A kind of production process of ACC car sign assembly

A technology for car signage and production process, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of positioning accuracy, such as the offset of the black background area, and achieve the effect of improving thickness accuracy, reducing influence and improving appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0040] refer to figure 1 , a production process of ACC automobile plate assembly, used for the production of ACC automobile plate assembly, in the production process need to use two-color injection machine, vacuum coating machine, two-shot vertical injection molding machine.

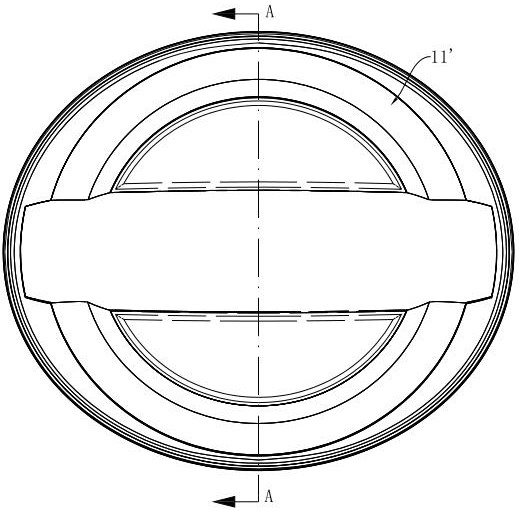

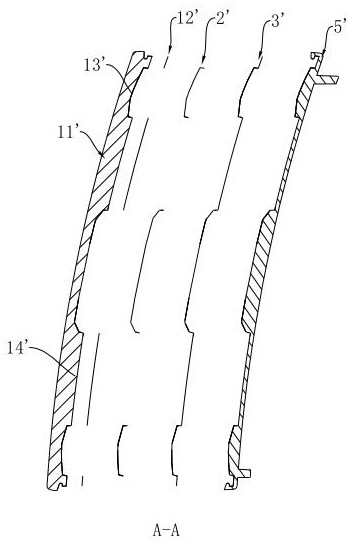

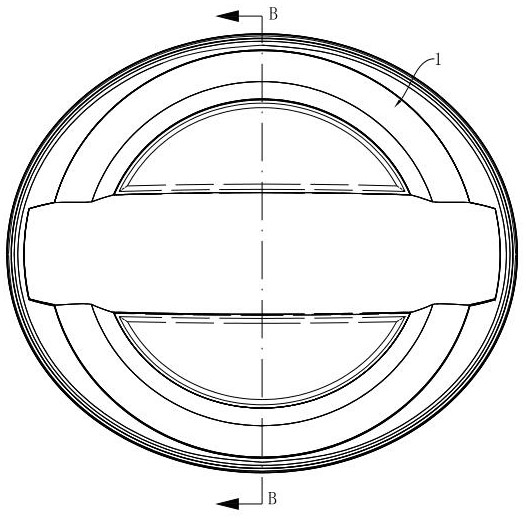

[0041] refer to image 3 and Figure 4 , an ACC automobile sign assembly, including a total panel 1, a special metal film layer 2, a protective paint layer 3, a high temperature resistant layer 4 and a base 5. Wherein, the direction in which people observe the ACC vehicle label is taken as the front of the ACC vehicle label assembly, and the direction in which the ACC vehicle label assembly is installed on the vehicle body is taken as the back side of the ACC vehicle label assembly.

[0042] refer to Figure 4 , the total panel 1 includes a transparent panel 11 and a base color plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com