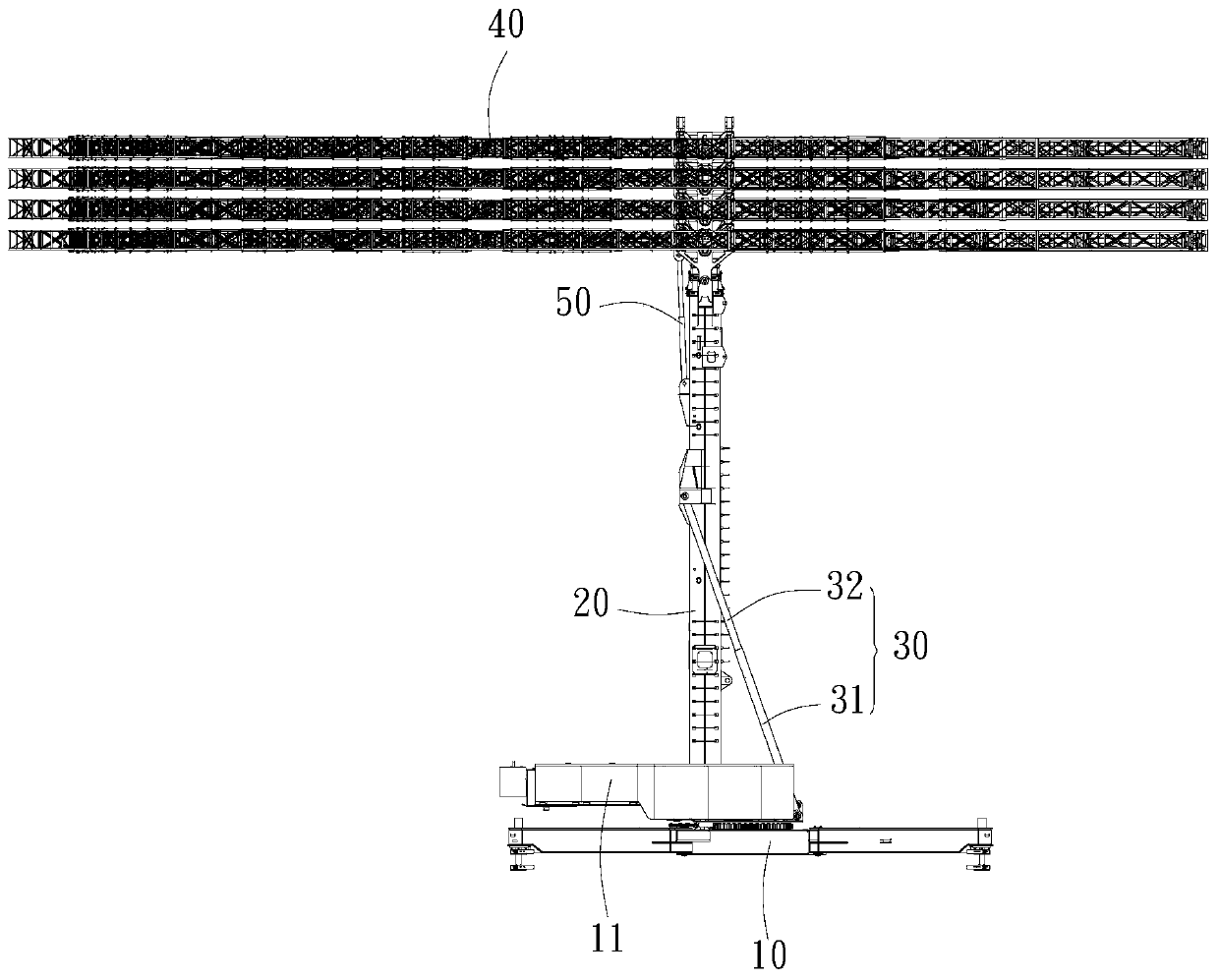

Antenna lifting control device and control method

ActiveCN110416693APosition unchangedAffect lifeAntenna supports/mountingsGravitationIndustrial engineering

Owner:SHENZHEN WAVE TELECOMM TECH CO LTD

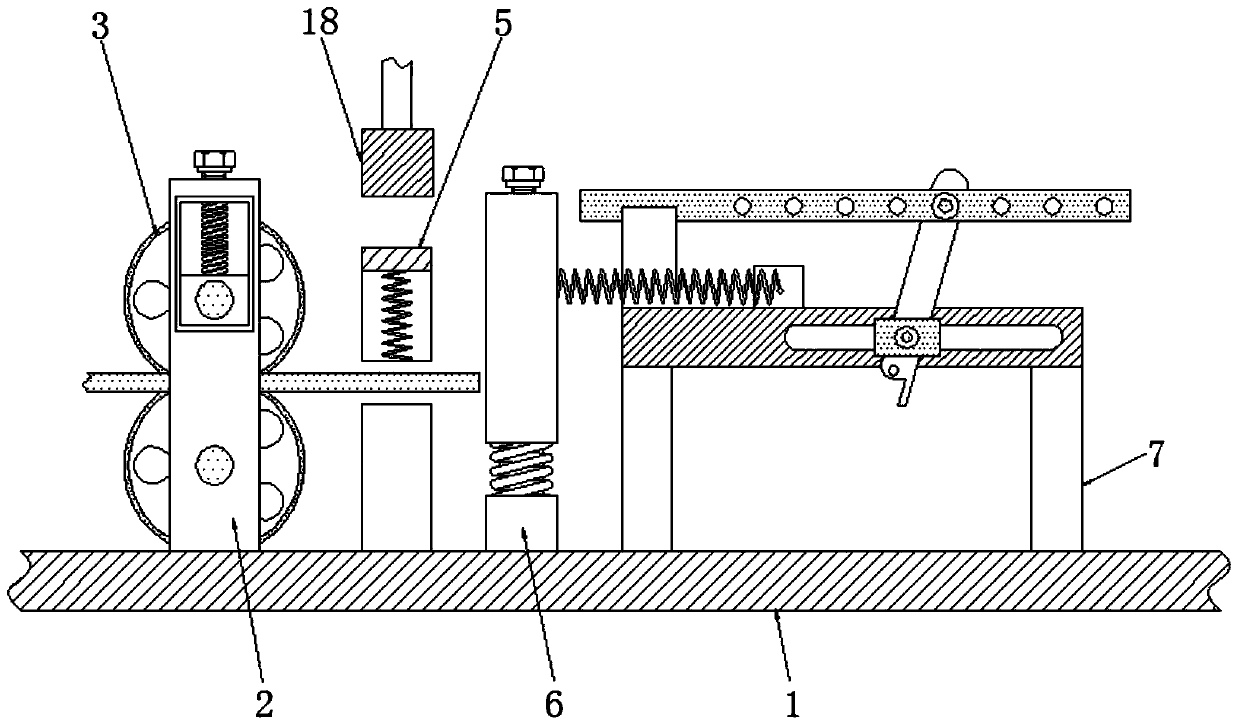

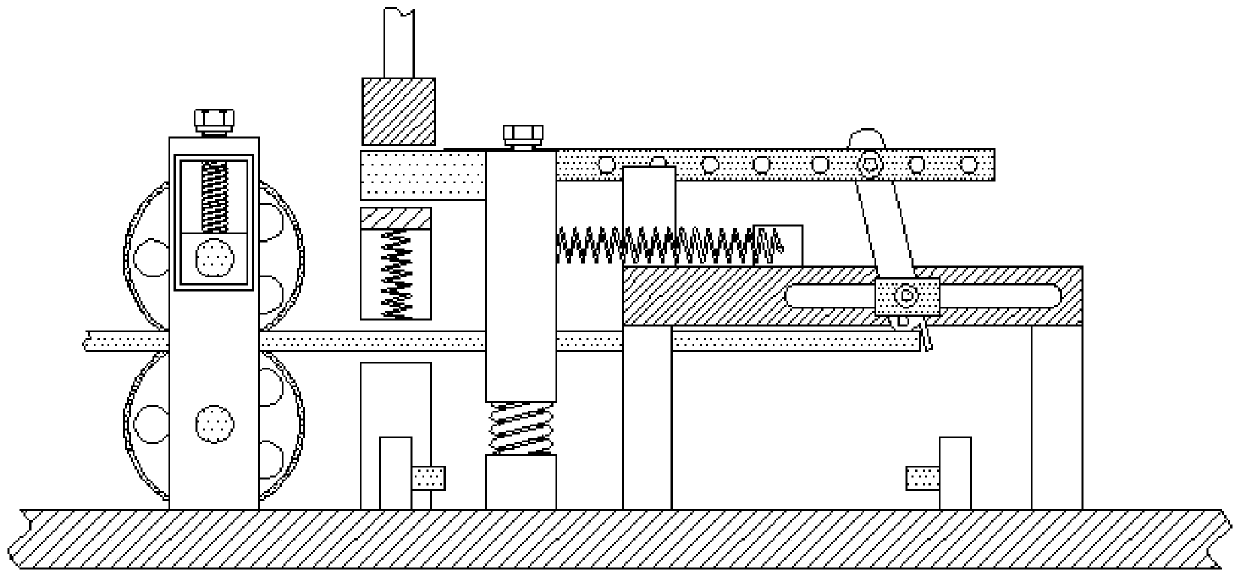

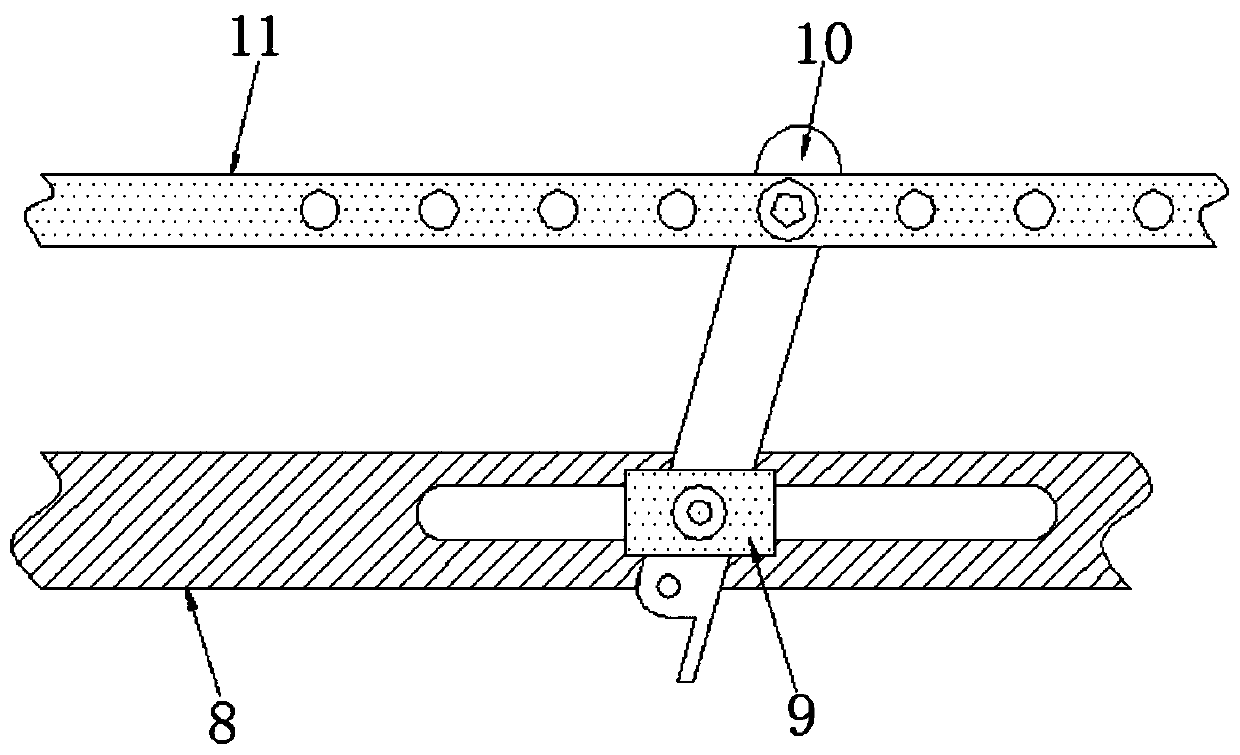

Roller adjusting device, adjusting method and application of device and bending machine comprising device

The invention discloses a roller adjusting device, an adjusting method and application of the device and a bending machine comprising the device, and belongs to the technical field of bending machines. The roller adjusting device is mounted on a cylinder of the bending machine; the roller adjusting device comprises a mounting base, a roller component and an adjusting component; the roller component is connected with the mounting base through the adjusting component; the adjusting component can be used for adjusting the roller component to move forwards and backwards relative to the mounting base; the roller component is in contact with a sliding block; the adjusting component comprises an adjusting thread sleeve, an adjusting screw nut and an adjusting screw; the adjusting thread sleeve is of a tubular structure and is in threaded connection with the mounting base; the adjusting screw nut sleeves the adjusting thread sleeve; the adjusting screw penetrates through the adjusting thread sleeve and is connected with the roller component. According to the adjusting method of the roller adjusting device, the roller component is adjusted by the adjusting component to move forwards and backwards so as to press the sliding block. By adopting the roller adjusting device, vibration of the sliding block can be alleviated in bending operation of a large-tonnage bending machine (the bending force is greater than 300t), the bending precision can be improved, the product pass percentage can be increased, and the service life of a cylinder can be prolonged.

Owner:ANHUI YAWEI MACHINE TOOL MFG

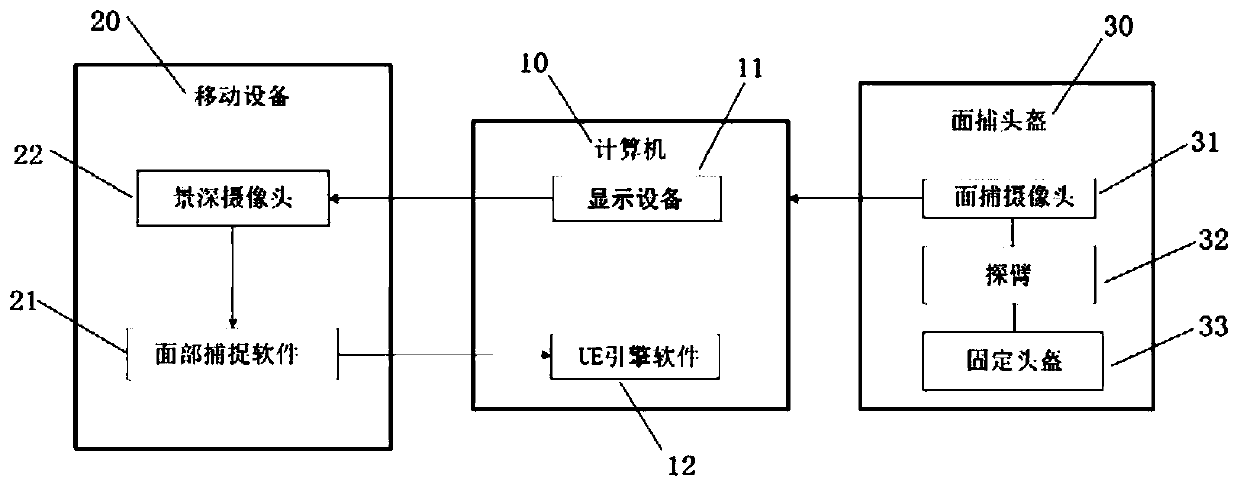

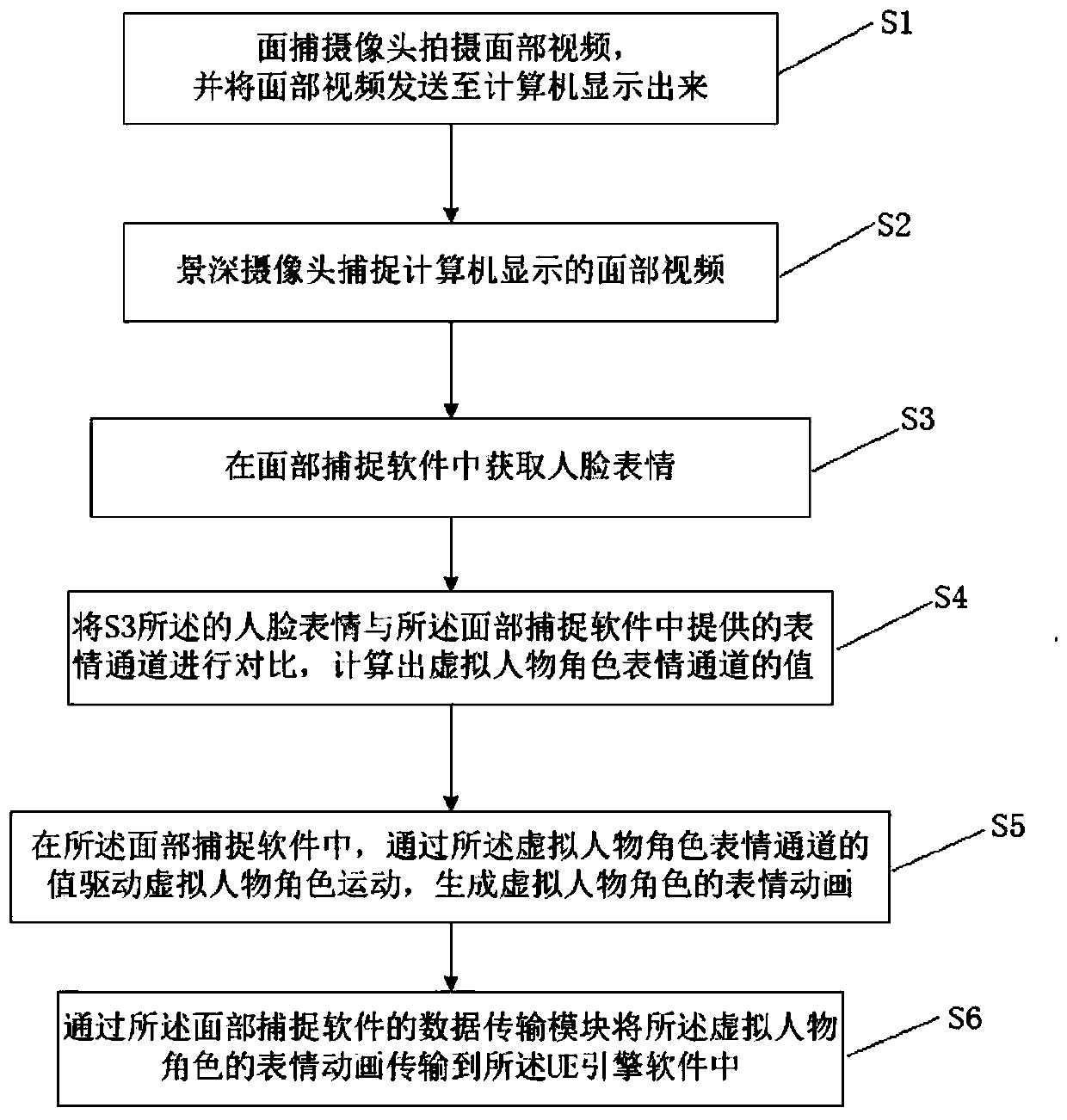

Mark-point-free face capturing device and method

ActiveCN109859297AGuaranteed stabilityPosition unchangedCharacter and pattern recognitionAnimationAnimationFacial expression

The invention provides a mark-point-free face capturing device and method. The device comprises a surface capture helmet, a computer and a mobile device, the computer comprises UE engine software, wherein the face capture helmet is used for shooting a face video and sending the face video to the computer for display, and the mobile device is used for capturing the face video displayed by the computer to obtain facial expressions, generating expression animations of virtual character roles and transmitting the expression animations to the UE engine software. High-standard face capture precisioncan be achieved under the condition that no mark point exists, and meanwhile the device is easy to operate and good in stability.

Owner:TIANJIN INSPIRATION & CREATIVITY SCI TECH DEVELOPMENT INC

Device for providing instantaneous pressure and integrating cutting and grinding on basis of reciprocating motion

ActiveCN110605795AImprove work efficiencyReduces individual grinding operationsGrinding drivesWorking accessoriesIntegrated circuit manufacturingReciprocating motion

The invention relates to the technical field of integrated circuits, and discloses a device for providing instantaneous pressure and integrating cutting and grinding on the basis of reciprocating motion. The device comprises a bottom plate, the entire device is supported by the bottom plate, through the cooperative use among a cutting knife, a grinding rod and a bearing frame, when the cutting knife cuts a plate, the plates are overlapped above a support frame under the gravity action, finally, the grinding rod is driven to move, so that the whole device can carry out cutting and grinding integrally, follow-up single grinding operations is omitted, the working efficiency during the whole integrated circuit manufacturing process is improved, through the cooperation among a vertical rod, a square block, a rotating rod, a connecting table and a push rod, the push rod moves forwards to drive the rotating rod to rotate, the vertical rod drives the square block to synchronously move downwards, and finally the cutting knife is driven to move downwards, and the downward force at the cutting moment is large and fast, so that cutting is more orderly compared with traditional up-down reciprocating cutting, and the generation of debris is reduced.

Owner:诸暨市华能催化剂有限公司

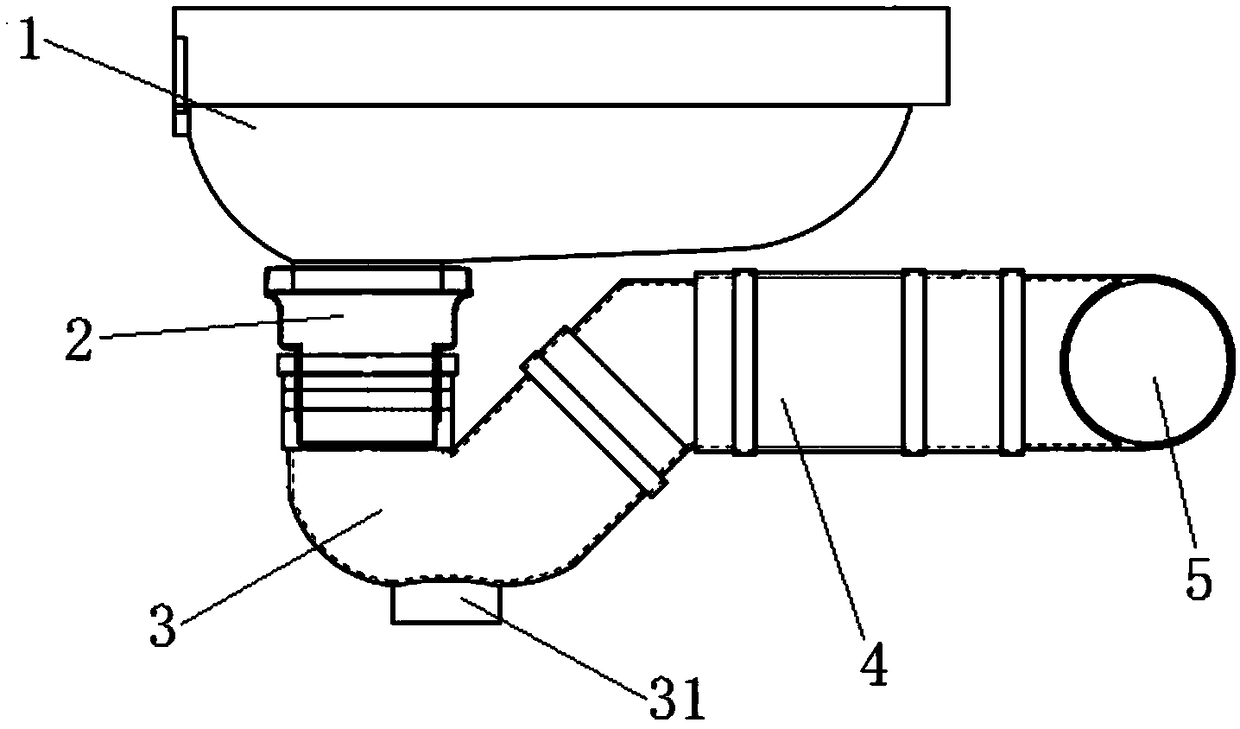

Box type toilet squatting pan and box room bathroom

PendingCN109113154AMeet the needs of useImprove satisfactionWater closetsDomestic plumbingWater trapEngineering

The invention provides a box type toilet squatting pan and box room bathroom, which relate to the technical field of temporary buildings. The box type toilet squatting pan comprises a squatting toiletpan body, a water trap and a telescopic pipe. The squatting pan body is installed on the floor of the toilet, the water trap is made of cold-resistant material and installed on the base of the toilet, and the two ends of the telescopic pipe are respectively sealed with the lower end of the squatting toilet body and the upper end of the water trap. The squatting pan alleviates the technical problems that the tightness of the joint between the squatting toilet and the pipe and the water trap in the squatting toilet are easily damaged by freezing when the box room bathroom moves in the prior art.

Owner:中建机械有限公司

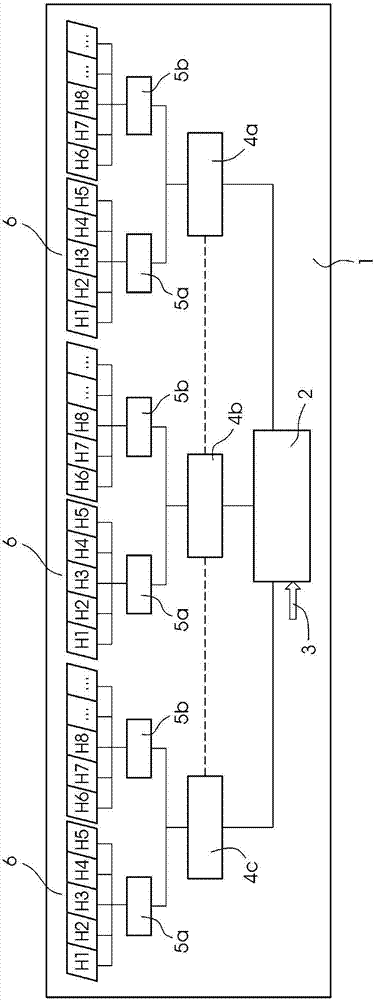

Method for density compensation by drop size adaptation

ActiveCN107009770AAvoid Brightness DifferencesEquilibrium volatilityVisual presentationOther printing apparatusMechanical engineeringDrop size

Owner:HEIDELBERGER DRUCKMASCHINEN AG

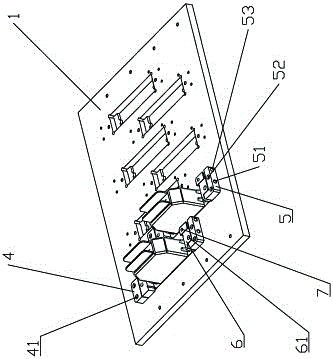

Nozzle installation adjusting device and ink jet printing device

InactiveCN106515218AMachining accuracy is easy to realize and guaranteeAvoid harmPrintingEngineeringNozzle

The invention proposes a nozzle installation adjusting device. The device comprises a baseplate, a nozzle and an adjusting mechanism; and the nozzle and the adjusting mechanism are mounted on the nozzle baseplate. The device is characterized in that the adjusting mechanism includes a first adjusting mechanism and a second adjusting mechanism; the first adjusting mechanism is used for adjusting movement of the nozzle in the nozzle connecting line direction; and the second adjusting mechanism is used for adjusting the rotating movement of the nozzle around one end of the nozzle.

Owner:NANJING HANQIAN DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com