Patents

Literature

42results about How to "Reduce deviation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

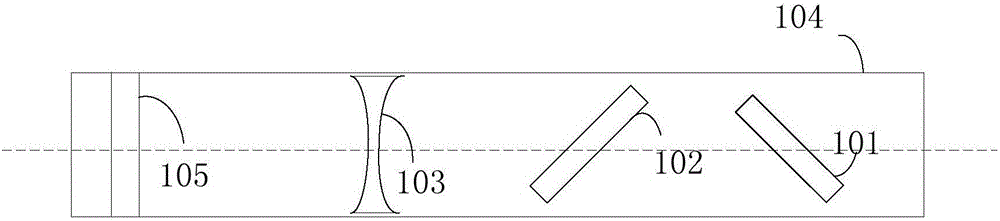

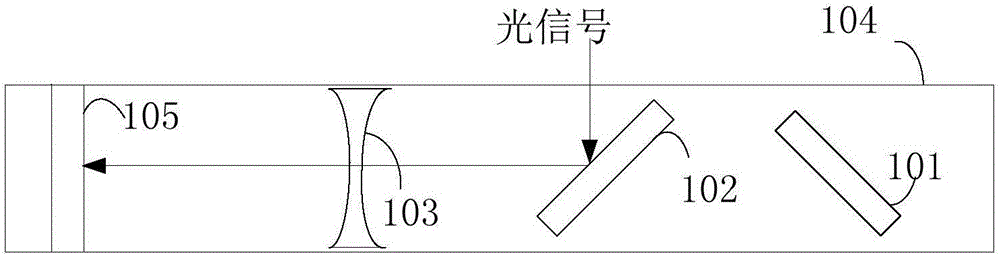

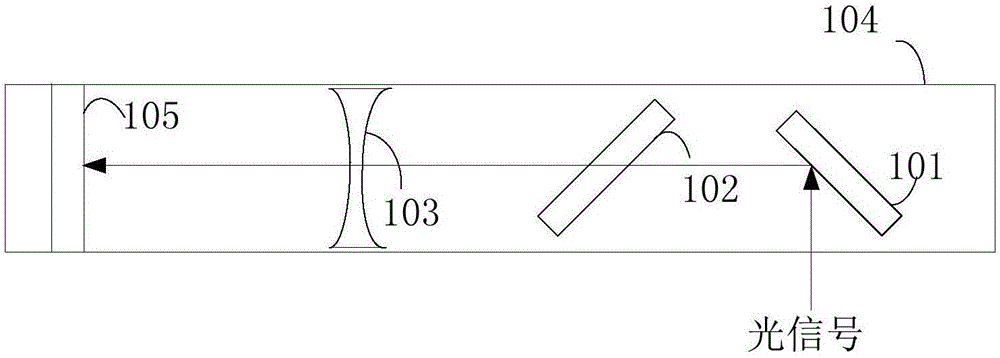

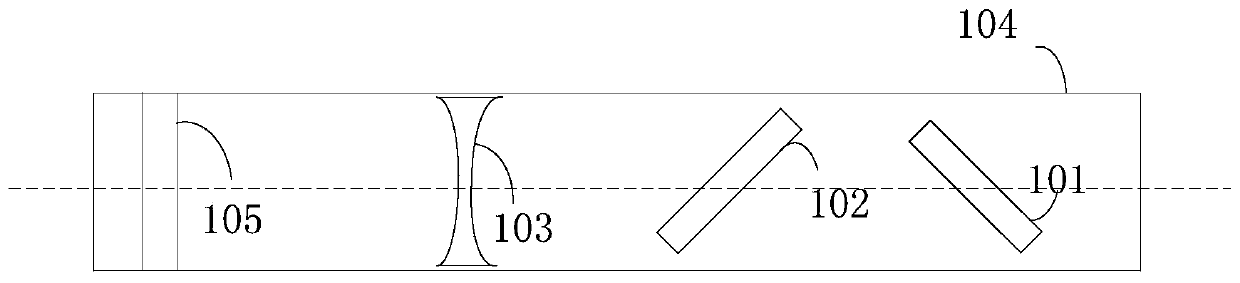

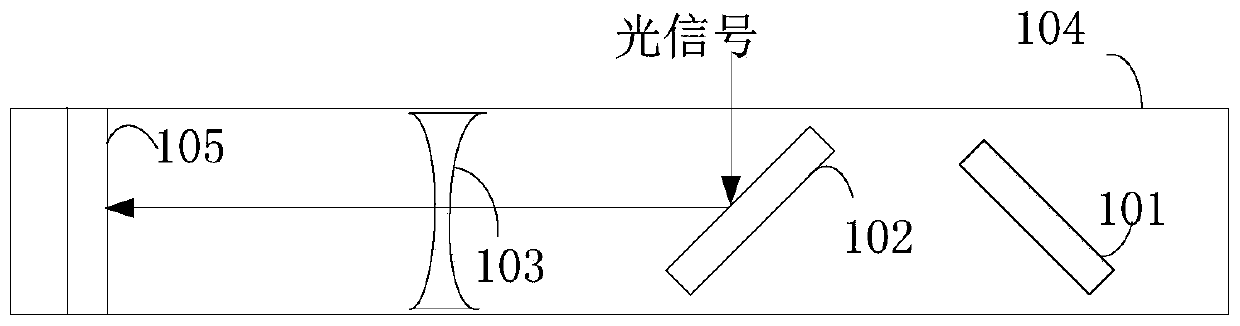

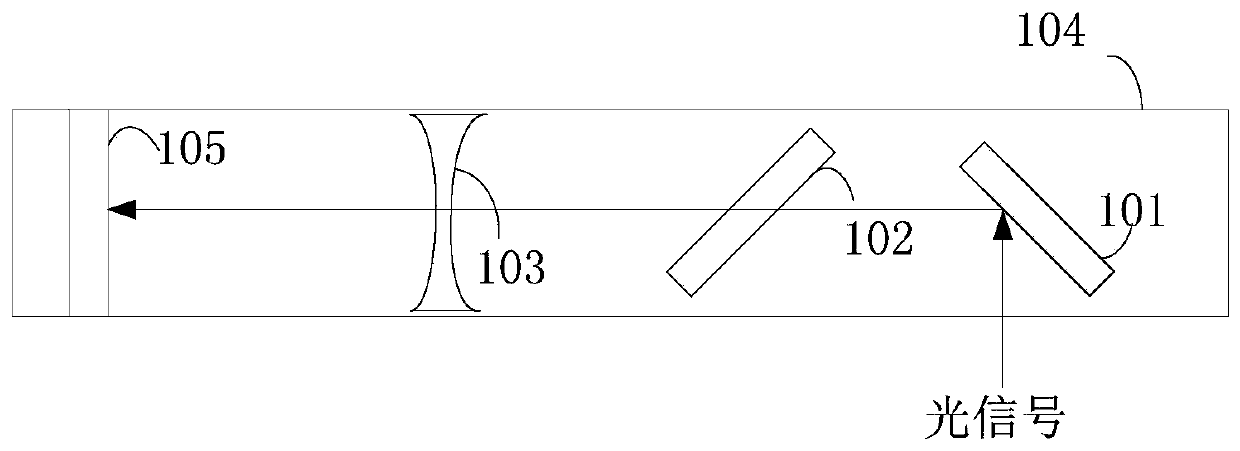

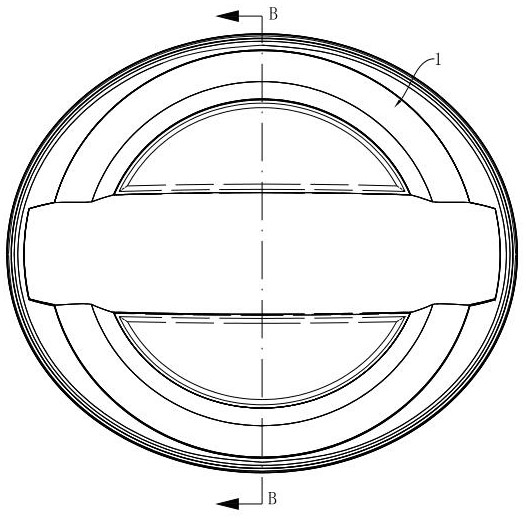

Camera module and terminal device

ActiveCN106550181ASmall footprintSmall sizeTelevision system detailsMirrorsOptical axisTerminal equipment

The invention discloses a camera module and a terminal device, and belongs to the technical field of electronics. The camera module comprises a rotatable reflector, a lens group, a shell and an image sensor; the shell comprises a first surface and a second surface; a first mirror surface of the rotatable reflector is a reflecting surface, and a part of the first mirror surface located in a first reflecting area is a first sub mirror surface; when the rotatable reflector is located at a first position, the first mirror surface reflects a first light signal, an image is generated after the reflected first light signal is transmitted along a straight line where an optical axis is located, when the rotatable reflector is located at a second position, the first mirror surface reflects a second light signal, and an image is generated after the reflected second light signal is transmitted along the straight line where the optical axis is located. According to the camera module provided by the embodiment of the invention, the function of double-channel shooting is realized by using just one rotatable reflector, thereby reducing the number of reflectors, shortening the size and saving the occupied space.

Owner:HUAWEI MACHINERY

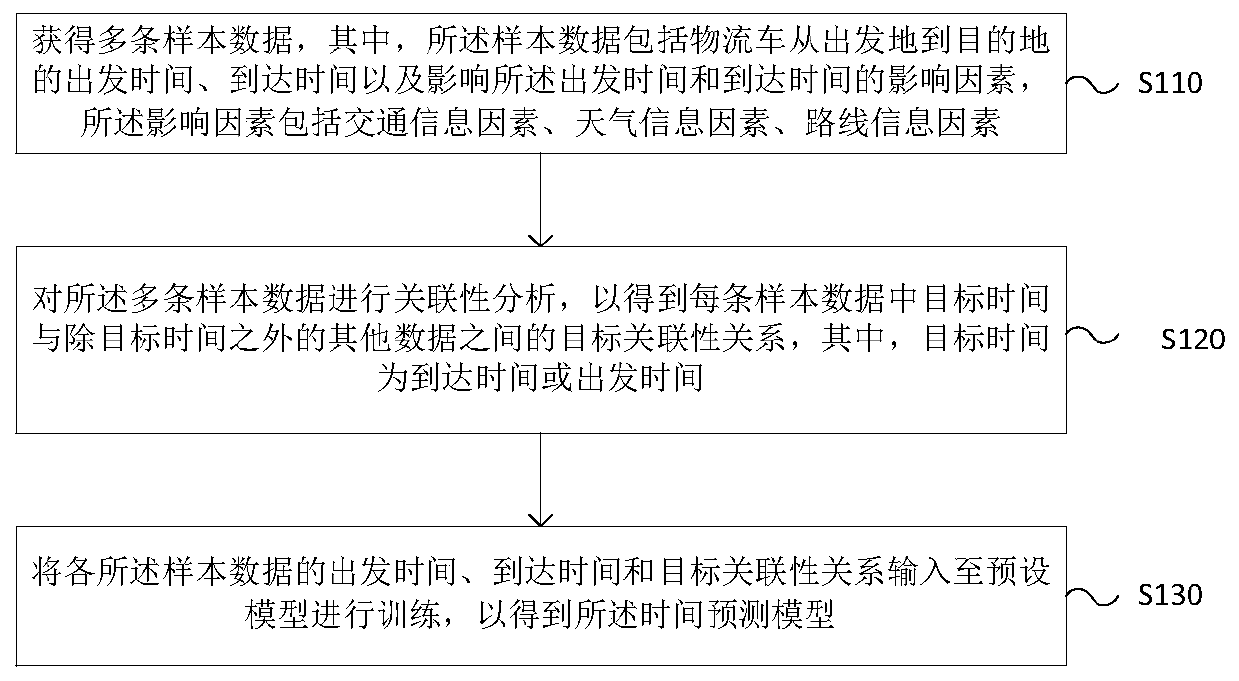

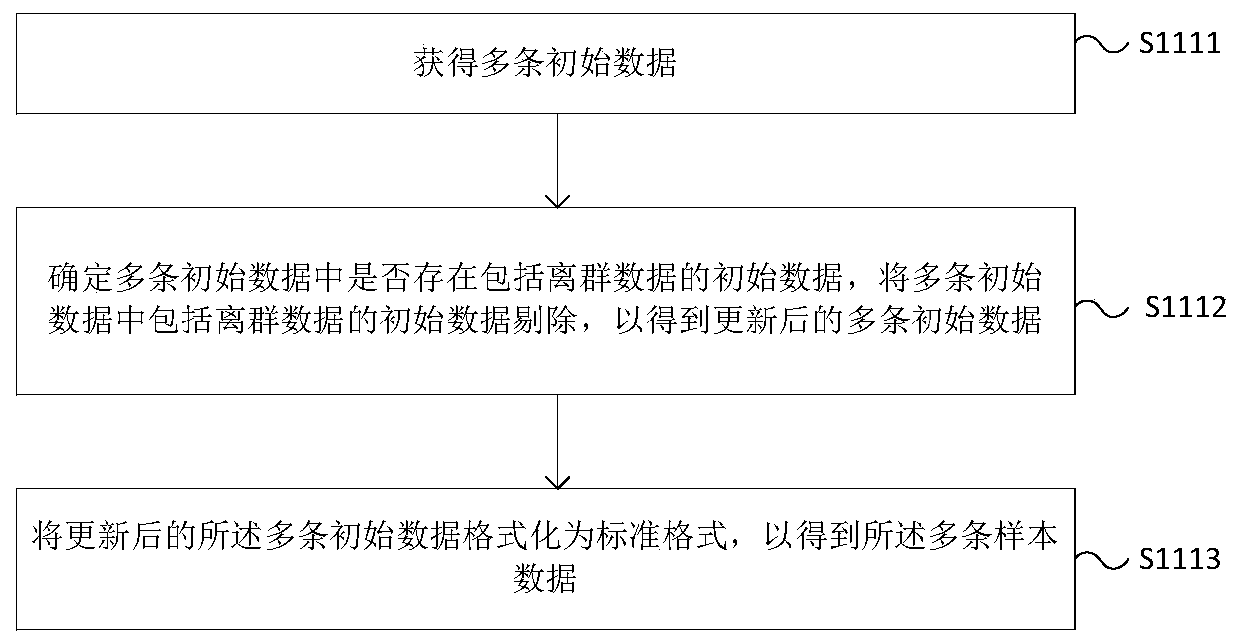

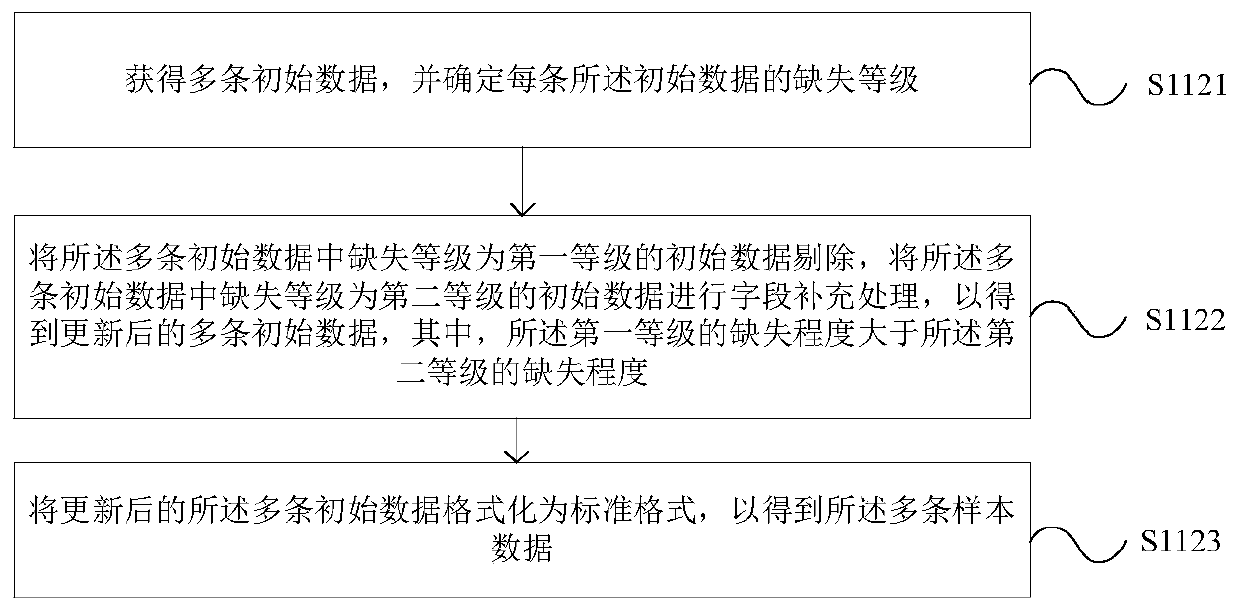

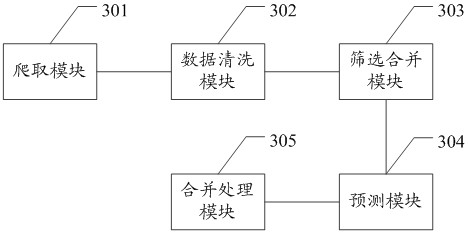

Prediction model training method, time prediction method, training device and terminal

ActiveCN111091231AReduce deviation rateImprove accuracyForecastingLogisticsData packLogistics management

The invention relates to the technical field of electronic information and particularly relates to a prediction model training method, a time prediction method, a training device and a terminal. Multiple pieces of sample data are obtained, the sample data comprise departure time and arrival time of the logistics vehicle from a departure place to a destination and influence factors influencing thedeparture time and the arrival time, and the influence factors comprise traffic information factors, weather information factors and route information factors; correlation analysis is carried out on the plurality of pieces of sample data; wherein the target time is arrival time or departure time, and correlation analysis is performed on the multiple pieces of sample data, so that the probability of deviation of the time prediction model is reduced, and the accuracy of the time prediction model is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

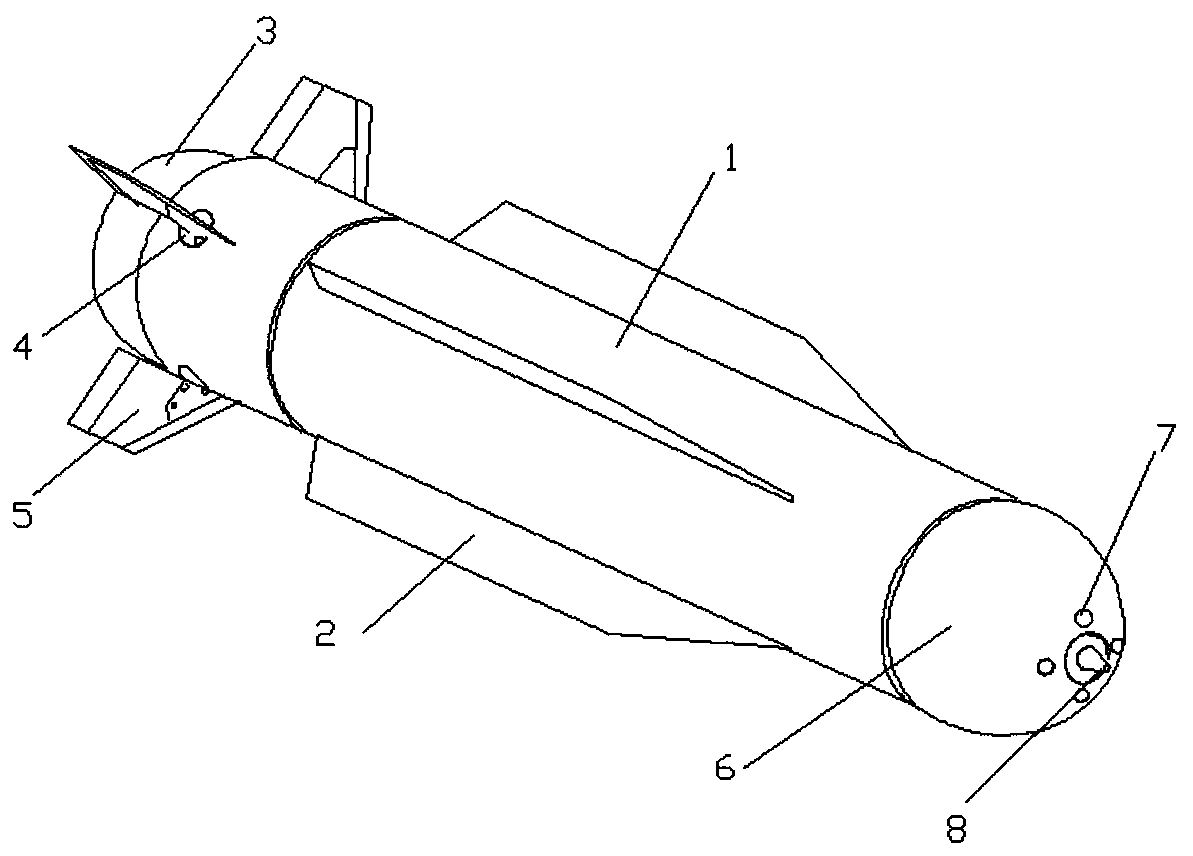

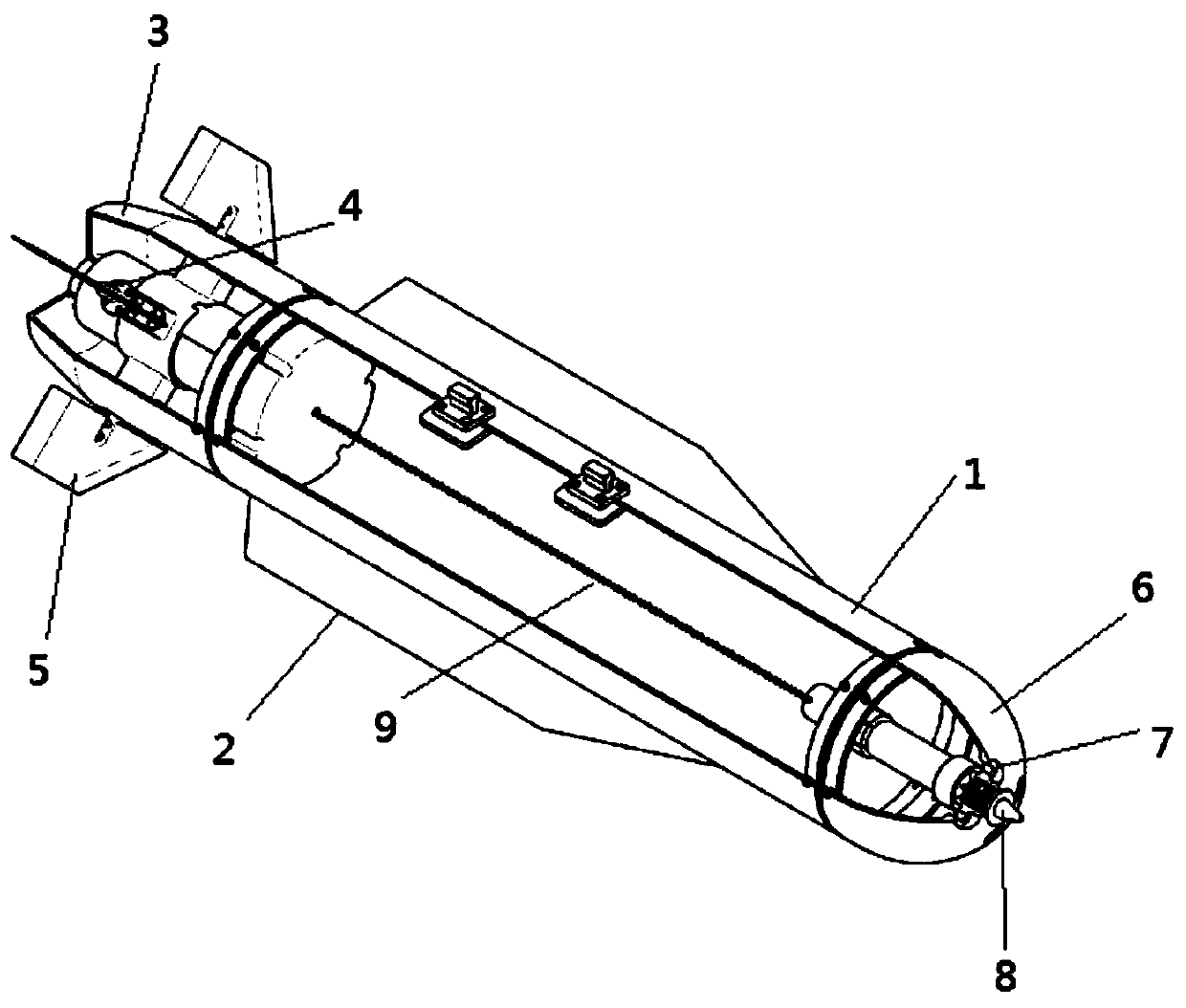

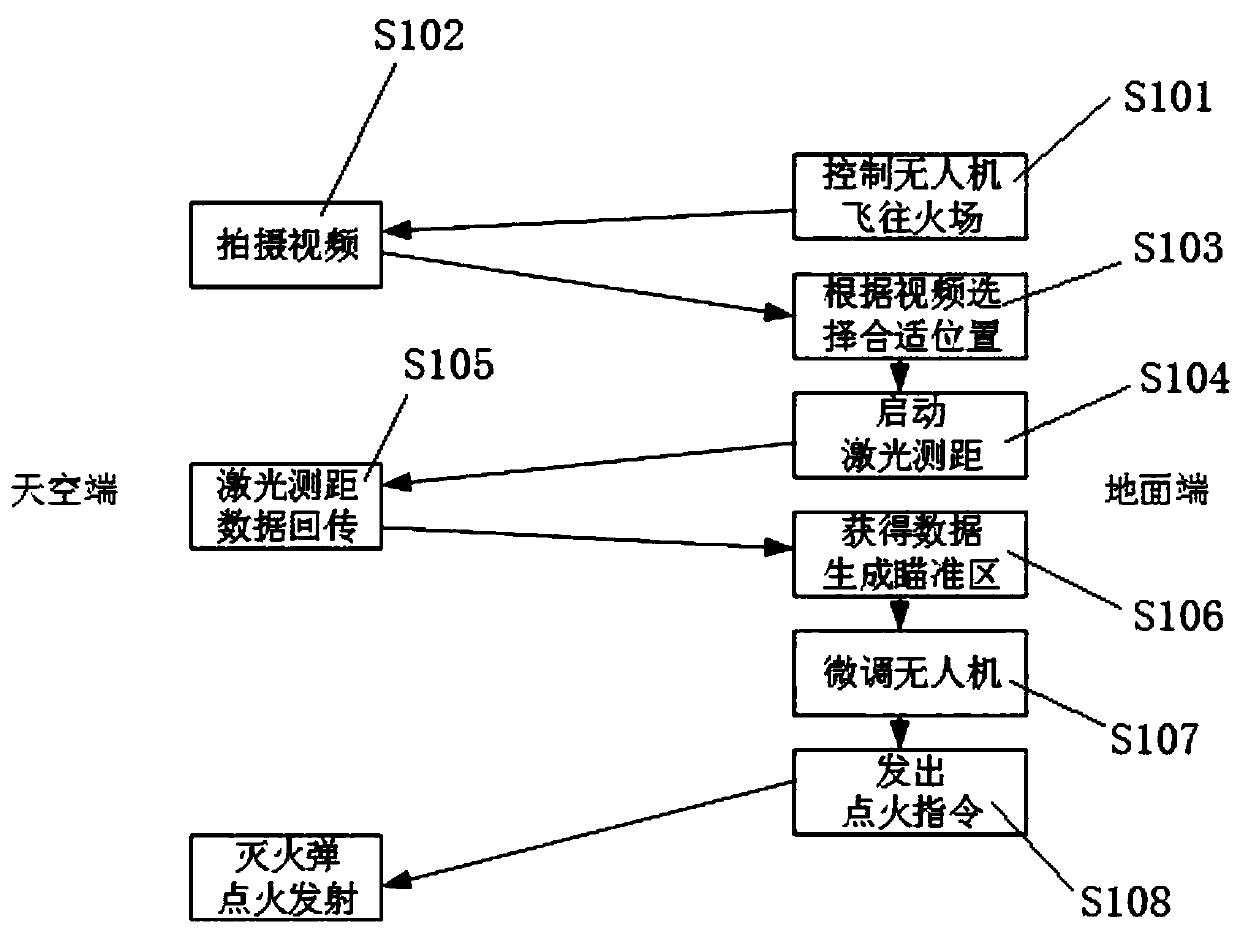

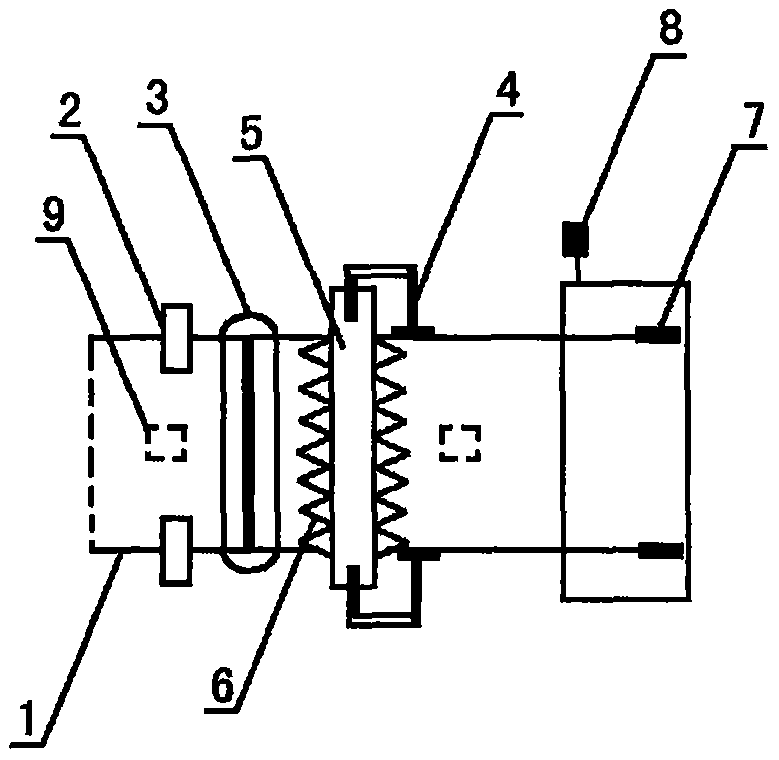

Controllable guided fire extinguishing bomb and fire extinguishing system and fire extinguishing method

PendingCN110465036AAccurately obtain temperatureImprove fire extinguishing efficiencyFire rescueStructural engineeringMechanical engineering

The invention provides a controllable guided fire extinguishing bomb, a fire extinguishing system and a fire extinguishing method. The controllable guided fire extinguishing bomb comprises a bomb body, wherein the front end of the bomb body is connected to a warhead; a four-quadrant seeker is arranged inside the bomb body and is used for measuring the temperature information of each orientation infront of the warhead; the rear end of the warhead is connected to a control bin; and a controller, a plurality of steering engines and a rocket engine are arranged in the control bin. The four-quadrant seeker is adopted in the controllable guided fire extinguishing bomb, so that the temperatures of the warhead in different directions can be accurately obtained, the position of an ignition point is judged according to the temperature difference; and the steering engines are controlled by the controller to adjust the orientation of a tail vane, so that the controllable guided fire extinguishingbomb flies toward the ignition point, and finally the controllable guided fire extinguishing bomb precisely extinguishes fire of the ignition point; the fire extinguishing efficiency is improved; andthe deviation rate is reduced.

Owner:西安恒宇众科空间技术有限公司

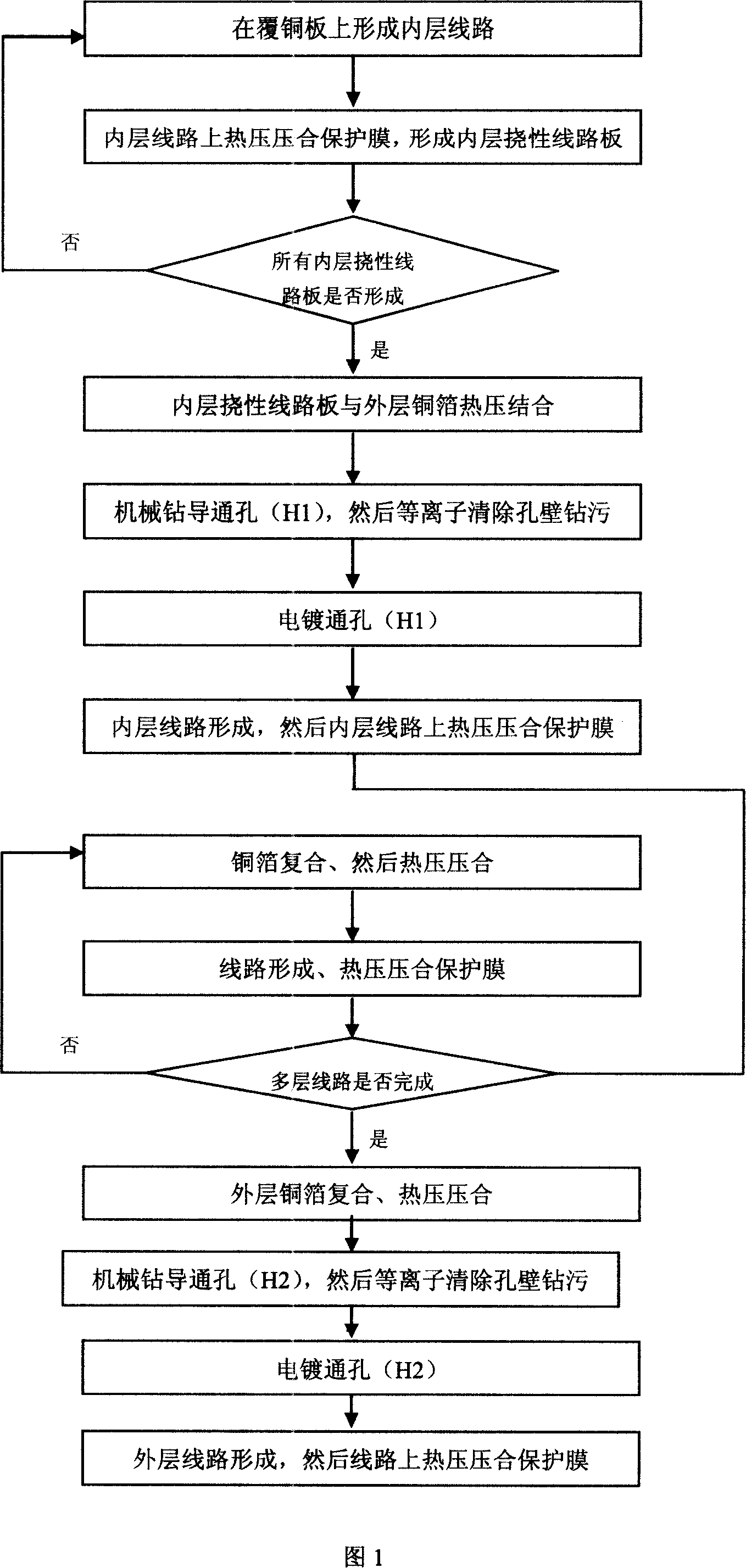

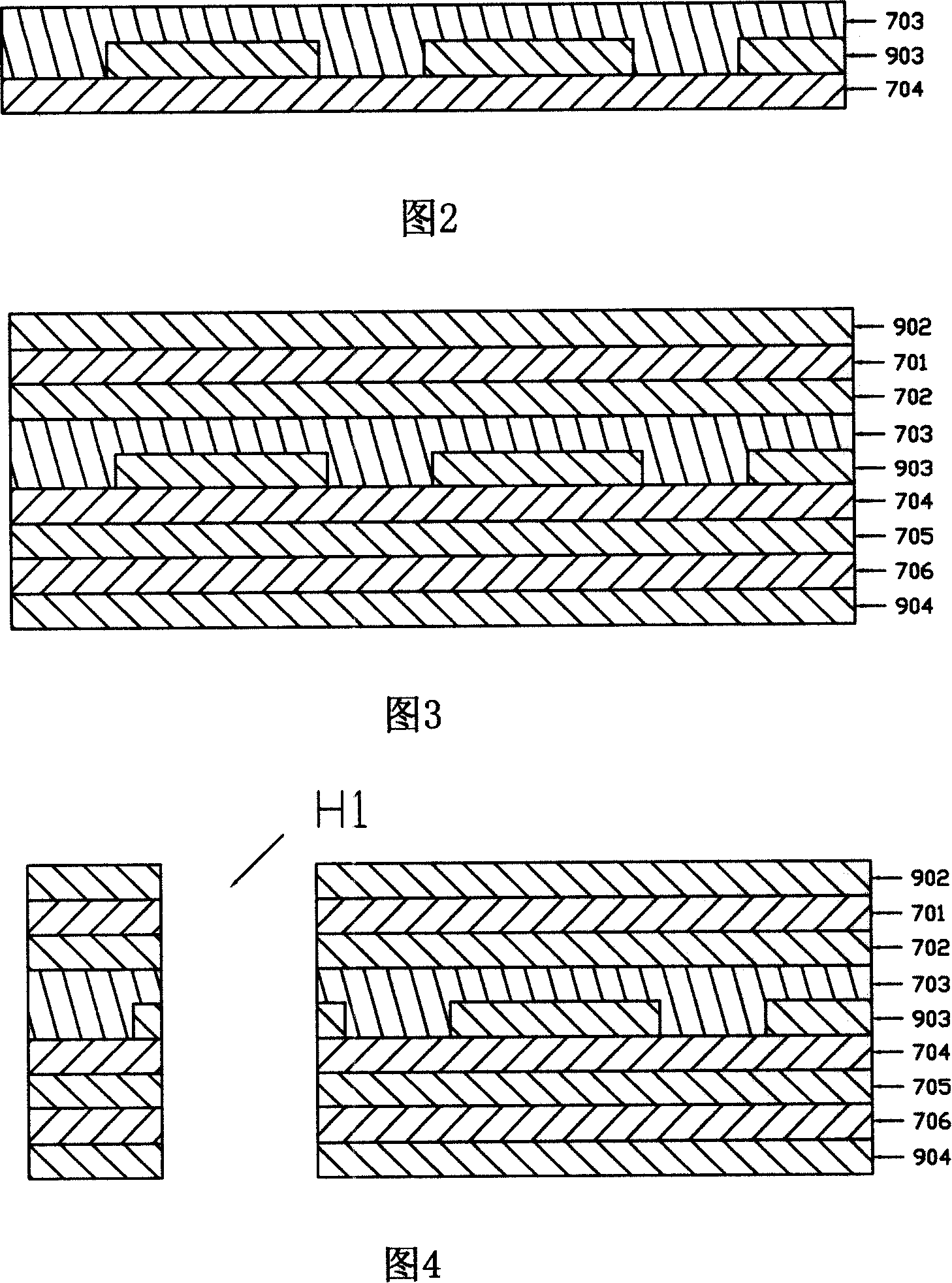

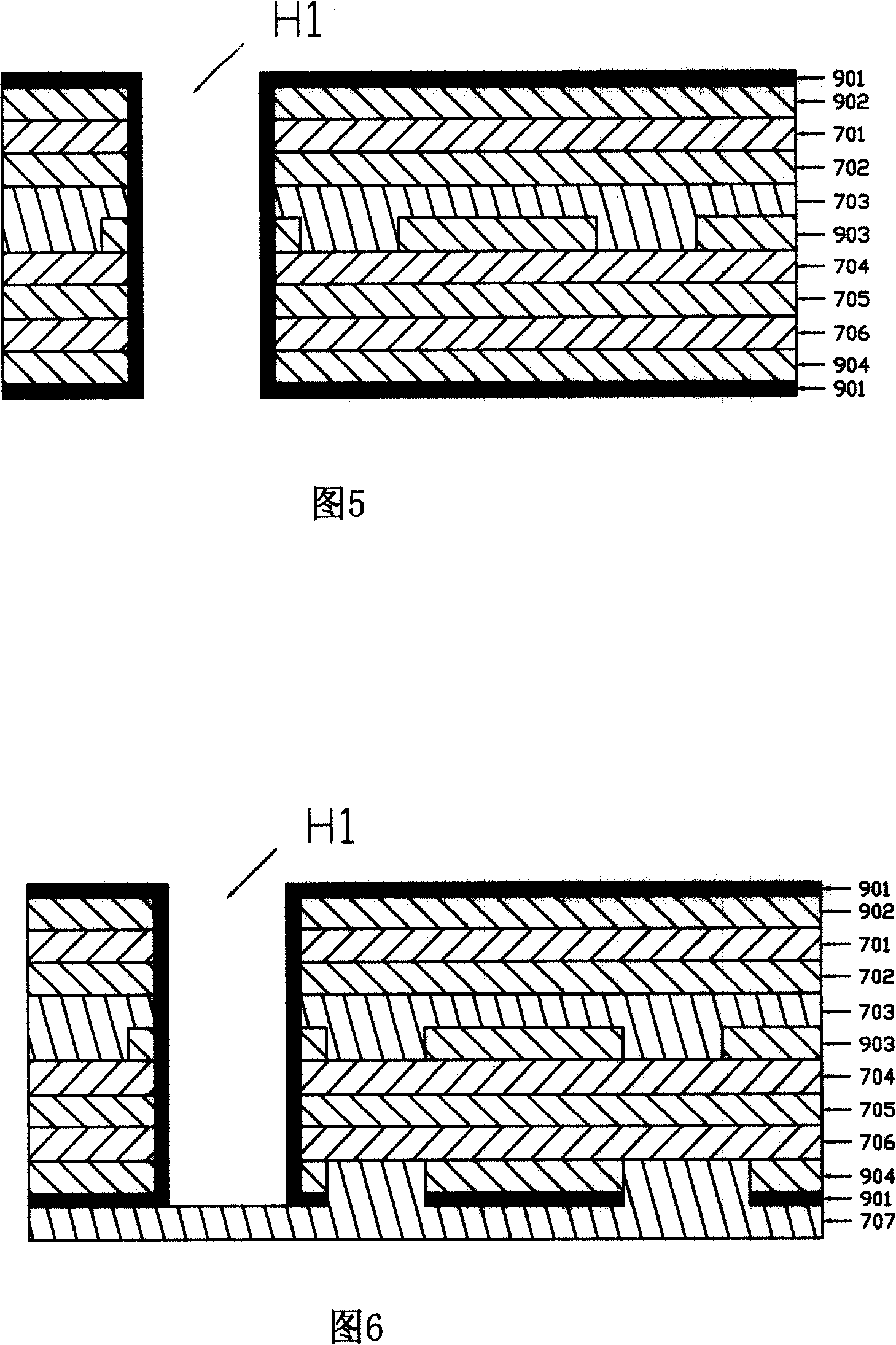

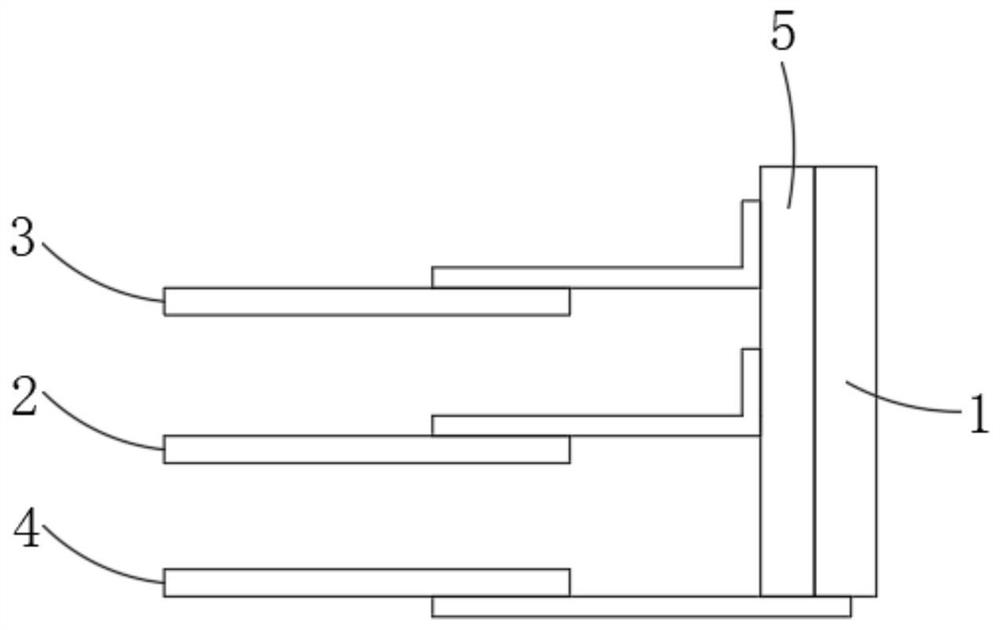

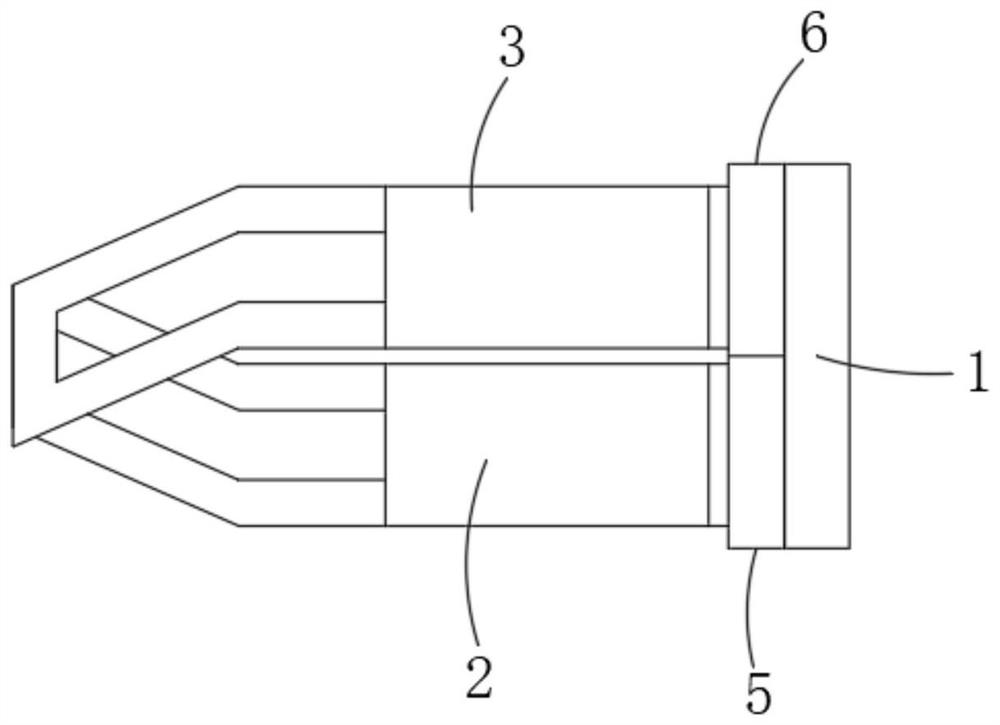

Flexible multi-layer circuit board and its producing method

InactiveCN101137270AReduce deviation rateReduce the number of contactsMultilayer circuit manufactureBlind holeShort circuit

The invention discloses a multi-layer flexible wiring board and manufacturing method therefor. The multi-layer flexible wiring board has at least three layers, which is characterized in that the wiring board comprises blind holes which only penetrate part of layer wiring boards and through holes penetrate all layer wiring boards. The invention adopts blind holes and through holes to connect layer by layer of the wiring board, the blind holes only need to drill through part of wiring boards, thereby wiring boards which are not be drilled through increase usable area, not all holes adopt perforated method, aligned deviation ratio between each layer is reduced, the number of joints is reduced, thereby reducing derivtion probability of short curcuits and open curcuits.

Owner:深圳市合力泰光电有限公司

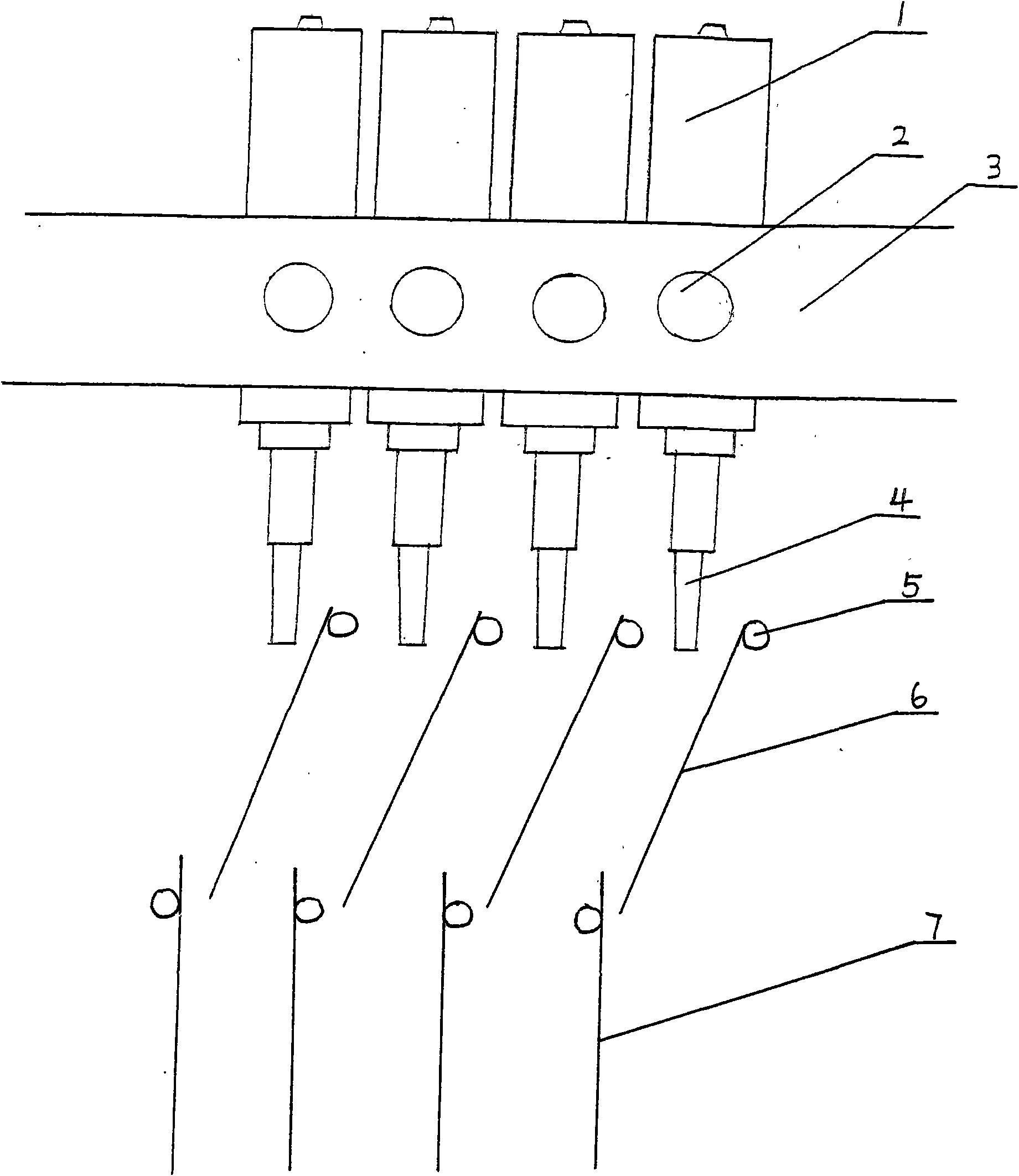

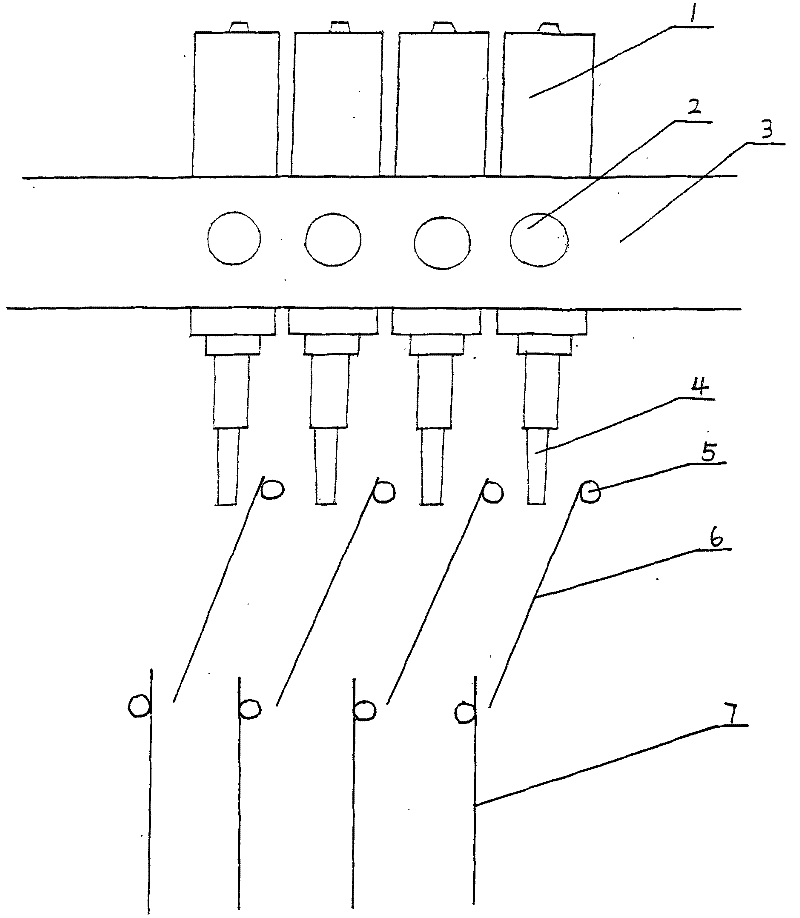

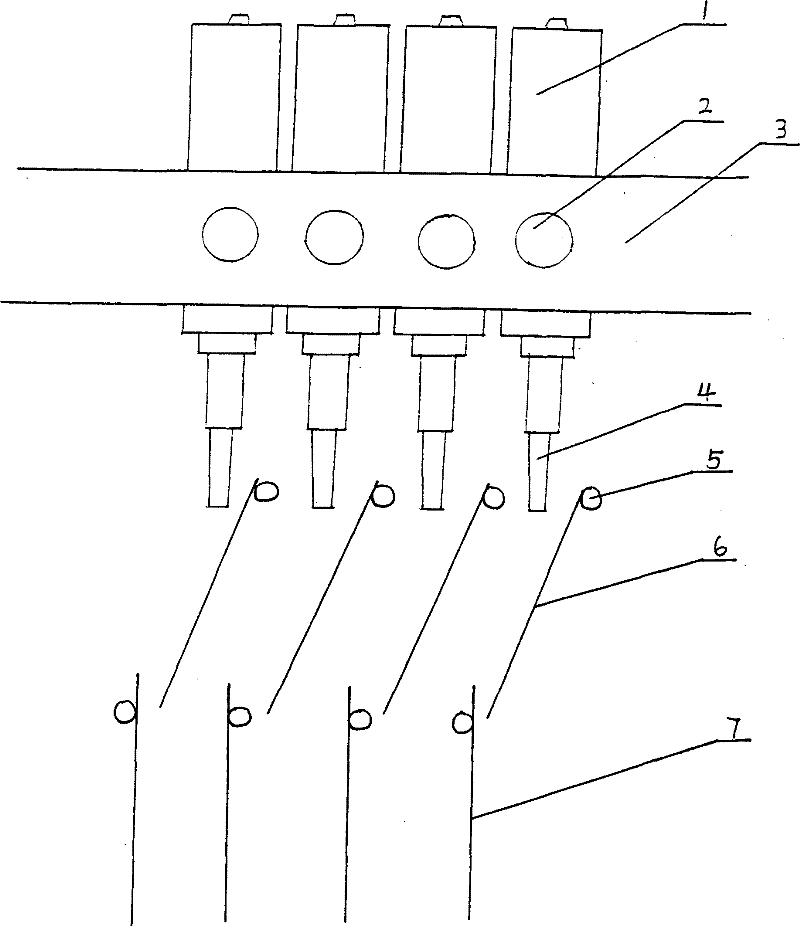

Tube-type drawing devillicating method

A tube-type drawing devillicating method comprises a special air flow drawing device and reciprocators. A plurality of tube-typed extension apparatus are arranged on an air flow guide device, the centre distances of the tube-typed extension apparatus are between 35 to 55mm, the tube-typed extension apparatus are communicated with the air holes which are arranged on the air flow guide device, separators are connected with the lower ends of tube-typed extension apparatus, reciprocators are separately connected with every separator, the reciprocators are composed of a swing board, a pick-up device and a fixed shaft, and the centre distances among the reciprocators are 35-55mm. The invention has the following advantages: a non-woven fabric which is made by the method has high density, the fiber web is uniform and the deviation ratio of the thickness and mass per square meter of the product is small.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

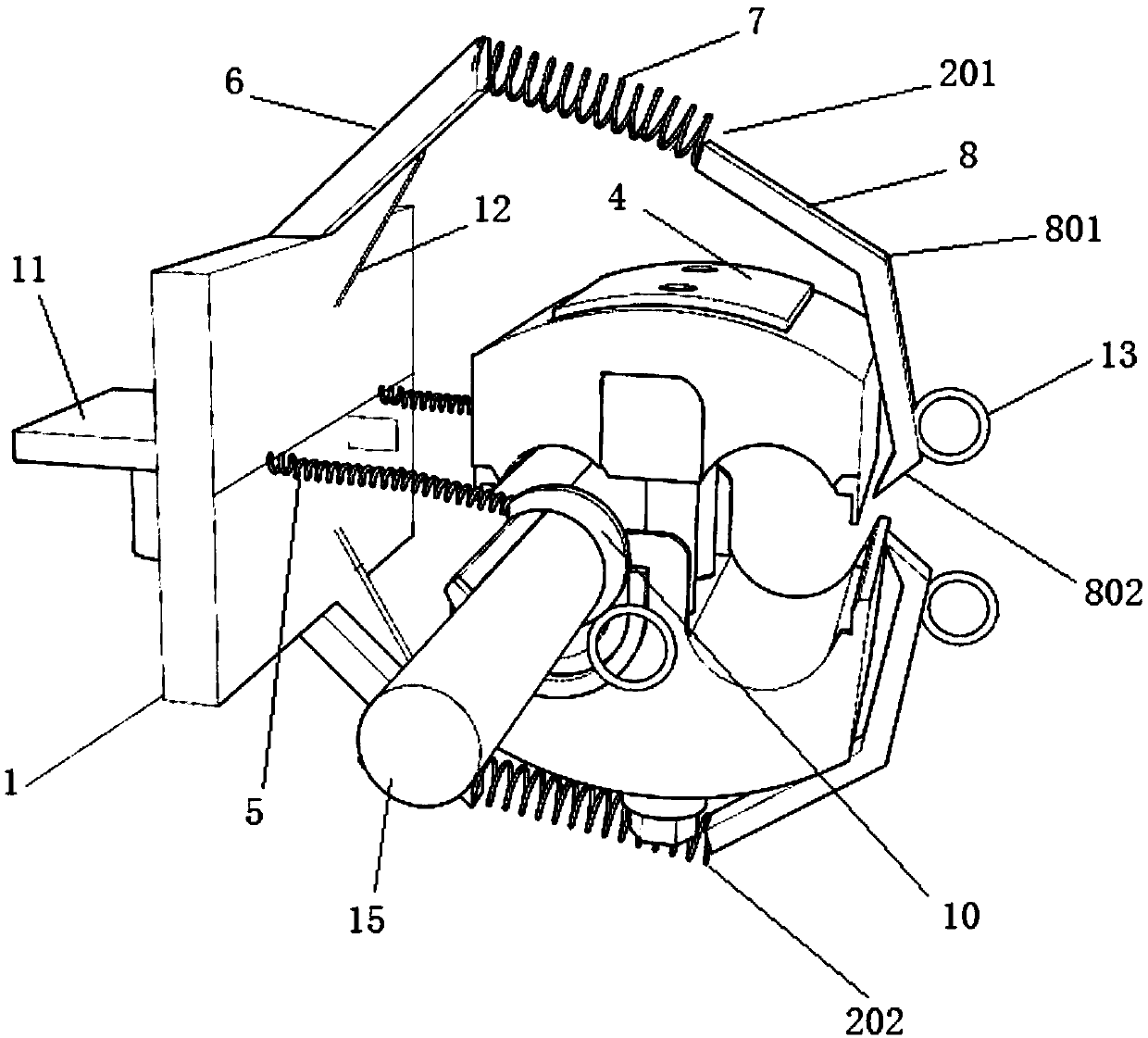

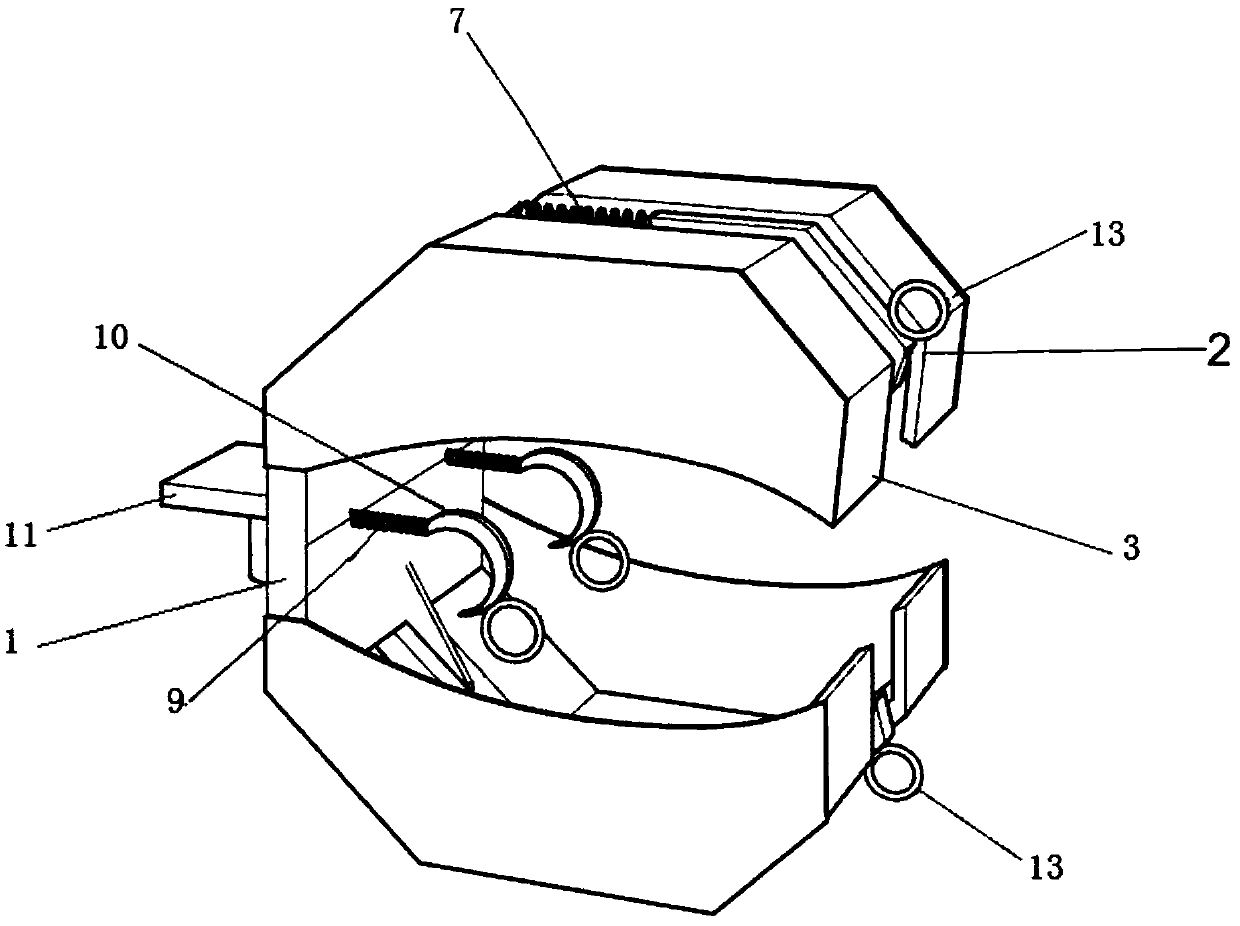

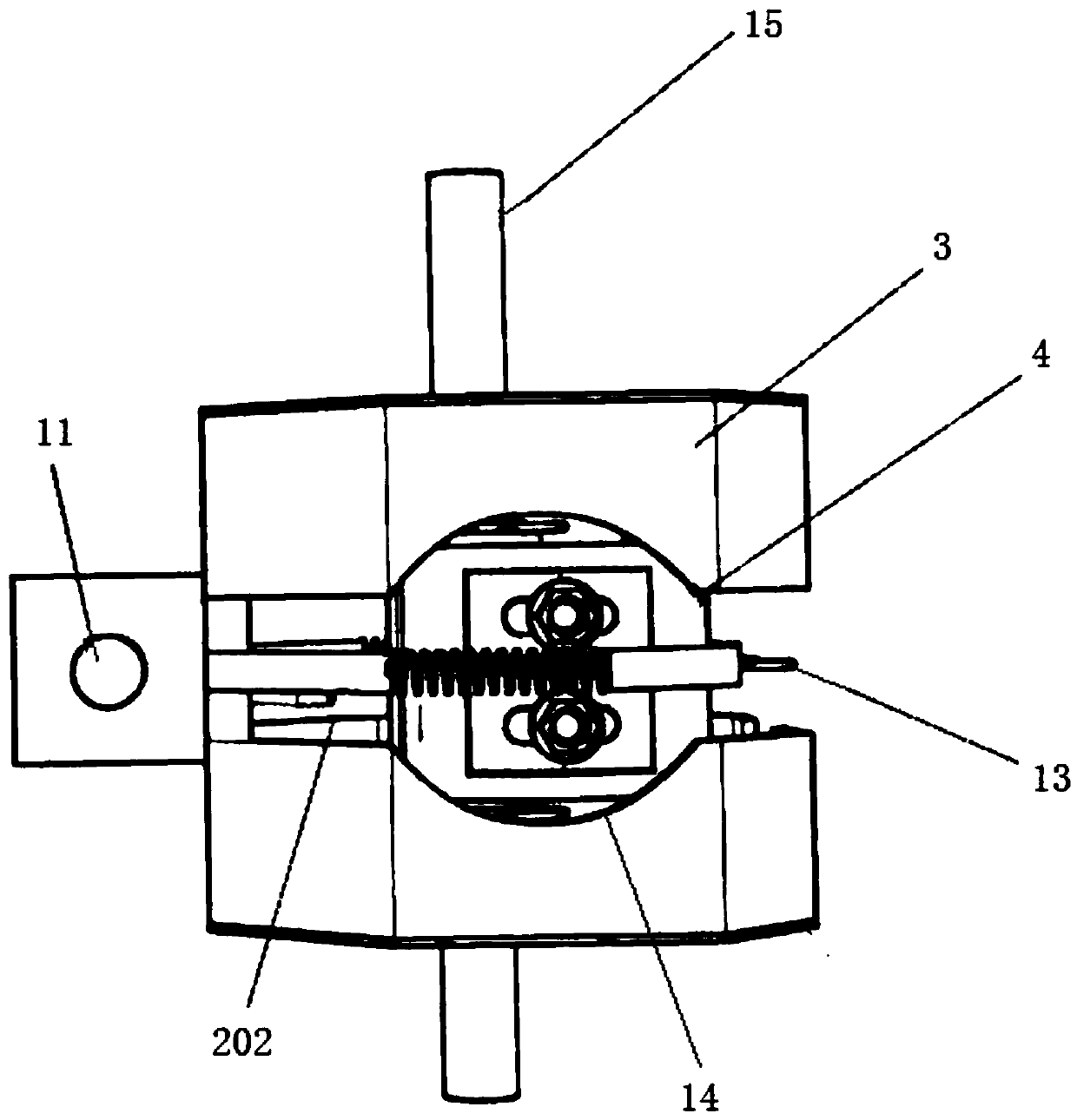

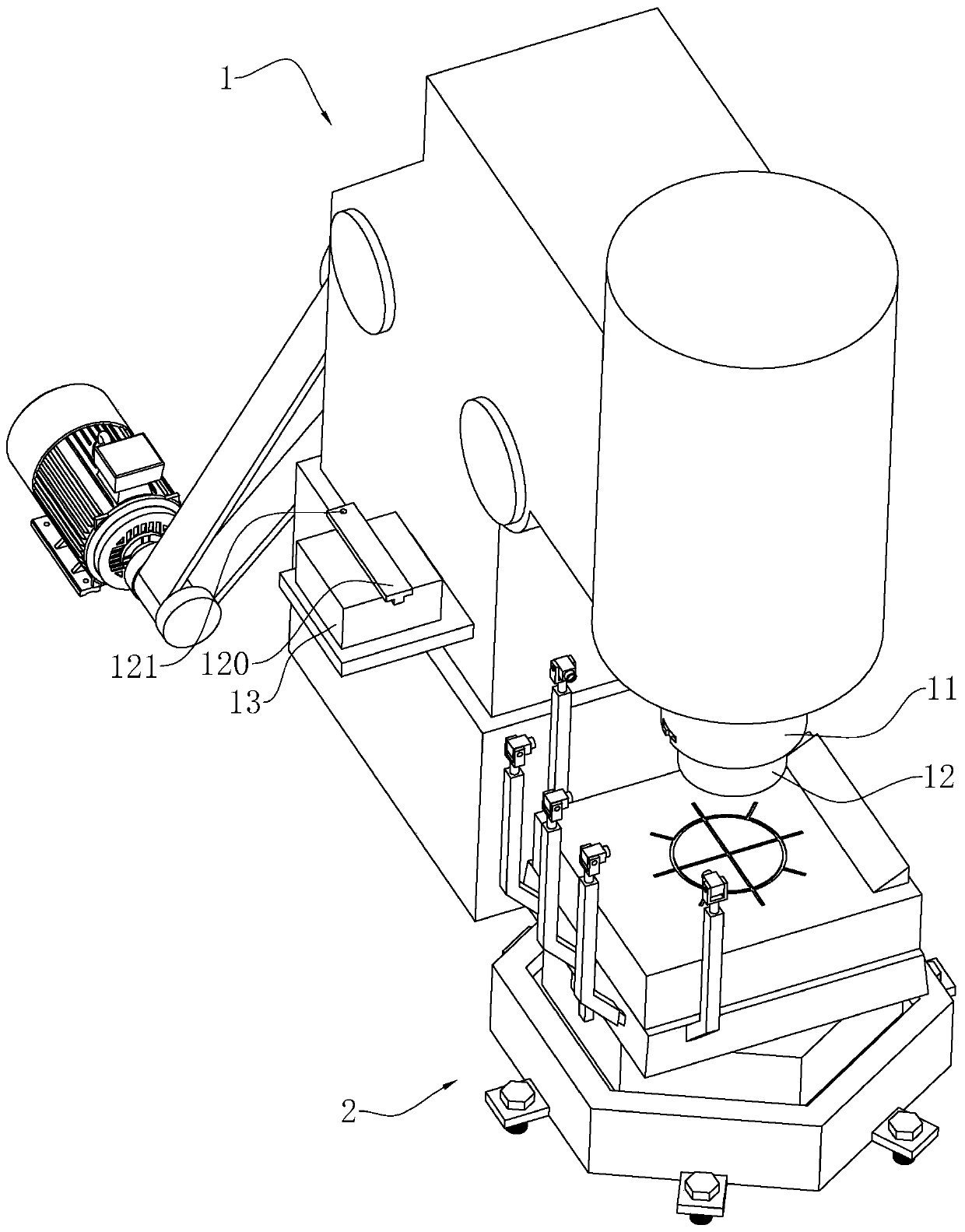

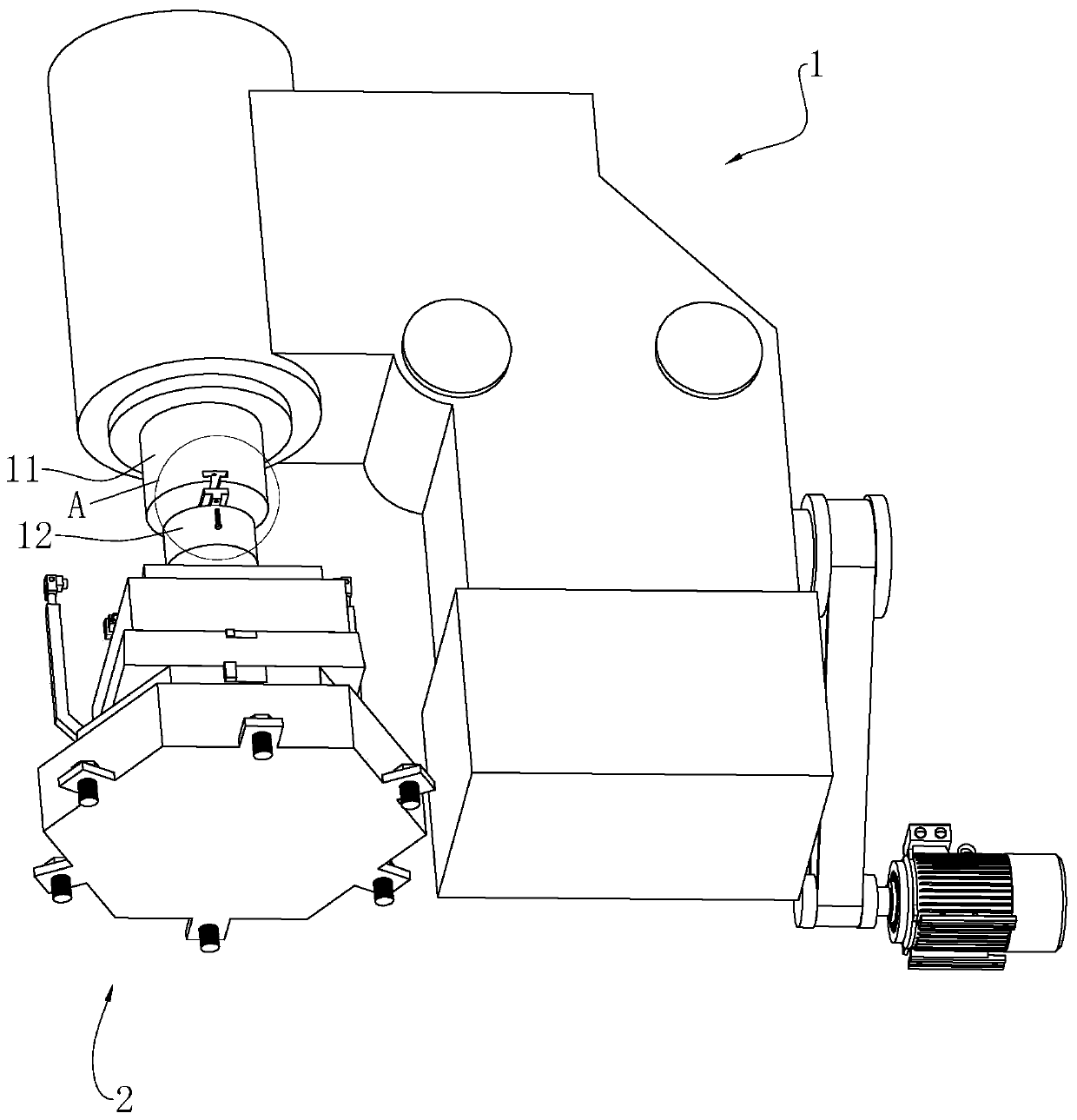

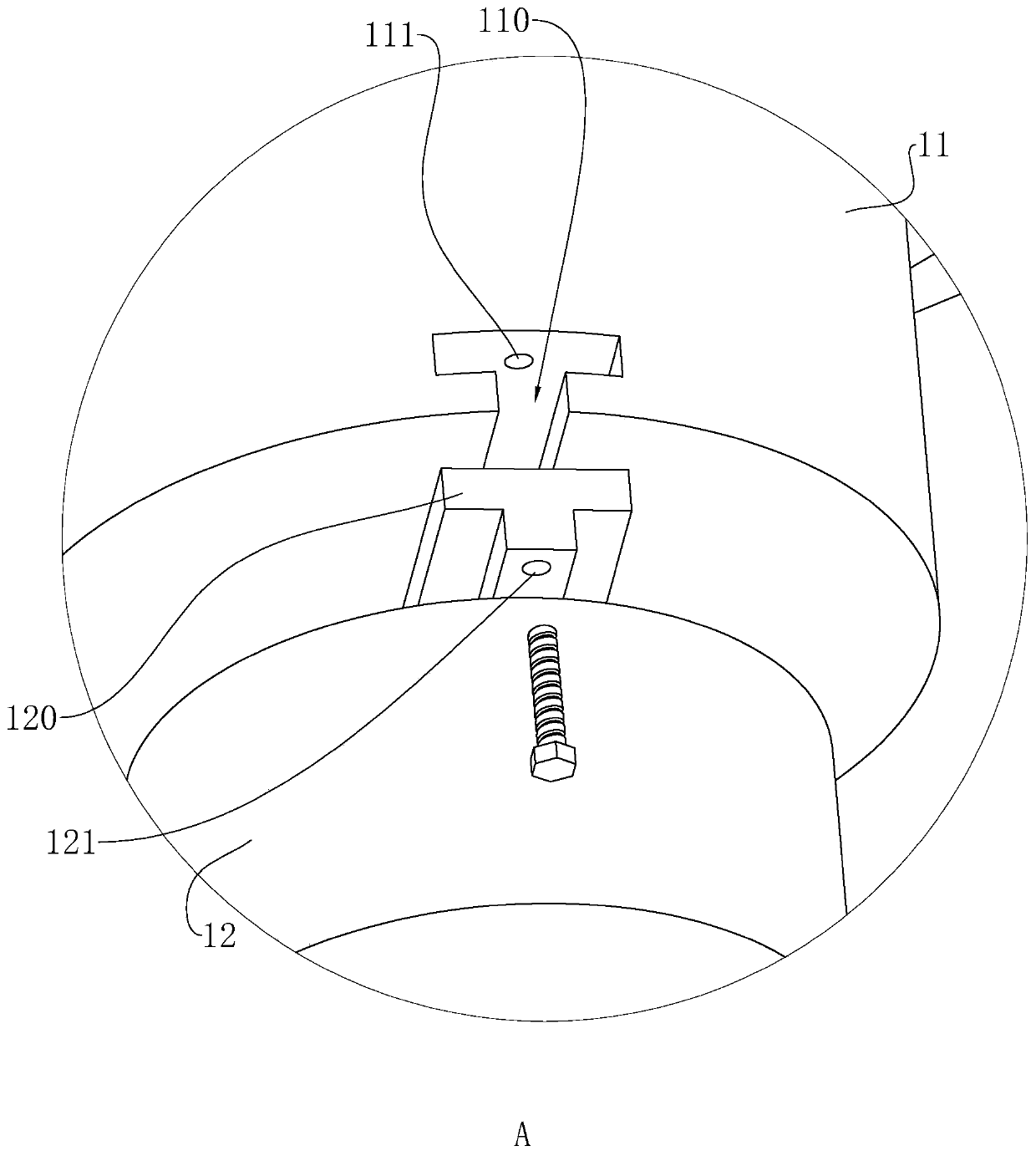

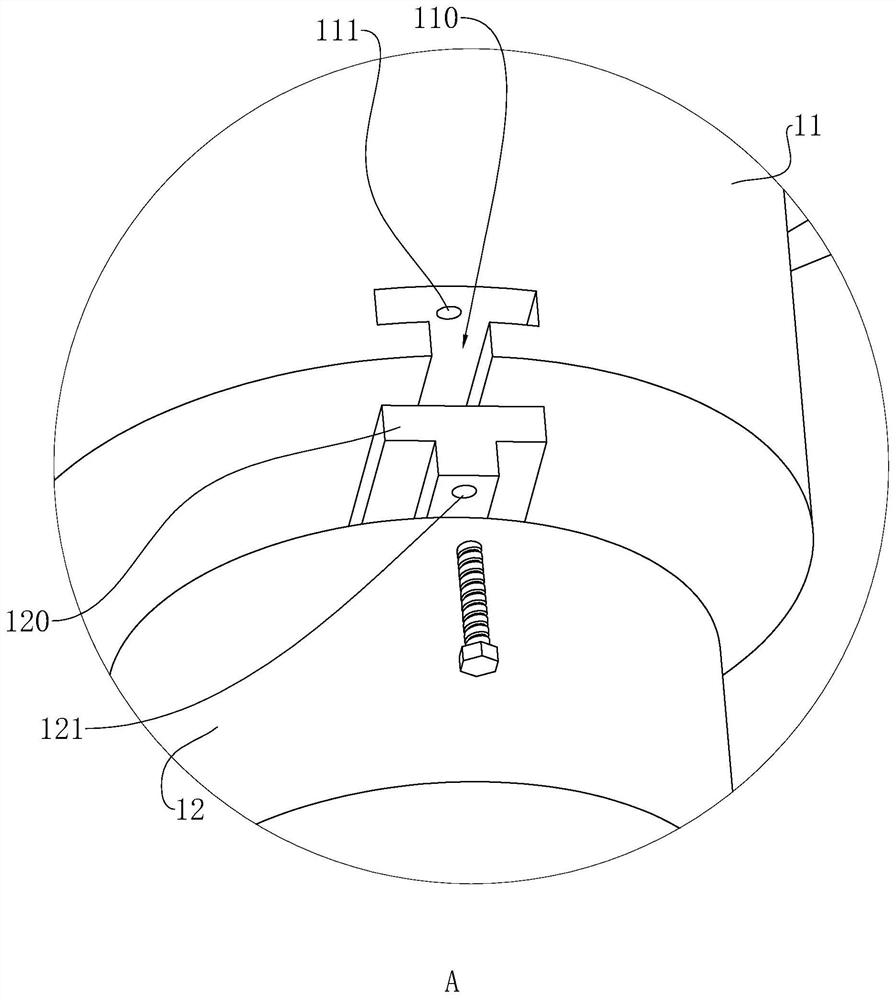

Quick mould changing mechanism used for injection molding processing

The invention relates to the field of injection molding processing, in particular to a quick mould changing mechanism used for injection molding processing. The quick mould changing mechanism comprises an injection molding machine, a positive mould seat and a negative mould seat, wherein the positive mould seat and the negative mould seat are installed on the injection molding machine. The quick mould changing mechanism also comprises a positive mould, a negative mould, a clamping claw movement mechanism, an elastic tight-plugging mechanism, a mechanical clamping claw, a preheating mechanism,a placement frame and four demoulding mechanisms. The quick mould changing mechanism used for injection molding processing preheats a mould on the placement frame through a preheating mechanism so asto prevent a worker from transporting the mould, a possibility that the worker is at risk is lowered, a situation that the positive mould and the negative mould are clamped and installed for two timescan be avoided, and a mould replacement process is quickened. Since the positive mould is taken down from the negative mould, a possibility that mould installation has a deviation is lowered, the positive mould and the negative mould are tightly connected, only one-time clamping and disassembling needs to be carried out, a mould replacement process is quickened, a situation that the positive mould and the negative module are assembled by the worker is not required, the positive mould and the negative mould are assembled into a whole, and land occupation of the mould is reduced.

Owner:长春百思特汽车零部件有限公司

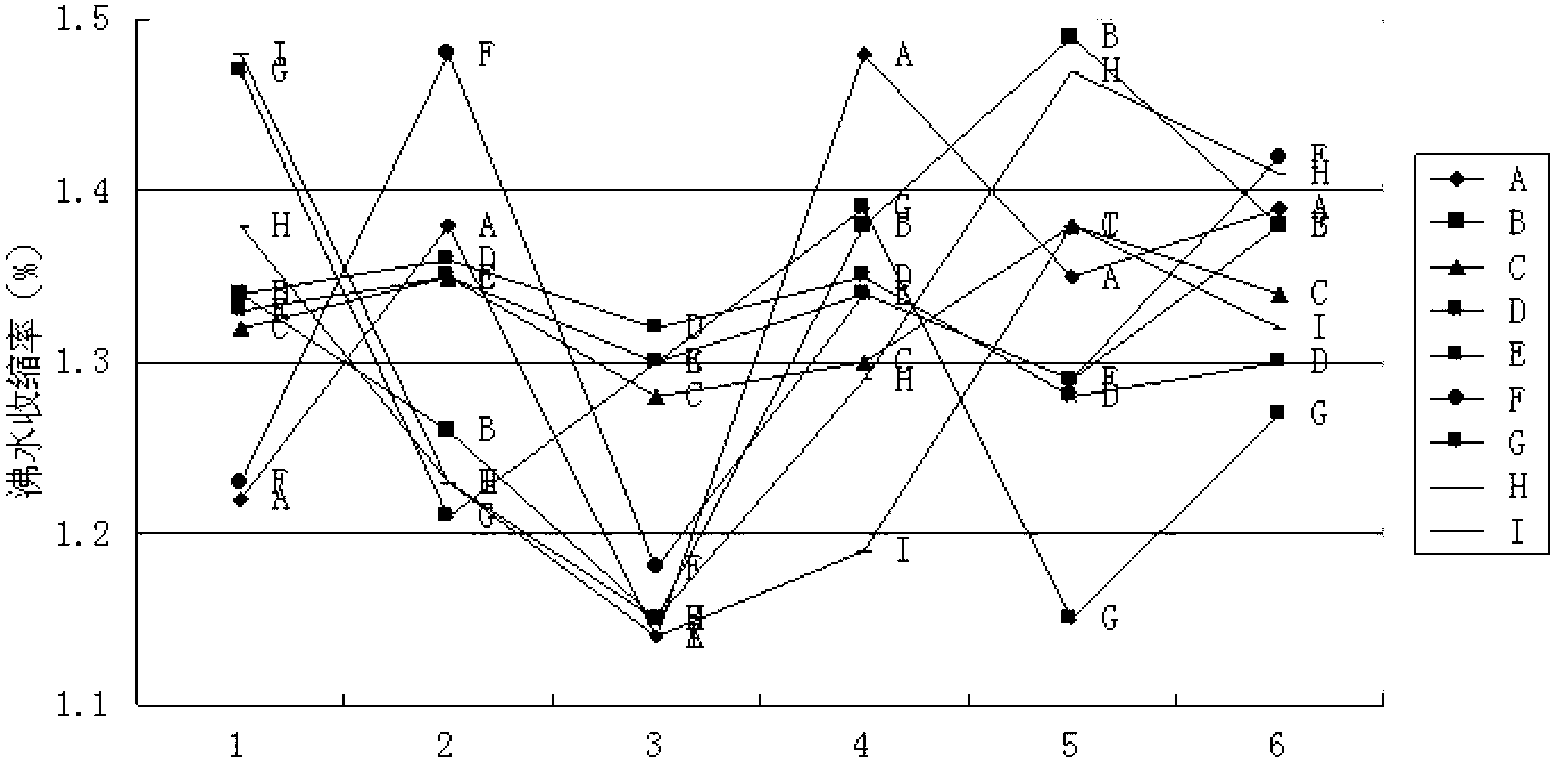

Method for online detection of polyester staple fiber shrinkage in boiling water

ActiveCN102914476AIncrease authenticityGuarantee authenticityInvestigating material ductilityPolyesterFiber

The invention discloses a method for online detection of polyester staple fiber shrinkage in boiling water. Polyester staple fiber samples are selected to reach moisture absorption balance through pre-wetting and wetting processes, at least 6 polyester staple fibers in the samples which reach moisture absorption balance are selected to be put in a neutral or weak alkaline aqueous medium at a specific temperature and are heated until boiling according to a specific heating rate, and the boiling state is kept for 30-40 minutes, so that the samples can fully shrink; and the samples are dried and put at standard atmospheric pressure to be balanced, and the lengths of the shrunk samples are measured and are compared with the lengths before shrinkage to calculate the polyester staple fiber shrinkage in boiling water. By the method for testing, the influences of factors of different types and contents of additives, different polyester staple fiber processing technologies and other factors to the polyester staple fiber shrinkage in boiling water can be eliminated during the polyester staple fiber production process, a measurement result has good repeatability, the evaluation is in accordance with the self characteristics of fibers, and the method has an active guiding meaning to production and is worthy of being widely popularized.

Owner:福建鑫华股份有限公司

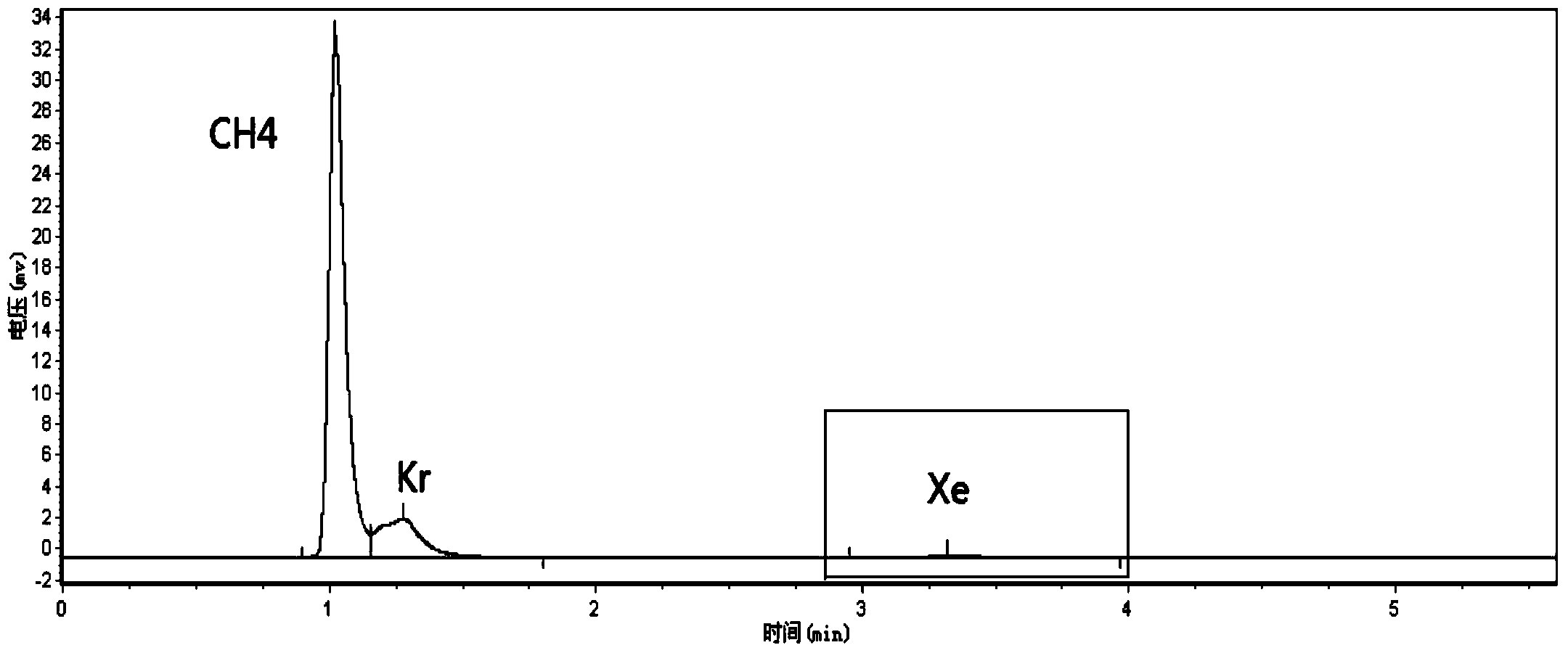

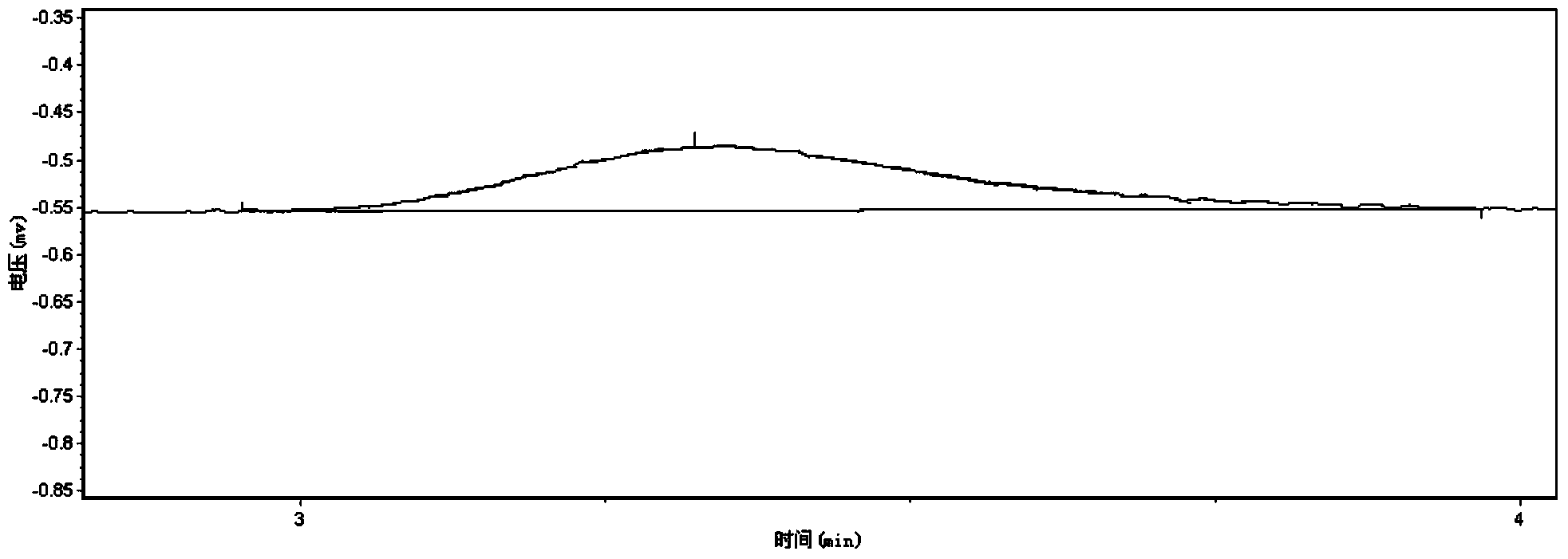

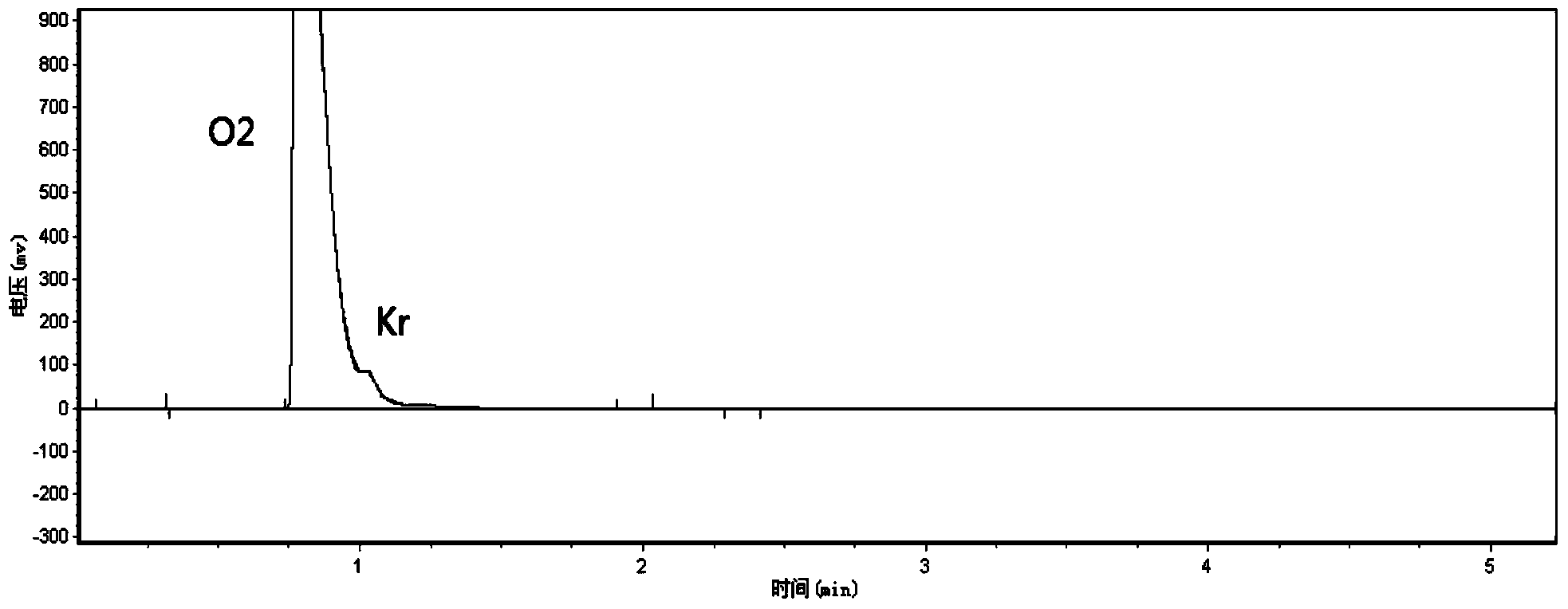

Method for analyzing content of krypton and xenon in krypton and xenon feed gas

ActiveCN103487543ASatisfy quality requirements for selectionAccurate detectionComponent separationKryptonChromatographic column

The invention relates to a method for analyzing content of krypton and xenon in krypton and xenon feed gas, and the problem that the content of krypton and xenon in existing krypton and xenon feed gas can not be analyzed accurately is solved. According to the method, a mini-type thermal conductance analyzer serves as a main body, measurement is carried out by a capillary chromatographic column, helium serves as carrier gas, the mini-type thermal conductance analyzer is used for measuring the peak area of the krypton and the peak area of the xenon in the krypton and xenon feed gas, and then the volume content of the krypton and the volume content of the xenon are calculated. The method can accurately measure the content of the main components such as the krypton and the xenon in the krypton and xenon feed gas, can meet the requirement for selecting the mass of the feed gas in the early stage of production of the krypton and the xenon, and is fast and accurate in detection, the deviation ratio is far less than 3%, and the detection time can be shortened to be within 50 seconds.

Owner:WUHAN IRON & STEEL GRP GAS CO LTD

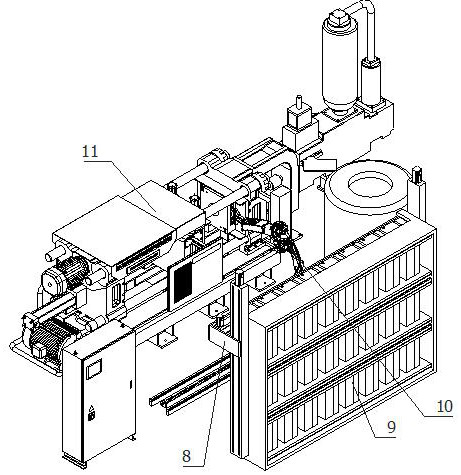

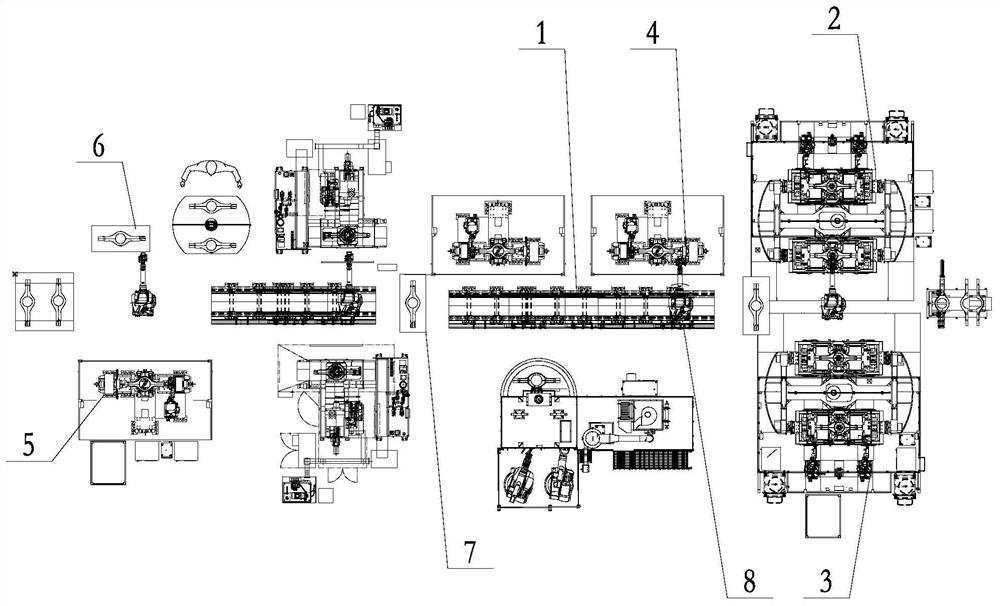

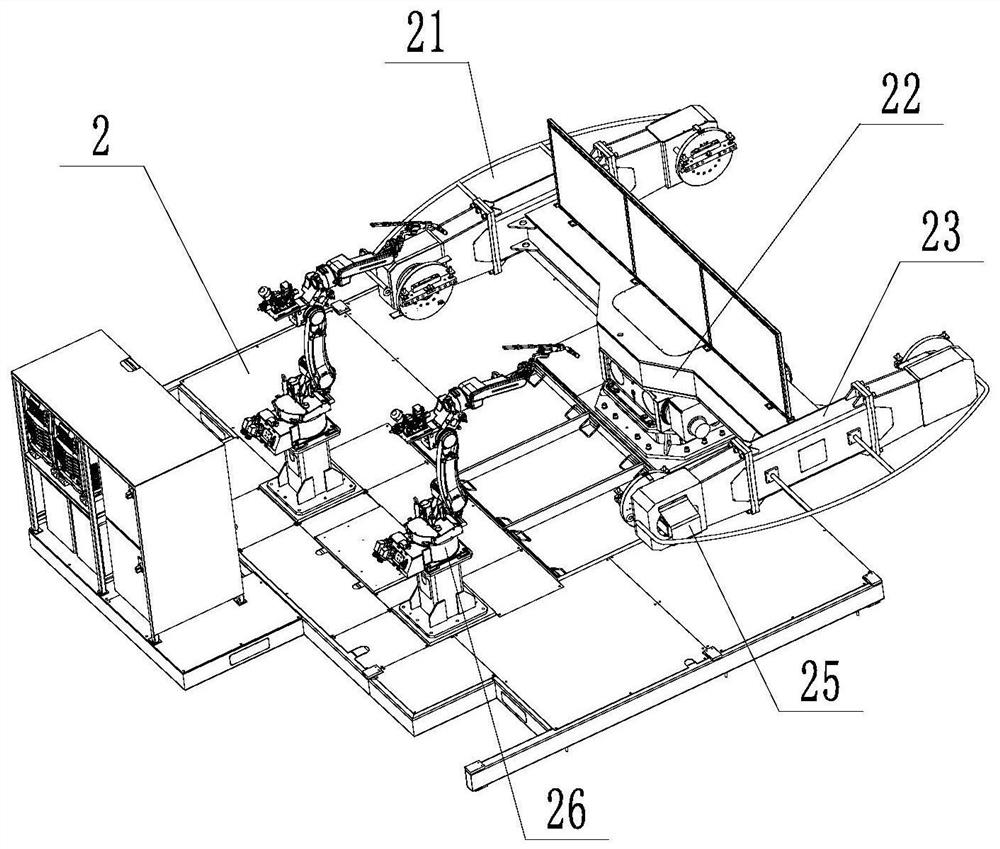

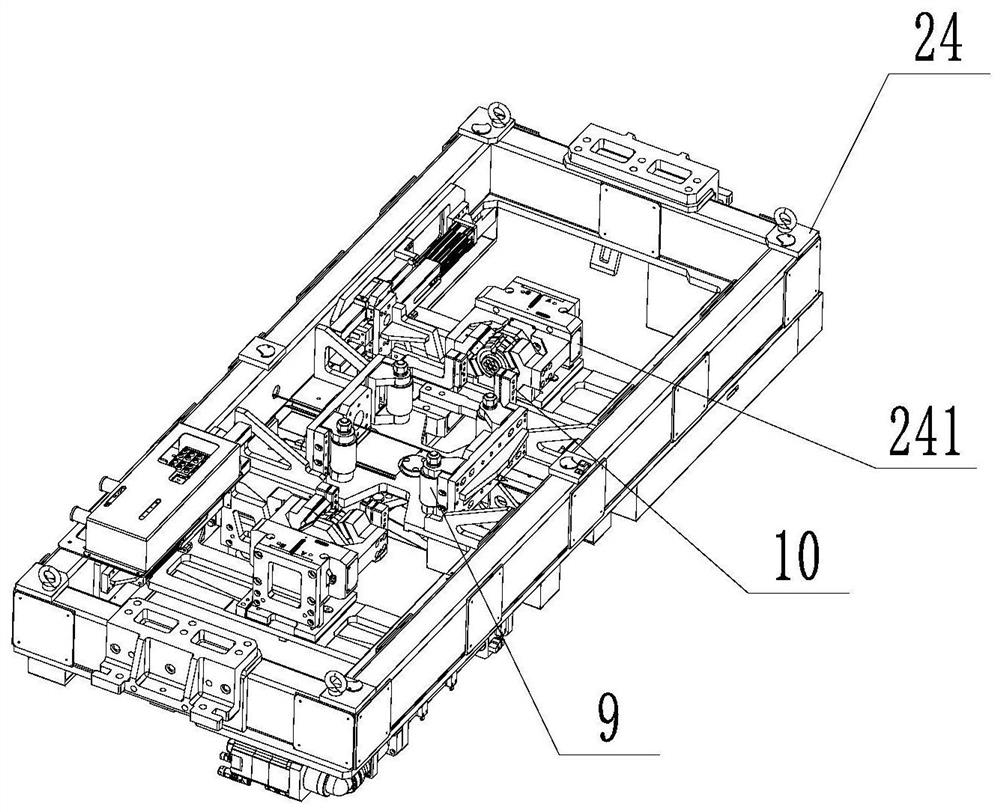

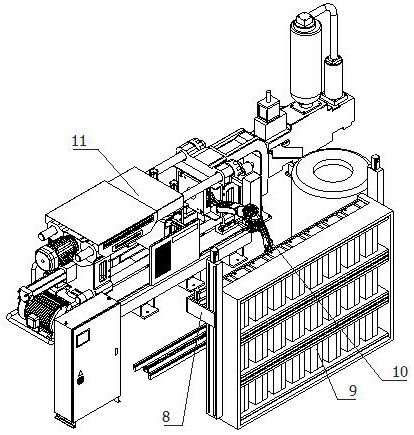

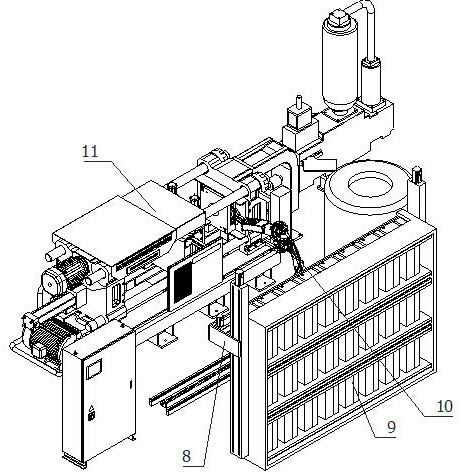

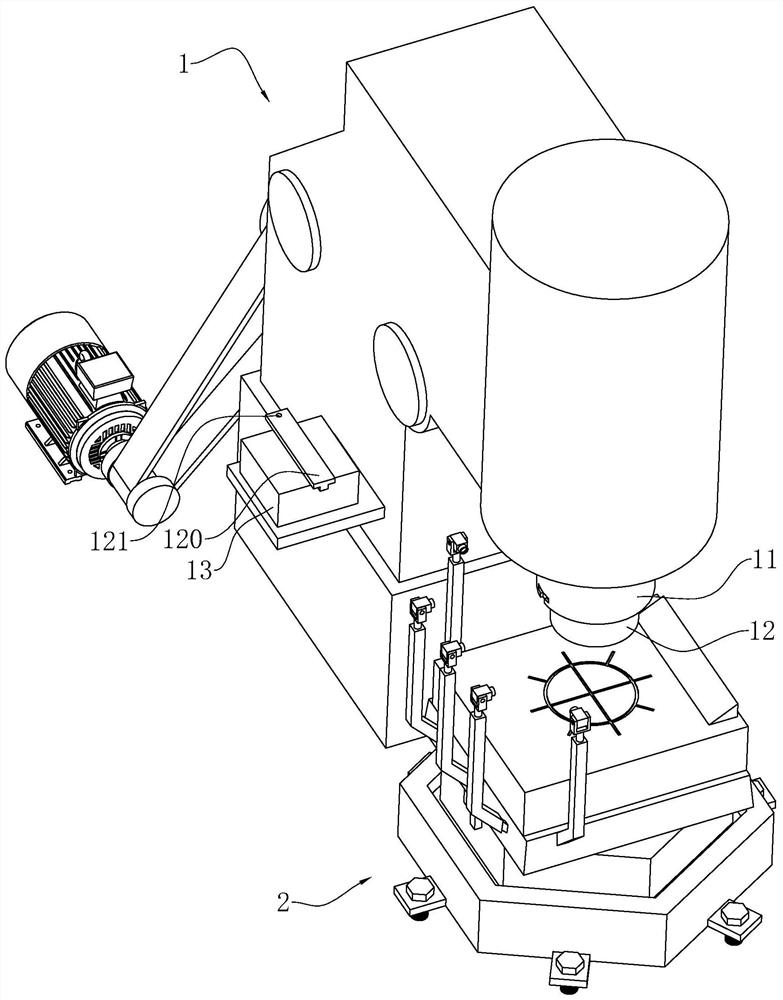

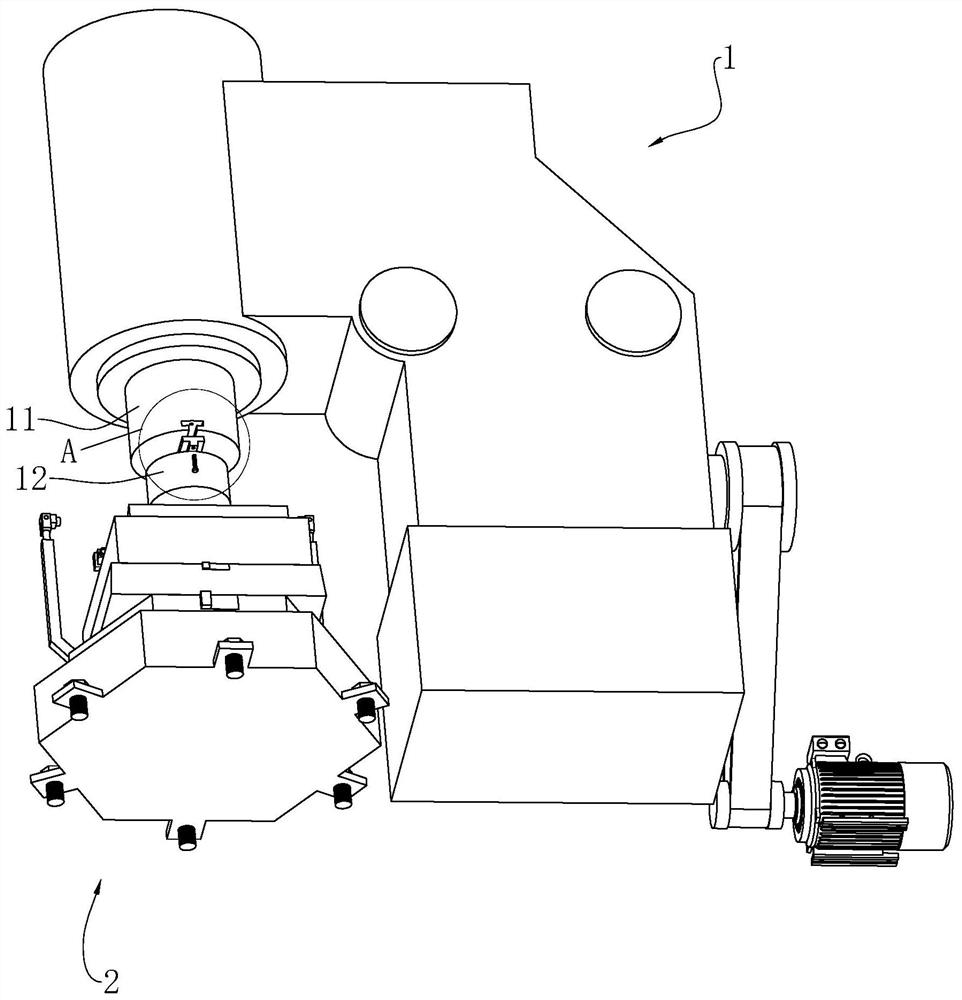

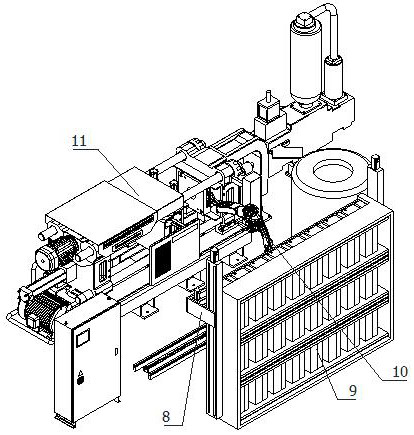

Axle housing body automatic production line based on multi-vehicle-type flexible production

PendingCN113182879APrecise positioningThe probability of deviation in handling is reducedWelding/cutting auxillary devicesOther manufacturing equipments/toolsElectric machineryManufacturing line

The invention discloses an axle housing body automatic production line based on multi-vehicle-type flexible production, belongs to the technical field of automobile manufacturing, and solves the problems that existing production relies on manual switching positioning and manual transferring switching equipment is complex and inaccurate in positioning. The axle housing body automatic production line based on multi-vehicle-type flexible production comprises a sliding table, a half-housing combination welding unit and an axle housing repair welding unit, wherein the half-housing combination welding unit and the axle housing repair welding unit are sequentially connected to the ground in the contour direction of the sliding table; a carrying robot is arranged on the sliding table; the half-housing combination welding unit and the axle housing repair welding unit each comprise a positioner, a rotary table, a tool frame, a welding robot and a motor; and the half-housing combination welding unit further comprises a welding clamp, and the axle housing repair welding unit further comprises a repair welding clamp. Switching can be completed by controlling the stroke of each air cylinder and the carrying distance of the carrying robot through a preset program, rapid switching of multiple kinds of positioning points can be achieved, the labor cost is reduced, and the switching time is shortened.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

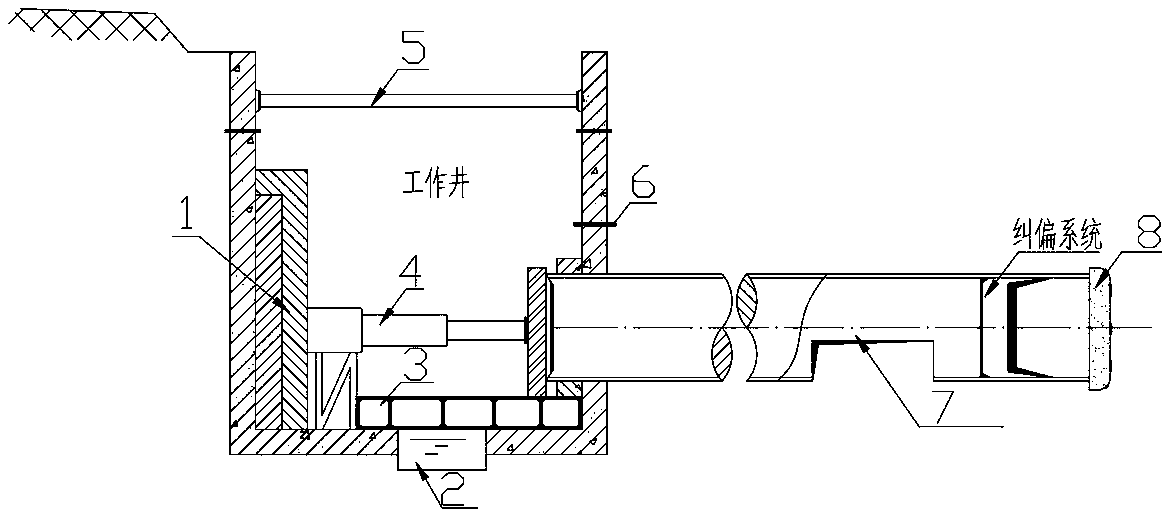

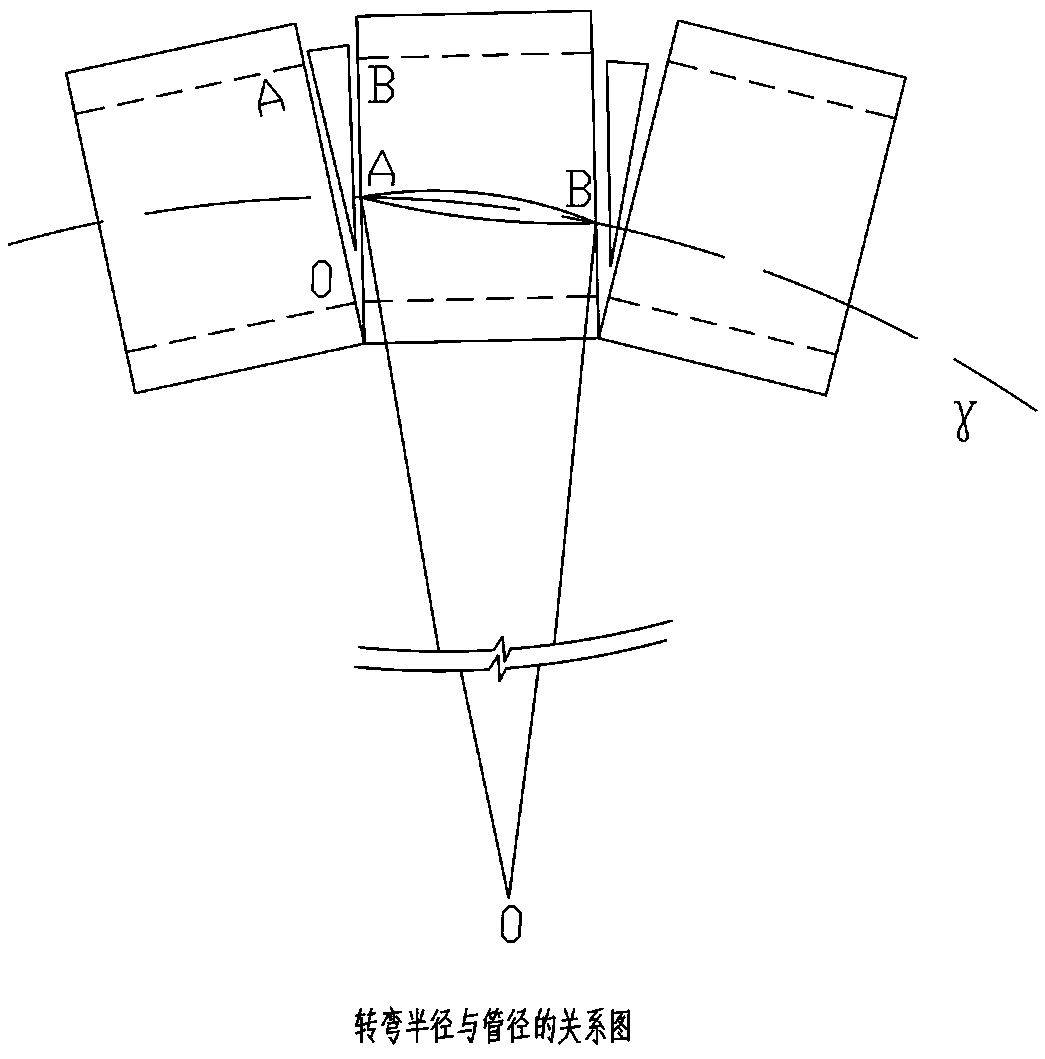

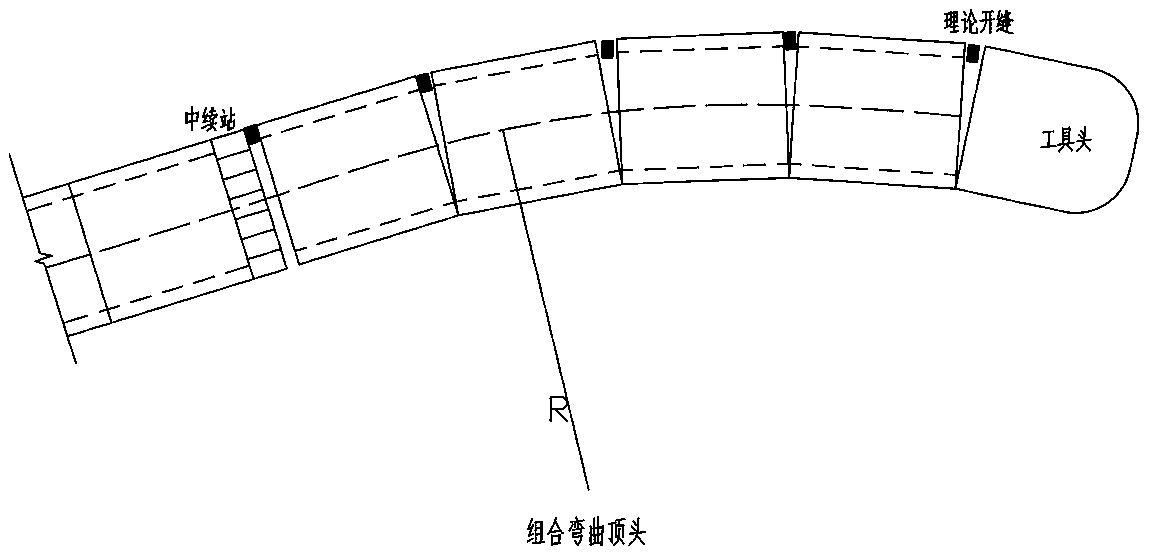

Arc-shaped pipe jacking construction device and construction method

InactiveCN111058858APropel route is correct and perfectReduce the probability of biasTunnelsWater stopData lines

The invention discloses an arc-shaped pipe jacking construction device. The arc-shaped pipe jacking construction device comprises a tool pipe body. A driving system, a deviation rectifying system, a screw mud conveying system, an electric appliance control system and a hydraulic control system are also arranged in the tool pipe body. The electric appliance control system comprises a programmable interrupt controller (PIC). The programmable interrupt controller (PIC) is connected with a crystal oscillator, a storage battery, a processor, an LED display screen and a tripping device through datalines. The arc-shaped pipe jacking construction method comprises the following steps that S1, foundation pit excavating and processing are carried out, excavating is carried out on a construction site, a foundation pit is excavated, the back of the foundation pit is installed, a muck pool is excavated, the surface of the ground at the bottom of the pit is leveled, guide rails are fixedly installedon the upper portion of the muck pool, and a water stop valve plate is installed in the foundation pit. By means of the arc-shaped pipe jacking construction device, the problems of curved pipe jacking pushing, leakage prevention of pipe joints, uneven stress distribution at curve points of pipe joints and the like can be solved, and the aims of feasible technology, safety and high efficiency areachieved through an actual implementation effect and calculation analysis.

Owner:福建建中建设科技有限责任公司

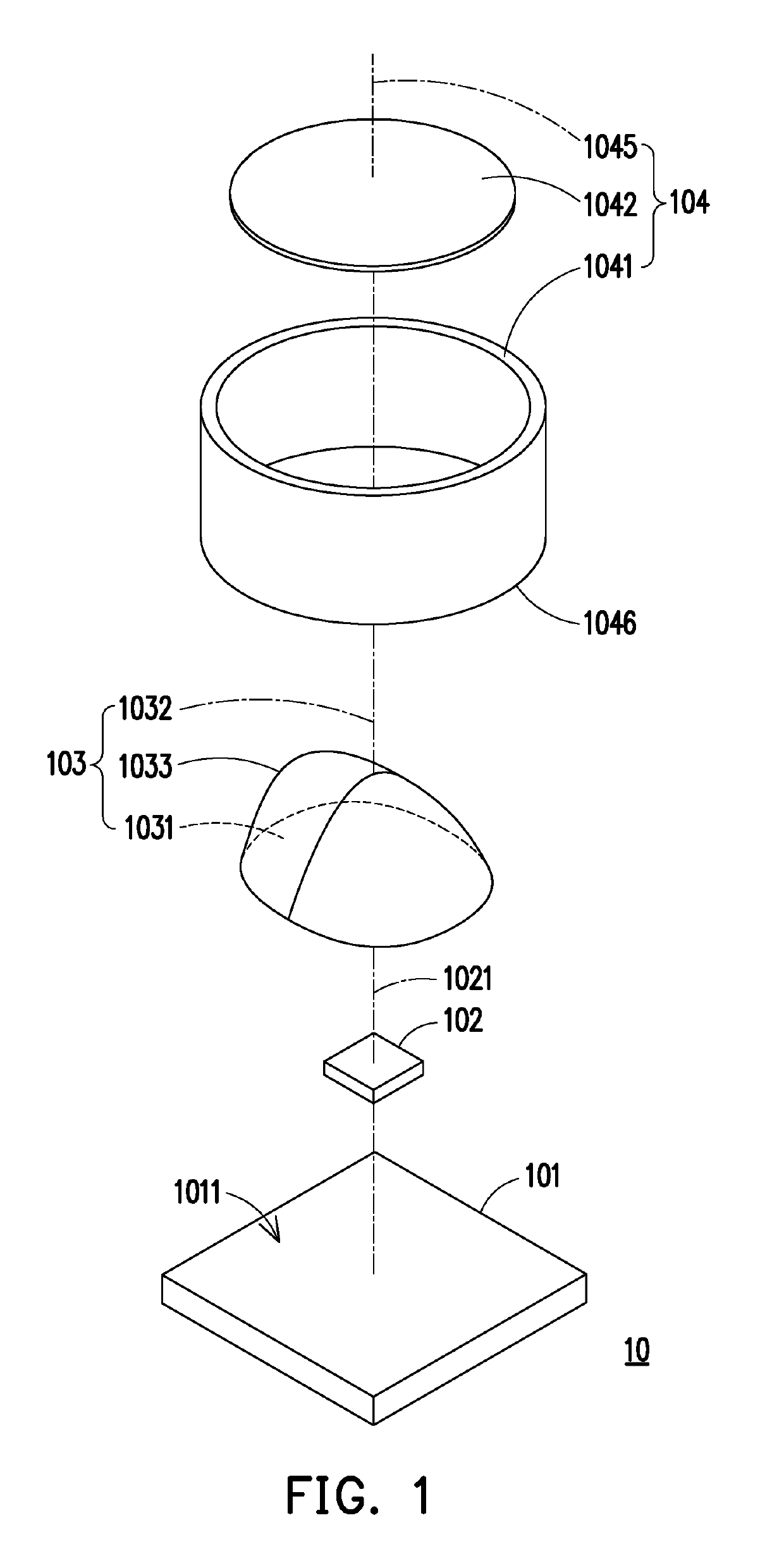

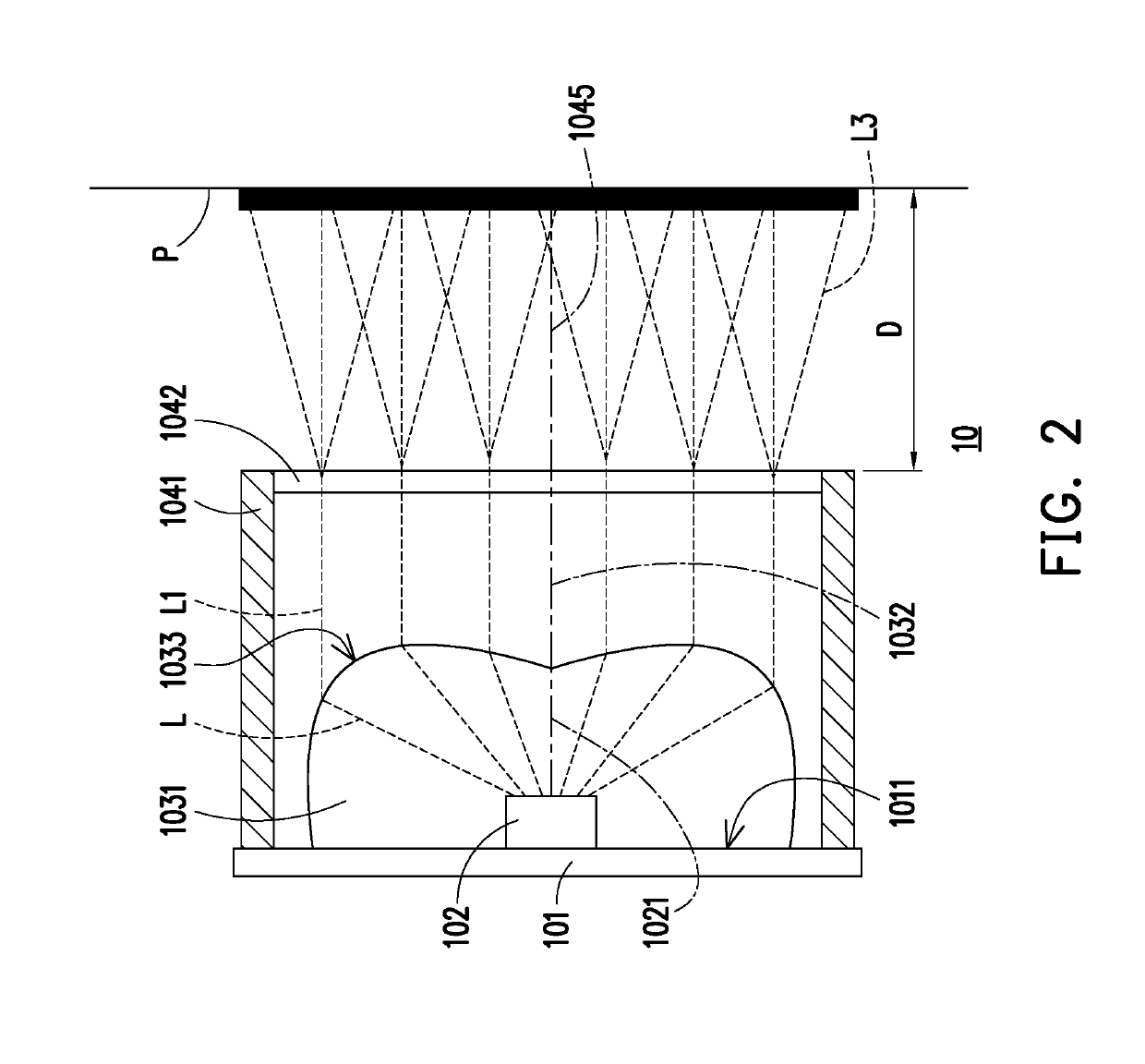

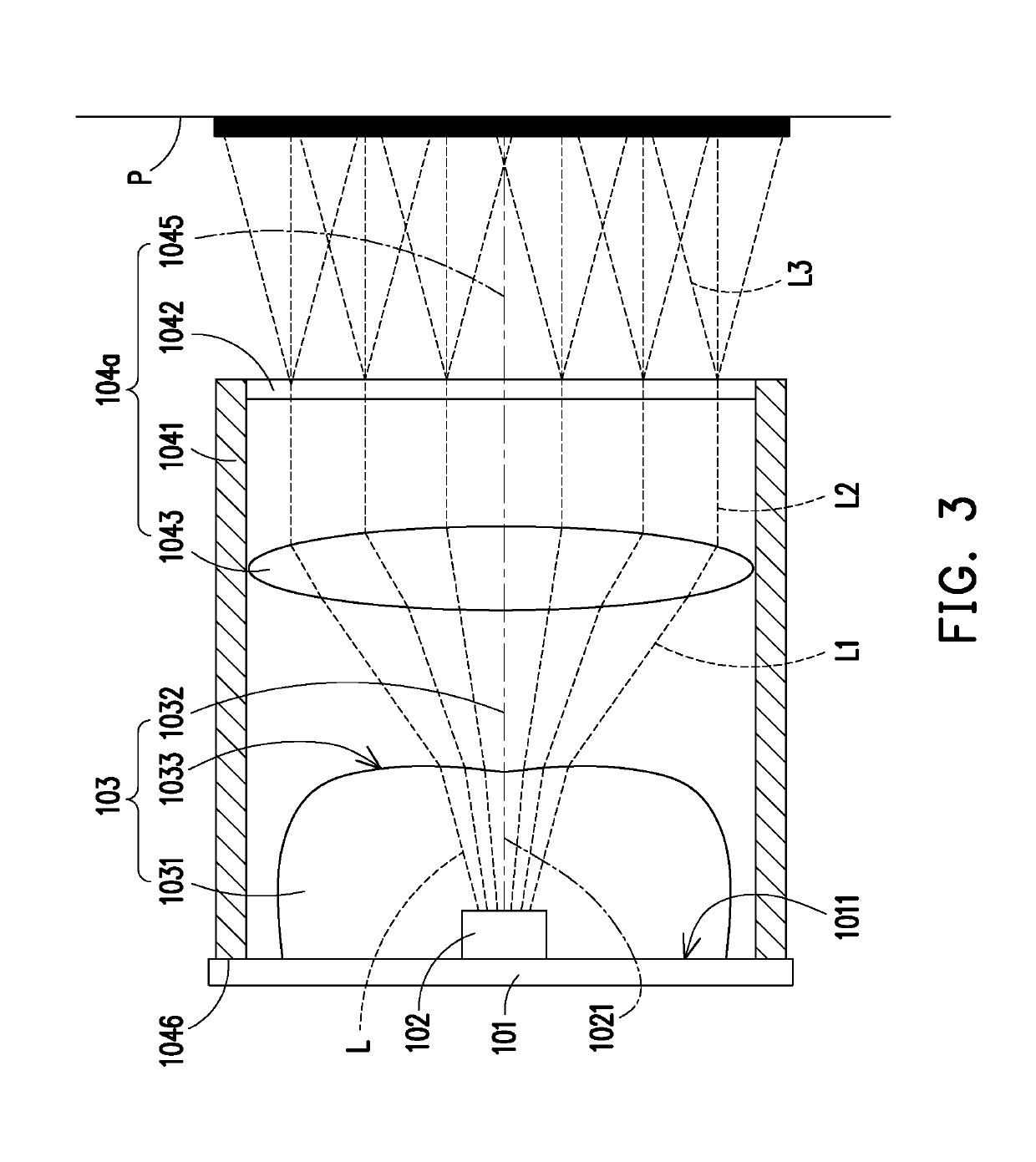

Structured light projection system

A structured light projection system including a substrate, a semiconductor laser chip, a first optical module, and a second optical module is provided. The semiconductor laser chip is electrically connected to the substrate. The first optical module is disposed on the substrate. The second optical module is disposed on the first optical module. The deviation rate between optical axes of the optical modules and the semiconductor laser chip and the calibration time thereof are reduced by the first optical module directly packaging the substrate through a primary optics design, so as to increase the yield of the structured light projection.

Owner:LIGITEK ELECTRONICS

Working method of quick mold changing mechanism for injection molding

The invention relates to the field of injection molding, in particular to a working method of a quick mold changing mechanism for injection molding. The mechanism comprises an injection molding machine, a positive mold base and a negative mold base, the positive mold base and the negative mold base are arranged on the injection molding machine, and the mechanism further comprises a positive mold,a negative mold, a clamping jaw moving mechanism, an elastic inserting mechanism, a mechanical clamping jaw, a preheating mechanism, a placing frame and four demoulding mechanisms. According to the quick mold changing mechanism for the injection molding, a mold on the placing frame is preheated by the preheating mechanism, workers are prevented from carrying the mold, the possibility that the workers are dangerous is reduced, two times of clamping and mounting the positive mold and the negative mold are avoided, the process of replacing the molds is accelerated, the probability of deviation ofthe mounting of the mold is reduced due to the fact that the positive mold is taken down from the negative mold, the positive mold and the negative mold are tightly connected, only one time of clamping and dismounting is needed, the process of replacing the mold is accelerated, the workers are not needed to assemble the positive mold and the negative mold together, the positive mold and the negative mold are assembled together, and the occupied area of the mold is reduced.

Owner:佛山市顺德区鸿研电器有限公司

Multi-wire clamp universal live working tool and using method thereof

PendingCN109616946AReduce error rateReduce deviation rateApparatus for overhead lines/cablesSafety coefficientEngineering

The invention provides a multi-wire clamp universal live working tool and a using method thereof. The multi-wire clamp universal live working tool comprises an installation side plate, the installation side plate is provided with an upper hook arm and a lower hook arm which face to each other vertically and are stretchable and further provided with lead wire hook rods which are elastically stretchable, and the lead wire hook rod are located between the upper hook arm and the lower hook arm. A lead wire is fixed by the two lead wire hook rods with springs, then a wire clamp is opened by the upper and lower stretchable hook arms with springs to enable an opening of the wire clamp to be maximum, the error rate and deviation rate of wire clamp installation are significantly decreased, and convenience is brought to operation in actual work. In addition, the live working tool is encapsulated by adopting an insulating material and externally connected with a protection shell, the protection shell protects hooks and internal devices from being destroyed by collision, therefore, the safety coefficient can be better improved, and the safety of a worker is guaranteed.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD HANGZHOU POWER SUPPLY CO +2

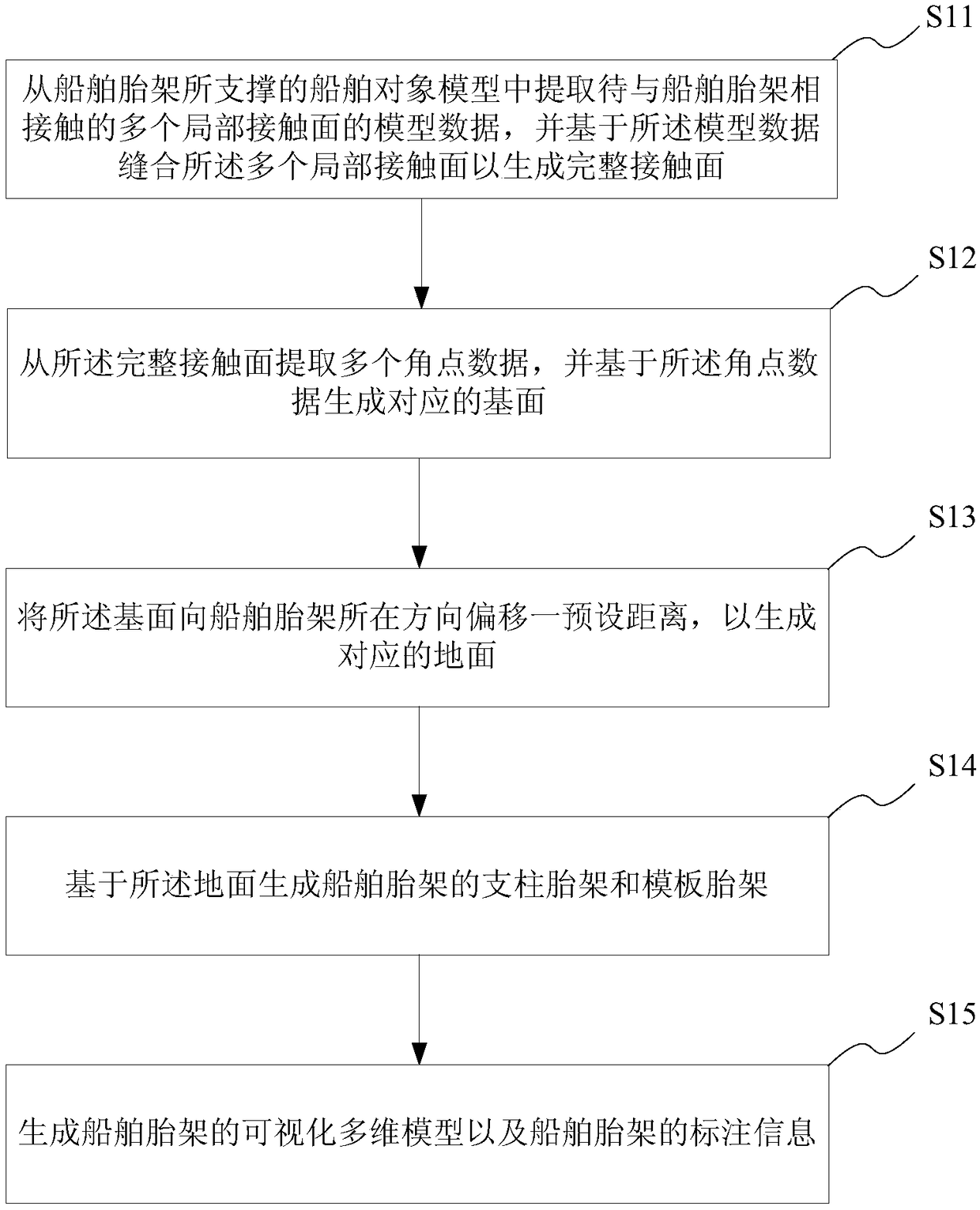

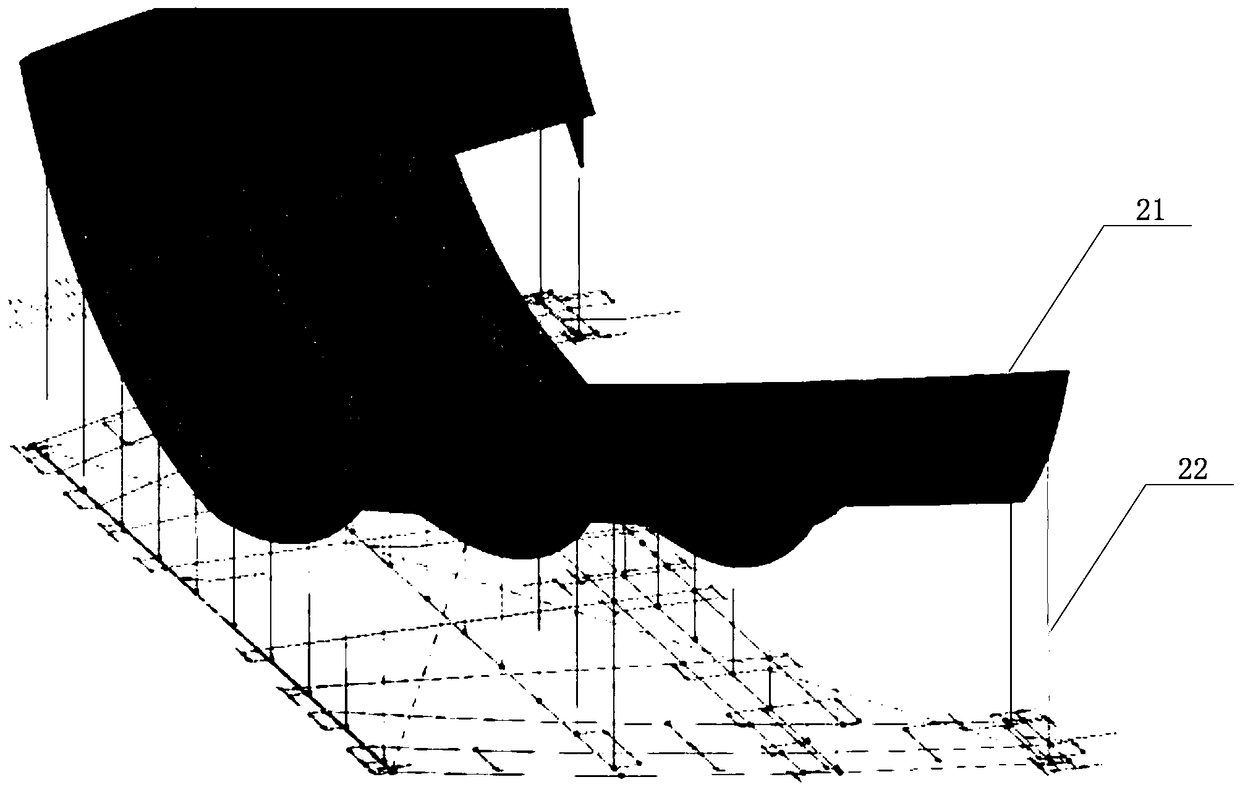

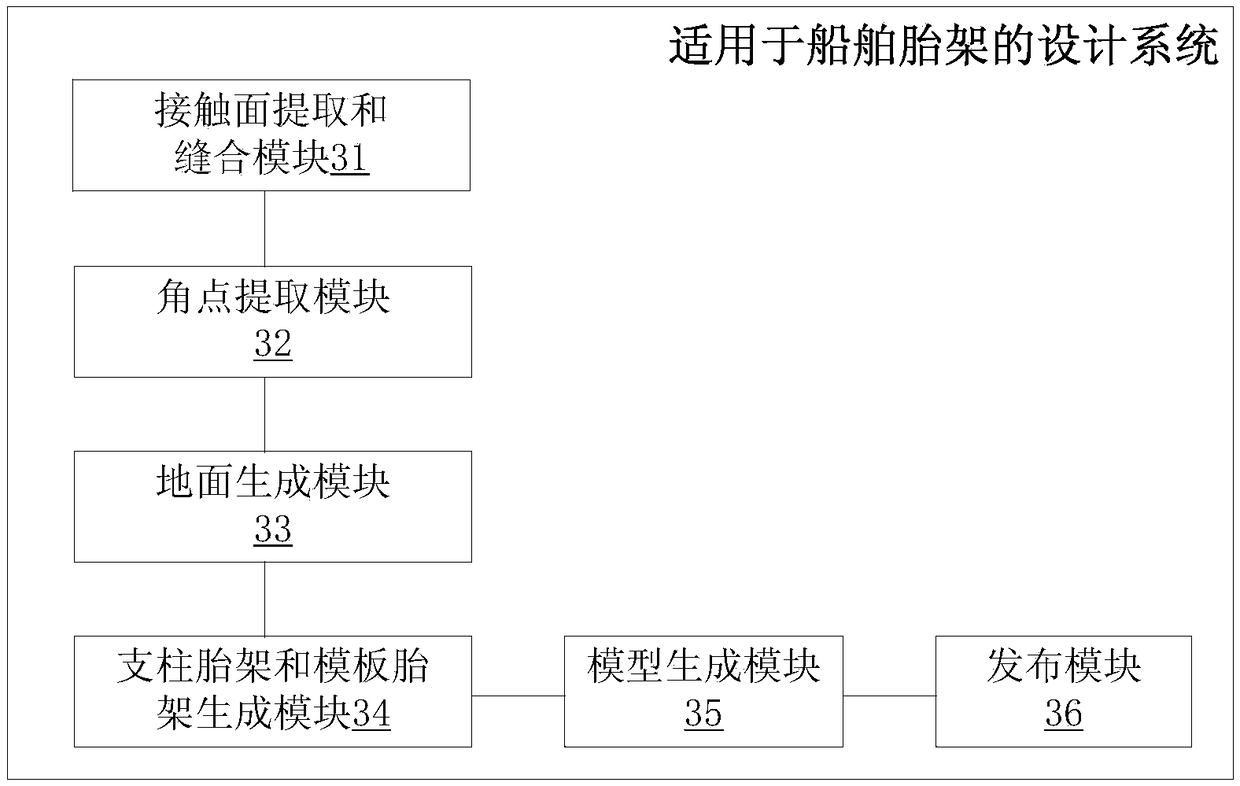

Design method and system suitable for ship jig frame, electronic terminal and storage medium

ActiveCN109446749AShorten the construction periodShorten read timeGeometric CADSustainable transportationInformatizationMarine engineering

The invention provides a design method and system suitable for a ship jig frame, an electronic terminal and a storage medium, and the design system suitable for the ship jig frame comprises a contactsurface extraction and sewing module, an angular point extraction module, a ground generation module, a pillar jig frame, a template jig frame generation module and a model generation module. According to the present invention, the three-dimensional model of the ship jig frame can be provided, so that the data information of the ship jig frame is displayed in a more comprehensive and more visual manner, the picture reading time of constructors is shortened, and the deviation rate of the constructors in understanding drawings is also reduced; secondly, the paperless design and construction areachieved, and the design cost is greatly reduced; and finally, the informatization level of on-site construction is further improved, the construction period of the ship jig frame is shortened, and the construction quality is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

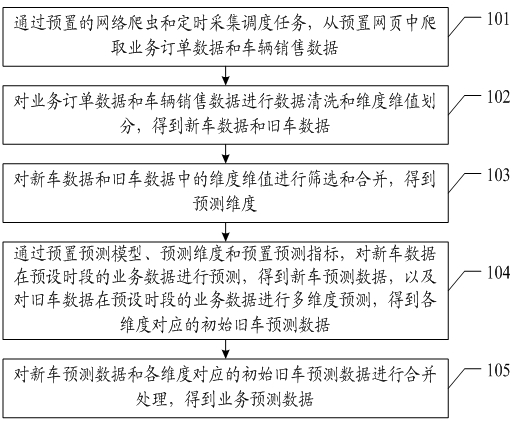

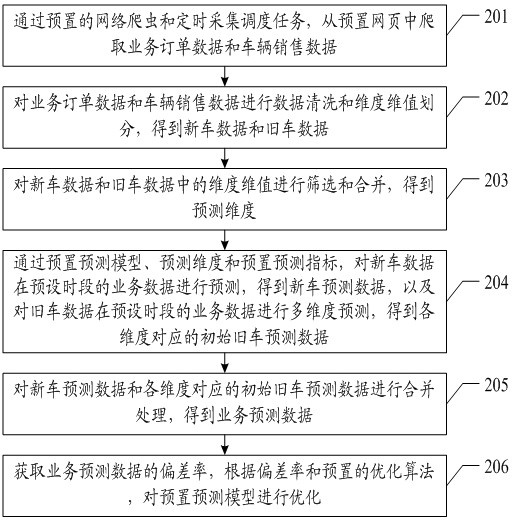

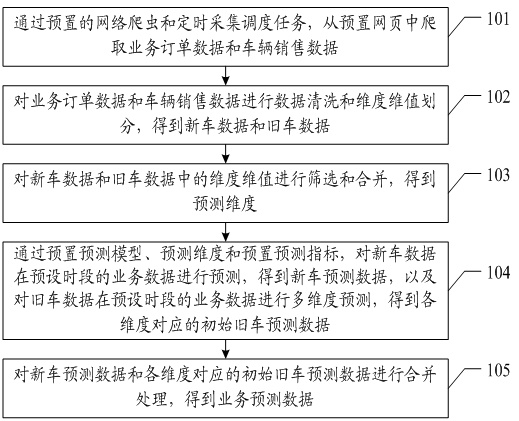

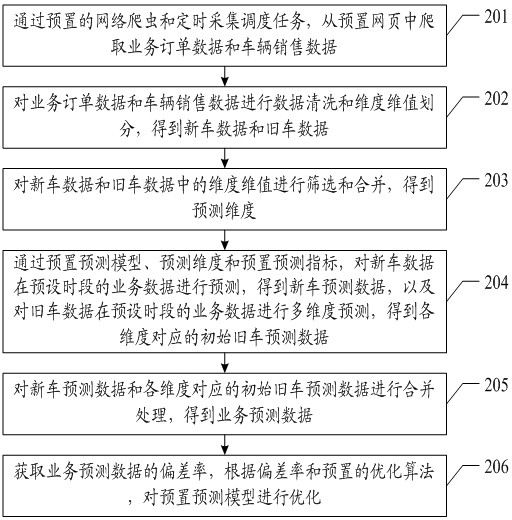

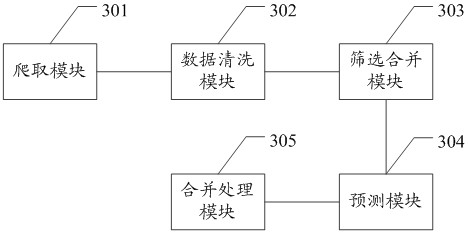

Service data prediction method and device, equipment and storage medium

ActiveCN112232606AImprove forecast accuracyFit closelyWeb data indexingForecastingWeb crawlerBusiness forecasting

The invention relates to the technical field of artificial intelligence, and provides a service data prediction method and device, equipment and a storage medium, which are used for improving the prediction accuracy of service data. The service data prediction method comprises the steps of performing data cleaning and dimension value division on service order data and vehicle sales data crawled bya web crawler to obtain new vehicle data and old vehicle data; screening and combining dimension values in the new vehicle data and the old vehicle data to obtain a prediction dimension; predicting the service data of the new vehicle data and the old vehicle data in a preset time period through a preset prediction model, prediction dimensions and a preset prediction index to obtain new vehicle prediction data and initial old vehicle prediction data corresponding to each dimension; and performing merging processing on the new vehicle prediction data and the initial old vehicle prediction datacorresponding to each dimension to obtain service prediction data. In addition, the invention also relates to a blockchain technology, and new vehicle data and old vehicle data can be stored in the blockchain.

Owner:PING AN TECH (SHENZHEN) CO LTD

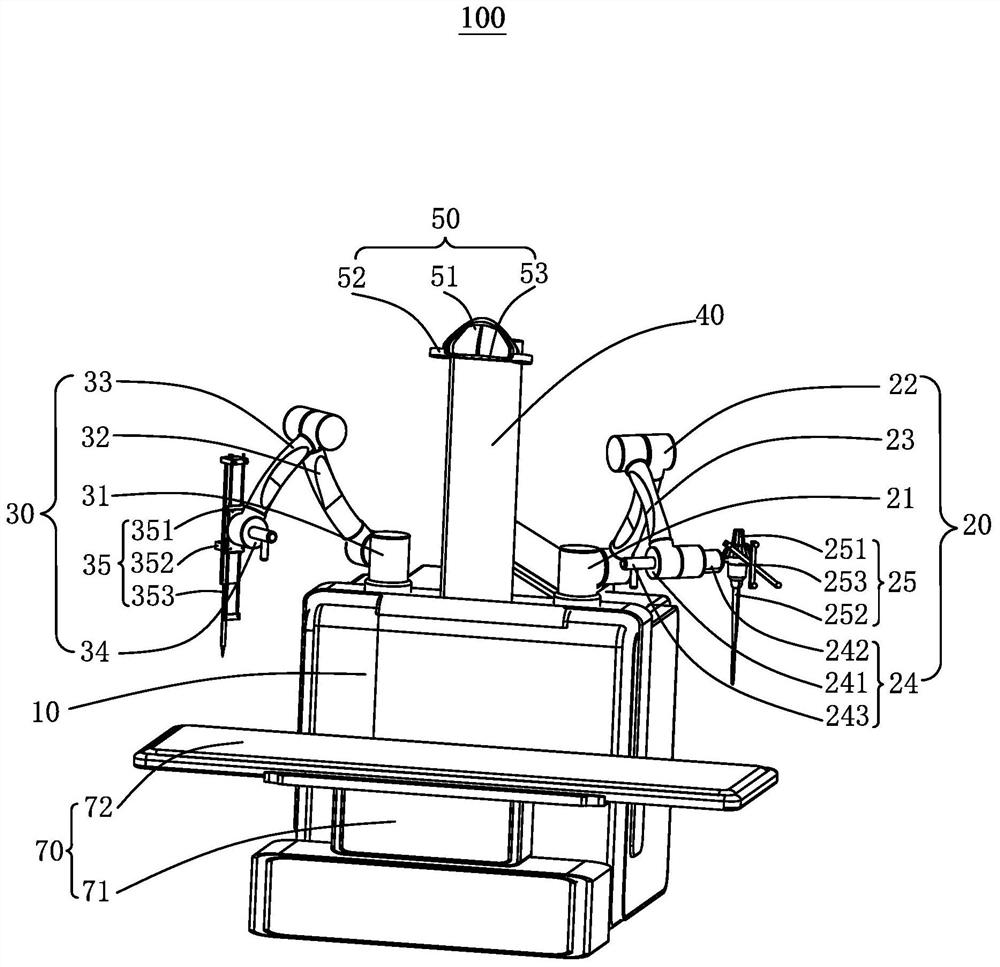

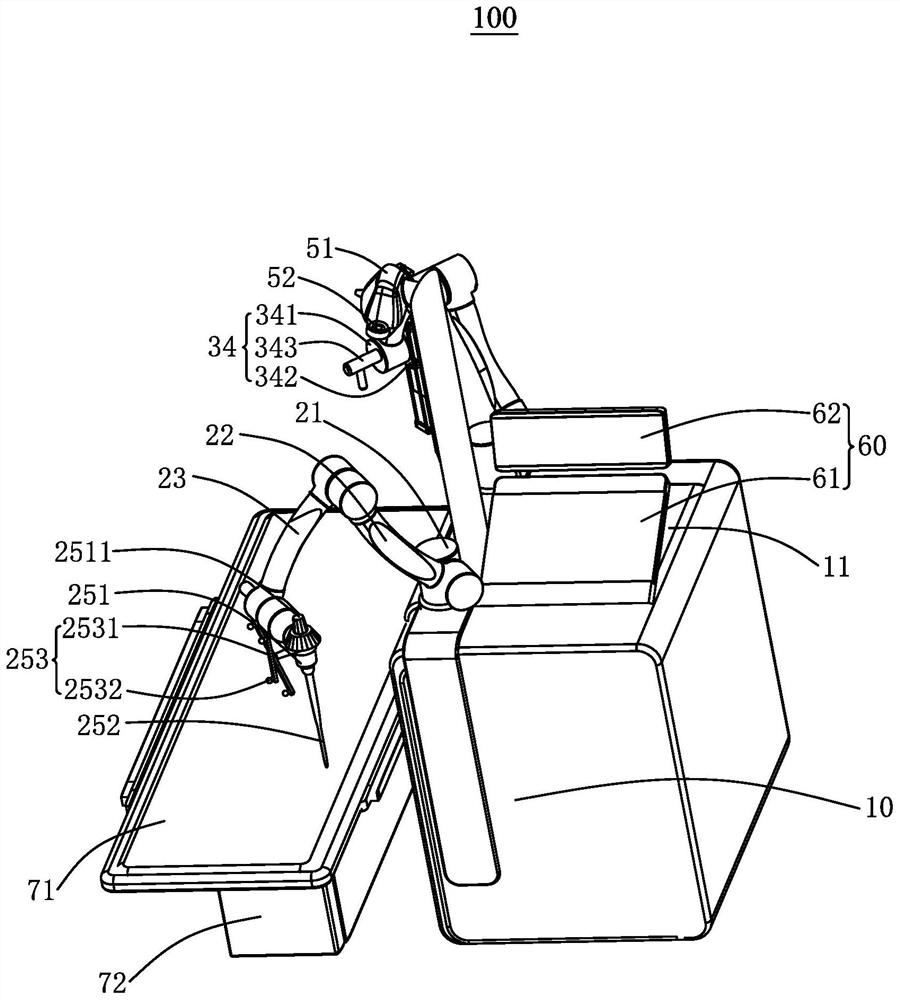

Dual Arm Surgical Robot

ActiveCN112155736BGuaranteed accuracyReduce deviation rateSurgical navigation systemsSurgical manipulatorsPhysical medicine and rehabilitationRobotic arm

The invention discloses a double-arm surgical robot, which comprises a workbench, a support piece arranged on the workbench, and a navigation positioning module fixed on the support piece. The double-arm surgical robot also includes a first mechanical arm and a second mechanical arm movably arranged on the workbench, wherein the first mechanical arm is used to locate the surgical site, and the second mechanical arm is used to communicate with The first robotic arm cooperates to perform surgical actions, and the first robotic arm and the second robotic arm perform surgical actions according to the surgical path planned by the positioning and navigation module. The above-mentioned dual-arm surgical robot first uses the first robotic arm to position the initial path of the surgical path, and then cooperates the second robotic arm with the first robotic arm to ensure the accuracy of the surgical site of the first robotic arm and the second robotic arm. It greatly reduces the probability of deviations in the surgical paths of the first mechanical arm and the second mechanical arm, and is easy to operate, with high positioning accuracy and small errors.

Owner:德智鸿(上海)机器人有限责任公司

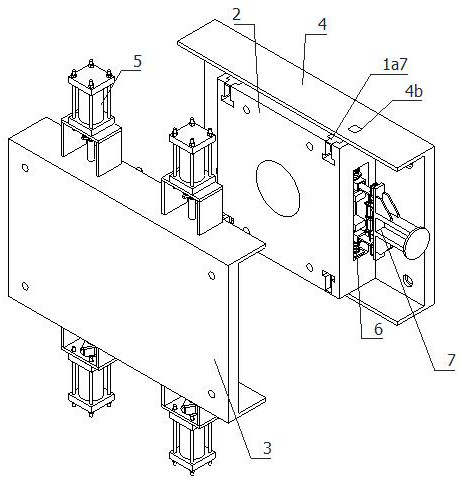

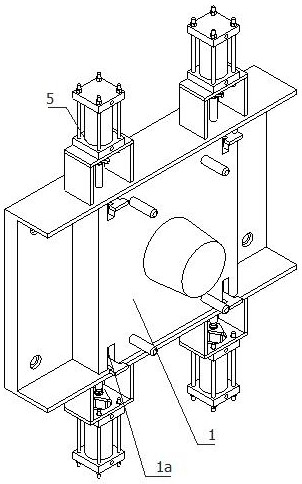

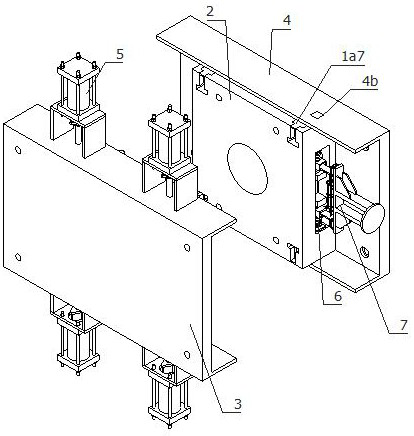

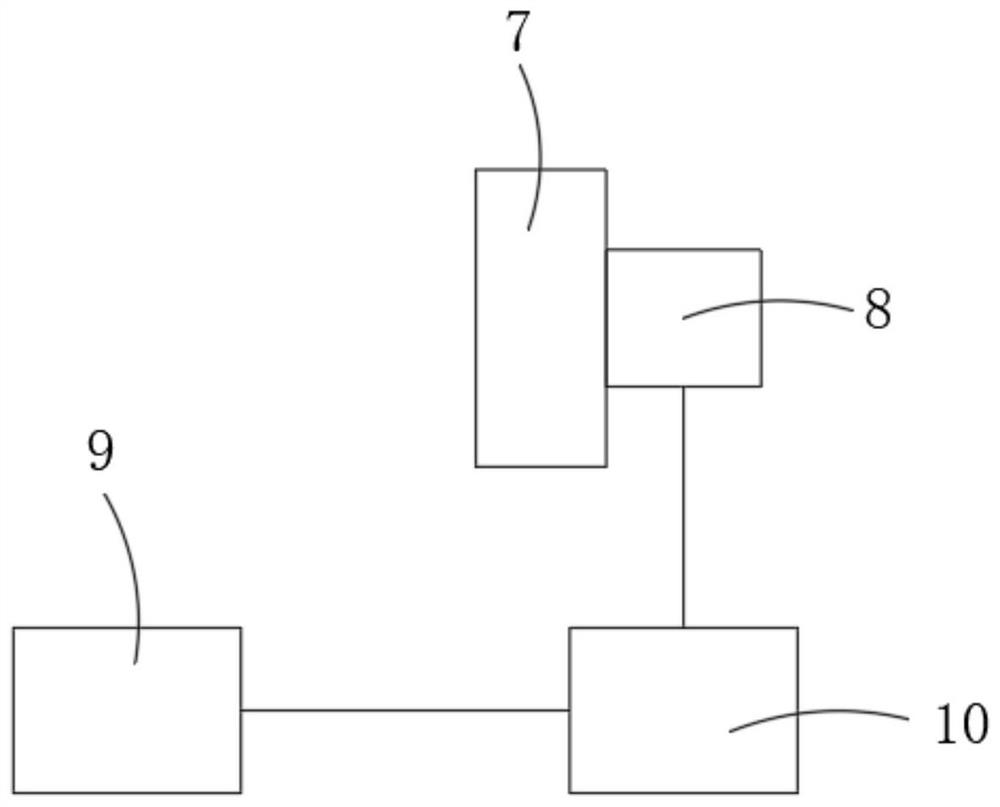

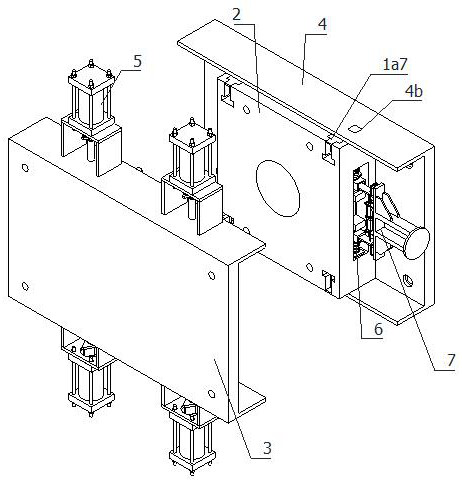

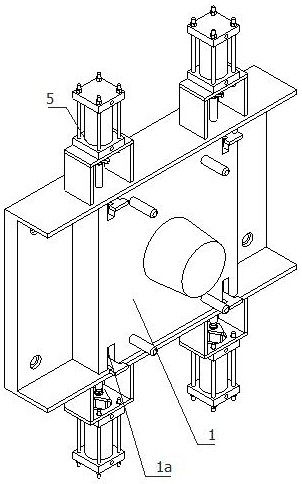

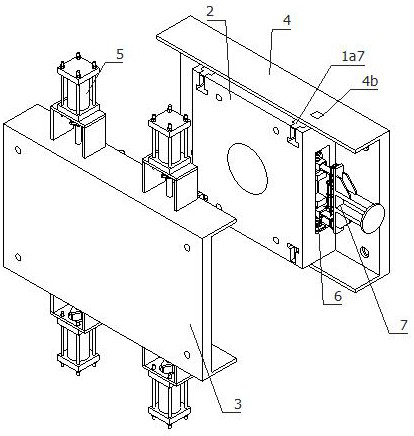

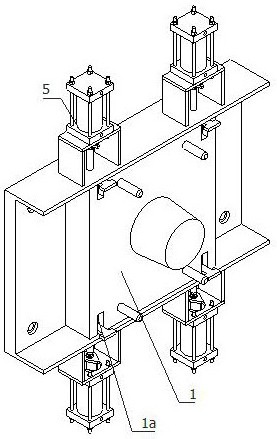

Positioning push device of silica gel slitting machine

InactiveCN107283495AEffectively integrated processingReasonable structural layout designMetal working apparatusComputer moduleSilica gel

A positioning push device of a silica gel slitting machine comprises a slitting machine body (1), a clamping device (2) is arranged at the front end of a conveying belt of the machine body (1) and is of a side concave structure, the clamping device (2) and a flat pressing roller device (3) in a matched manner, a pressing mark structure is arranged in the middle and comprises an adjusting support (4), a width limiting plate device (5) and a sawtooth structure (6), a width detection module (7) is arranged at the cutting tail end of the machine body (1), during running, silica gel pieces are subject to integration and light pressing work, single-side or dual-side pressing marks are formed, and positioning cutting is implemented; a prompt device (8) is arranged, the information prompt manner is sound or LED lamplight display, multiple running state induction devices (9) are distributed on the surface of the conveying belt and are connected with the prompt device (8), the structural layout is reasonable in design, the piece-shaped silica gel can be effectively integrated, meanwhile, the light pressing mode is implemented, it is ensured that cutting and positioning are accurate, the deviation rate is reduced, intelligent detection is achieved, and the higher practicability is achieved.

Owner:XINCHANG DONGMING BAOYU MACHINERY FACTORY

Air hammer for steel piece forging and stamping

ActiveCN110918851AReduce scrap rateReduce deviation rateNon-rotating vibration suppressionPower hammersClassical mechanicsStructural engineering

The invention discloses an air hammer for steel piece forging and stamping, and relates to the field of air hammers. The problems that an operator cannot easily adjust the position of a to-be-machinedworkpiece accurately, thus, deviation of the pounding and stamping position of a hammer head occurs, and the to-be-machined workpiece is low in machining quality and prone to being wasted are solved.According to the technical scheme, the air hammer comprises an air hammer body, the air hammer body is internally provided with a hammer column, and the lower end of the hammer column is detachably connected with a hammer head; an anvil block is arranged below the hammer head, and the upper surface of the anvil block is provided with a scale groove; the shape formed by the scale groove is the same with the shape of the cross section of the hammer head, the middle of the shape formed by the scale groove is provided with a cross-shaped auxiliary groove, and the periphery of the scale groove isprovided with a plurality of mark grooves; the vertical side surface of the anvil block is provided with a main irradiation lamp and a plurality of auxiliary irradiation lamps; and the air hammer hasthe technical effects that an operator determines the position where the to-be-machined workpiece should be located through prompting of the scale groove, the auxiliary groove, the mark grooves, the main irradiation lamp and the auxiliary irradiation lamps, so that the pounding and stamping position is not prone to deviating, and the rejection rate is decreased.

Owner:苏州乾元机械配件有限公司

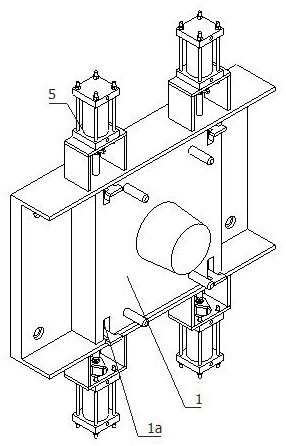

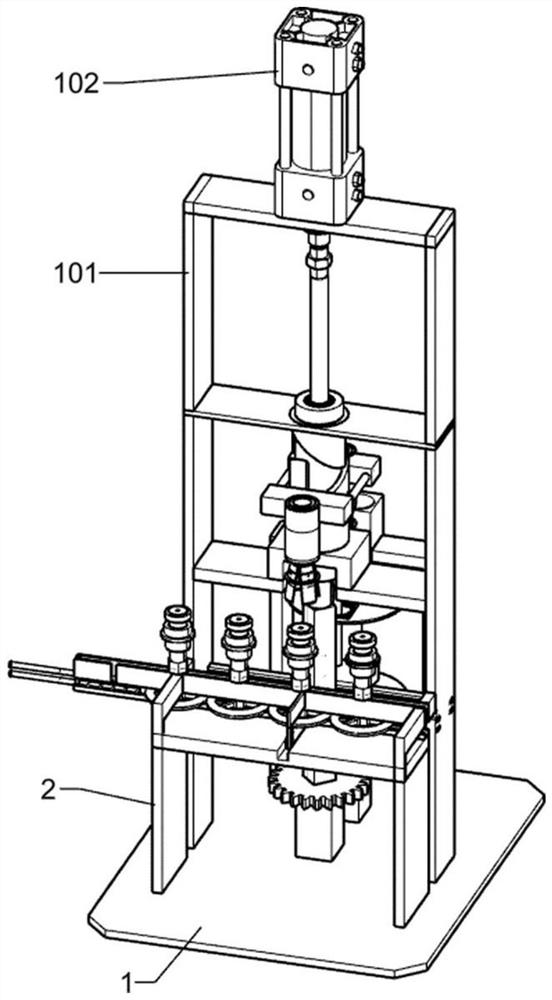

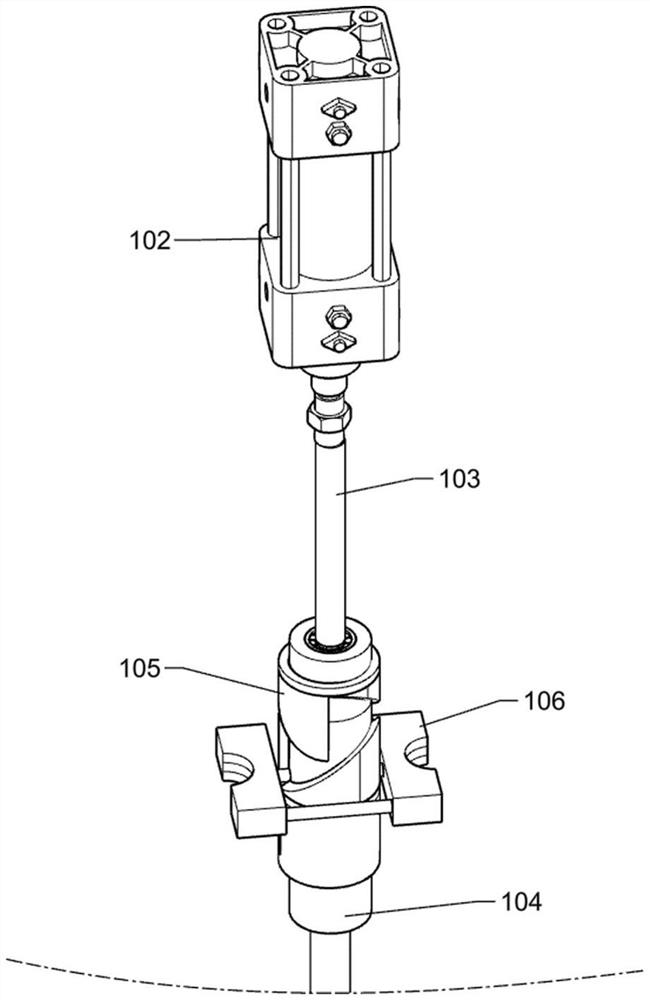

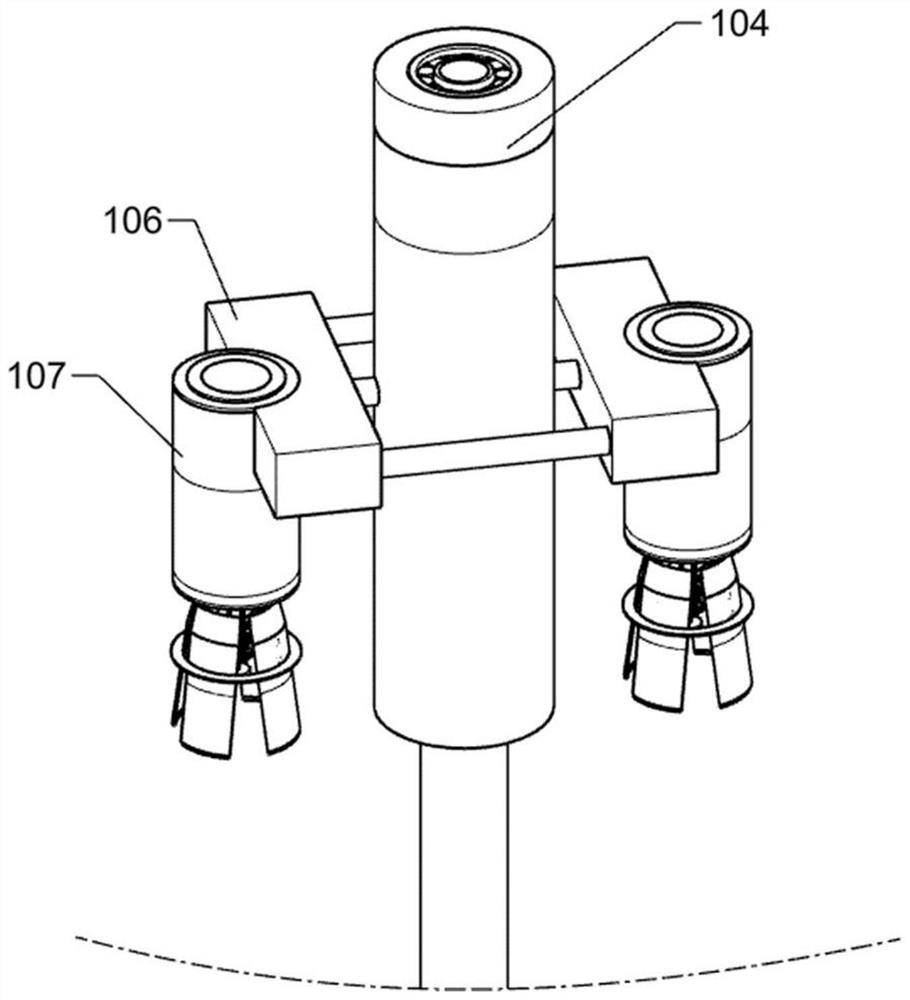

Water conservancy pipeline stop valve assembling device

The invention relates to the field of water conservancy pipeline valve body machining, in particular to a water conservancy pipeline stop valve assembling device. The invention aims to solve the technical problem of providing the water conservancy pipeline stop valve assembling device which can accurately and moderately assemble a stop valve and a gasket, and is in accurate in positioning and highin assembling efficiency. According to the technical scheme, the water conservancy pipeline stop valve assembling device comprises a bottom plate, a main rack, double shift levers and an air cylinder; and the bottom plate is arranged at the bottommost portion, the main rack is fixedly connected over the bottom plate, the air cylinder is fixedly connected to the uppermost end of the main rack, anda piston rod of the air cylinder penetrates through a baffle at the upper end of the main rack and extends downwards. According to the water conservancy pipeline stop valve assembling device, the aircylinder, a slotted pipe, a material taking and placing device and the like are additionally arranged, the air cylinder can complete the gasket taking action and the gasket assembling action after stretching out and drawing back by one cycle, and therefore the gasket assembling speed of the stop valve is greatly increased.

Owner:丁红乐

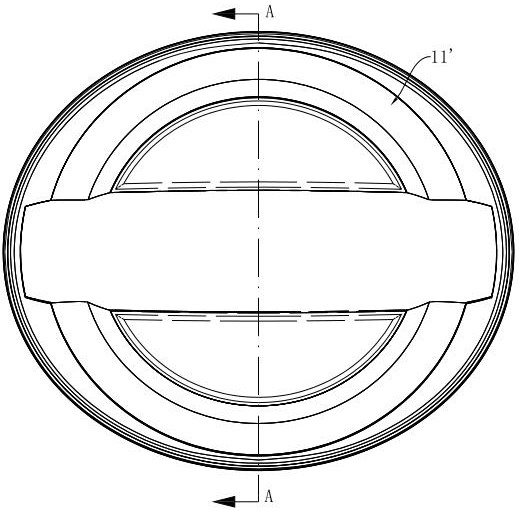

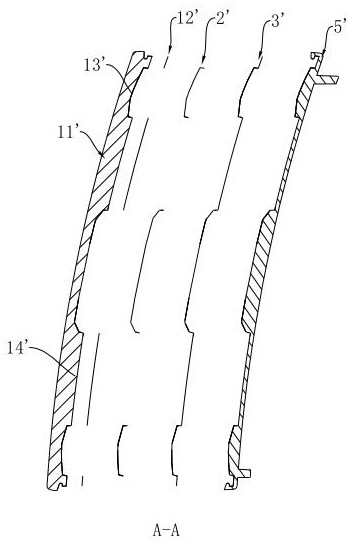

Camera module and terminal equipment

ActiveCN106550181BSmall footprintSmall sizeTelevision system detailsMirrorsOptical axisTerminal equipment

The invention discloses a camera module and terminal equipment, which belong to the field of electronic technology. The camera module includes: a rotatable mirror, a lens group, a housing and an image sensor; the housing includes a first surface and a second surface; the first mirror of the rotatable mirror is a reflective surface, and the first mirror is located in the first reflective area The part is the first sub-mirror; when the rotatable mirror is at the first position, the first mirror reflects the first optical signal, and the reflected first optical signal is transmitted along the straight line where the optical axis is located to generate an image , when the rotatable mirror is at the second position, the first mirror reflects the second optical signal, and the reflected second optical signal is transmitted along the straight line where the optical axis is located to generate an image. The camera module provided by the embodiment of the present invention only uses one rotatable reflector, realizes the function of dual-channel camera, reduces the number of reflectors, reduces the size, and saves the occupied space.

Owner:HUAWEI MACHINERY

Business data prediction method, device, equipment and storage medium

ActiveCN112232606BImprove forecast accuracyFit closelyWeb data indexingForecastingBusiness dataWeb crawler

The invention relates to the technical field of artificial intelligence, and provides a business data prediction method, device, equipment and storage medium, which are used to improve the accuracy of business data prediction. The business data prediction method includes: data cleaning and dimension value division of business order data and vehicle sales data crawled by web crawlers to obtain new car data and old car data; Screening and merging to obtain the forecast dimension; through the preset forecast model, forecast dimension and preset forecast index, the business data of the new car data and the old car data in the preset period are predicted respectively, and the new car forecast data and the initial old car data corresponding to each dimension are obtained. Vehicle forecast data; the new car forecast data and the initial used car forecast data corresponding to each dimension are merged to obtain business forecast data. In addition, the present invention also relates to block chain technology, and new car data and old car data can be stored in the block chain.

Owner:PING AN TECH (SHENZHEN) CO LTD

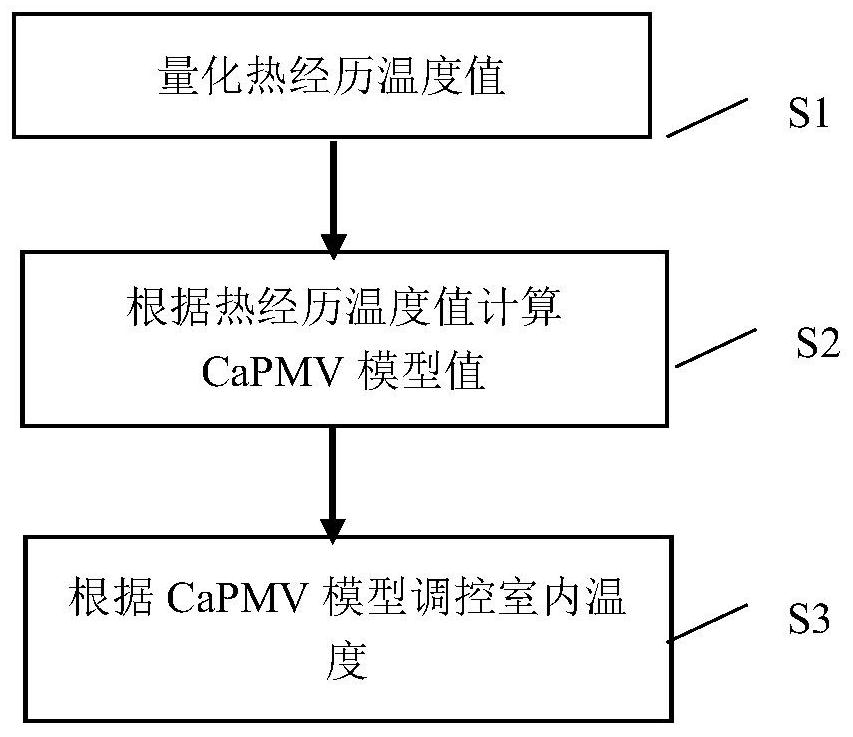

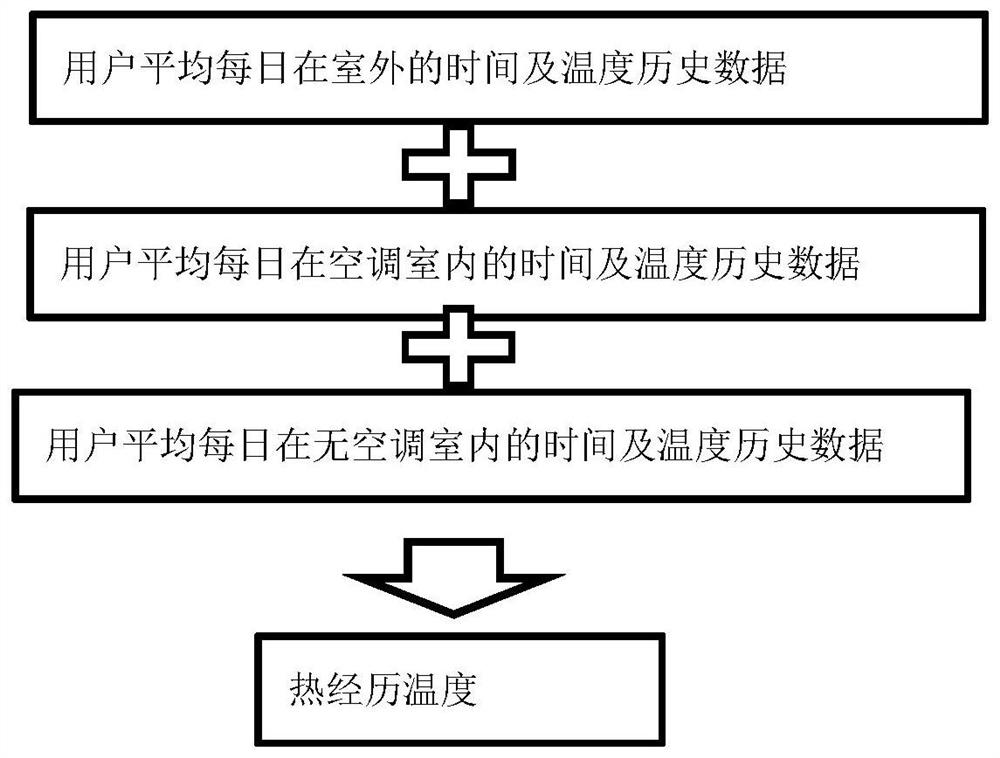

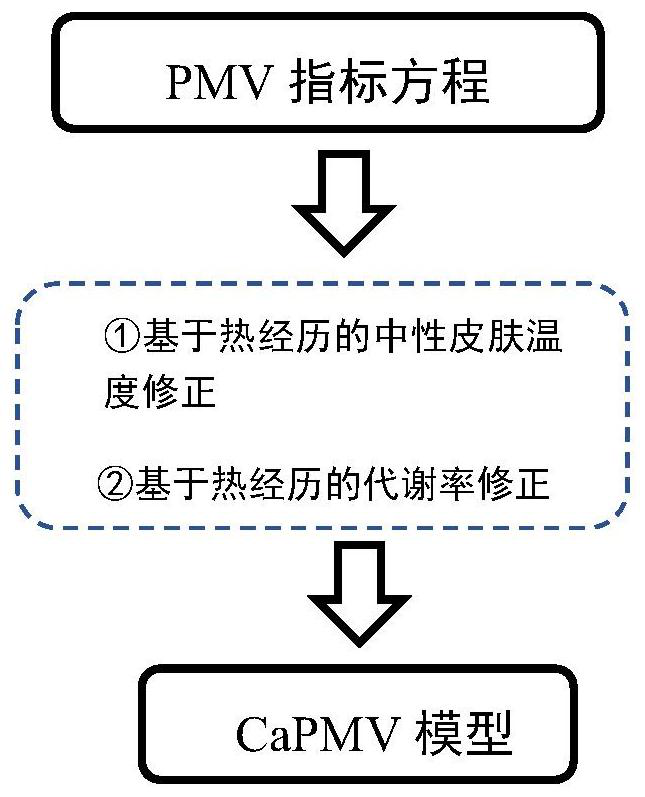

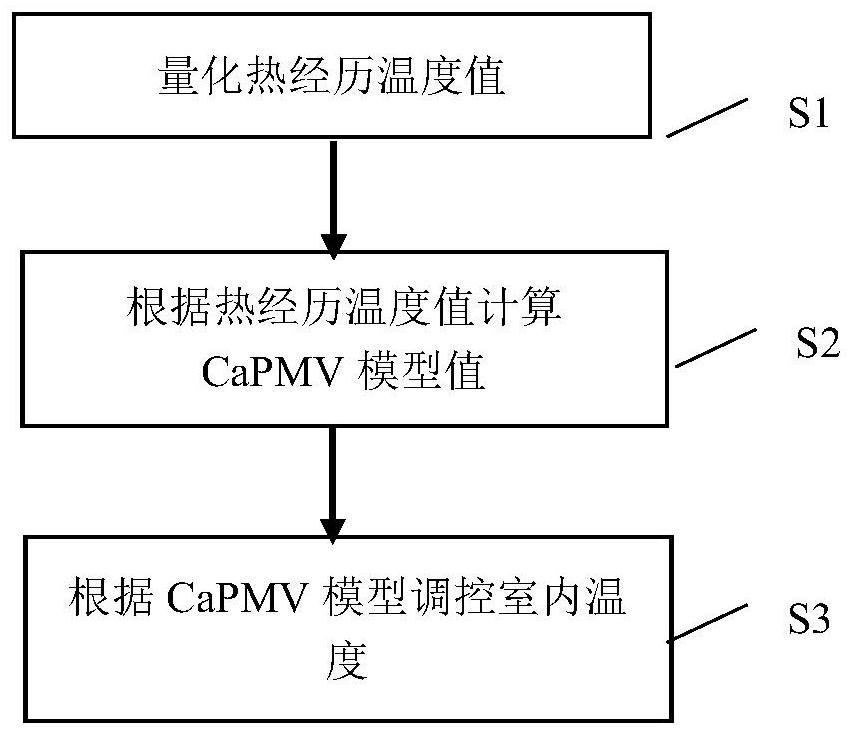

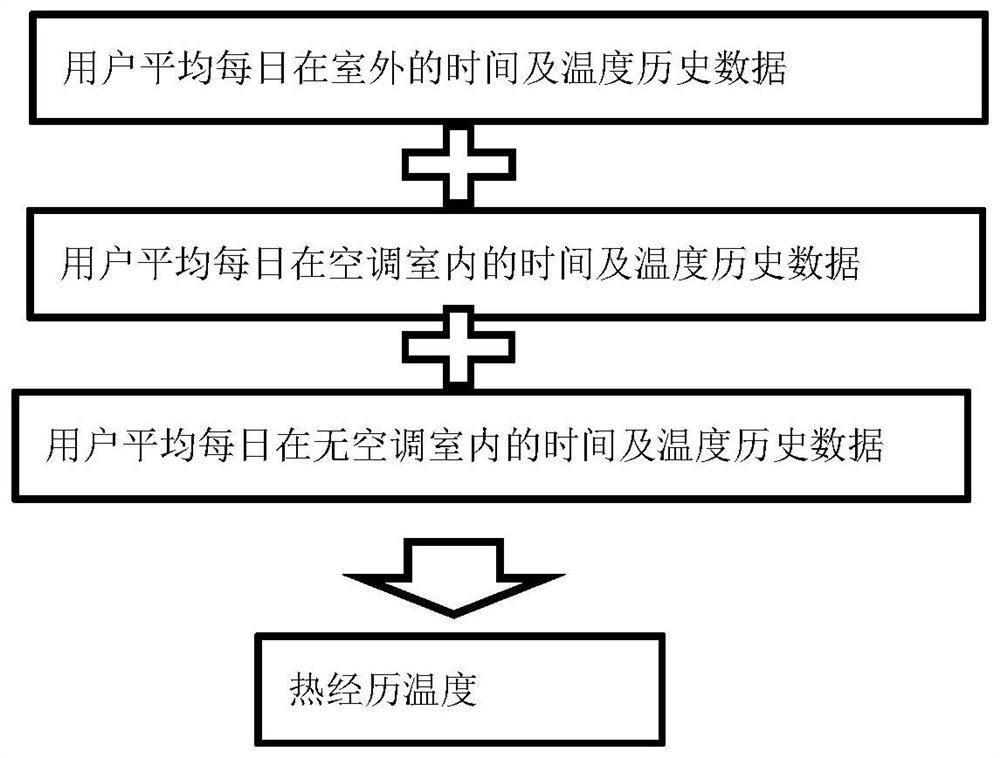

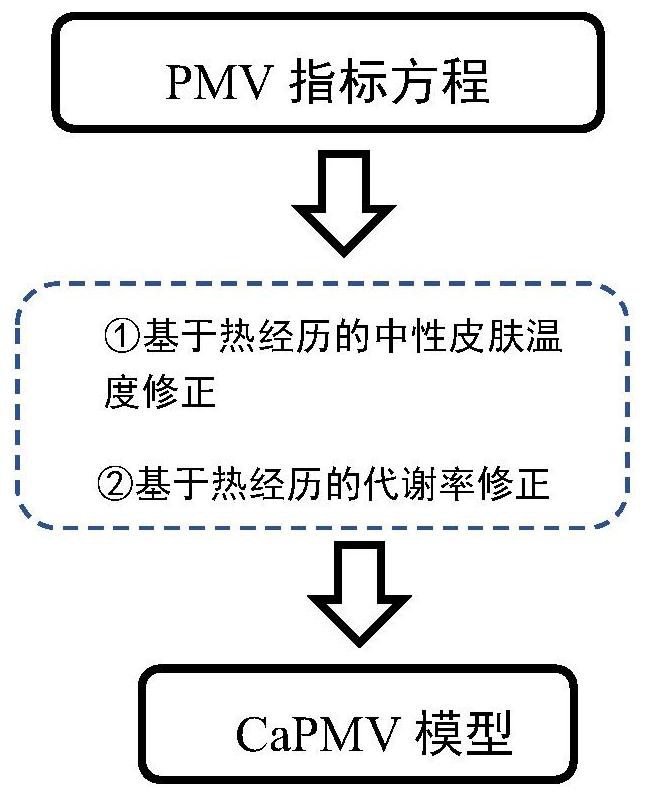

Intelligent temperature control method and system based on human body heat sensation

ActiveCN112923530AAccurate evaluationReduce deviation rateMechanical apparatusSpace heating and ventilation safety systemsTemperature controlNatural ventilation

The invention discloses an intelligent temperature control system and method based on human body heat sensation. The method comprises the steps that according to user preset information and indoor and outdoor air temperature historical data, a comprehensive heat experience temperature value is quantified; and according to the heat experience temperature value, a CaPMV model value is calculated; and according to the CaPMV model value, the indoor temperature is regulated and controlled. According to the intelligent temperature control system and method, the quantitative indexes and methods of natural ventilation heat experience, heating air conditioner heat experience and outdoor air temperature heat experience are comprehensively considered, the defect that an existing intelligent control air conditioner system based on the PMV index only considers objective thermophysical parameters and does not consider the influence of crowd heat experience is overcome, the heating air conditioner heat environment comfort under the crowd diversified heat experience condition can be evaluated more accurately, and a scientific basis is provided for control over heating air conditioner systems with distributed and intermittent characteristics in areas with hot summer, cold winter and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Tube-type drawing devillicating method

A tube-type drawing devillicating method comprises a special air flow drawing device and reciprocators. A plurality of tube-typed extension apparatus are arranged on an air flow guide device, the centre distances of the tube-typed extension apparatus are between 35 to 55mm, the tube-typed extension apparatus are communicated with the air holes which are arranged on the air flow guide device, separators are connected with the lower ends of tube-typed extension apparatus, reciprocators are separately connected with every separator, the reciprocators are composed of a swing board, a pick-up device and a fixed shaft, and the centre distances among the reciprocators are 35-55mm. The invention has the following advantages: a non-woven fabric which is made by the method has high density, the fiber web is uniform and the deviation ratio of the thickness and mass per square meter of the product is small.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

Intelligent temperature control method and system based on human thermal sensation

ActiveCN112923530BAccurate evaluationReduce deviation rateMechanical apparatusSpace heating and ventilation safety systemsTemperature controlNatural ventilation

The invention discloses an intelligent temperature control system and method based on human thermal sensation. The method includes the steps of: quantifying the comprehensive heat history temperature value according to user preset information and indoor and outdoor air temperature historical data; calculating the CaPMV model value according to the heat history temperature value; The indoor temperature is regulated according to the CaPMV model value. The present invention comprehensively considers the quantitative index and method of natural ventilation heat history, heating and air conditioning heat history, and outdoor air temperature heat history, and makes up for the fact that the existing intelligent control air-conditioning system based on PMV index only considers objective thermophysical parameters and does not consider the influence of crowd heat history Insufficient, it can more accurately evaluate the thermal environment comfort of heating and air-conditioning under the conditions of diverse thermal experiences of the population, and provide a scientific basis for the control of heating and air-conditioning systems with decentralized and intermittent characteristics in hot summer and cold winter regions.

Owner:ZHEJIANG SCI-TECH UNIV

Puncture control method of puncture robot

PendingCN111759421ALess traumaReduce deviation rateSurgical needlesCatheterPhysical medicine and rehabilitationControl system

The invention provides a puncture control method of a puncture robot, and relates to the technical field of medical instruments. According to the puncture control method of the puncture robot, a robotbody, a needle feeding mechanical assembly, a PCS system and a PLC control system are included; the needle feeding mechanical assembly is fixedly connected with the robot body; the PCS system is connected with the PLC control system; and the PLC control system is connected with the needle feeding mechanical assembly. According to the puncture control method, the puncture success rate is increased, the number of traumas to a patient in one-time treatment is reduced, the probability that the puncture needle deviates in the advancing direction in the body of the patient is reduced, and deviationcaused by human factors is avoided; the puncture control method can adapt to various age groups and different skin characteristics, accurate puncture is carried out, and it is ensured that the needleinserting direction does not deviate due to skin characteristics and muscle resistance in the initial skin puncture stage of puncture.

Owner:JINAN YOUKE MEDICAL TECH CO LTD

A quick mold change mechanism for injection molding

The invention relates to the field of injection molding processing, in particular to a quick mold change mechanism for injection molding processing, which includes an injection molding machine, a positive mold base and a negative mold base installed on the injection molding machine, and also includes a positive mold, a negative mold, a jaw moving mechanism, Elastic clamping mechanism, mechanical grippers, preheating mechanism, placement frame and four demoulding mechanisms, the rapid mold change mechanism for injection molding, preheats the mold on the placement frame through the preheating mechanism, avoiding workers Handling reduces the possibility of workers being in danger, avoids double clamping and installation of the front and back molds, speeds up the process of mold replacement, and reduces the probability of deviation in mold installation due to the removal of the positive mold from the negative mold , the positive mold and the negative mold are tightly connected, only one clamping and disassembly is required, the process of mold replacement is accelerated, and workers are not required to assemble the positive mold and the negative mold together, and the positive mold and the negative mold are assembled together , reducing the footprint of the mold.

Owner:长春百思特汽车零部件有限公司

A kind of production process of ACC car sign assembly

ActiveCN111391230BProduction environmental protectionReduce deviation rateDomestic articlesInjection molding machineMetal membrane

The invention discloses a production process of an ACC automobile mark assembly and solves the problems of deviation and cracking of a ground color area in the ACC automobile mark assembly at the present stage, scalding of a special metal film layer in the manufacturing process, and cracking of a finished product due to the internal stress of a base. The key point of the technical scheme is the production process of the ACC automobile mark assembly. The production process comprises the following steps of S1, producing a general panel by using a double-color injection machine, wherein the backof the general panel is provided with a concave area and a convex area, the general panel comprises a transparent panel and a ground color plastic layer, and the ground color plastic layer is arrangedin the convex area of the general panel; S2, arranging the special metal film layer in the concave area of the general panel; S3, coating a protective paint layer on the surface, back to the generalpanel, of the special metal film layer; and S4, producing the base by using an injection molding machine. The production process of the ACC automobile mark assembly enables the ACC automobile mark assembly to have a high-precision ground color area boundary, and the production process of the ACC automobile mark assembly is more environment-friendly.

Owner:NINGBO FULLSTATE AUTOMOBILE PARTS

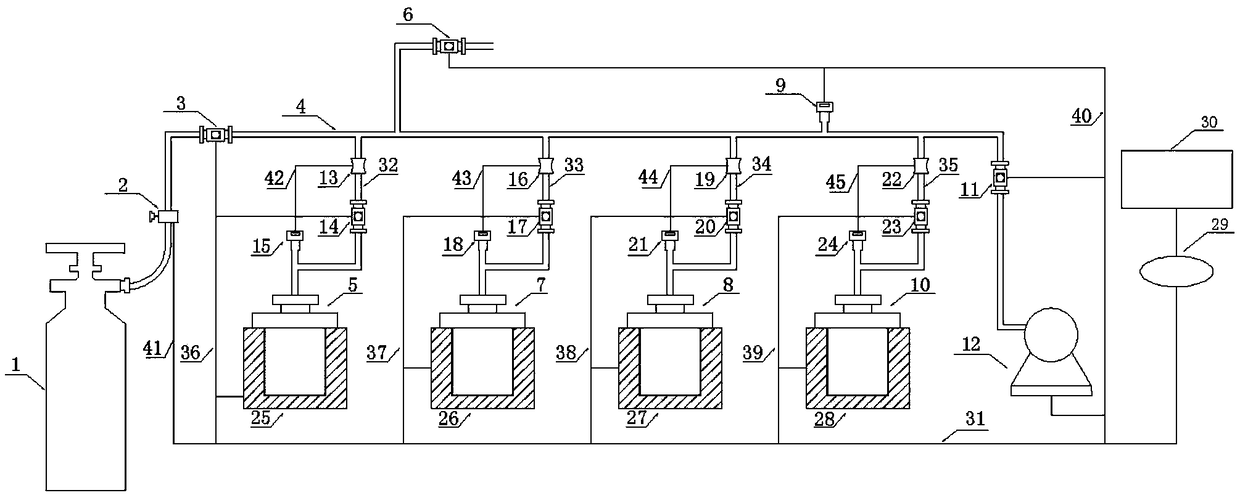

A fully automatic gas adsorption and desorption system and process

ActiveCN106018164BImprove experimental efficiencyReduce deviation rateMaterial analysisTest efficiencyDesorption

The invention relates to a full-automatic gas adsorption and desorption system and a full-automatic gas adsorption and desorption process. A gas source (1) is adjusted by an automatic valve via a pipeline and respectively connected with four adsorption tanks connected with an electronic pressure gauge, a vacuum pump (12) is connected with the adsorption tanks by virtue of pipelines; the automatic valve, an intelligent flowmeter, the electronic pressure gauge, a temperature adjuster and the vacuum pump are connected with a central controller (29) by virtue of circuits; and a touch screen (30) is connected with the central controller. The opening and closing of the automatic valve, the intelligent flowmeter, the electronic pressure gauge, the temperature adjuster and the vacuum pump are controlled by the touch screen and the central controller so as to realize the full automation of a gas adsorption and desorption test and to collect data in the test process; and the system and process are high in determination precision; the tests of different test samples under different pressures and different temperatures can be simultaneously performed; a one-key operation can be realized; the process is simple and convenient; the test efficiency of gas adsorption and desorption can be greatly improved; and the test data is accurate, and the error rate of the test data is decreased.

Owner:CHINA UNIV OF MINING & TECH

An air hammer for forging steel parts

ActiveCN110918851BReduce scrap rateReduce deviation rateNon-rotating vibration suppressionPower hammersEngineeringPhysics

The invention discloses an air hammer for forging steel parts, relates to the field of air hammers, and aims to solve the problem that it is difficult for an operator to accurately adjust the position of a workpiece to be processed, so that the position of the hammer to be pressed is deviated, resulting in low processing quality of the workpiece to be processed The key point of the technical solution is to include the air hammer body, the air hammer body is equipped with a hammer column, the lower end of the hammer column is detachably connected to the hammer head, the hammer head is provided with an anvil, and the upper surface of the anvil is provided with a scale The shape of the scale groove is the same as that of the cross section of the hammer head. The middle of the shape of the scale groove is provided with an auxiliary groove in the shape of a "ten". The outer circumference of the scale groove is provided with several identification grooves. There are main lighting lamps and several auxiliary lighting lamps; the technical effect is that the operator can determine the position of the workpiece to be processed through the prompts of the scale groove, auxiliary groove, identification groove, main lighting lamp and auxiliary lighting lamp, so that the crushing and pressing The position is not easy to deviate, reducing the discard rate.

Owner:苏州乾元机械配件有限公司

A working method of a quick mold change mechanism for injection molding

The invention relates to the field of injection molding processing, in particular to a working method of a quick mold change mechanism for injection molding processing, comprising an injection molding machine, a positive mold base and a negative mold base installed on the injection molding machine, and a positive mold, a negative mold, and grippers Moving mechanism, elastic inserting mechanism, mechanical gripper, preheating mechanism, placing frame and four demoulding mechanisms, the rapid mold change mechanism for injection molding process preheats the mold on the placing frame through the preheating mechanism, avoiding the Workers carry the mold, which reduces the possibility of workers being in danger, avoids double clamping and installation of the front and back molds, speeds up the process of mold replacement, and reduces the occurrence of mold installation by removing the positive mold from the negative mold. The probability of deviation, the tight connection between the positive mold and the negative mold, only needs to be clamped and disassembled once, which speeds up the process of mold replacement, and does not require workers to assemble the positive mold and the negative mold together. Packed together, the footprint of the mold is reduced.

Owner:佛山市顺德区鸿研电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com