Positioning push device of silica gel slitting machine

A push device and slitting machine technology, applied in metal processing and other directions, can solve the problems of low self-monitoring and single function, and achieve the effects of reasonable structural layout design, accurate cutting and positioning, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

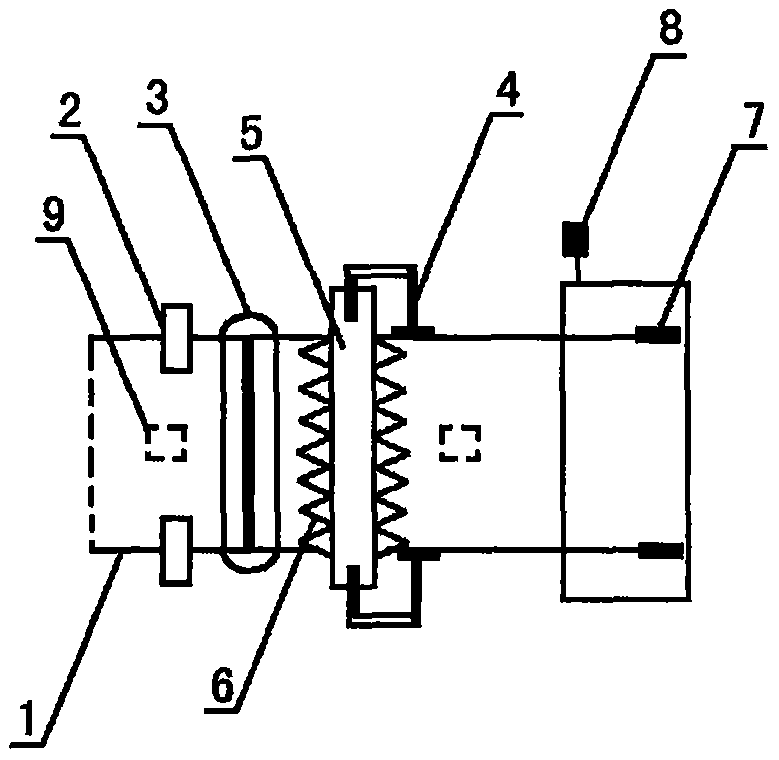

[0012] Embodiment: as shown in the accompanying drawing. The positioning and pushing device of the silicone slitting machine includes a slitting machine body (1), and a locking device (2) is set at the front end of the conveyor belt of the body (1) in a side concave structure and forms a matching mode with the flat pressing roller device (3) , the indentation structure is set in the middle, including the adjustment bracket (4), the width-limiting plate device (5), and the sawtooth structure (6). The cutting end of the body (1) is equipped with a width detection module (7). During operation, the silicone sheet is integrated and shallowly pressed Positioning cutting is carried out after the operation forms unilateral or bilateral indentation.

[0013] The positioning push device of the silica gel slitting machine is provided with a prompting device (8), and the mode of prompting information is sound or LED light display.

[0014] The positioning and pushing device of the silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com