Tube-type drawing devillicating method

A tubular drafter and drafting technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of unfavorable non-woven fabrics, and achieve the effect of uniform fiber web, high density and small deviation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

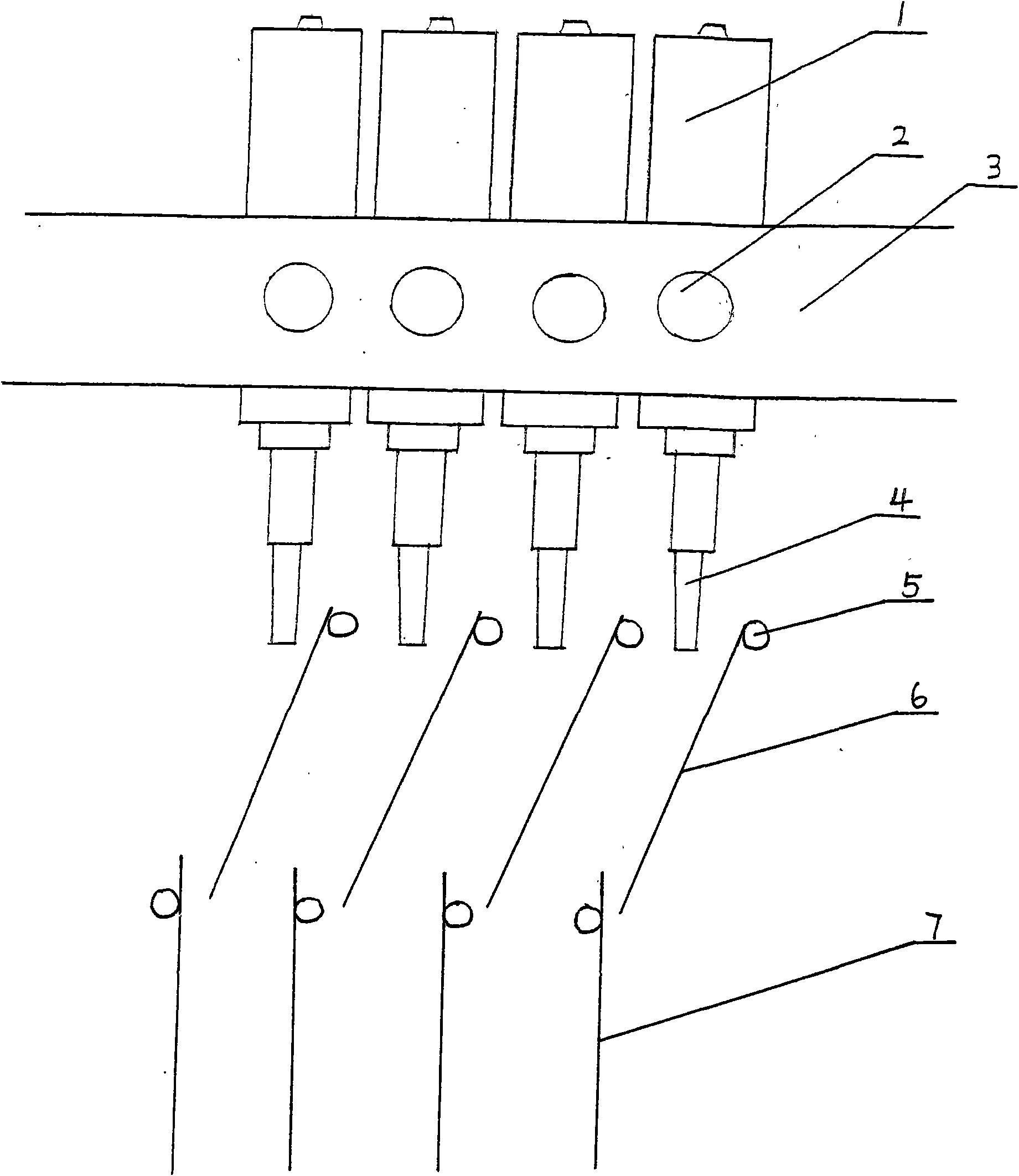

[0006] Such as figure 1 As shown, the present invention is realized by adopting special-purpose airflow drafting device and spinning device, and airflow drafting device is that several tubular drafters 1 are fixed on the air guiding device 3, and the The center distance is between 35 and 55mm, and it communicates with the air hole 2 on the air guiding device. The device is composed of a spinning plate 6. The yarn receiving device 7 and the fixed shaft 5 are composed of the center distance between the spinning devices of 35-55 mm. The high-speed compressed air flows into the tubular drafter through the air guide device 3, and the primary fiber is in the tubular drafter. Under the action of high-speed compressed air, it is drawn to a fineness of 1.5-3 deniers, and the fibers are dispersed by a spinning device to form a fiber web.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com