Hydraulic stopper used for weighing apparatus

A limiter, hydraulic technology, applied in the field of hydraulic limiters, can solve the problems of low manufacturing cost, no impact buffering effect, high maintenance cost, and achieve long service life, large buffer capacity and simple maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, not limitation to its protection scope:

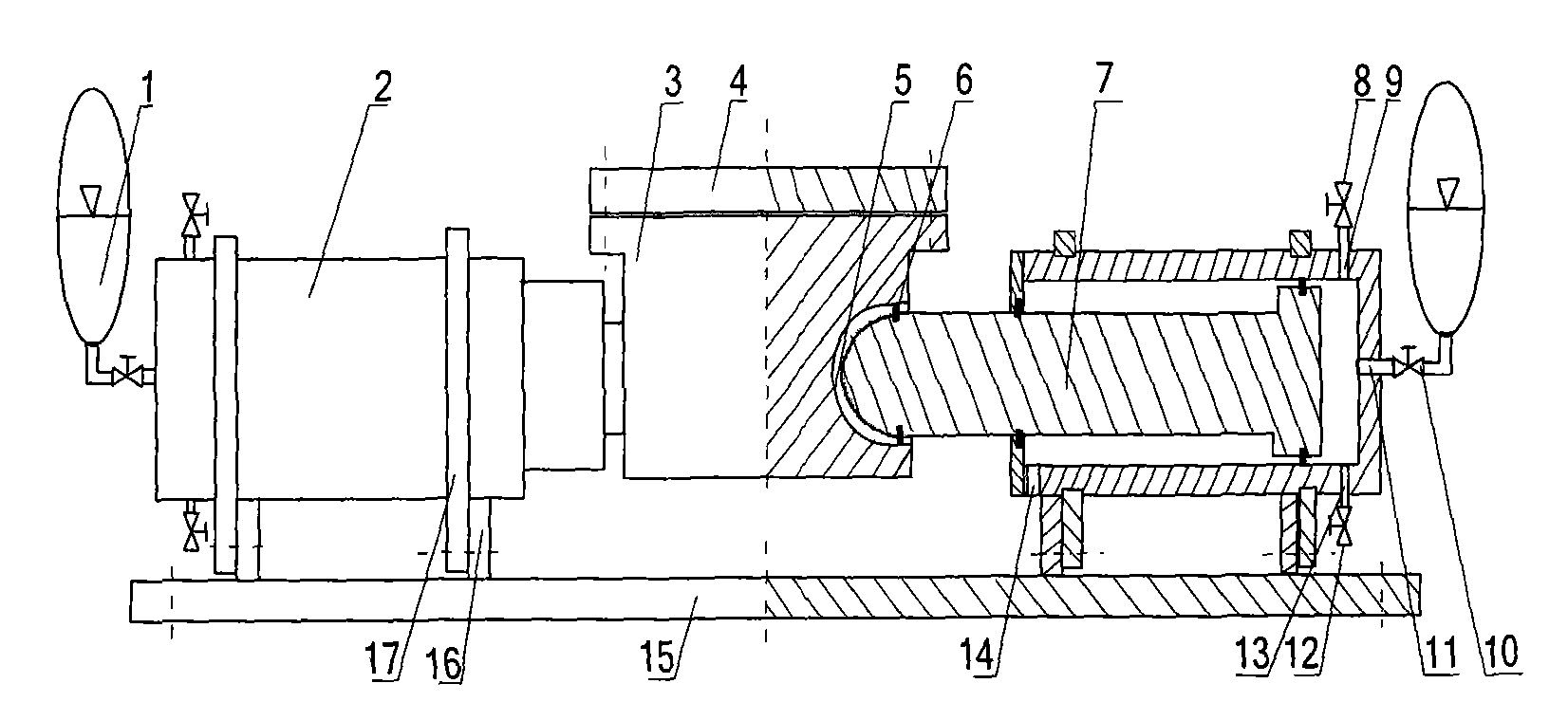

[0014] A hydraulic limiter for weighing scales. Such as figure 1 Shown: the limiter includes two identical hydraulic piston cylinders 2, two identical bladder accumulators 1, a coupling 3, a transition plate 4 and a bottom plate 15. The pistons 7 of the two hydraulic piston cylinders 2 symmetrically arranged on the base plate support 16 are respectively connected with the coupler 3, and each hydraulic piston cylinder 2 is fixedly connected with the corresponding base plate support 16 through two identical cylinder liner fixing brackets 17 The oil inlet 9 above the rodless chamber of each hydraulic piston cylinder 2, the oil outlet 13 below the rodless chamber and the throttle port 11 at the end of the rodless chamber are all equipped with oil inlet shut-off valves 8, The oil outlet cut-off valve 12 and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com