Grating fabricating equipment and process

A technology for manufacturing a device and a grating, which is applied to the manufacturing device of the grating and the manufacturing field of the grating, can solve the problems of the limitation of the grating and the difficulty of practical application, and achieve the effect of reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

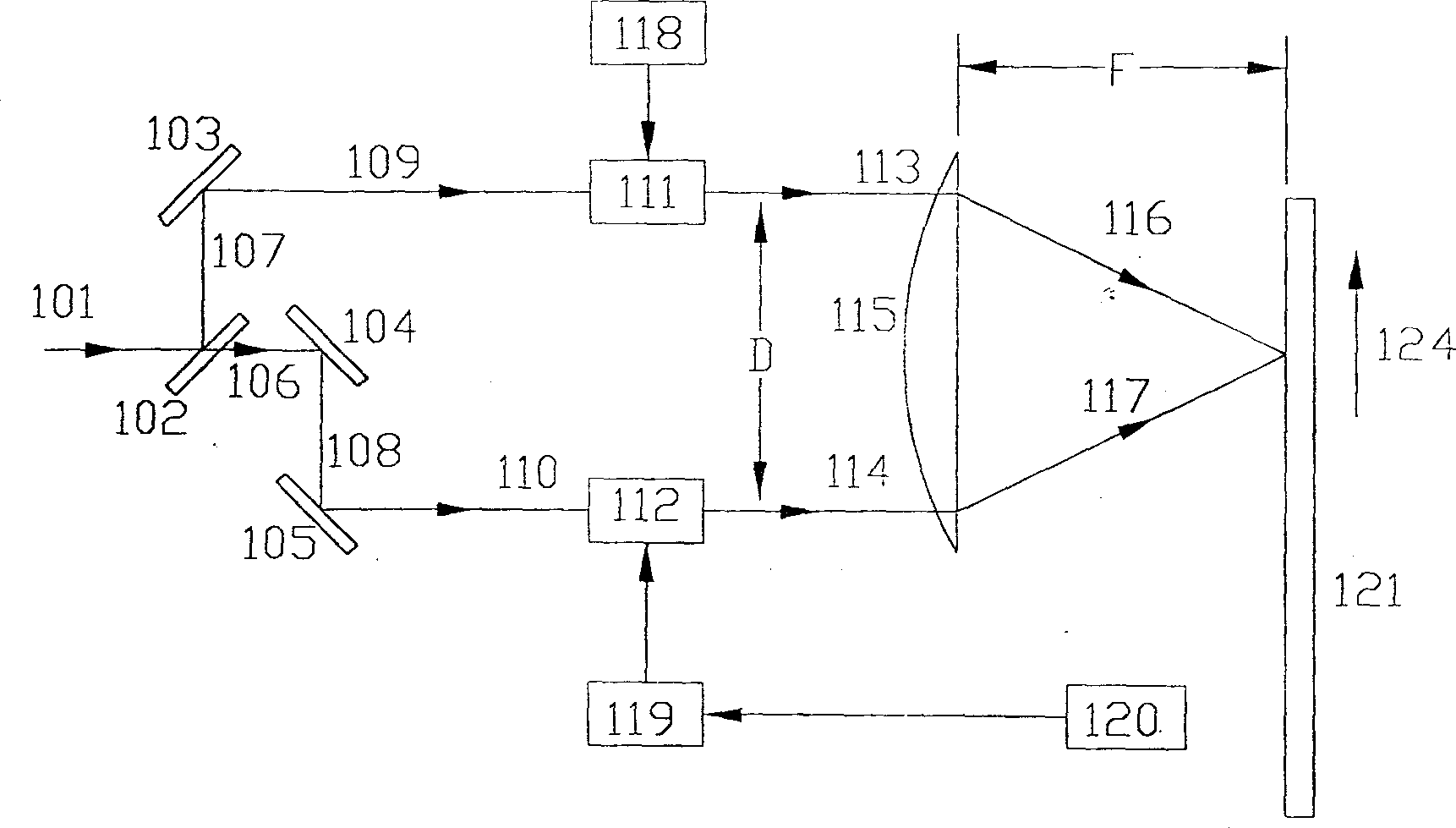

[0034] attached figure 1 Among them, a continuous laser beam 101 is split into beams 106 and 107 after passing through a half-mirror 102 . The light intensity of the light beam 106 and the light beam 107 are equal or nearly equal. The beam 106 and the beam 107 are respectively reflected by the total reflection mirrors 105 and 103 to obtain a parallel beam 109 and a beam 110 . The mirrors 102, 103, 104, 105 can be replaced by prisms or other forms of optical elements to complete the beam splitting function. Light beam 109 and light beam 110 pass through optical frequency shifters 111 and 112, respectively. In the embodiment of the present invention presented here, optical frequency shifters 111 and 112 are acousto-optic frequency modulators, but they may also be electro-optic or other forms of optical frequency modulators.

[0035] attached image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com