Water conservancy pipeline stop valve assembling device

A technology of assembly device and globe valve, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of slow assembly efficiency and achieve the effect of improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

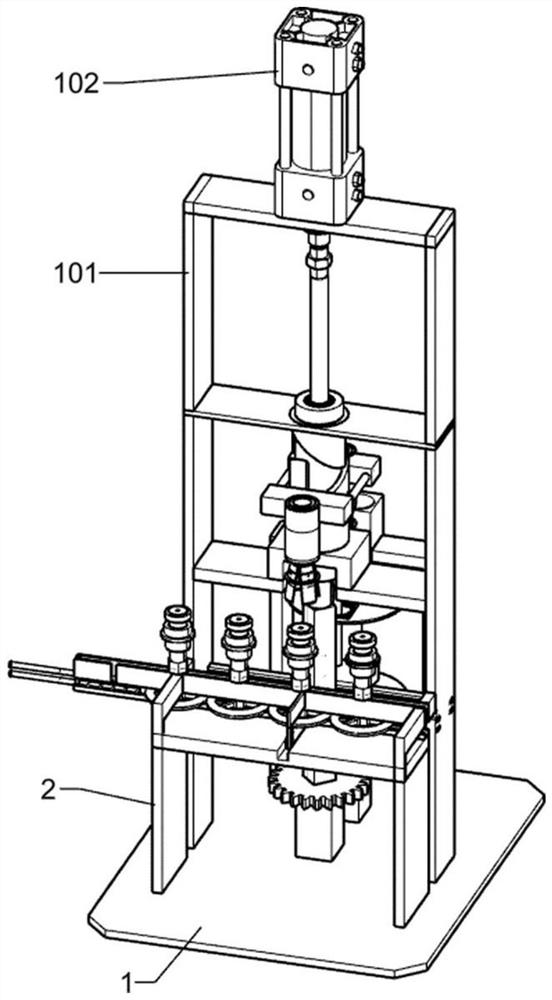

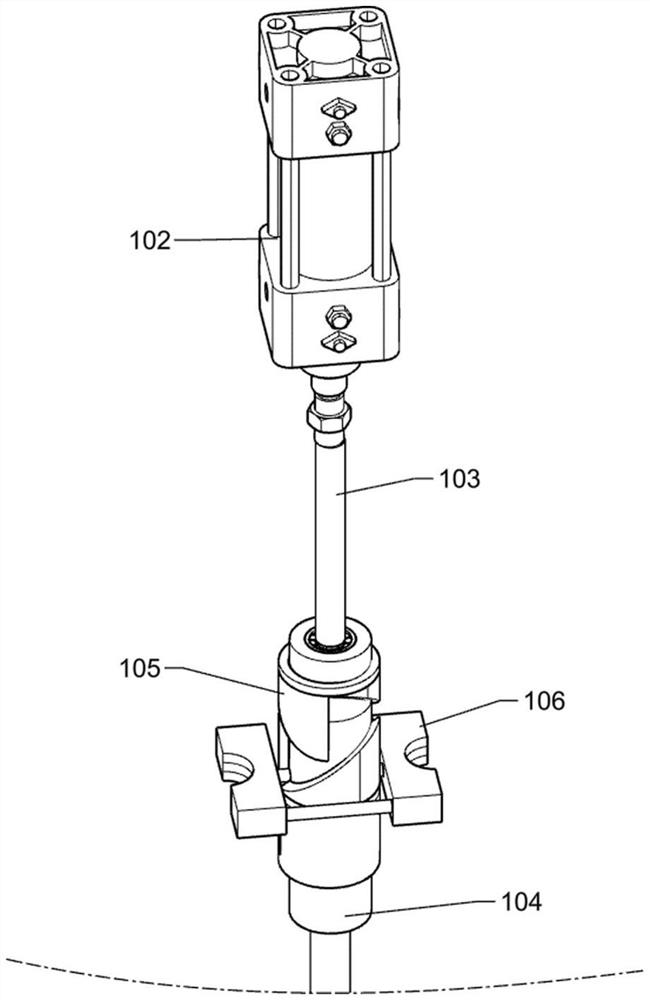

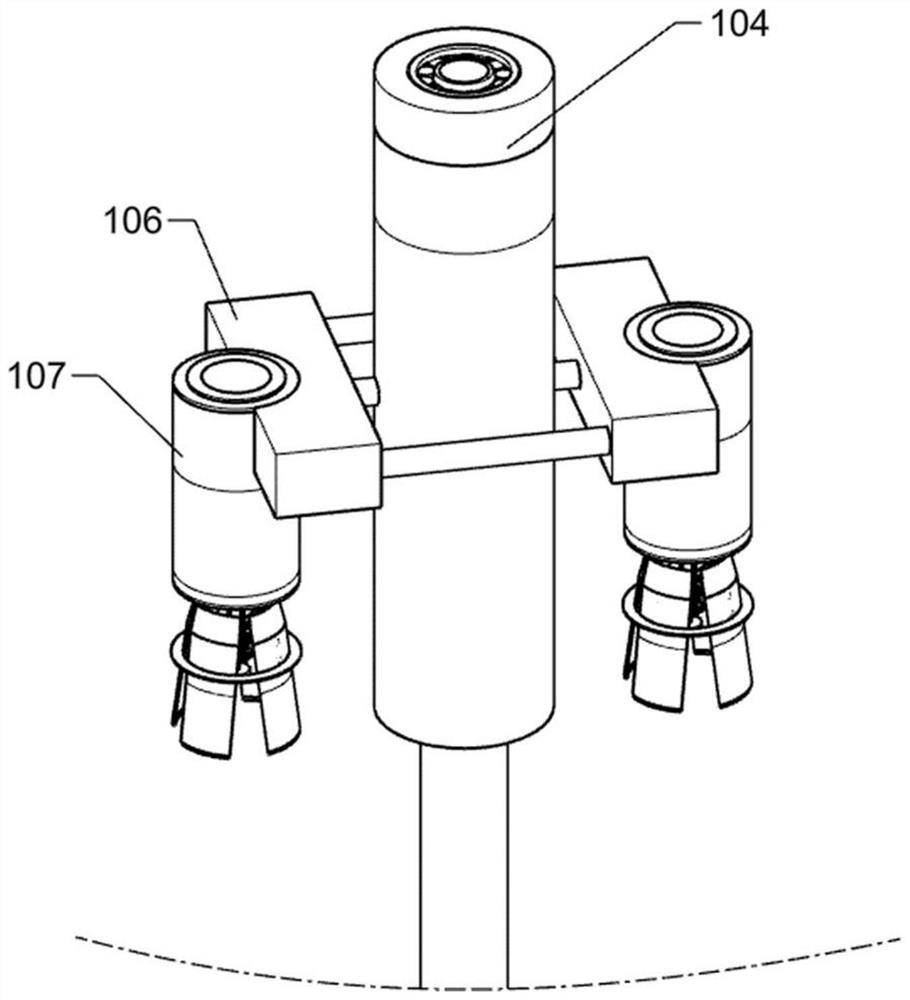

[0076] Such as Figure 1-6 As shown, a water conservancy pipeline shut-off valve assembly device includes a bottom plate 1, a main frame 101, a double gear rod 1011, a cylinder 102, a long shaft 103, a sliding column 104, a slotted pipe 105, a semicircular clamp 106, and a small sleeve 107 , small cylinder 108, small spring 109, groove plate 110, thin tube 111, thin rod 1110, round handle 112, short round tube 113, support groove rod 114, rectangular pole 115, square frame support 116, cross-shaped chute 117, connection block 118, slotted round block 119, connector 120, short straight rod 121, short round pin 122, connection concave block 123, thin spring 124 and clamping piece 125, bottom plate 1 is arranged at the bottom, main frame 101 Fixedly connected directly above the base plate 1, there is a groove in the middle of the upper panel of the workbench 2, the workbench 2 is fixedly connected to the front side of the base plate 1, the two sides of the workbench 2 extend to b...

Embodiment 2

[0079] Such as Figure 7-8 As shown, a water conservancy pipeline shut-off valve assembly device includes a workbench 2, a limit groove baffle 201, a push rod 3, a long spring 301, a bow-shaped clamping plate 4, a prismatic rotating rod 5, a cam 501, and a connecting rod 502 and short spring 503, the limit groove baffle plate 201 left front and the middle part respectively have a hole groove, the limit groove baffle plate 201 is fixedly connected to the rear end of the workbench 2 upper surface, the limit groove baffle plate 201 Pass through both sides of the workbench 2 and be in the middle of the workbench 2 and the main frame 101. The push rod 3 is slidably connected to the inner side of the left part of the limit groove baffle plate 201. The long spring 301 is sleeved on the push rod 3. The left end of the long spring 301 is in contact with the main frame 101. The limit groove baffle plate 201 contacts, and a slider is connected to the lower part of the arc clamp plate 4, ...

Embodiment 3

[0082] Such as Figure 9 As shown, a water conservancy pipeline shut-off valve assembly device includes a T-shaped bracket 6, a recess 601, a first gear 602, a second gear 603, a rotating column 604, a disc 605, a boss 606, a receiving tray 607, The bin 608, the limit plate 609 and the touch lever 610, two T-shaped brackets 6 are symmetrically arranged, the T-shaped bracket 6 is fixedly connected to the back side of the bottom plate 1, and the recess 601 is fixed to the connecting plate on the back side of the bottom plate 1 The concave seat 601 is located in the middle of the T-shaped bracket 6 and the main frame 101, the prismatic rotating rod 5 is rotatably connected to the front end of the concave seat 601, the first gear 602 is set on the lower end of the prismatic rotating rod 5, and the second gear 603 is rotatably connected to the concave On the rear side of the seat 601, the second gear 603 meshes with the first gear 602, the lower end of the rotating column 604 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com