Axle housing body automatic production line based on multi-vehicle-type flexible production

An automatic production line and flexible production technology, applied in the field of automobile manufacturing, can solve the problems of complex positioning and inaccurate manual transfer switching equipment, and achieve the effect of reducing the probability of deviation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

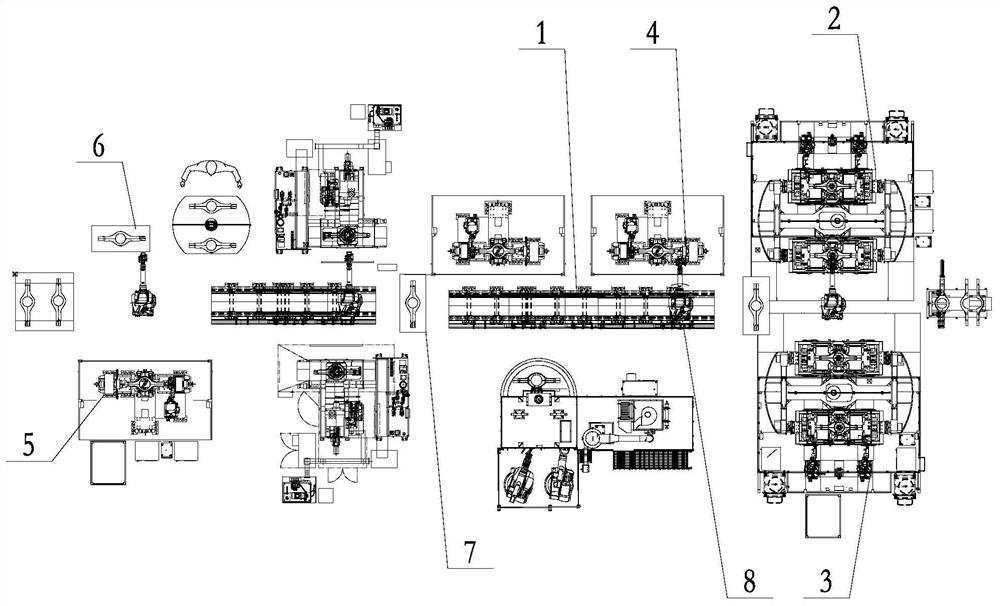

[0044] Such as figure 1 As shown, an automatic axle housing casing production line based on the flexible production of multiple models includes a sliding table 1 and a half-shell team welding unit 2 connected to the ground along the circumferential direction of the sliding table 1, an axle housing repair welding unit 3, Cutting circle and notch unit 4, plug seat automatic welding unit 5 and coding unit 6;

[0045] A transfer robot 8 is arranged on the slide table 1 , and the transfer robot 8 is slidably connected with the slide table 1 .

[0046]In the above structure, in order to relieve the workers from reciprocatingly transporting workpieces to each independent station to complete various welding tasks, this plan designs a sliding table 1, and installs two pairs of half-shell team welding units along the sliding table 1 in sequence. The work of welding the half shells, the axle housing repair welding unit 3 for the secondary welding of the previously welded axle housing, t...

Embodiment 2

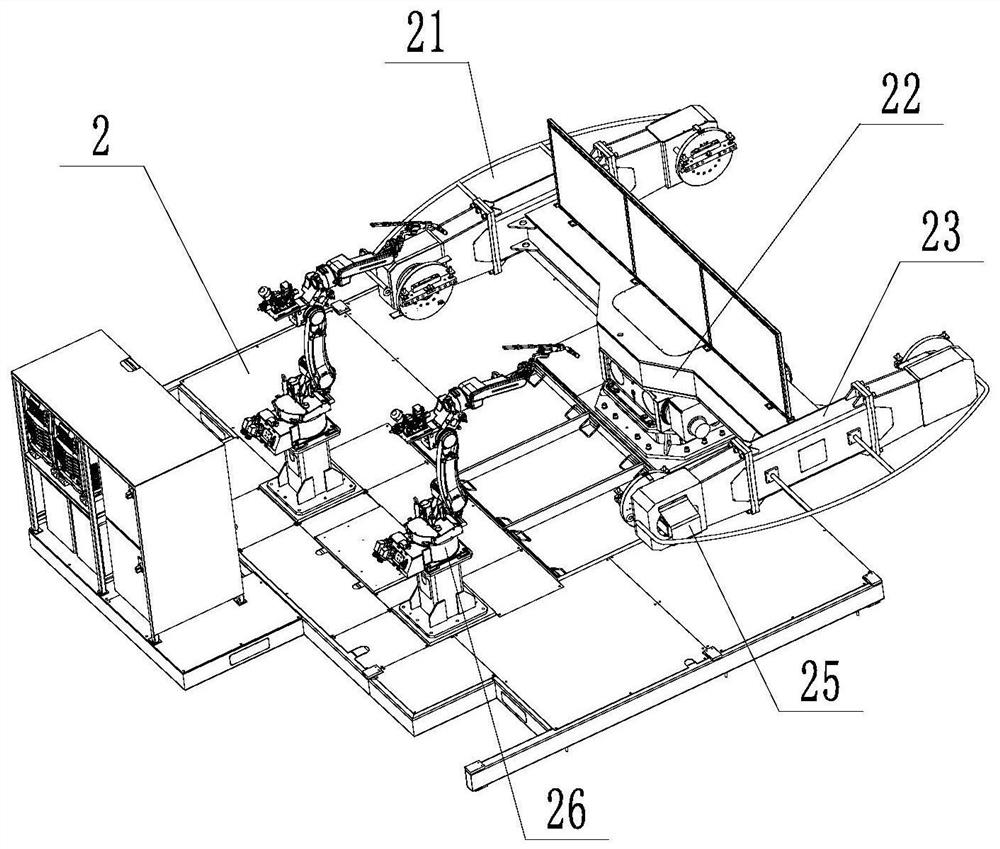

[0048] This embodiment is expanded on the basis of Embodiment 1, such as figure 2 As shown, the half-shell team welding unit 2 includes a first positioner 21, and the first positioner 21 includes a first turntable 22, and the first turntable 22 is provided with a first tooling frame 23, and the first tooling frame 23 A welding jig 24 for clamping is arranged on the top, and a first driving motor 25 for driving the welding jig 24 to rotate at an angle is arranged on the first tool frame 23. The half-shell team welding unit 2 also includes a first welding robot 26 for welding, The designed first positioner 21 is installed on the base at the bottom, and the base is fixed on the ground. The first turntable 22 of the first positioner 21 provides 360° rotation of the first tool frame 23 in the horizontal plane, and the welding fixture 24 is installed on the On the two stations of the first tooling frame 23, the welding jig 24 can be switched when rotating horizontally, and the rota...

Embodiment 3

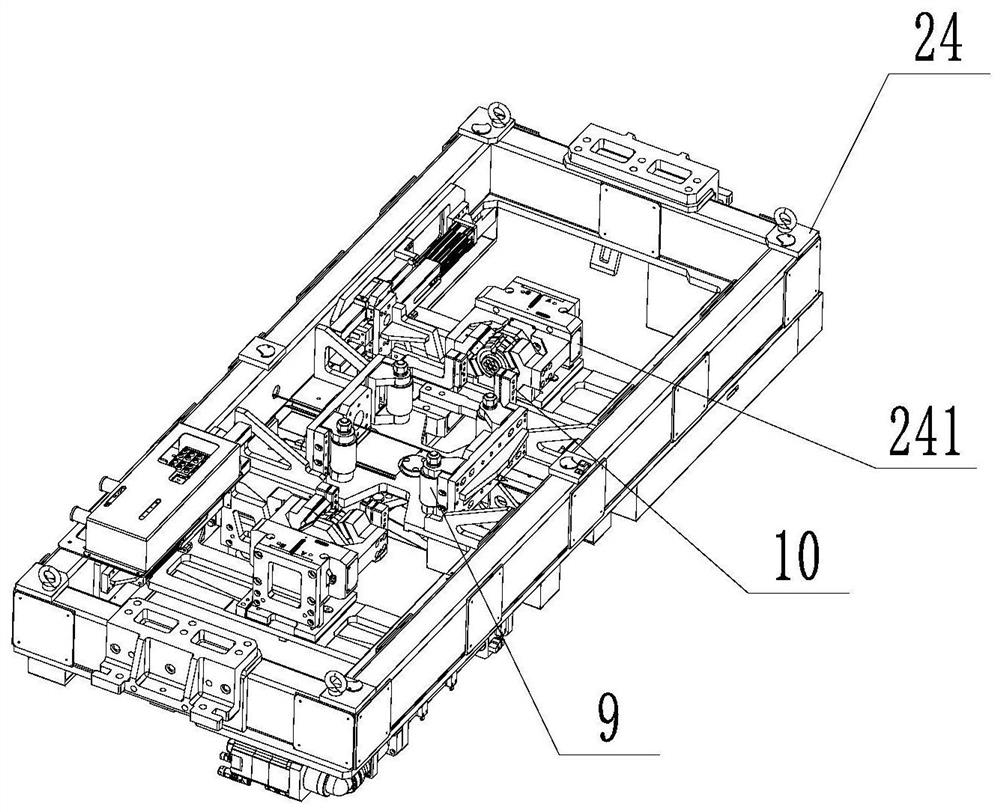

[0050] This embodiment is expanded on the basis of Embodiment 1, such as Figure 4 As shown, the axle housing repair welding unit 3 includes a second positioner 31, the second positioner 31 includes a second turntable 32, the second turntable 32 is provided with a second tooling frame 33, on the second tooling frame 33 A repair welding fixture 34 for clamping is provided, and a second drive motor 35 for driving the repair welding fixture 34 to rotate at an angle is arranged on the second tool frame 33. The axle housing repair welding unit 3 also includes a second welding robot 36 for repair welding , the designed second positioner 31 is installed on the base at the bottom, and the base is fixed on the ground. The second turntable 32 of the second positioner 31 provides a 360° rotation of the second tool frame 33 in the horizontal plane, and the repair welding fixture 34 Installed on the two stations of the second tooling frame 33, the repair welding jig 34 can be switched when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com