Environment-friendly complete-set mud cycling replacing processing system

A processing system and environment-friendly technology, applied in clay preparation devices, mixing operation control, mixing plants, etc., can solve problems such as damage to the construction environment, waste of personnel and resources, waste of mud outflow, etc., and achieve high recycling rate and water saving. The effect of resources and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

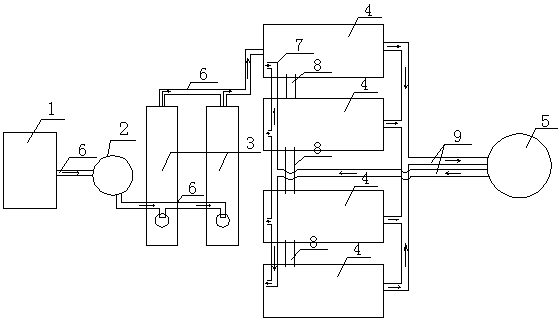

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0015] Such as figure 1 As shown, an environment-friendly complete set of mud circulation replacement treatment system, the system includes a clear water tank, a mud mixing pump 2, a new mud tank 3, a mixed mud tank 4, a mud separator 5, a mud delivery pipe 6, a mud outlet 7, Connecting pipe 8 and mud output pipe 9; one side of the clear water tank 1 is connected to the mud stirring pump 2 provided through the mud conveying pipe 6, and the mud stirring pump 2 is connected to the new mud tank 3 arranged in parallel through the mud conveying pipe 6; The top of the newly made mud tank 3 is connected with the first mixed mud tank 4 through the mud delivery pipe 6 respectively, and the upper and lower intervals of the mixed mud tank 4 are correspondingly arranged, and each mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com