Method for analyzing content of krypton and xenon in krypton and xenon feed gas

An analysis method and raw gas technology, which are applied in material separation, analysis materials, measurement devices, etc., can solve the problems of chromatographic peak masking, roughness, and inability to accurately quantify content, and achieve the effect of fast and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The present invention is further described as follows: the krypton-xenon raw material gas is collected from the rare production line of Oxygen Company.

[0030] 1) Prepare the xenon-containing gas with a volume content of 101×10 -6 (volume fraction), the volume content of krypton gas is 1006×10 -6 (volume fraction), methane gas volume content is 1005×10 -6 (volume fraction) of 8L standard gas bottle, the rest is helium (standard gas).

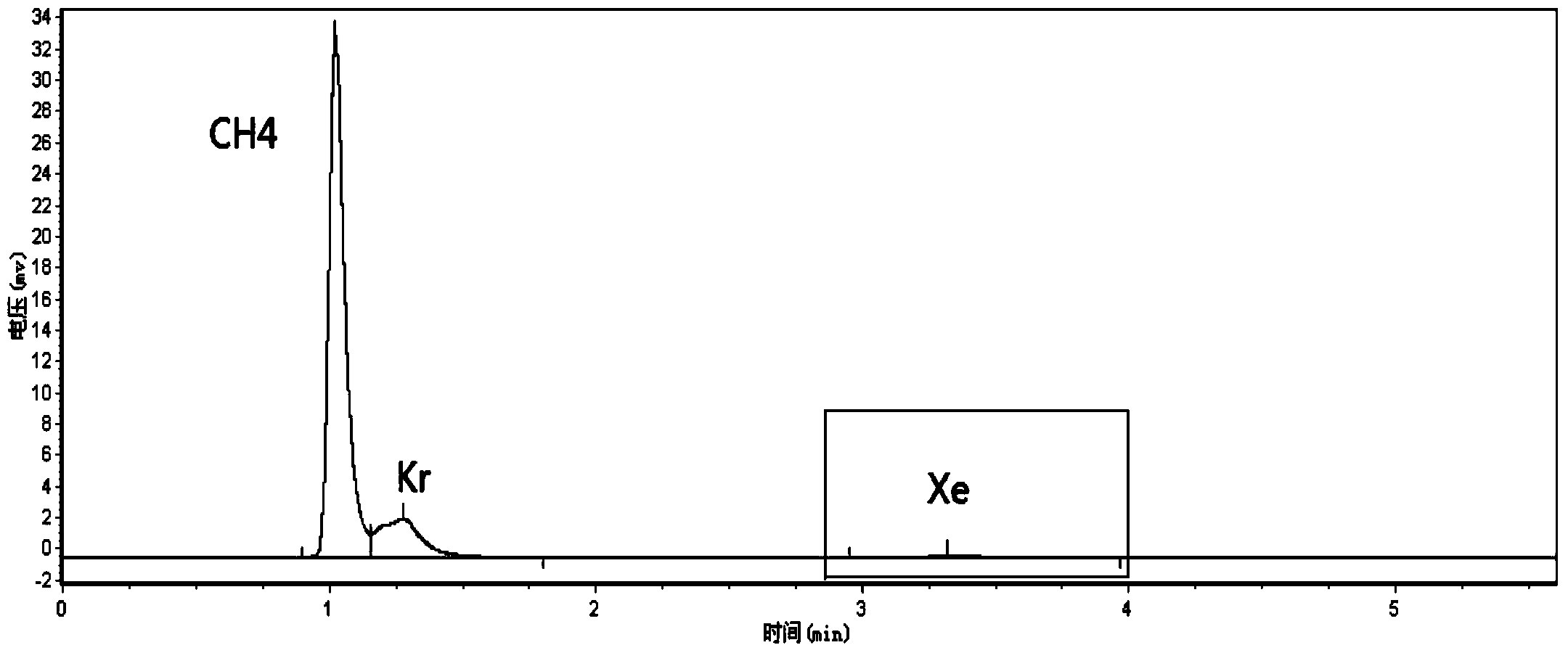

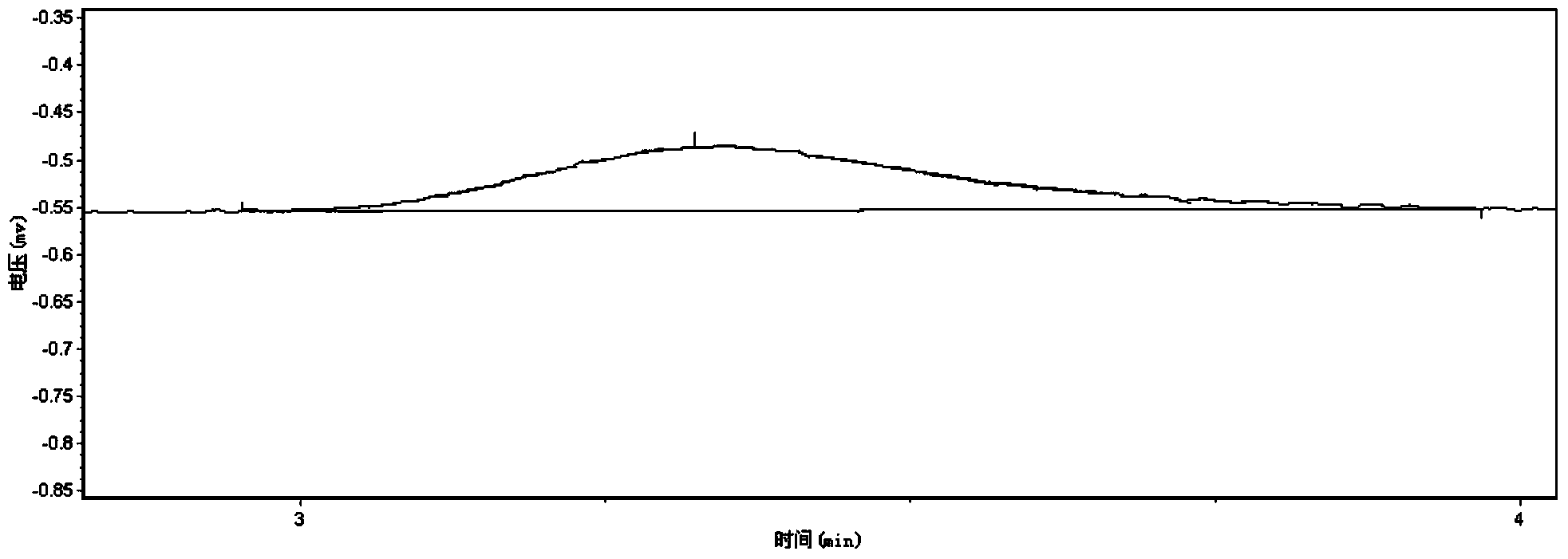

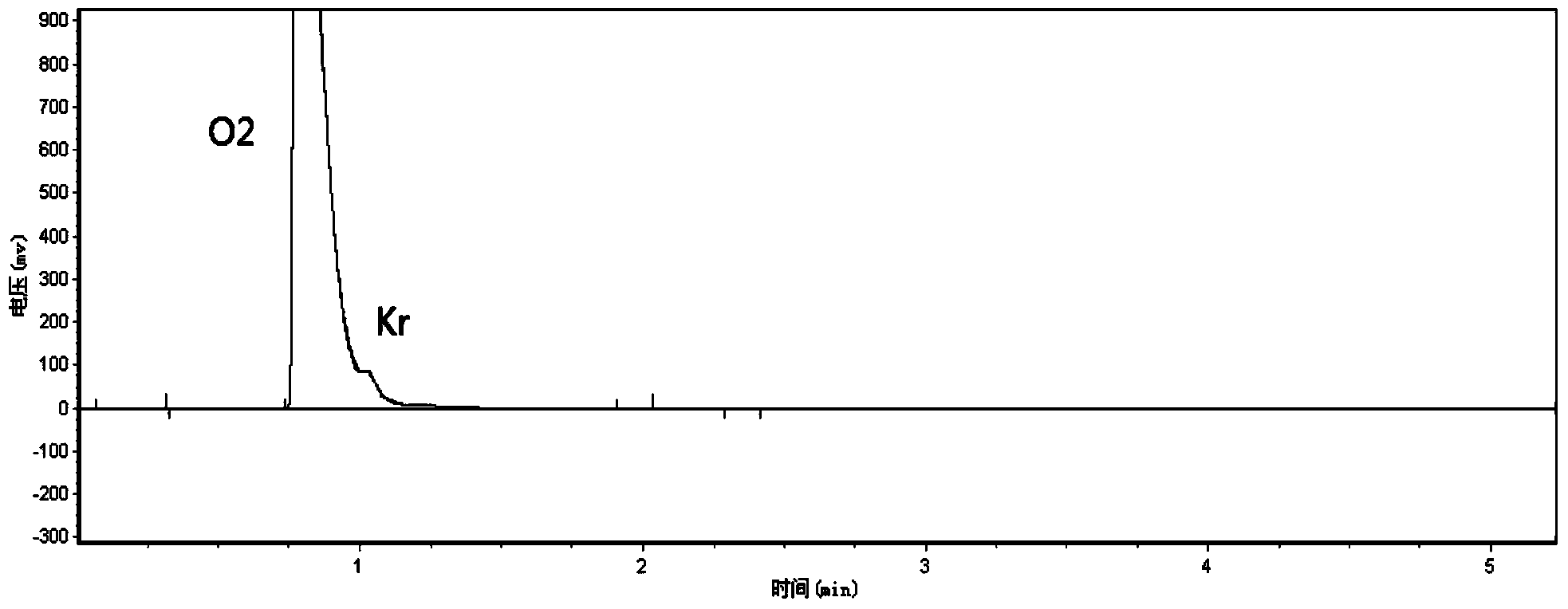

[0031] 2) Using helium as the carrier gas, use a miniature thermal conductivity analyzer (produced by Varian, model CP4900) to measure the standard gas and krypton-xenon raw material gas respectively, Figure 4 and Figure 5 The instrument test conditions:

[0032] The instrument uses N5 grade (99.999%) high-purity helium as the carrier gas.

[0033] Chromatographic column: Propark Q column Column length: 10 meters Column diameter: 0.32mm Column temperature: 80°C

[0034] Control gas pressure: 0.3 MPa Carrier gas pressure: 150 kPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com