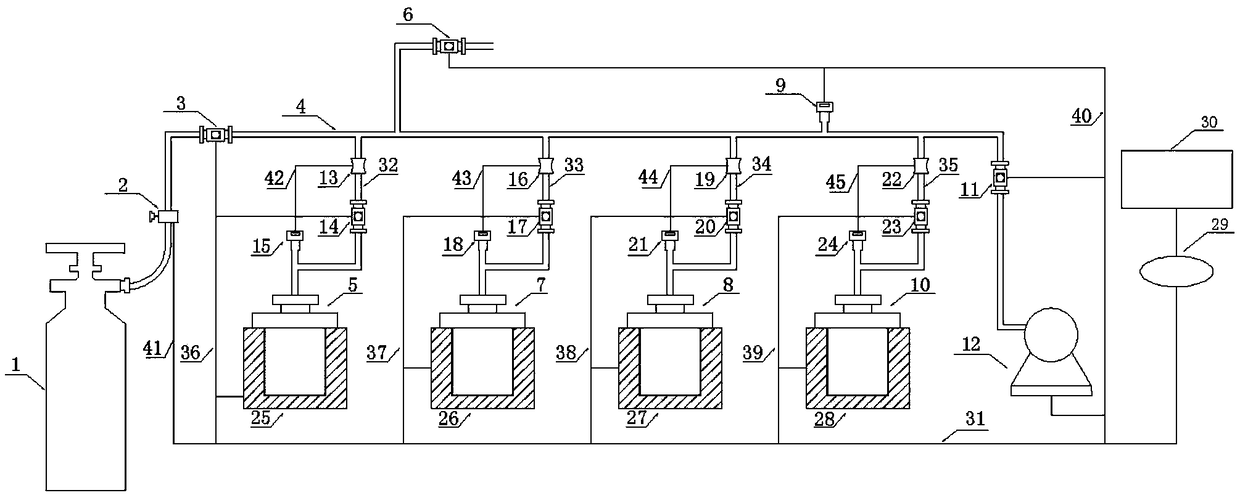

A fully automatic gas adsorption and desorption system and process

A fully automatic and desorption technology, applied in the field of gas experimental system, can solve problems such as a lot of time, cumbersome experimental process, complex structure, etc., and achieve the effect of reducing the deviation rate of experimental data, accurate experimental data, and improving experimental efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] ① Prepare samples required for experiment;

[0039] ②Turn on the power of the test system, connect the data lines of the electrical components and the central controller 29, turn on the touch screen 30; click the air tightness detection button on the touch screen 30, and the central controller 29 will open the automatic valve Ⅲ11, automatic valve Ⅳ14, Automatic valve Ⅴ17, automatic valve Ⅵ20, automatic valve Ⅶ23, close automatic valve Ⅰ3, automatic valve Ⅱ6, turn on vacuum pump 12, set the degassing time to 3-5 minutes, after degassing, the central controller 29 will close the automatic valve Ⅲ11, automatic valve Ⅳ14. Automatic valve Ⅴ17, automatic valve Ⅵ20, and automatic valve Ⅶ23. After 10-15 minutes, click the check air tightness button on the touch screen 30 to judge the air tightness of the system;

[0040] ③Load the samples required for the experiment, different adsorption tanks can be loaded with different samples, click the degas button on the touch screen 30, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com