Rubber powder epoxy resin asphalt material as well as preparation method and using method thereof

A technology of powdered epoxy resin and asphalt materials, which is applied to roof insulation materials, building insulation materials, building components, etc., can solve the problems of large energy, low utilization rate of rubber powder, cumbersome process, etc., and achieve simple preparation process and easy use Long life and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

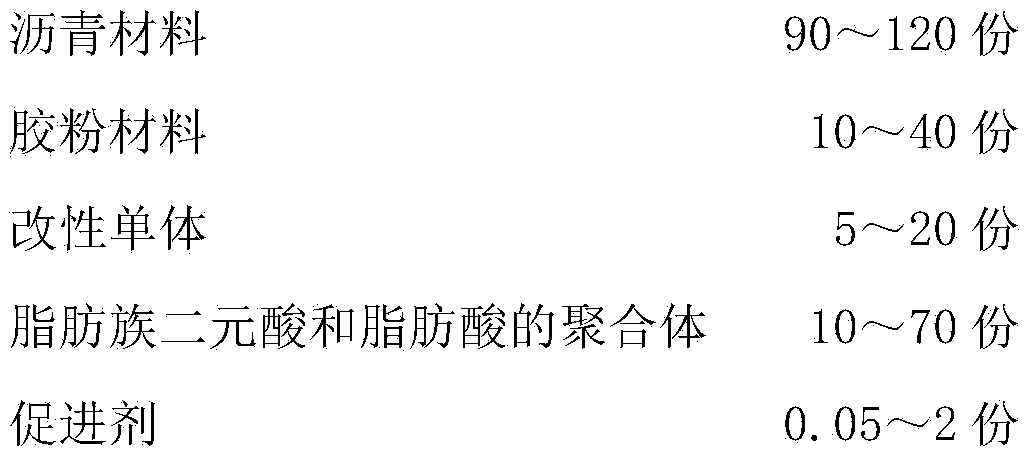

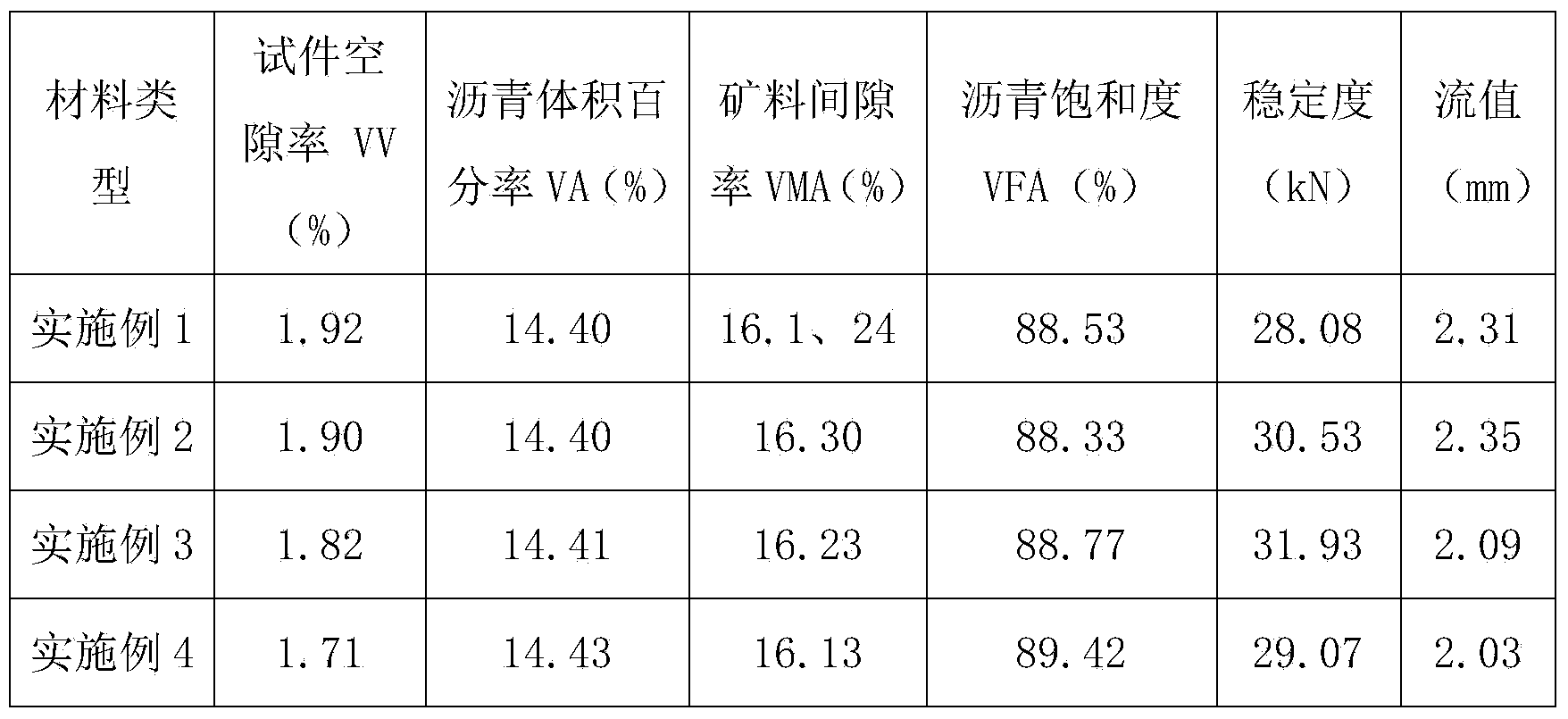

[0046] A rubber powder epoxy resin asphalt material, the asphalt material comprises epoxy resin asphalt A component and epoxy resin asphalt B component, the weight ratio of the two is 1:5; epoxy resin asphalt A component is epoxy resin asphalt Resin; epoxy resin asphalt B component is made of the following components by weight: 90 parts of asphalt material, 15 parts of rubber powder material, 5 parts of modified monomer, 30 parts of aliphatic dibasic acid and fatty acid polymer, Accelerator 0.5 parts.

[0047] A kind of preparation method of above-mentioned rubber powder epoxy resin asphalt material, comprises the following steps:

[0048] (1) Use 90 parts of petroleum asphalt (Zhonghai Asphalt Taizhou Co., Ltd., 70# petroleum asphalt), heat it to 160°C, add 15 parts of rubber powder and 5 parts of acrylic acid (Shandong Qilu Petrochemical Kaitai Industrial Co., Ltd.), and mix well Afterwards, the reaction was carried out by a mechanochemical device for 10 minutes to obtain r...

Embodiment 2

[0056] Use 100 parts of petroleum asphalt (Zhonghai Asphalt Taizhou Co., Ltd., 70# petroleum asphalt), heat it to 200 ° C, add 30 parts of rubber powder and 15 parts of maleic anhydride (Changzhou Shuguang Chemical Plant), mix well and carry out through a mechanochemical device React for 20 minutes to prepare rubber powder modified asphalt; add 50 parts of fumaric acid (Nanjing Xinyuan Chemical Co., Ltd.) and 1 part of aliphatic amine, and fully mix at 150°C to obtain component B of rubber powder epoxy resin asphalt material .

[0057] Heat component B to 130°C, heat component A epoxy resin (Wuxi Resin Factory, E51) to 90°C, mix component A and component B at a ratio of 1:10, and pour it into the preheated test mold. After curing in an oven at 120°C for 6 hours, use a punching machine to prepare a standard dumbbell-shaped specimen, keep it warm at 23°C (test temperature) for at least 2 hours, and use a universal tensile machine to perform a tensile test at a test rate of 500mm...

Embodiment 3

[0059] Use 100 parts of petroleum asphalt (Zhonghai Asphalt Taizhou Co., Ltd., 70# petroleum asphalt), mix and heat to 180°C, add 30 parts of rubber powder and 25 parts of acrylic acid (Shandong Qilu Petrochemical Kaitai Industrial Co., Ltd.), and mix well The rubber powder modified asphalt was prepared by reacting in a mechanochemical device for 15 minutes; adding 70 parts of fatty acid dimer and 2 parts of fatty amine, and fully mixed at 160°C to obtain component B of rubber powder epoxy resin asphalt material.

[0060] Heat component B to 150°C, heat component A epoxy resin (Wuxi Resin Factory, E51) to 100°C, mix component A and component B at a ratio of 1:15, and pour it into the preheated test mold. After curing in an oven at 120°C for 6 hours, use a punching machine to prepare a standard dumbbell-shaped specimen, keep it warm at 23°C (test temperature) for at least 2 hours, and use a universal tensile machine to perform a tensile test at a test rate of 500mm / min. The tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com