Article support structure and article attachment kit

A support structure and product technology, applied in the product support structure and product attachment kit, resulting in stretch-field, can solve the problems of tearing the wall surface, damage, etc., to achieve the suppression of tearing and damage, compactness, ease of handling, The effect of excellent ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0083] Manufacturing of Substrates

[0084] The base plate incorporating the holding member and / or the spacer member was made of styrene resin for experimental use.

[0085] (1) Base plate with clamping parts only

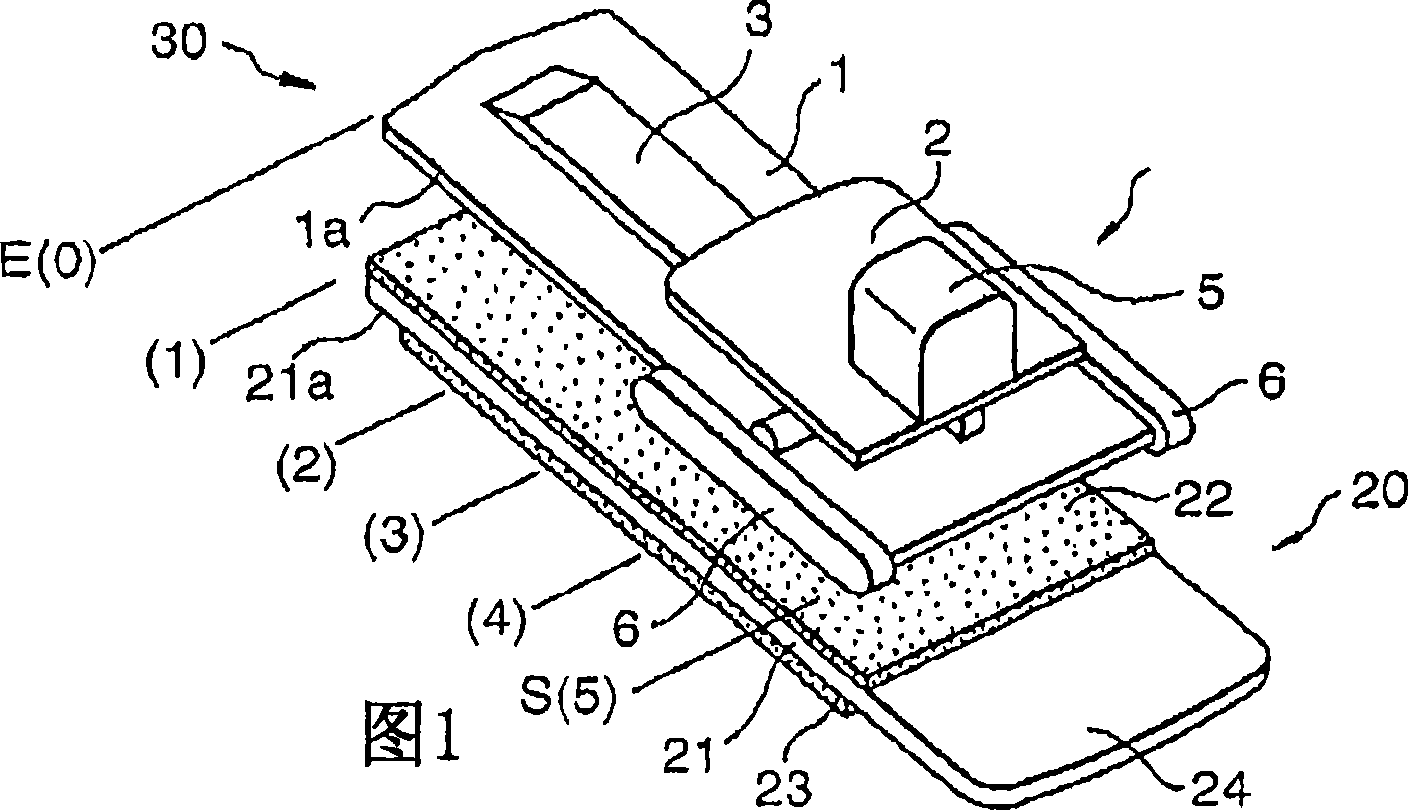

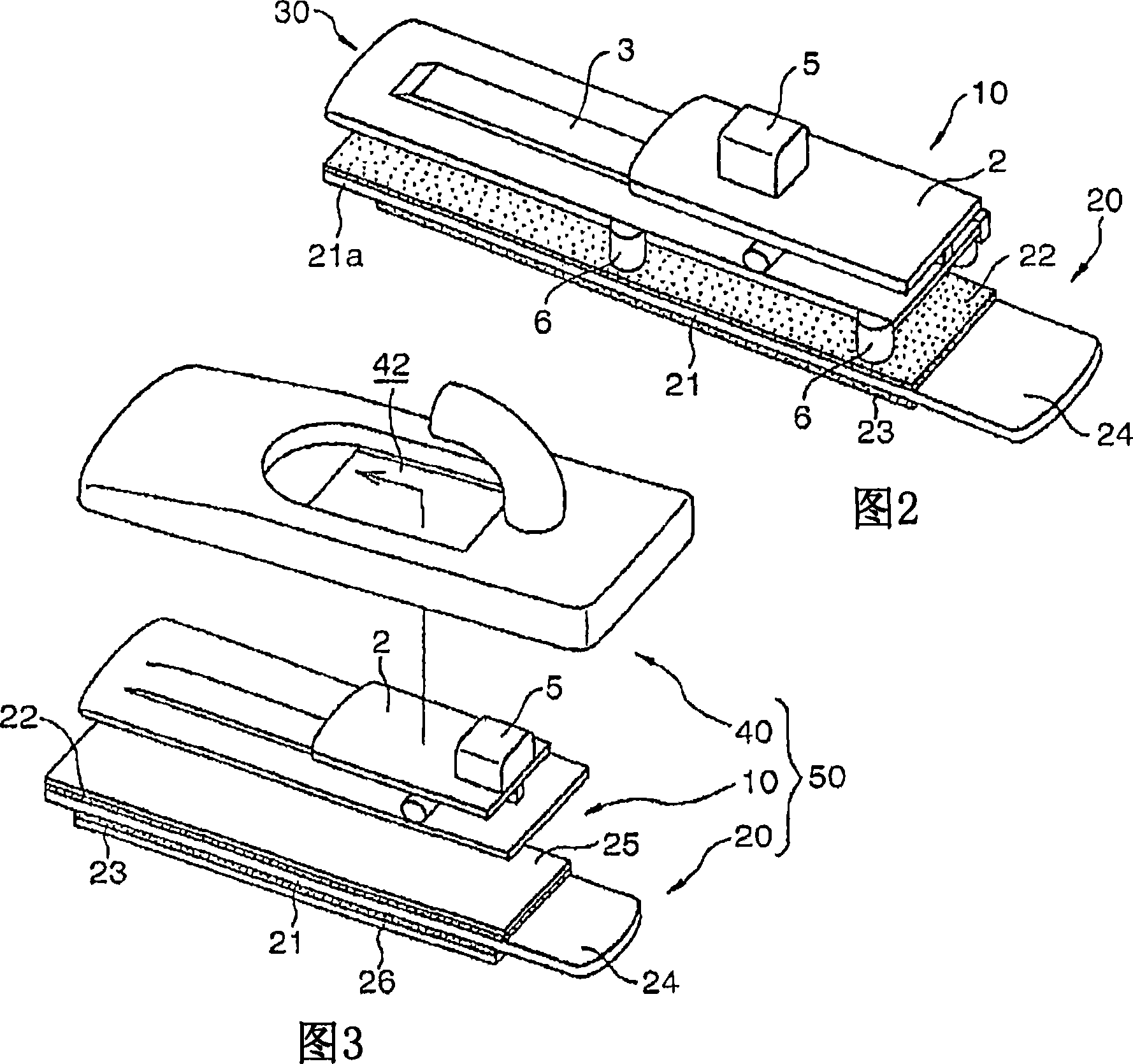

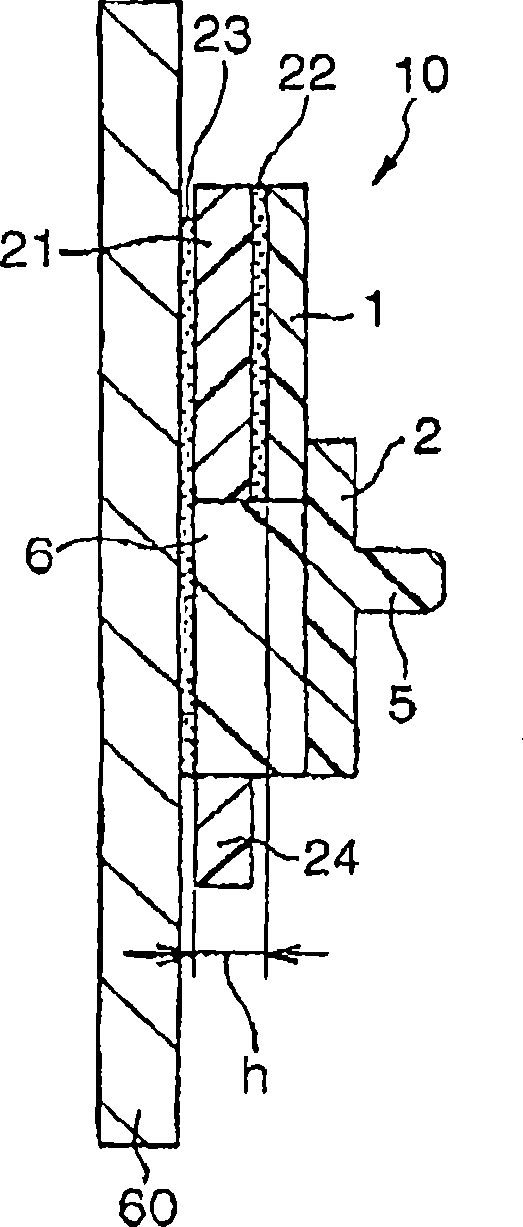

[0086] have with Figure 5 The schematically shown substrate 10 has a similar shape. The size of the base 1 is 50mm (length) x 15mm (width) x 1.5mm (thickness). Clamping parts (5mm (vertical) x 5mm (horizontal) x 5mm (height)) 5 are attached at different points in the figure (0), (1), (2), (3), (4), and (5). The shape of the substrate 10 is similar to that of the substrate 10 detailed in FIG. 1 except for the lack of spacer features.

[0087] (2) Substrate with spacer only

[0088] Its shape is similar to that of the base plate 10 shown schematically in FIG. 1 , except for the absence of the clamping member 5 . The size of the base 1 is 50mm (length) x 15mm (width) x 1.5mm (thickness). Attach the pair of spacer members (10mm (length) x 3mm (width) 6 t...

manufacture example 2

[0092] Manufacture of double-sided adhesive tape

[0093] A double-sided adhesive tape schematically shown in Fig. 1 was manufactured.

[0094] First, an 800 μm thick foamed polymer film (Volara TM)6EO, manufactured by Sekisui Corporation (USA)) and a 50 μm thick solid polymer film (XMAX TM 161.1, Consolidated Thermoplastics Co.). The solid polymer film was laminated to both sides of the foamed polymer film and heat sealed.

[0095] After the base 1 was manufactured, both sides of the base 1 were subjected to corona discharge treatment and a primer was applied. The primer used here was a reactive type synthetic resin primer (product name: K500, manufactured by 3M Company). After the primer has been applied, an acrylic adhesive sheet with release paper (manufactured by 3M) is applied to both sides of the substrate to form adhesive layers 22 and 23, and a 5 mm adhesive layer 23 is removed from the end of the adhesive layer 23 to expose the substrate of the backing.

[0...

experiment example 1

[0097] Experimental example 1 (reference example 1)

[0098] In this example, a substrate with a spacer and without a clamping part was applied to wallpaper in order to evaluate the functionality of the spacer on the substrate. The wallpaper used here is a polyvinyl chloride-based wallpaper manufactured by Lilycolor Co., Ltd. (product number LY9540, mentioned in the "Lilycolor Substrates" catalog).

[0099] The double-sided adhesive tape in Production Example 2 was applied to the bottom surface of the substrate produced in Production Example 1(2) to which spacers were attached at various positions as disclosed in Table 1 below. One hour after the completion of the application of the substrate, the peel test was performed. As disclosed in Table 1 below, at points (0.5; midway between points 0 and 1), (1.5), (2.5), (3.5), (4.5), and ( 5) while stretching the tab in the horizontal direction, and stretching-peeling the adhesive tape. Twelve (partially 17) stretch-peel tests w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com