Straw precision forming extrusion machine and seedling raising substrate straw plate extrusion preparation method

A precision forming and extruding machine technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of seedling rice seedling injury, farmers' economic losses, vegetation damage, etc., to achieve the benefits of transformation, structure Good stability and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

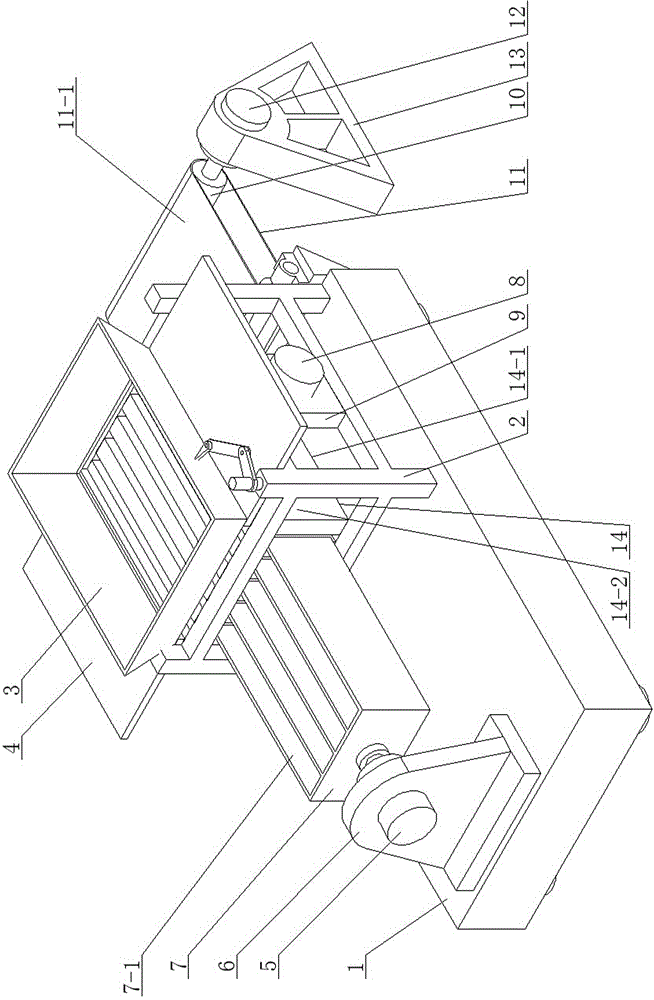

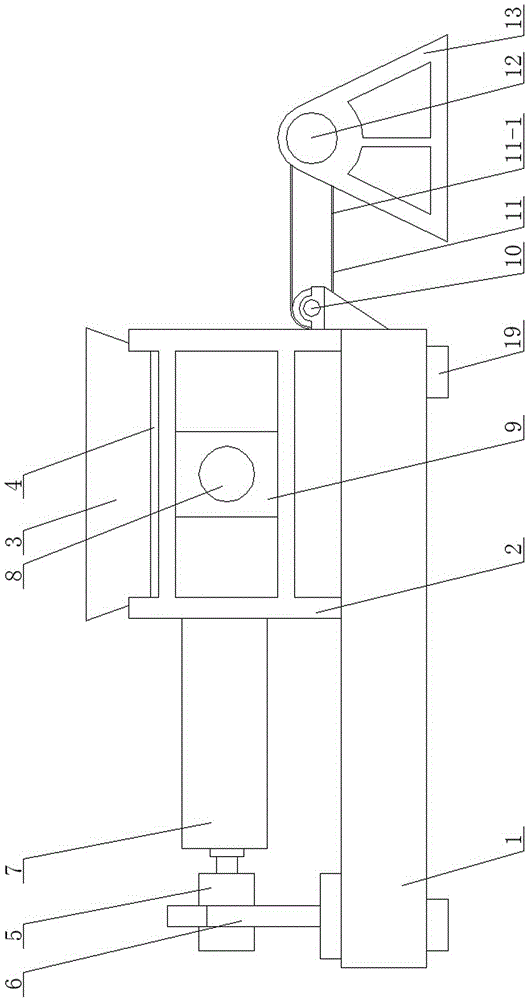

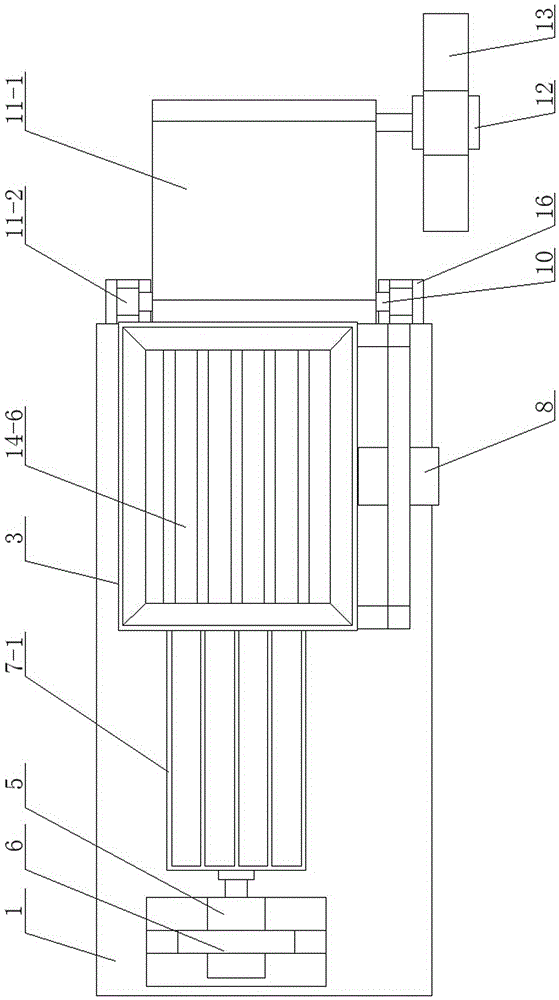

[0029] Specific implementation mode one: as Figure 1~Figure 8 As shown, this embodiment describes a straw precision molding extruder, including a base 1, a support frame 2, a feed hopper 3 and a sealing baffle 4, and the support frame 2 is fixed on the right side of the base 1, The feed hopper 3 is located on the support frame 2, and the lower end of the feed hopper 3 is provided with a discharge port,

[0030] The straw precision forming extrusion machine also includes a cylinder 5, a cylinder seat 6, a push rod 7, a hydraulic cylinder 8, a hydraulic cylinder support 9, a rotating shaft 10, a belt transmission mechanism 11, a motor one 12, a motor base one 13, and a mold 14 , driving device 18, two bearings 15, two bearing housings 16 and a plurality of electric heating devices 17, the mold 14 includes a housing 14-1, a pressing plate 14-2, two guide rails 14-3, a plurality of Slider one 14-4, multiple springs 14-5 and multiple mold plates 14-6;

[0031]The housing 14-1 is...

specific Embodiment approach 2

[0035] Specific implementation mode two: as figure 1 , figure 2 and Figure 7 As shown, the straw precision molding extruder described in Embodiment 1, the driving device 18 includes a second motor 18-1, a second motor seat 18-2, a gear 18-3, a rack 18-4, two Two guide rails 18-5 and two sliders 18-6; the second motor 18-1 is fixed on the support frame 2 through the second motor base 18-2, and the gear 18-3 is installed on the second motor 18-2 On the output shaft of 1, the gear 18-3 meshes with the rack 18-4, the two guide rails 18-5 are horizontally fixed on the support frame 2, and the lower end surface of the sealing baffle 4 is fixed with two Two slide blocks 18-6, the two slide blocks 18-6 are slidingly connected with two guide rails two 18-5, and one side of the sealing baffle plate 4 is connected with the rack 18-4.

[0036] In this embodiment, the second motor 18-1 is used to drive the gear 18-3 to rotate, and through the meshing between the gear 18-3 and the rack...

specific Embodiment approach 3

[0037] Specific implementation mode three: as figure 2 As shown, in the straw precision molding extrusion machine described in Embodiment 1, the four corners of the bottom surface of the base 1 are fixed with feet 19 . Utilize four feet 19 to ensure that the whole machine is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com