Direct acting electric valve

An electric valve, direct-acting technology, used in lift valves, valve details, valve devices, etc., can solve problems such as refrigerant leakage, failure of axial locking force, and inability to effectively ensure that the valve core position remains unchanged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

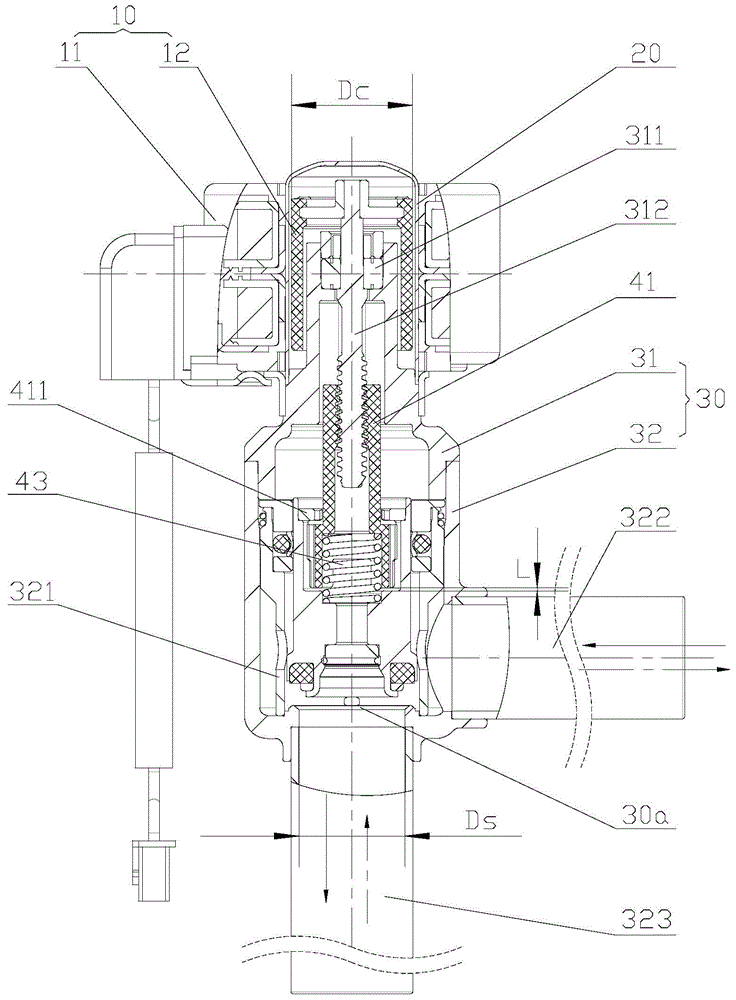

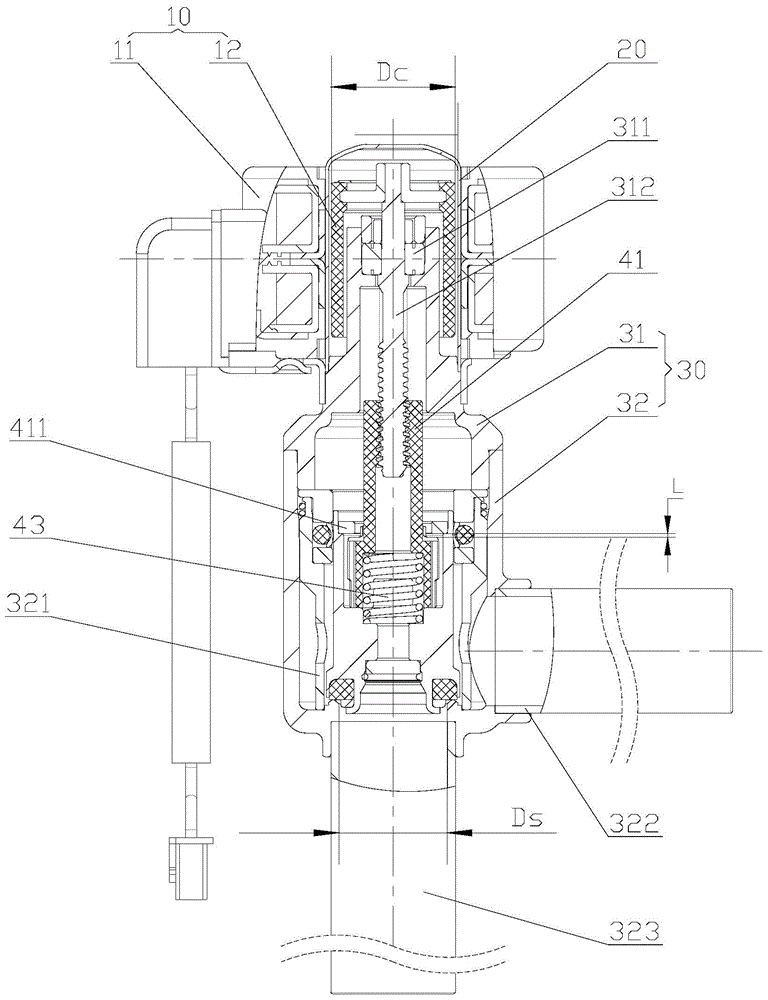

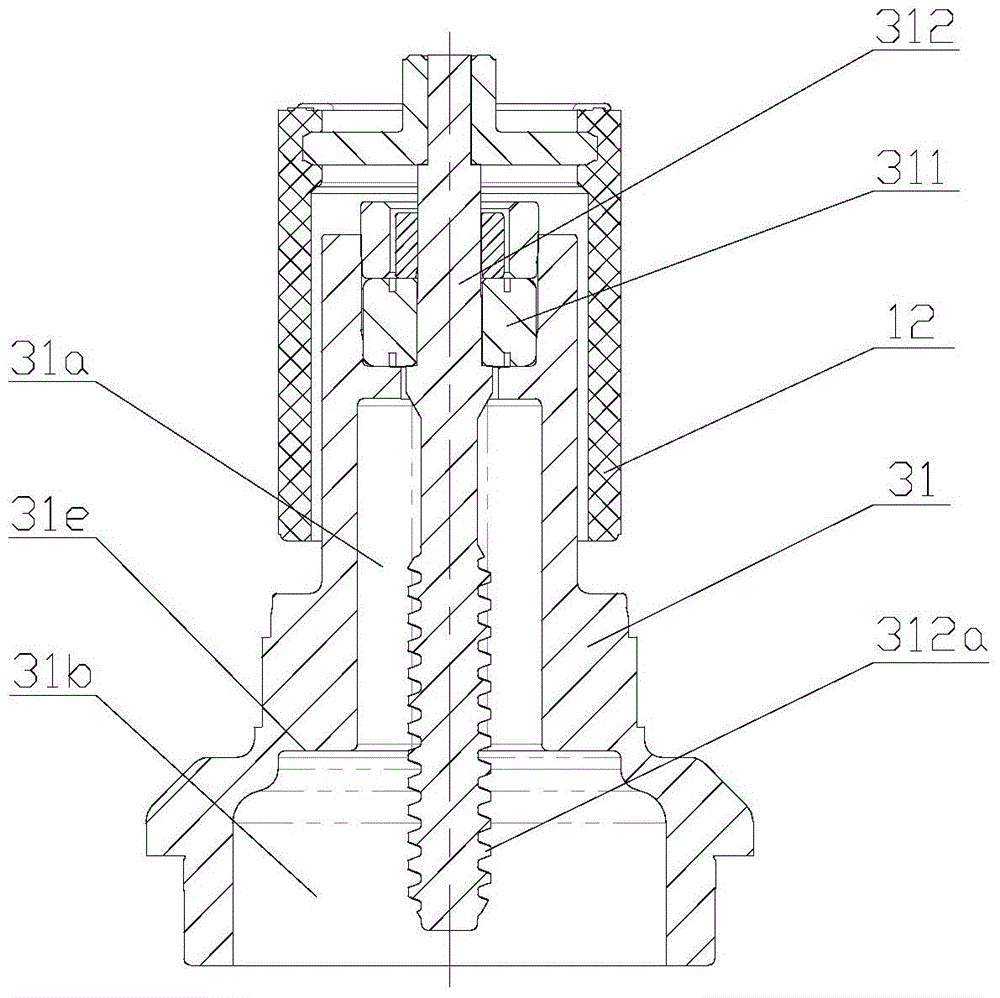

[0031] The core of the present invention is to provide a direct-acting electric valve, which can ensure that the position of the valve core remains unchanged after the motor is powered off, so that the valve core is always in contact with the valve port, effectively avoiding valve port leakage.

[0032] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] What needs to be explained here is that the upper and lower localizers involved in this article are based on Figure 1 to Figure 4 The components are located in the drawings and the positions of the components are defined only for the clarity and convenience of expressing the technical solution. It should be understood that the orientation words used herein shall not limit the scope of protection claimed in this application.

[0034...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Middle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com