Bottling machine

A bottle-feeding mechanism and bottle-feeding technology, applied in packaging and other directions, can solve problems such as large differences and inconvenience in automatic production of bottled products, and achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

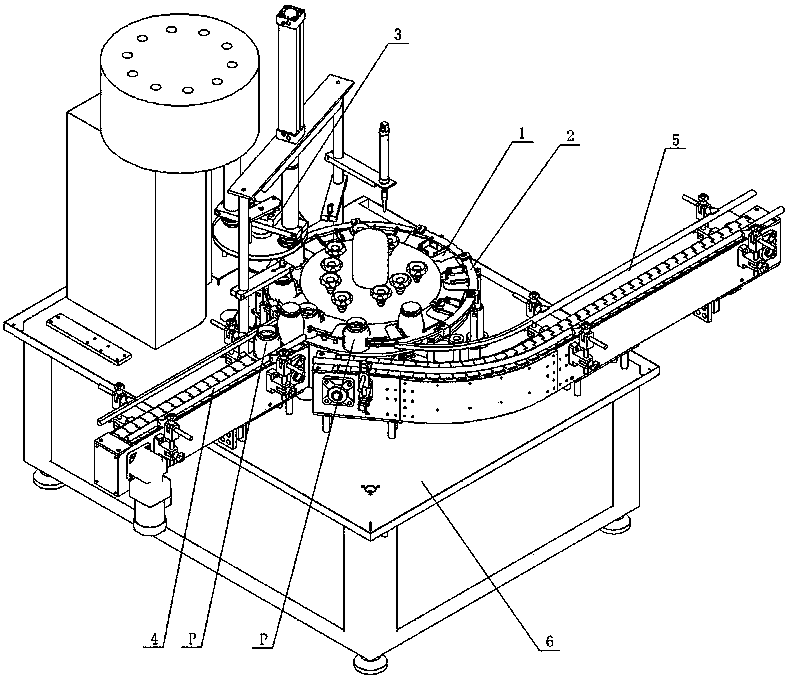

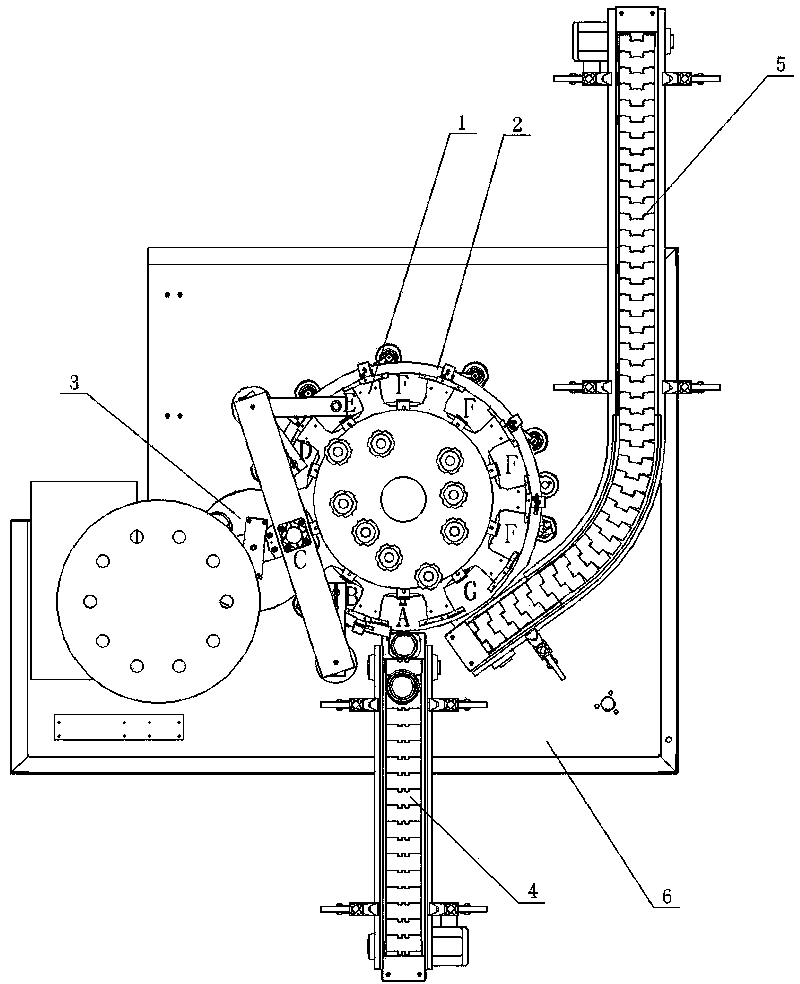

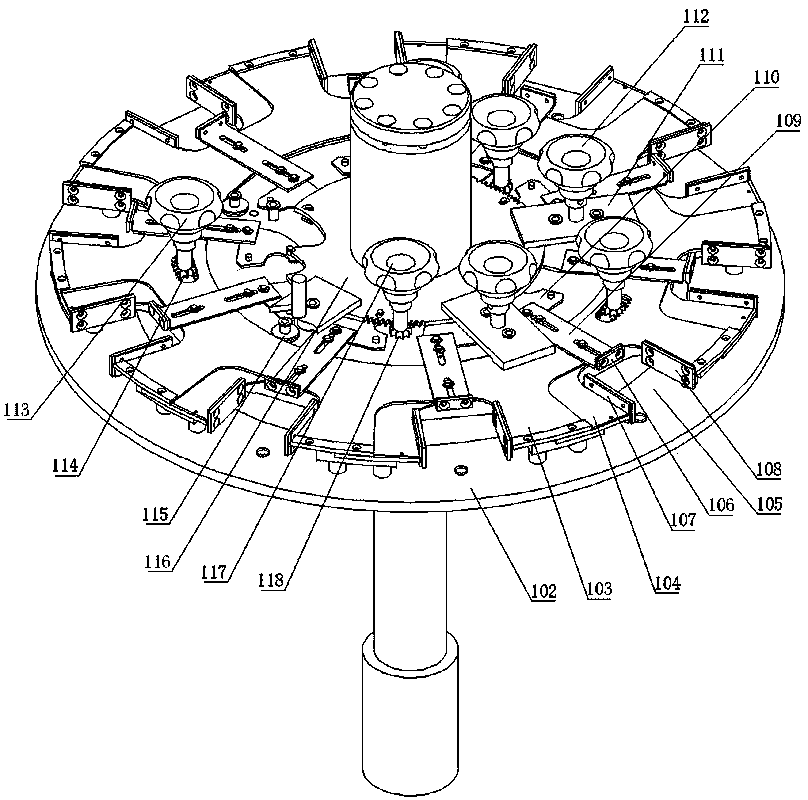

[0028] As shown in the figure, the bottle filling machine of the present invention includes a turntable mechanism 1, a guardrail mechanism 2, a feeding mechanism 3, a bottle feeding mechanism 4 and a bottle discharging mechanism 5, and the turntable mechanism 1 includes a turntable 102 driven by a motor for indexing rotation. The turntable 102 is rotatably installed above the workbench 6. The turntable 102 is provided with a bottle feeding station A, a primary juice injection station B, a filling station C, a secondary juice injection station D, a poking and extrusion station E, four Ten stations such as a spare station F and a bottle output station G, each station turntable 102 is provided with a bottle placement chamber 105 for storing bottles P, and the bottle placement chamber 105 is a semi-enclosed shape with an opening facing outwards, from the inside Board 106, left side board 107 and right side board 108 encircle, the radial position of the inner board 106 is adjustable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com