Circuit board welding clamp

A welding fixture and circuit board technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as incompetence for welding multiple circuit boards, and achieve improved welding accuracy, simple structure, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

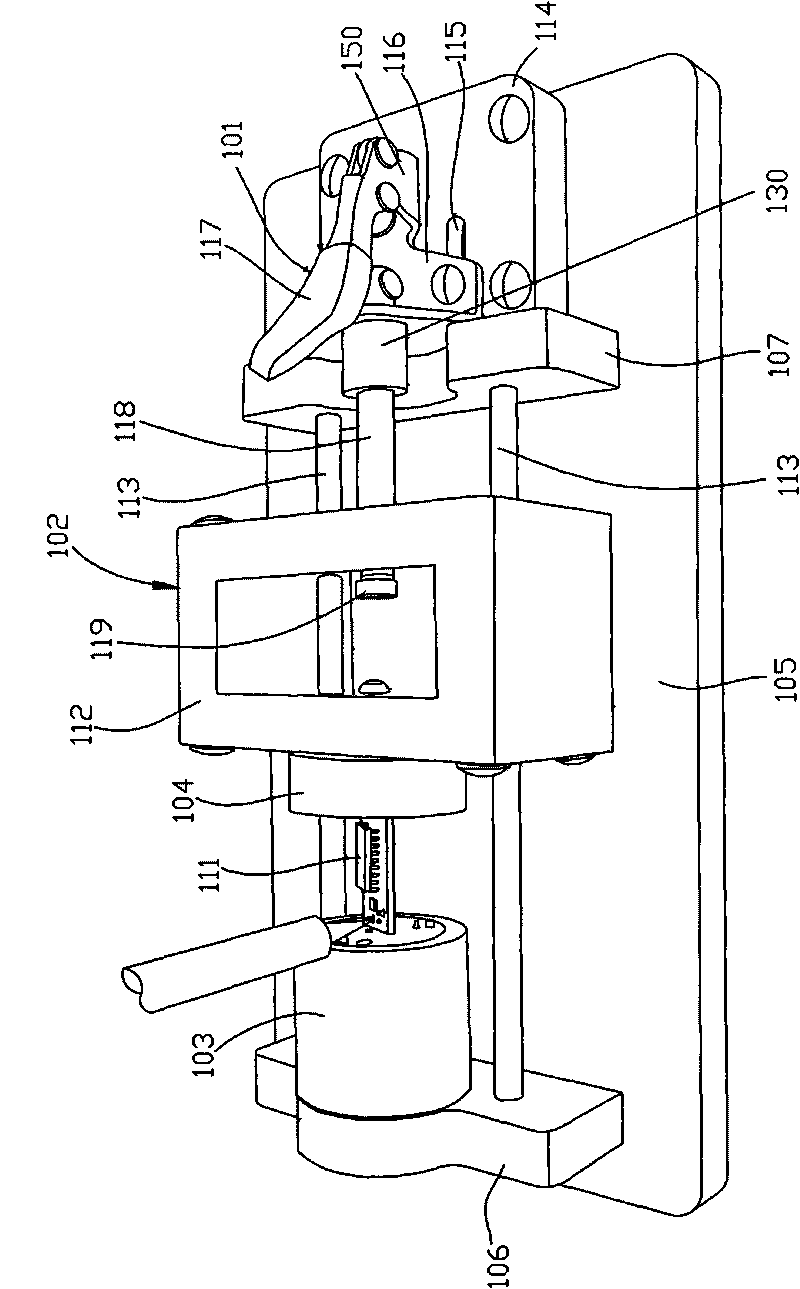

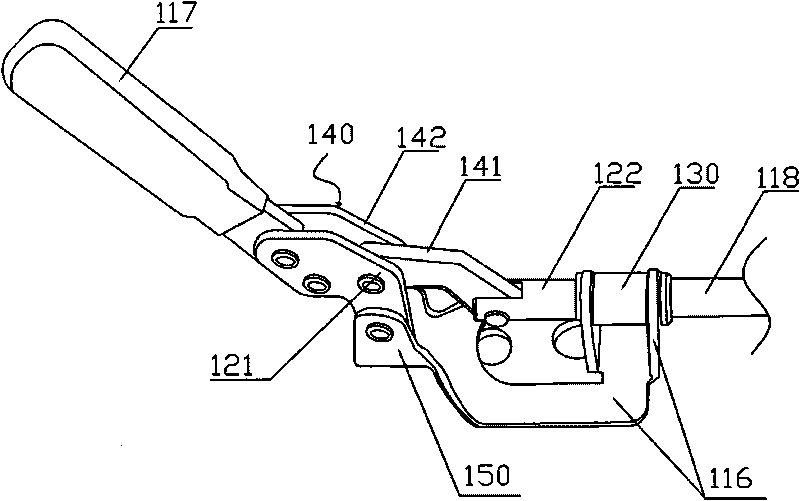

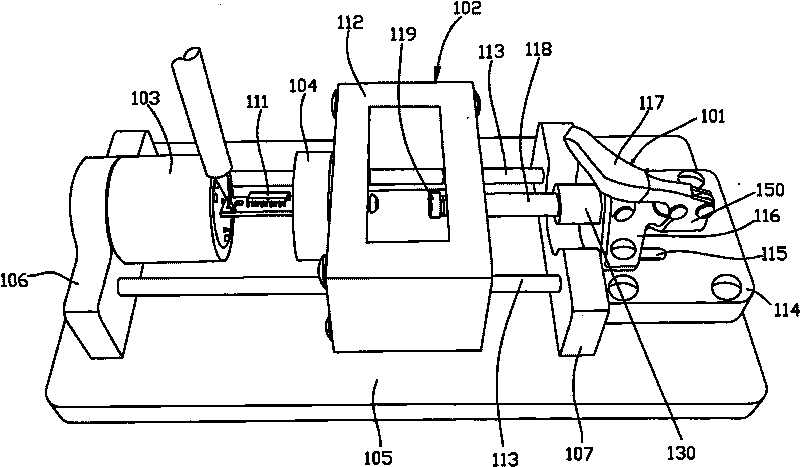

[0017] figure 1 It is a structural schematic diagram of the circuit board welding jig in the present invention. like figure 1 As shown, the circuit board soldering fixture includes:

[0018] The first support 106, the first clamping block 103 arranged on the first support 106, the second clamping block 104 arranged opposite to the first clamping block 103, the push-pull rod 118 and used to drive the Push-pull rod 118 is the drive mechanism 101 that carries out linear motion; Described first clamping block 103 and first support 106 constitute cylindrical kinematic pair; One end of push-pull rod 118 is arranged on the drive mechanism 101, and its other end is provided with second clamping Block 104 , the other end of the push-pull rod 118 and the second clamping block 104 form a cylindrical kinematic pair.

[0019] It can be seen from the above structure that the rotation axes of the first clamping block and the second clamping block are on the same straight line, that is, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com