Bi-directional rotary handle and vehicle with same

A two-way turning and turning technology, which is applied in the field of electric vehicles equipped with turning handles, can solve problems such as the decline of electric energy recovery rate, control restrictions, and the influence of riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

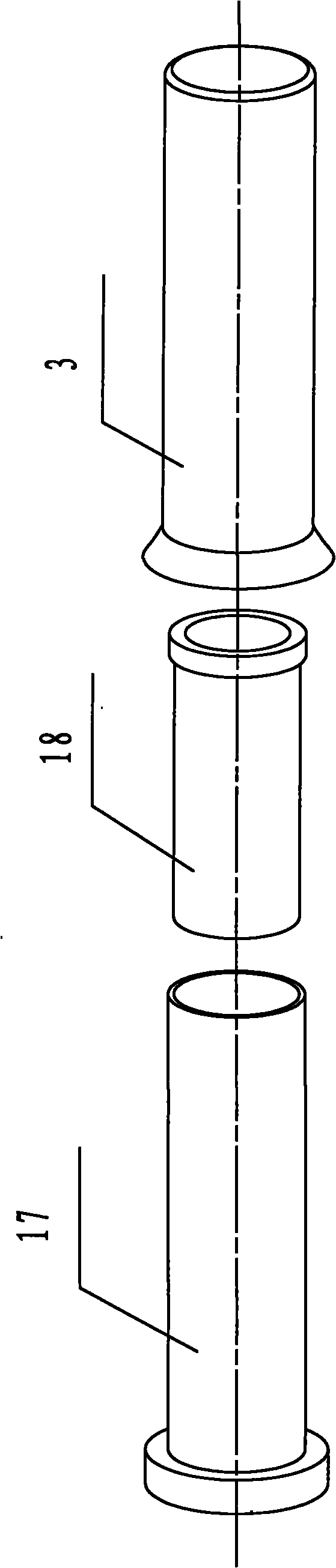

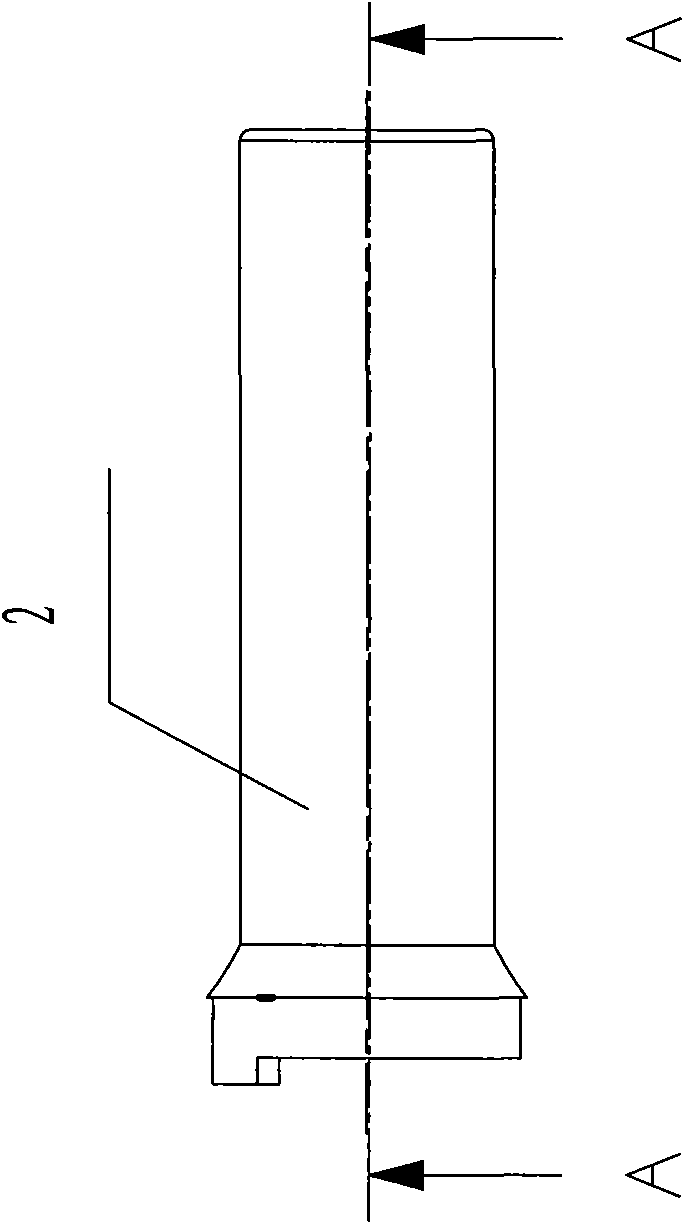

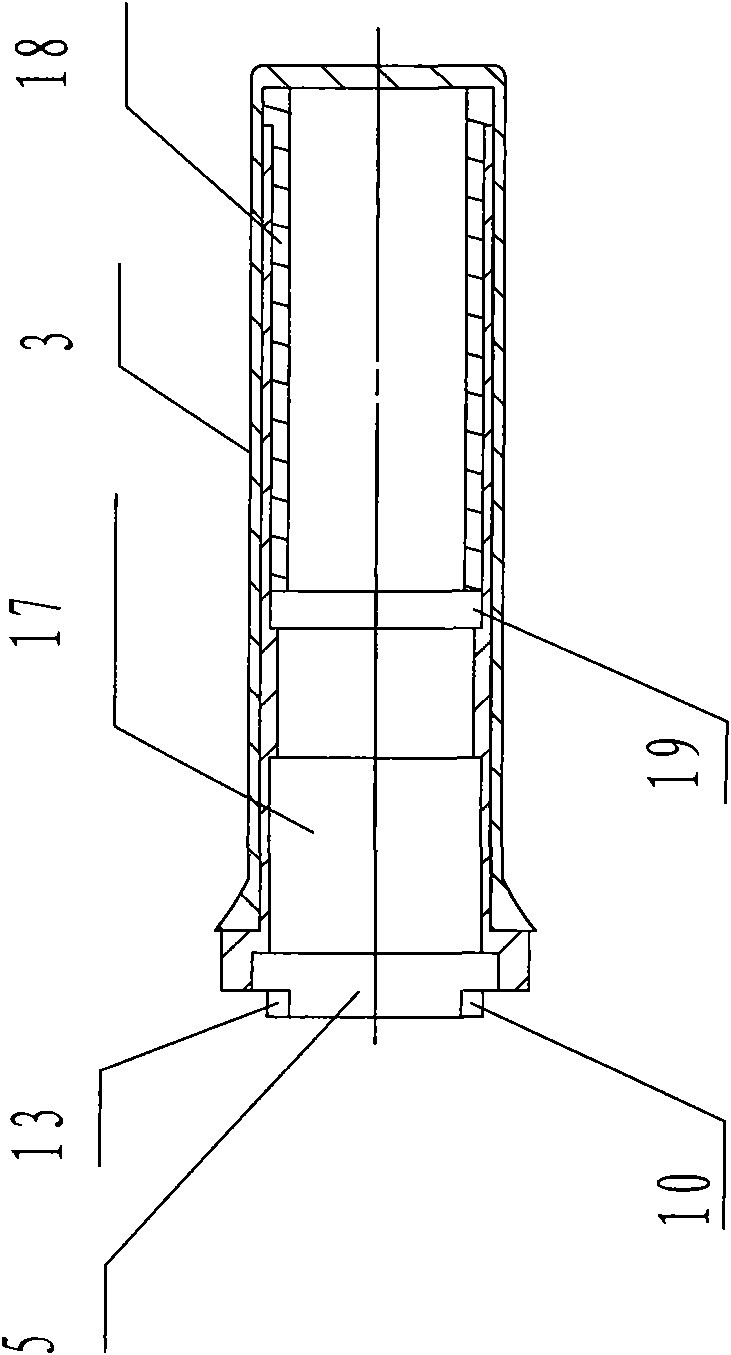

[0013] A two-way handlebar, comprising a handlebar seat 1, a handlebar handle 2, and a Hall sensing element 4. The handlebar handle is provided with a magnetic steel 5, which is characterized in that the handlebar seat and the handlebar handle An intermediate rotating part 6 is provided between the intermediate rotating part and the handle seat. A reverse return spring 7 is arranged between the intermediate rotating part and the handle seat. One end of the reverse return spring is connected to the handle seat 30 and the other end is connected to the handle seat 30. The intermediate rotating part 31 is connected, and a forward return spring 8 is provided between the intermediate rotating part and the handle handle. One end of the forward return spring is connected to the intermediate rotating part 32 and the other end is connected to the The handle is connected to the handle; the middle rotating part is provided with a forward reset point 9, and the handle is provided with anothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com