Air hammer for steel piece forging and stamping

An air hammer and forging technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machines, power hammers, etc., can solve the problem of inability to accurately adjust the position of the workpiece to be processed and the positional deviation of the air hammer. , low forging quality of workpieces to be processed, etc., to achieve the effect of improving processing quality, improving processing efficiency and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

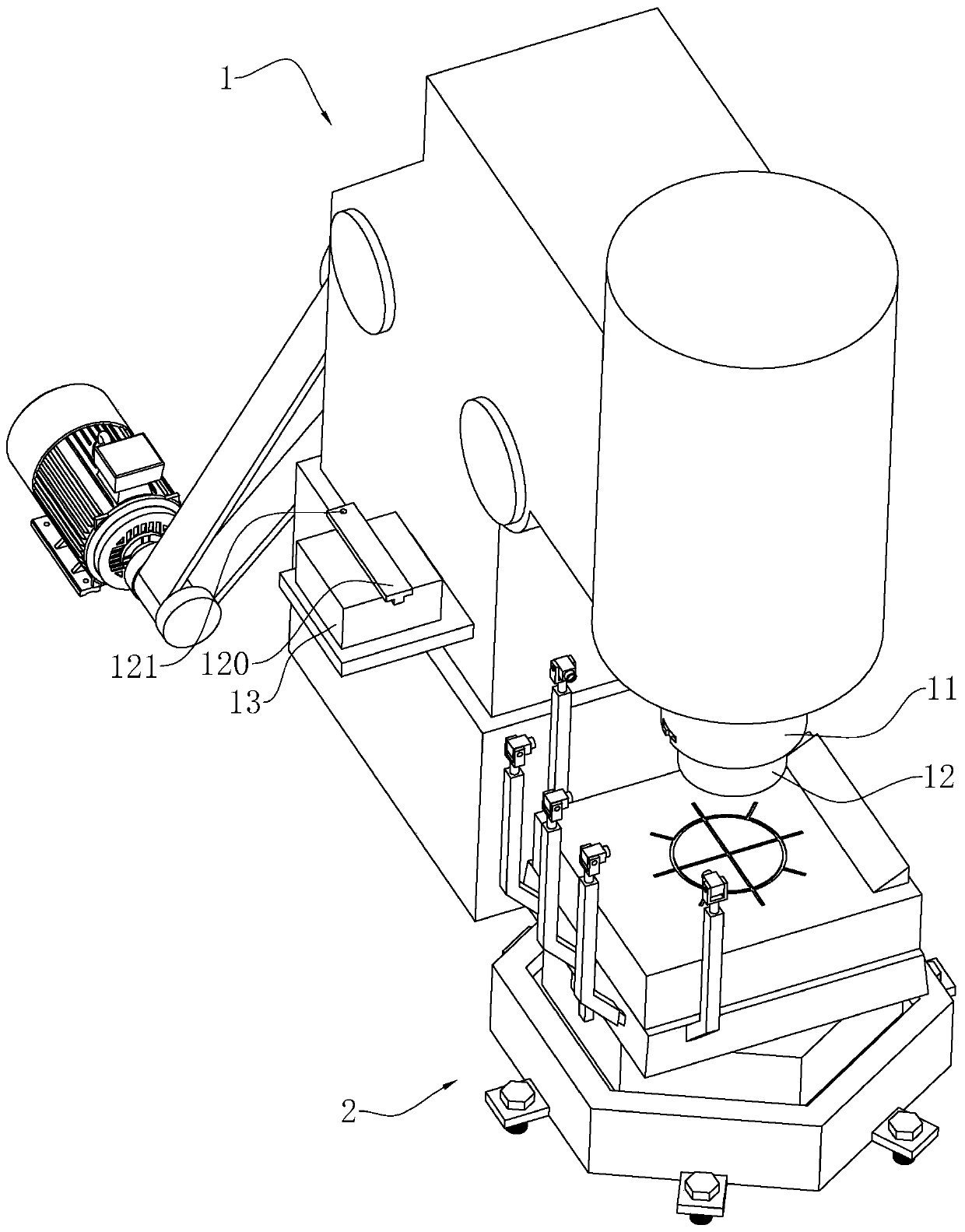

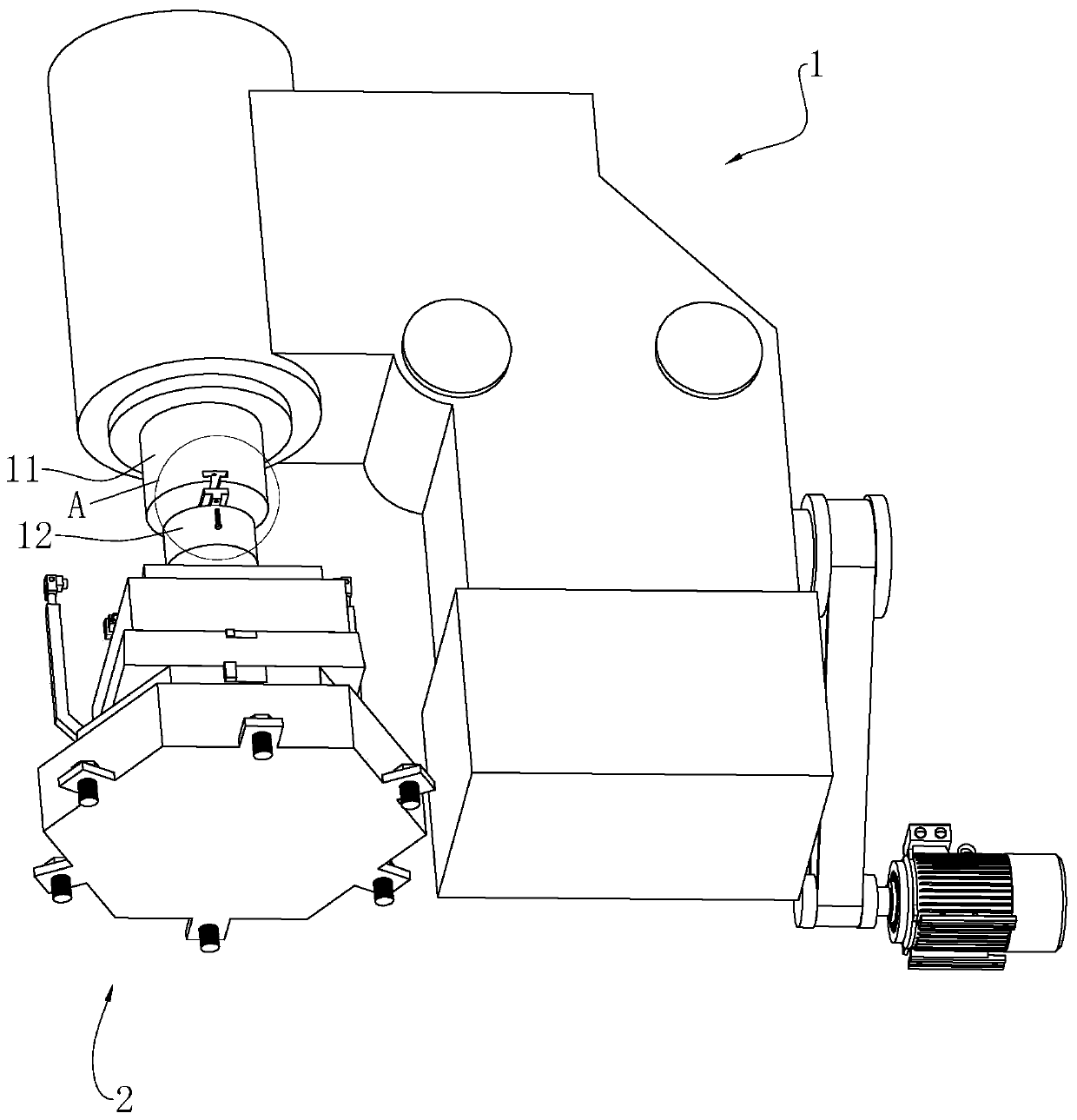

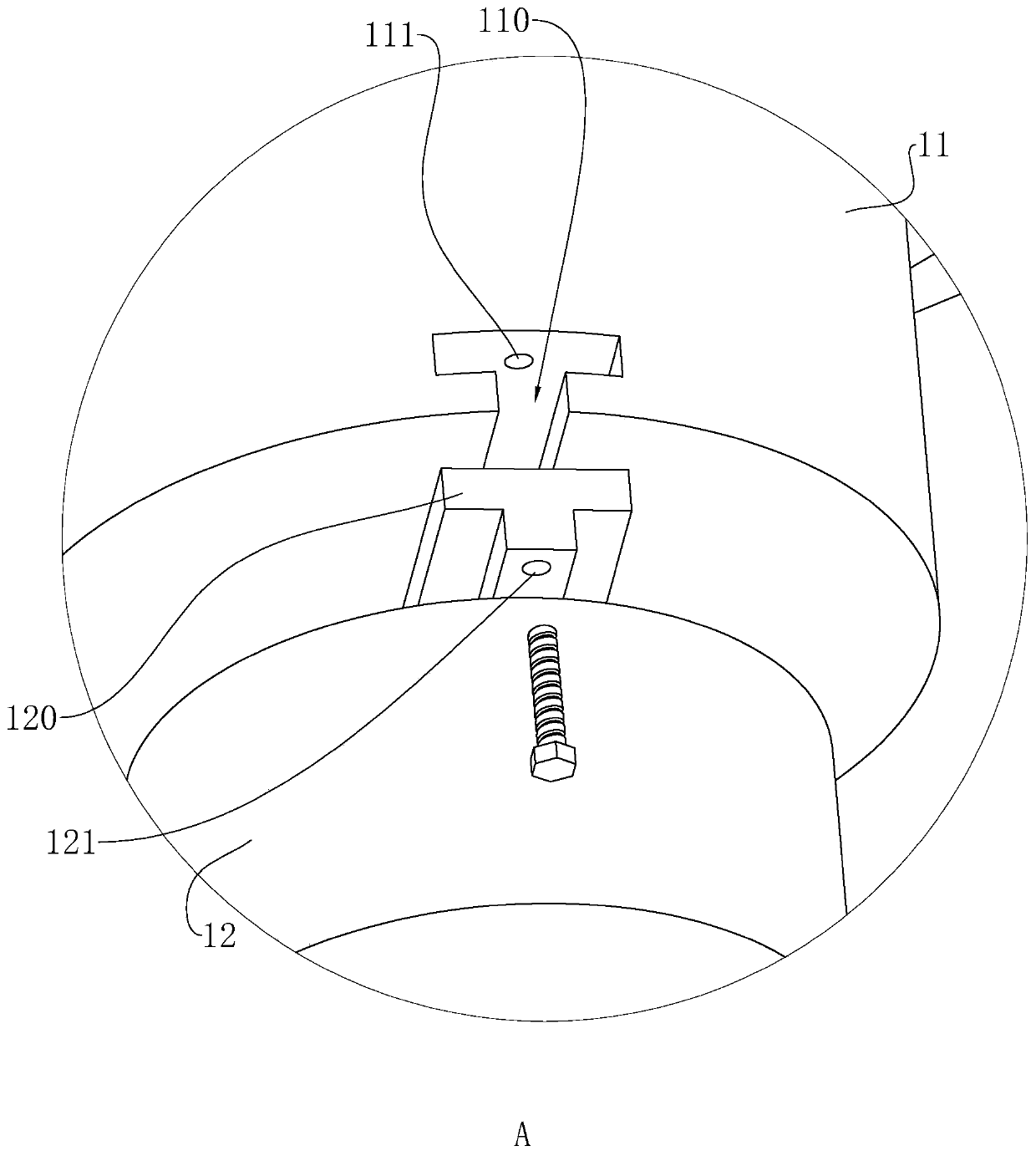

[0037] refer to figure 1 , is an air hammer for steel forging disclosed by the present invention, including air hammer body 1, air hammer body 1 includes motor, crankshaft, gear shaft, connecting rod, piston, down-swing valve, compression cylinder, and up-swing valve , working cylinder, hammer column 11 and hammer head 12, the motor is exposed to the outside world, the motor provides power for the air hammer, and the motor is decelerated by the pulley and gear two-stage reduction mechanism, driving the crankshaft and connecting rod to drive the piston to do linear reciprocation up and down in the compression cylinder Movement, the upper and lower chambers of the compression cylinder respectively form pressure air, which is input into the upper and lower chambers of the working cylinder through the upper and lower rotary valves. The working cylinder is vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com