Method for online detection of polyester staple fiber shrinkage in boiling water

A technology of polyester staple fiber and boiling water shrinkage rate, which is applied in the field of on-line detection of the boiling water shrinkage rate of polyester staple fiber, can solve the problems of judgment deviation, difficulty in accurately characterizing the boiling water shrinkage performance of polyester staple fiber, etc., to achieve the best detection accuracy and ensure authenticity. , the effect of increasing realism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

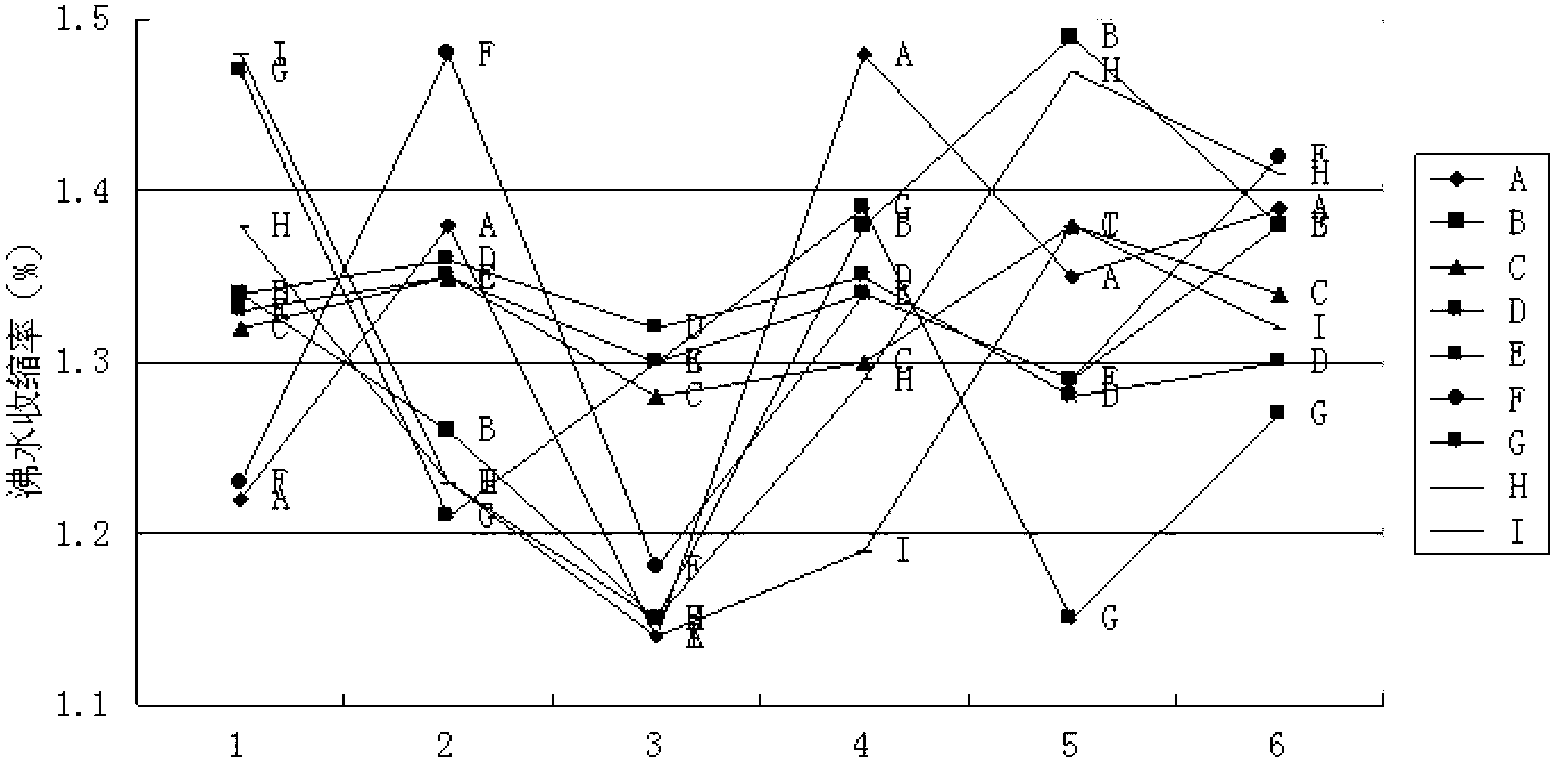

Image

Examples

Embodiment 1

[0040] 1. Select an 80cm polyester staple fiber sample after the relaxation heat setting process and before the cutting process, and carry out pre-conditioning for 2 hours under the conditions of standard atmospheric pressure, 40°C-45°C, and humidity 15%-20%, and then pre-conditioning Afterwards, the sample is placed under the conditions of standard atmospheric pressure, 18°C-20°C, and humidity of 65%-70% for 2 hours of humidity-conditioning treatment.

[0041] 2. Select a bunch of polyester staple fibers with a length of 60cm and a fineness of 50D from the samples that have reached the moisture absorption balance after pre-humidity and humidity-conditioning treatment, and use a pre-tensioning force of Clamped by a 5cm pre-tension clamp, the length L0 of the polyester staple fiber before boiling is measured by a vertical measuring ruler and marked.

[0042] 3. Fold the sample in half to a loose state, wrap it in gauze and place it in the test mesh bag. When the water temperatu...

Embodiment 2

[0046] 1. Select an 80cm polyester staple fiber sample after the relaxation heat setting process and before the cutting process, and carry out pre-conditioning for 1 hour under the conditions of standard atmospheric pressure, 45°C-50°C, and humidity 15%-20%, and then pre-conditioning Afterwards, the samples were placed under the conditions of standard atmospheric pressure, 18°C-20°C, and humidity of 65%-70% for 4 hours of humidity-conditioning treatment.

[0047] 2. Select a bunch of polyester staple fibers with a length of 70cm and a fineness of 100D from the samples that have reached the moisture absorption balance after the pre-humidity and humidity-conditioning treatment, and use a pre-tensioning force of 10cm pre-tension clamp clamps, measures and marks the length Lo of the polyester staple fiber before boiling by a vertical measuring ruler.

[0048]3. Place the sample in the test mesh bag with gauze wrapped in the relaxed state. When the water temperature is 60°C, immers...

Embodiment 3

[0052] 1. Select an 80cm polyester staple fiber sample after the relaxation heat setting process and before the cutting process, and carry out pre-conditioning for 2 hours under the conditions of standard atmospheric pressure, 40°C-45°C, and humidity 20%-25%, and then pre-conditioning Afterwards, the samples were placed under the conditions of standard atmospheric pressure, 18°C-20°C, and humidity of 65%-70% for 4 hours of humidity-conditioning treatment.

[0053] 2. Select a bundle of polyester staple fibers with a length of 60cm and a fineness of 100D from the samples that have reached the moisture absorption balance after pre-humidity and humidity-conditioning treatment, and use a pre-tensioning force of 10cm pre-tension clamp clamps, measures and marks the length Lo of the polyester staple fiber before boiling by a vertical measuring ruler.

[0054] 3. Place the sample in a test mesh bag with gauze wrapped in a relaxed state. When the water temperature is 75°C, immerse the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com